Transfer molding is a well-liked manufacturing process that our customers use to make durable parts. Let’s go into what it is exactly and its most common applications.

What is Transfer Molding?

Transfer molding is a process in manufacturing that involves transferring a preheated and softened material that has already been measured, into a closed mold cavity under pressure. That way, it can cure or solidify into whichever shape you need. This method is not quite the same as compression molding because it uses an enclosed mold. It has a lot going for it, though. For example, it’s easy to integrate inserts, it can make complex shapes with sharp edges, it makes parts with minimal to no flash, and isn’t excessively expensive because its design is fairly simple.

One of the most popular uses of transfer molding is to wrap electronic components in rubber or plastic. It’s also a great way of making plastic parts with metal inserts like prongs or semiconductor chips. You can also make things like connectors, studs, pins, and molded terminals. Another advantage of using this molding method is that it can make parts with sharp corners and edges. That’s especially useful in sectors like hydraulics which require proper fluid sealing. Lip seals are one example of this. It’s also a hit in the natural gas industry for face seals and the medical industry for medical device handles and surgical instrument components. Here’s a video we made all about transfer molding:

What Is the Primary Purpose of Transfer Molding?

Transfer molding is primarily used to encase electronic components in rubber or plastic. It enables the fabrication of plastic parts with metal inserts, such as prongs or semiconductor chips. Pins, studs, connectors, and molded terminals can all be produced using this method. Furthermore, transfer molding allows for the production of parts with sharper corners and edges. This feature is particularly advantageous in industries such as hydraulics, where the sealing of fluids is crucial. Lip seals, which are used to prevent fluid leakage in hydraulic systems, often require precise edges to ensure effective sealing. Transfer molding enables the creation of sharp and well-defined edges, which enhances the performance and reliability of such seals.

How Does Transfer Molding Work?

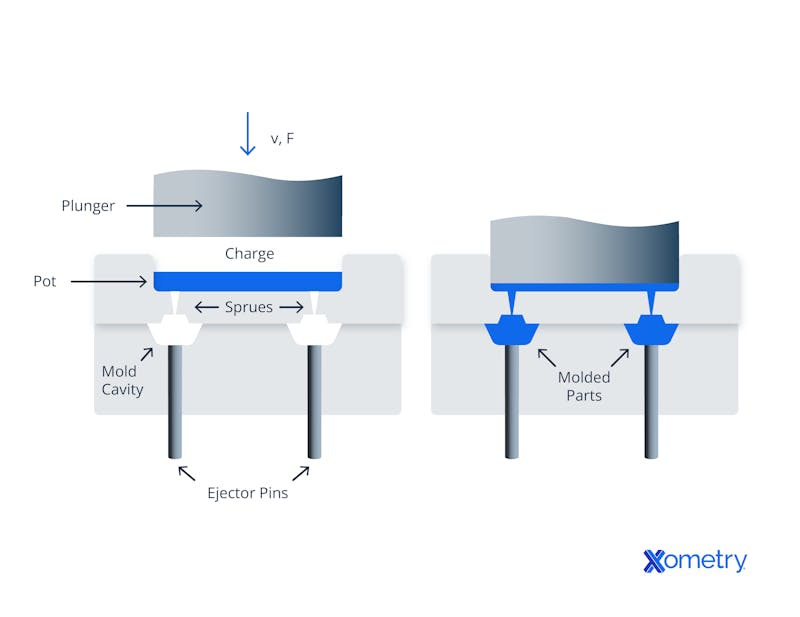

The technical explanation of this method is that it combines compression and transfer of the polymer charge. What does this mean? This means that a pre-weighed polymer charge is fed into a transfer pot by gravity feed and introduced into the mold cavity under pressure from a plunger. When the resin cures and is ready to be taken out, it’s ejected using an ejector pin. It’s not uncommon to have to do some post-processing after this, like trimming off the sprue and gate. The following image breaks down the basic process:

The Transfer Molding Process

Transfer molding is usually faster than compression molding but slower than injection molding. Of course, it all depends on what materials you’re working with and how complex the part is. The reason it typically has faster cycle times is that it injects the material into the mold with a higher pressure.

