Swiss machining has become a staple in modern manufacturing thanks to its ability to create components with remarkable accuracy… no wonder it’s a hit in demanding sectors like aerospace and medical. In this article, we’ll discuss what exactly Swiss machining is, how it works, and how it can be — and is — used.

What is Swiss Machining?

It all starts with the machine itself (also referred to as a Swiss lathe/machine/automatic lathe) that can carry out several tasks using different tools to work on a material or workpiece at the same time. The initial costs of buying and setting up a machine like this are most often higher than other basic equipment, but manufacturers feel that they end up paying for themselves. Although we don’t know exactly when it was invented, this machining procedure has gone through many refinements and developments that continue even today.

What Is the Origin of Swiss Machining?

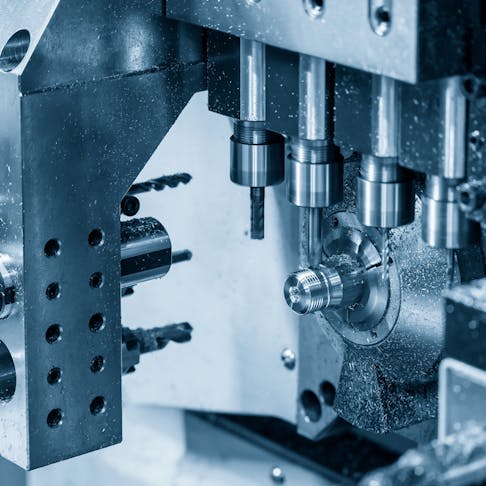

As you may have guessed, Swiss machining comes from Switzerland, back when almost every quality watchmaker was based there. In fact, it was originally developed in the late 19th century (generally attributed to Swiss watchmaker Jacob Schweizer) as a lower-cost and more precise way of making watch components, as the traditional manufacturing methods just weren’t cutting it. It eventually outgrew watchmaking and started being used for other products, like medical devices, electronics, and aerospace and automotive components. Some parts made with Swiss machining are shown in the image below.

Precision aside, the process offers many other benefits, too, including lower chatter, the ability to process longer and thinner parts quickly, and overall speed because it uses multiple tools at once. In addition to small and high-precision parts, it’s a great way of working on long pieces with small diameters that could bend with other methods, workpieces that need both turning and milling in a single setup, and components that are made in large quantities or are highly valuable. As they’re designed to work on small parts with extreme precision, these machines aren’t ideal for huge, bulky pieces. They also need a certain level of skill to operate.

How Does Swiss Lathe Machining Work?

It uses an automated clamp to push a long rod of material (called bar stock) into the machine. The clamp holds the material and just about feeds enough of it into the cutting area to make a part. Right behind that area, the material is supported by a rotating guide that keeps it steady and reduces vibrations. This design allows you to machine components with higher aspect ratios and tighter tolerances.

In a regular lathe, the material that’s being worked on is held in place, and it spins while tools work on shaping it. Longer parts can have extra support by means of a second holder to keep them in place. A Swiss lathe, though, is different in that the material can spin but also move back and forth, allowing multiple tools to work on it at the same time. This is great because it’s faster and much more versatile, allowing you to do other things like milling on the same machine.

The workpiece, which is usually a long, slim rod of metal or plastic, is fed into the machine from behind the headstock. Right next to the work area is a guide bushing, and the workpiece is inserted through it. That way it’s guided and supported during the work which reduces vibrations and helps everything run smoothly and precisely.

The machine also has a bar feeder that provides a continuous flow of the material, which means that it can keep going without you having to intervene all the time. When a part is finished, the bar feeder automatically releases the clamp, moves the material forward to the length of the next part, and then reclamps it. The machine’s headstock will hold and spin the material using its main spindle, and that will provide the needed rotation for machining.

