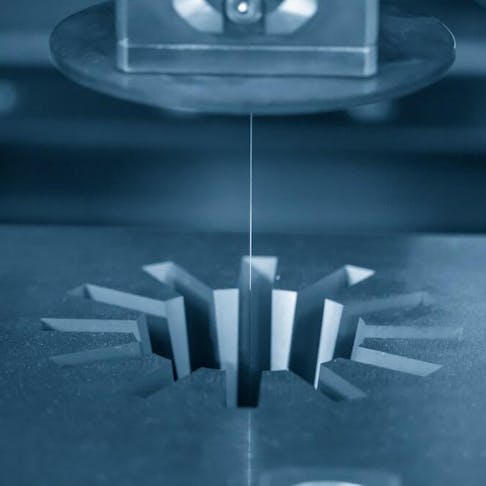

Wire EDM is one of two methods of EDM (electric discharge machining) used for the fabrication of small, intricate parts. Precise electrical sparks are generated in order to cut electrically conductive materials with unprecedented levels of accuracy. Wire EDM is ideal for small, precise, and complex shapes. It is commonly used to manufacture molds and dies because those items must contain minimal residual stress. Other candidates for the process are those items that are too small and/or intricate to be cut with traditional machining methods.

The best wire EDM machine (sometimes further abbreviated as WEDM) for you depends upon the parts you intend to create. Whether you prioritize machine runtime and efficiency or cut accuracy and part size, there’s a WEDM device that will meet your needs. Makino and Seibu WEDM machines are best for part accuracy, while Agie and Charmilles are best for efficiency, and AccuteX and Excetek are good introductory options with low prices. Makino perhaps offers the best wire EDM machines due to their exceptional accuracy, speed, easy-to-use interfaces, and a large network of customer support representatives. This article will review the ten best wire EDM machine manufacturers.

1. Mitsubishi

Mitsubishi has five different lines of wire EDM machines. Their flagship model, the MX600, has the highest accuracy but also the smallest possible part size out of all their offerings. The FA40V and FA50V, meanwhile, can make small parts but are their least precise models. Each of Mitsubishi’s WEDM machines is linearly driven, enabling a high degree of accuracy and precision no matter which you choose. Additionally, Mitsubishi’s WEDM offerings are easy to use and feature automatic wire threading.

2. ONA

ONA has four different series of wire EDM machines: compact, modular, hole-drilling, and custom models. Their compact WEDM options have small footprints but deliver maximal precision while their modular wire EDM machines allow for an astounding amount of flexibility. Hence, ONA has a wire EDM machine for every application, part size, and part geometry.

3. Makino

Makino is revered throughout the machining industry for their high-quality CNC machines and associated technologies. Their wire EDM machines are no different. Makino offers 14 different wire EDM machines. They range from compact, micromachining versions with 0.5-micron accuracies and 150 x 150 mm (UPN-01) working spaces to larger machines with 1.0-micron cutting accuracy and 2,000 x 1600 mm (U1310) worth of space to work with. With over 140 patents associated with the technology, their machines require 50% less maintenance than competitors’ machines because they contain fewer hard-wearing parts. BellyWizard, a state-of-the-art adaptive control technology, is also included in their WEDM units. This device automatically tensions the wire and optimizes it for each specific cut.

4. FANUC

The wire EDM machines offered by FANUC go by the proprietary name, ROBOCUT. FANUC offers three different ROBOCUT machines: a model for small, compact parts, a medium-sized, all-around model, and a model capable of cutting larger parts. Each ROBOCUT comes with a special, factory-calibrated compensation grid that allows pitch correction over the entire worktable —, not just a single point. Additionally, their machines come with automatic wire threading software that can rethread wires in just 10 seconds.

5. Sodick

Sodick offers six different series of wire EDM machines, at least one of which can accommodate any size of the part. Each of their machines is linear-motor driven, resulting in vibration-free operation and no backlash — a fact that enables both high cutting accuracy and fine surface finishes. Sodick is the only company in the EDM industry to guarantee the positional accuracy of their wire EDM machines for 10 years.

6. Agie

Agie, now known as GF Machining Solutions after merging with Charmilles (another popular EDM manufacturer) in 1996, has been one of the world leaders in EDM machines for several years. They offer six different lines of EDM machines, from their flagship CUT X series to their advanced CUT P series, so there’s a suitable machine for any part. Both experts and beginners will find the CUT X series simple to use thanks to its streamlined human-machine interface, collision protection, and the fact that it anneals its wire before threading. While simple to use, the CUT X series is extraordinarily fast compared to competitors. The company’s Intelligent Power Generator gets electricity through a direct power supply and their twin-wire technology gives machines unprecedented speeds and extreme accuracy.

7. Charmilles

The machines offered by Charmilles are the same ones offered by Agie, from the flagship CUT X series to the advanced CUT P series. The Intelligent Power Generator leads to faster cutting speeds while dedicated technologies for optimizing wire consumption efficiency keep costs down. Manufacturers thus spend less time tending to machine maintenance and more time on operations that maximize their profits.

