MIM (metal injection molding) is very popular among Xometry customers and is often preferred over plastic injection molding (PIM) because it’s better for small parts under 100 grams. The process differs slightly from PIM’s, and there are a few extra steps, which we’ll cover in this article, along with common MIM applications, and its pros and cons. You can also watch the below short video for a recap.

What is Metal Injection Molding?

MIM is great for making strong, hard, dense, and intricate parts with many other impressive mechanical properties, too. It’s able to produce large volumes at a time and can actually work out cheaper for big loads than investment casting, machining, and sometimes even stamping. It has a lot fewer design restrictions than some other processes, and you won’t need to put multiple components together to make a final part, no matter how complex—the process can do this in one go. In addition, MIM produces less material waste and scrap than other methods, meaning you get the most out of your money, and material—up to 98% can be turned into usable parts.

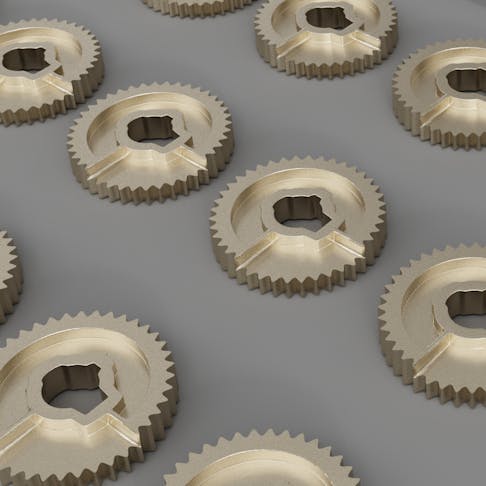

This type of injection molding is almost always used for high-volume production of small, complex parts that are hard to make using other methods (for instance, if they have really thin walls). That’s why sectors like automotive, weaponry, medical, and consumer goods seem to love MIM. The following picture shows a variety of different MIM parts.

An array of various metal injection molded parts.

The production method is similar to PIM—injecting material into a mold is involved—but since MIM works with metal, it’s a slightly more complicated method. A polymerized metal feedstock made up of minuscule metal particles with a plastic binder is injected into the mold at high pressure. When it cools and hardens, it can be released from the mold and trimmed as necessary. But it doesn’t end there! What you have now is called a “green part,” which needs debinding. During this next phase, the plastic binder is removed, leaving behind a rather fragile and porous metal piece. This new piece is known as the “brown part.”

The final bit of processing this part needs is to be put into a high-temperature furnace to fuse the metal particles together, known as sintering. This will make the part fully dense and pore-free, but it will shrink a bit. The best way around this is to allow for shrinkage and make the mold slightly bigger to begin with. "To offset the shrinkage that occurs in the parts between their green stage and sintered stage, manufacturers scale the part, just like injection molding,” advises Kevin Choate, Xometry’s Senior Solutions Engineer. “So the green part is usually 15–20% larger than the finished part."