The workpiece in the machine is surrounded by holders for tools, so you can mount anything you need in them. These tools can move independently on all three axes without any slack, and they’re extremely accurate. Each tool will either be a single-cutter or a rotating multi-cutter, and that way, you have everything happening at once—turning, drilling, milling, threading, or cross-drilling—depending on what you need. The tools are very close to the workpiece so the fact they don’t need to travel far is another reason why the whole thing is pretty quick. When the part is done, it’s separated from the rest of the material using a cut-off tool. Most modern Swiss lathe machines are usually CNC-controlled (computer numerical control).

What Is the Swiss Machine Used For?

Swiss lathes are generally used for small and high-value parts, high precision, high-volume manufacture, and various materials such as: stainless steel, brass, bronze, tool steels, etc.

How Is the Swiss Machine Used in the Manufacturing Industry?

In general, Swiss machines are used in two modes of manufacturing operation. In stable and high-volume setups in-house, making a limited range of parts—often dedicated to a single part made in very high volume. In subcontract machining services to supply varied clients in a batch-based production process that allows clients to access the skills and CAPEX of Swiss machining with lower commitment, at a higher per-component price.

What Other Industries Use Swiss Machines?

Any industry that requires small, high-precision components that are either turned or made by a mixture of turning and milling uses Swiss machines. For example,

Swiss machining is used in the manufacture of medical devices such as: surgical instruments, orthopedic implants, dental implants, and catheters to name a few areas. It is also employed to manufacture critical aerospace components such as: aircraft fasteners, hydraulic fittings, and sensor housings. In electronics, swiss machining is used to produce small, high-precision electronic components such as: connector pins, sockets, and contact probes.

When To Use CNC Swiss Machining

Swiss machining is best used for small and high-precision parts, long parts requiring small diameter operations that lose stiffness in ordinary turning, combined turning and milling parts, and higher-value and higher-volume components.

What Are the Materials Suitable for Swiss Machining?

We already mentioned that metals and plastics are quite common materials used in Swiss machining, but here’s a more detailed breakdown of some specific examples.

1. Copper

Electrical connectors, pins, sockets, and other components that need good electrical performance and heat dissipation.

2. Brass

Excellent palatability and used for connectors, fittings, valve bodies, decorative parts, and other things that need to be visually appealing and corrosion-resistant.

3. Nylon

Bushings, gears, insulators, and other components that require resistance to corrosion, as well as being low in density, and having a low friction coefficient (slippery surface).

4. Titanium

Amazing strength-to-weight ratio, corrosion-resistant, and biocompatible, often used for aerospace components, medical implants, and other high-performance parts.

5. Aluminum

Easy to machine, low in density, and impressive resistance to corrosion, so often used to make aerospace parts, automotive fittings, and consumer goods.

6. Nickel

High-temperature strength, corrosion resistant, and electrically conductive, found in aerospace, electronics, and chemical processing applications.

7. Plastics

Includes lots of different rigid and engineering plastics found almost everywhere, with qualities like low friction, low density, low cost, and resistance to corrosion.

8. Carbon Steel

Durable and cost-effective, usually found in automotive fasteners, shafts, firearms, and industrial machinery parts.

How Long Does the Swiss Machining Process Take?

It depends. A similar series of operations applied to a part by Swiss machining will generally be faster than a comparable capability by traditional or capstan lathe. Multiple operations can also occur simultaneously. Similar benefits accrue in comparison with 4+ axis CNC machining, which again generally uses only a single operation at a time.

How Accurate Is Swiss Machining?

It is typically possible to maintain diametral tolerances of +/- 0.0004 mm on small and flex-vulnerable parts. This compares favorably with traditional lathes that can only approach these tolerances by extremely fine cutting and much longer processing. Part length tolerances in Swiss machines also compare well with typical lathes. However, this is a result of better machine construction rather than the fundamental principles of the machine, as longitudinal processes differ very little between the machine classes.

What Are the Advantages of Swiss Machining?

Swiss machining offers some significant advantages over other machining approaches such as:

- Higher precision.