8. Seibu

Seibu is the only manufacturer in the EDM industry to guarantee cut accuracy to +1.0 microns. Seibu offers four different EDM series — an oil-type WEDM series and three water-type WEDM series. The MEX15, an oil-type machine, can achieve straight lines to a tolerance of fewer than 0.1 microns, contour and pitch shape accuracy of +0.5 microns, and radii as small as 0.4 microns. The wire is automatically annealed before being fed into the device, ensuring non-stop operation.

9. AccuteX

AccuteX offers fivr different series of wire EDM machines. Their devices are engineered and built with highly rigid structures that reduce vibrations to improve precision. Automatic wire threading and linear-driven servo motors further contribute to accuracy and machining efficiency.

10. Excetek

There are five series of WEDM machines offered by Excetek. Their machines are linearly driven, allowing for high machining efficiency and low energy consumption. Their user-friendly interface, coupled with their Intelligent Machining mode which enables automatic workpiece positioning and wire control, allows users to easily operate their machines and diagnose issues.

What is a Wire EDM Machine?

A wire EDM machine is a subtractive manufacturing machine used to fabricate parts with small and complex geometries to superb precision. The EDM process emits extremely high-temperature (8,000-12,000 °C) sparks from an electrically conductive wire. This high temperature allows wire EDM machines to cut any electrically conductive material — from metals to diamonds. Since the wire and the workpiece do not physically contact each other, there are no cutting forces during machining and the part is left with no residual stresses after manufacture. It also produces no burrs, so the surface finishes far outshine those of other machining processes. For more information, see our guide on All About Wire EDM Machining.

What Makes the Best Wire EDM Machine?

The criteria for best wire EDM machine largely depends on how the finished parts will be used. Wire EDM machines are far more accurate than conventional machining. Therefore, while some EDM machines (like those offered by AccuteX and Excetek) have lower accuracies than others, they still deliver highly precise and intricate parts. Some users place more emphasis on ultra-fine machining accuracy and precision (down to 0.5 microns) while others focus more on total X, Y, and Z travel and overall potential part size.

How To Choose the Best Wire EDM Machine

When deciding to purchase the best wire EDM machine for your application, consider the factors below:

- Part Complexity: While every wire EDM machine can cut more intricate features than traditional CNC machines, the degree of accuracy and precision varies from one device to the next. Consider the part you would like to create and how precise its tolerances should be.

- Part Size: Some manufacturers desire larger parts with the same degree of precision and accuracy that is associated with smaller WEDM offerings. These larger machines are typically more expensive than their smaller counterparts but can deliver intricate and remarkably accurate large parts. Make sure the EDM machine you plan to buy is large enough to make the parts you need.

- Desired Run Time: There’s a tradeoff to be made between machining speed and part accuracy when it comes to WEDM. While fast runs on WEDM units will still deliver more accurate parts than traditional CNC machining, they will not be as accurate as those cut at a slower pace by WEDM. If efficiency or overall runtime is your biggest concern, look for machines that satisfy these criteria.

How Does a Wire EDM Machine Work?

Wire EDM machines cut or pit conductive material using sparks that are emitted from an electrically conductive wire. The material removal is done in the presence of a dielectric, or a material that can act as both an electrical insulator and conductor. In WEDM processes, deionized water most often acts as the dielectric, and both the wire and the workpiece are submerged. The wire from the machine and the workpiece are brought into extremely close proximity but never actually touch. Instead, once the voltage across the wire becomes large enough, the dielectric ceases to inhibit electron flow and an electric discharge occurs. These sparks are exceptionally hot (8,000-12,000°C) and melt a small portion of the workpiece to form the desired shapes. This discharge also turns some of the surrounding water into plasma, forming a bubble inside the dielectric fluid. When the bubble collapses, the melted material from the workpiece is washed into the deionized water bath.

While the plasma collapses and carries the melted material away with it, electrical discharges continue to occur. WEDM machines often create around 250,000 sparks per second. This rapid succession of electrical discharges effectively cuts the metal workpiece to extremely fine tolerances and leaves burr-free surface finishes.

Where Can I Get the Best Wire EDM Machine?

New wire EDM machines can be purchased directly from their manufacturers while used EDM machines are often available from second-hand sellers. Contact an EDM machine manufacturer to receive a quote for a new machine or search the web for second-hand machines for sale.

Who Are the Wire EDM Machine Manufacturers?

There are a number of manufacturers of wire EDM machines. However, the best wire EDM manufacturers in terms of accuracy and speed are:

- Makino: Best overall

- Agie and Charmilles: Best for speed and efficiency

- AccuteX and Excetek: Best pricing

There are many other WEDM manufacturers that offer excellent products. Consider each manufacturer and pick the machine most suitable for your company and intended use.

Are Wire EDM Machines Easy to Use?

Yes, wire EDM machines are exceptionally easy to use. New WEDM devices come with advanced, streamlined user interfaces that make start-up, operation, optimization, and maintenance easy for experts and beginners alike.

Summary

Xometry provides a wide range of manufacturing capabilities, including CNC machining and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.