On the downside, you could waste material, especially during the prep and transfer stages. This could also contribute to a negative environmental impact. It also isn’t the quickest of molding methods because of the preparation involved, and it’s not unheard of to get air trapped in the mold during the transfer process. Needless to say, this can cause defects in your final product.

How Does Transfer Molding Differ From Injection Molding?

This is another worthy comparison. Both of these methods are used to make plastic parts, but they have some differences. Unlike transfer molding, which involves feeding material into a heated chamber through a screw and then using a plunger to force it into a mold cavity, injection molding uses a reciprocating screw to melt and inject the material straight into the cavity. That’s why injection molding is usually better for larger production runs, as well as bigger parts with thin walls.

Transfer molding can work out more expensive and time-consuming, too, because most of the time, you have to prepare the raw material before having it forced into the mold. With injection molding, you don’t have this issue because it mixes and gets the material ready straight away. Whether you choose transfer molding or injection molding for your next project depends entirely on your preference, as well as your time frame and budget. To find out more about injected plastics, you can read our guide.

Transfer molding and injection molding are similar -- transfer molding is used for thermoset plastic while injection molding is used for thermoplastic.Kevin ChoateSenior Solutions Engineer

What Are Some of the Materials Used in Transfer Molding?

Transfer molding is compatible with a few different materials. These are some of the typical ones:

1. Epoxy

A thermosetting polymer that’s surprisingly versatile, epoxy has really good electrical insulation properties and is very resistant to chemicals. It’s also quite low in viscosity, meaning it flows easily during the process. One potential downside is that it will likely need post-curing because it can be quite brittle.

2. Silicone

Another versatile polymer, silicone is known for how flexible it is. It’s durable, temperature resistant, and biocompatible. But, it’s not the cheapest material out there, and it has a relatively long curing time.

3. Polymers

This is a broader category, but when it comes to certain polymers like polyurethane and polyester, they work very well with transfer molding. Polyurethane is very strong, flexible, and chemical resistant, and polyester is heat resistant and has good mechanical strength.

4. Rubber

Rubber is basically elastomers that have high elasticity and resilience. Whether natural or synthetic, rubber is easy to make with transfer molding. Depending on the type, you may need post-curing or vulcanization to improve its properties. We have a guide on TPR material, which you can read to learn more.

5. Plastics

We’ll use two plastics as examples: polypropylene and polycarbonate. Both of these work very well with transfer molding. Polypropylene flows well and can fill every crevice of the mold cavity. It’s also chemical resistant and has good dimensional stability. Polycarbonate has high impact strength, transparency, and heat resistance. Some plastics, like polyethylene, will be limited in terms of temperature resistance, strength, and dimensional stability.

How Long Does the Transfer Molding Process Take?

The duration of the transfer molding process can vary depending on several factors, including: the size and complexity of the part, the type of material being used, and the specific production requirements. Compared to compression molding, transfer molding generally offers faster cycle times due to its ability to inject the material into the mold under higher pressure. On the other hand, injection molding typically has shorter cycle times than transfer molding, as it involves injecting molten material directly into the mold at high speed.

RTM (Resin Transfer Molding) is a process where liquid resin is injected into a closed mold containing pre-placed reinforcements and then cured to form a solid composite part. HP-RTM (High-Pressure Resin Transfer Molding) is a variant of RTM that utilizes higher injection pressures to reduce resin injection times and improve part consolidation. However, in the case of high-pressure resin transfer molding (HP-RTM), the resin injection time is typically around 1-5 minutes. This is significantly shorter than traditional resin transfer molding (RTM), which can take approximately 30-60 minutes. This shorter production cycle time makes HP-RTM an attractive manufacturing process for large composite parts in the automotive industry.

How Durable Are Transfer Molded Products?

Products made by transfer molding are renowned for their exceptional durability. Because they have a good strength-to-weight ratio, they can be used for many different things, including heavy objects. The addition of reinforcing fibers and the high strength-to-weight ratio that is made possible with a fiber load of 25–50% also contribute to transfer molding's improved quality and durability, particularly in thicker-walled parts.

Are Transfer Molded Products Heat-Resistant?