- Lower chatter.

- Longer and thinner parts can be processed faster.

- More rapid processing results from multiple, parallel operations being applied.

What Are the Disadvantages of Swiss Machining?

The disadvantages of Swiss machining are listed below:

- These machines are poorly adapted to larger jobs, both in diameter and length of parts.

- The CAPEX costs of Swiss machines are generally higher than more basic equipment.

- Operator skills in operation or programming are of a higher standard and the sector is quite skill-dependent.

How Does Swiss Machining Differ From Traditional Milling?

There are various differences between Swiss machining and the more commonly available processing methods. Swiss machining offers higher precision and higher productivity than other methods. The process is only applicable to smaller parts. Establishing production and developing good operational skills in Swiss machining takes longer and costs more than more basic tool setups.

What Is the Quality of Products Produced Through Swiss Machining?

When correctly set up, Swiss machining delivers very high-quality parts, with low per-part processing times and a reduced per-part cost as long as volumes/batch sizes are appropriate.

Are Swiss Machine Products Durable?

It depends. The durability of parts is a design and materials selection issue. In situations in which metal parts are not exercised beyond their intrinsic strength, abrasion, and corrosion limitations, they can serve indefinitely. Swiss machining can be applied to a wide range of materials, so no generalized description of durability offers any insight. However, higher precision can result in longer component life. Lower chatter makes surfaces that are less susceptible to wear. Lower machining stresses can result in overall better strength in delicate components.

How Much Does Swiss Machining Cost?

No two machining jobs are ever easy to compare for cost, but a few guiding principles can be applied in general. For example, for smaller batches, Swiss machining will always be more expensive than more traditional methods. This is a result of greater setup and programming/operational complexity. For higher-precision applications, Swiss machining is ideally suited to producing better precision and repeatability in parts, making it the only choice, so cost comparisons are redundant. For high precision and larger production volumes, Swiss machining is highly cost-competitive.

Is Swiss Machining Expensive Compared to CNC Machining?

It depends. For identical parts produced by more normal CNC machining and Swiss machining, some comparisons are useful. For comparable precision, CNC machining generally requires a considerably longer per-part processing time than Swiss machining. This is a result of the need for very low cut depths for higher tolerance in CNC processing. In setup terms, the two processes are relatively cost-comparable. However, Swiss machining carries extra setup/programming costs in the operation of multiple cuts at the same time, which reduces per-part processing times. For high-volume production of high-precision small parts, Swiss machining is highly competitive with CNC machining.

What Is the Difference Between Swiss Machining and CNC Machining?

The differentials between the processes depend heavily on the nature of the CNC process being referenced. Swiss machining involves the following:

- Close support by a sliding bushing at the cut point.

- Part rotation and stationary rotational axis for different tasks.

- Multiple cooperating cut points by several cutters, both point application and rotating.

- Full auto-feed of bar stock to produce multiple parts in sequence from a single material billet/bar.

- Swiss machines generally have less than 10 cutters set up and ready to present to the workpiece in a setup.

Overall, the difference between Swiss machining and the most advanced CNC machining centers is becoming blurred, as CNC capabilities continuously grow more intricate and advanced. CNC machining involves:

- In 3-axis CNC machining, the part is held stationary and the rotating cutter moves.

- In 4+ axis CNC machining the part can be rotated, either for positioning or for lathe-style cutting operations as required.

- No localized support is presented to resist the application of forces by the cutter. This introduces the possibility of distorting the part or the position of the part during cutting operations and requires careful programming to avoid.

- No automated material feed is generally included in CNC machines.

- It is common for CNC machines to have up to 30–40 individual cutters racked and set up ready to change.

How Xometry Can Help

If you need further clarification on the topic of Swiss machining, why not reach out to one of our representatives? Xometry also offers a plethora of related services, including CNC machining, laser cutting, and 3D printing. You can get your project started as soon as possible by requesting a free, no-obligation quote directly from our website.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.