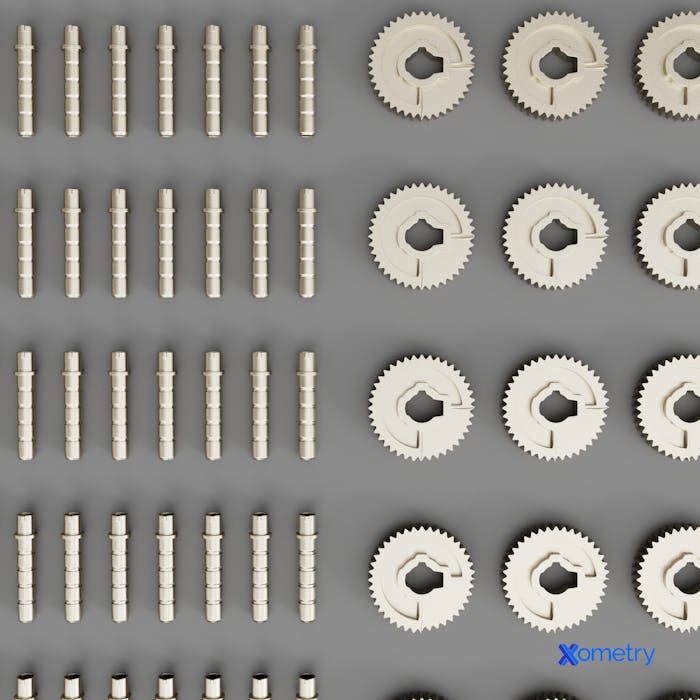

After parts have been sintered, they’ll usually be sitting at around 96%-99% density. This number is huge, especially when compared to other processes because MIM uses more refined powders, which help decrease porosity. The image below shows some more parts made using MIM.

Compatible Materials

Various metals can be used in the MIM process, and these can be sorted into four main categories:

- Ferrous metals (stainless steel, tool steel, and nickel-iron alloys like invar and kovar)

- Hard metals (cobalt-chromium, cemented carbides, and cermets—a ceramic and metal composite)

- Special metals (aluminum, titanium, nickel, and molybdenum)

- Tungsten alloys

If you’re after any of these metals or powders for use in MIM, we’ve got many services that could be a good fit. We’ve put our relevant capabilities in the table below.

| Alloy Group | Specific Alloys | Description |

|---|---|---|

Alloy Group Stainless steel | Specific Alloys 316, 316L, 17-4 PH, 303, 304, 440C, and 420P | Description Great heat and corrosion resistance due to high nickel and chromium content, used for surgical tools |

Alloy Group Low-alloy steel | Specific Alloys Fe-Ni (iron-nickel), FN02, FN08, 4140, 8620, and 100Cr6 | Description Cost-effective due to low carbon and alloying elements, moderately machinable |

Alloy Group Tool steel | Specific Alloys M2 | Description High carbon gives it excellent hardness and abrasion resistance and is used to make mold and cutting tools after going through rigorous testing and quality checks |

Alloy Group Soft magnetic steel | Specific Alloys Fe-Ni50, Fe3Si, FeCo50, and FeCoV | Description Good magnetic reaction used a lot in solenoids, electric motors, and relays |

Alloy Group Tungsten heavy alloy | Specific Alloys W-Ni-Fe (tungsten nickel iron) and W-Ni-Cu (tungsten nickel copper) | Description Composed of tungsten and other alloying elements, has a very high density, making it ideal for electromagnetic shielding |

Alloy Group Tungsten carbide-cobalt | Specific Alloys WC-Co | Description A hard and wear-resistant metal used for cutting and mining tools and machine parts |

Metal Injection Molding Metals and Powders Available Through Xometry

How accurate is metal injection molding?

The short answer is that it’s very accurate. It can achieve dimensional tolerances of between +/- 0.3–0.5%. Xometry’s MIM manufacturers also offer post-machining that can make parts even more accurate. MIM is usually much more accurate than other methods, like die casting, because they tend to need extra machining to get smooth finishes or tight dimensions. Large parts have the potential to be less accurate because of the shrinkage, which could cause small variations.

What’s the difference between MIM and die casting?

The difference between MIM and die casting is similar to that of plastic injection molding in that MIM requires more post-processing. Die casting doesn’t require that many steps and is generally quicker. It’s also very good for making larger metal parts.

Are there any disadvantages to metal injection molding?

There are a few downsides to MIM, but its pros list is far longer than its cons. This method is somewhat limited to small- and medium-sized parts, and the parts shrink by the time they get to sintering, so this is something that has to be fixed by the manufacturer (not the designer). Tooling and setup for MIM can be very expensive to purchase and get up and running, and the cost of parts can also be pricey for fewer parts. Not many low-volume manufacturers would be enticed by that. If you’re looking for something in between, we highly recommend CNC machining—something we offer here at Xometry.

How Xometry Can Help

We hope we answered all your MIM-related queries, but if you happen to have more, please feel free to reach out to one of our representatives, who will be happy to help you out. You can also use any of our manufacturing services, from metal injection molding to laser cutting to 3D printing, and it’s quick, easy, and free to get a no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.