Yes, transfer-molded products can be heat resistant, depending on the specific material used in the process. Certain materials, such as silicone and certain thermosetting plastics, exhibit excellent heat resistance. They can withstand high temperatures without deformation or degradation. It's important to keep in mind that not all thermoplastics are suitable for transfer molding, even though certain materials can provide heat resistance when used in this process. Polyethylene is one type of thermoplastic that has a reputation for being less suitable for transfer molding because of its weaker heat resistance. Due to its low melting point, polyethylene might not be able to withstand the high temperatures and pressures used in transfer molding. To ensure the desired heat resistance for a specific application, it is advised to consult the material specifications and carry out the necessary testing.

Are Transfer Molded Products Stretchable?

Yes. Transfer molding products can be stretchable if they are made from stretchable materials and molded into shapes that allow for stretching, such as flat sheets. The stretchability of transfer-molded products is primarily determined by the material used and the geometry of the part. Certain materials, such as elastomers or flexible polymers, can be utilized in transfer molding to create flexible and stretchable products.

How Long Do Transfer Molded Products Last?

The lifespan of products made by transfer molding can vary widely depending on factors such as: the material used, the intended application, and the environmental conditions in which they are used. Generally, transfer molding products are designed to be durable and long-lasting. With proper maintenance and care, they can withstand normal wear and tear for many years. However, the specific longevity of a transfer molding product will ultimately depend on its individual characteristics and usage conditions.

What Are the Applications of Transfer Molding?

Transfer molding finds applications in various industries:

- Electrical Industry: Connector seals can be molded around wires, with spark plug wires being a common example.

- Natural Gas Industry: Transfer molding is used to create metal-to-rubber face seals, providing a reliable interface for gas valves.

- Medical Industry: In the medical field, transfer molding is extensively utilized for silicone overmolding, particularly for medical device handles and surgical instrument components.

What Are the Advantages of Transfer Molding?

Transfer molding offers several advantages over other molding techniques:

- Allows for the easy integration of inserts, such as metal components of electronic parts, into the molded product

- Allows for intricate designs with sharper edges, providing greater design flexibility compared to other molding methods

- Produces parts with minimal or no flash, eliminating the need for additional deflashing processes

- Typically involves simpler pot and plunger designs, resulting in lower tooling and equipment costs compared to other molding techniques

What Are the Disadvantages of Transfer Molding?

Transfer molding also has certain disadvantages to consider, including:

- Has the potential for material wastage, particularly during the preparation and transfer stages. This is primarily due to the use of sprue and overflow grooves, which can result in excess material that is discarded. Additionally, transfer molding is not conducive to recycling thermosetting polymers into the process, further increasing production costs and environmental impact.

- Generally has a slower production rate compared to injection molding due to the additional steps involved in material preparation and transfer

- Air can get trapped in the mold during the transfer process. This can lead to defects in the final product and require additional measures to ensure air is properly evacuated

What Is the Difference Between Transfer Molding and Compression Molding?

Transfer molding and compression molding are similar processes, but they differ in how the molding material is pressurized. In transfer molding, the material is preheated and pressurized in a separate chamber before being forced through an opening into a closed mold cavity. In compression molding, the material is directly placed into the mold cavity, and pressure is applied to the entire mold to shape the material.

What is the Difference Between Transfer Molding and Resin Transfer Molding (RTM)?

They sound very similar, but they’re not the same thing. Resin transfer molding injects liquid resin into a closed mold that contains dry fibers like glass or Kevlar. When the resin impregnates the fibers, the part is cured inside the mold and you have a solid composite part. Another type of RTM is high-pressure RTM (HP-RTM) which has higher injection pressures to speed things up. If you’re in a hurry, like those in the automotive industry tend to be, HP-RTM is the way to go. It has an impressive resin injection time of just 1–5 minutes, unlike the 30–60 minutes of RTM.

How Xometry Can Help

We recommend reaching out to one of Xometry’s representatives if you have any questions about transfer molding, or any type of molding for that matter. Xometry also provides an abundance of manufacturing services like CNC machining, 3D printing, laser cutting, and compression molding. You can request a free, no-obligation quote to get started right away.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.