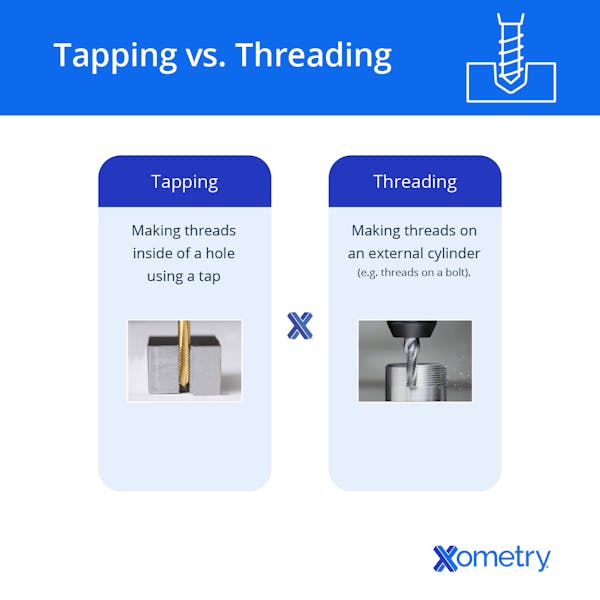

Thread milling and tapping are two methods of making threads in metal; those spiral grooves inside or outside of a hole that screws are meant to fit into. They’re both popular milling processes in the manufacturing industry, but they are very different. Let’s take a look at these two threading processes, the differences between them, their pros and cons, and when each should be used.

What is Thread Milling?

Thread milling is a manufacturing technique used to create threads. Instead of using a standard tool (like a tap), thread milling uses a specialized cutting tool designed for just this purpose called a thread mill. This mill is guided by a CNC machine for precise control, and its key feature is that, to make a thread, it moves the tool sideways in a circular pattern and carves it out in just one full turn.

This means that it can make threads with very precise spacing (thread pitch) — perfect if you need various sizes and completely customized threads to fit specific needs, without having to buy pricey rigid taps. For example, a 16-pitch thread mill can cut any 16-pitch thread, and you can easily switch to other sizes or pitches with the same tool, just by changing the machine’s program.

Thread mills are usually made from carbide which can last through thousands of holes before needing replacement, something that can be further extended when it’s kept clean and properly maintained. A thread mill looks a bit like an end mill but with a special thread pattern on the sides. There’s a shank for easy mounting on a tool holder, lots of teeth for cutting threads, and protective coatings to help them last longer.

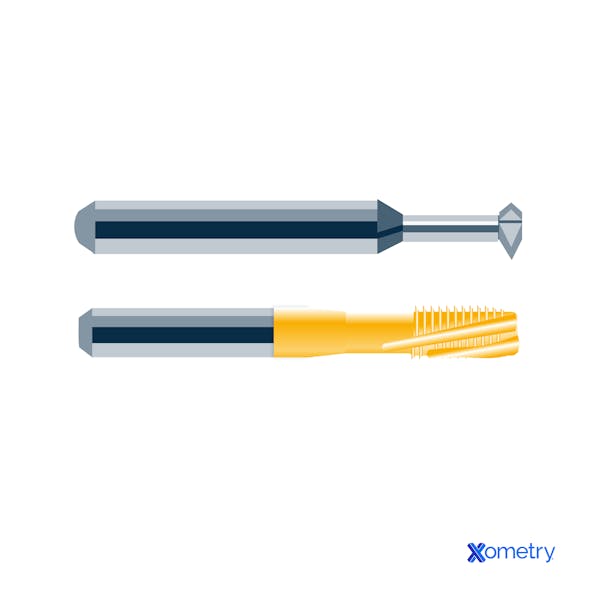

What Does Thread Mill Look Like?

A thread mill bears a resemblance to an end mill but features a thread profile on its side. A thread mill features a shank for secure mounting in tool holders, multiple teeth for cutting threads, a tailored thread profile, an end mill design for precise sizing, and optional coatings to enhance performance. Thread mills come in various sizes and lengths. Their appearance varies based on factors like size and design. Below is a picture so you can get an idea of what a thread mill looks like.

This is just an example as their appearance will vary on their size, length, and design — and there’s a whole bunch to choose from.

How Does Thread Milling Work?

Thread milling works by an operator inserting the thread milling cutter into the hole along the spindle axis until the desired full thread depth is achieved. Subsequently, the controller guides the thread cutter to the entry position, initiating the cutting of threads on the hole's sidewalls. Afterward, it moves in a 360° circular path and returns to its initial position.

As the threading tool follows this circular trajectory, it must incline towards the upper edge of the hole or travel one increment along the machine's Z-axis to form the thread effectively. Typically, the extent of the threading's depth remains within a range of one and a half times the diameter of the hole to minimize deflection and ensure precise results.

How Is Thread Milling Used in Manufacturing?

Thread milling plays a crucial role in manufacturing as a versatile and precise machining process. It is extensively utilized across various industries for creating threads on a wide range of materials and components. One of its primary applications is in the production of precision components. It excels at generating high-precision threads, ensuring tight tolerances and accurate profiles. Thread milling offers versatility in thread types, capable of producing internal and external threads, right-hand and left-hand threads, and various thread profiles to meet diverse manufacturing needs. It is particularly suitable for machining large threaded holes, eliminating the need for costly rigid taps. Custom thread designs are achievable, making it advantageous for unique or proprietary thread requirements. Thread milling is versatile enough to work with materials spanning metals like: aluminum, stainless steel, titanium, and high-temperature alloys, as well as non-metallic materials like plastics and composites.

What Are the Advantages of Thread Milling?

With thread milling, you have very accurate control over the size and fit of the threads you want to make. A single tool can make all different sizes and types of threads, even in tough materials like titanium or stainless steel, and it can make custom threads without you needing to splash out on custom taps. You also won’t need another tool to adjust the thread’s size if need be. It offers a high level of accuracy, and can make both interior and exterior threads, and both right- and left-handed ones.

What Are the Disadvantages of Thread Milling?

On the flip side, thread milling requires quite specialized machinery with a high spindle speed (up to 60,000 RPM), and this could be quite the investment. Also, for very tiny threads (like those you’d find in watches or some medical devices), thread milling might not be the best option—the tools and process just aren’t ideal for the superfine precision needed for those tiny threads.

What is Tapping?

Tapping is another way to create threads but mainly inside a hole. It involves using a tool called a “tap,” which basically looks like your average screw with grooves, and it works almost like a standard drill. The tap is turned into a hole, and it cuts threads as it goes. It’s a fairly straightforward process that can either be done by hand or with a machine and can be used to make threads in aluminum or steel.

In tapping, a hole that's just the right size for the tap is drilled — it needs to be big enough for the tap to fit but small enough to make room for cutting the threads. After drilling, the tap is lined up with the hole, and some lubricant is added to help reduce friction and heat. Then, the tap is carefully turned into the hole, cutting the threads as it goes. The direction has to sometimes be reversed to clear out the chips created. Once the threads are cut, you’ll need to clean up any leftover chips or lubricant.

What Does Thread Tapping look like?

A tap looks kind of like a screw or bolt and has groves with sharp edges all the way down its sides that remove the chips from metal to make threads. They’re held in place by a collet, chuck, or other type of tool holder and then moved toward the material. Here’s an example of what a tap looks like.

Taps are designed directly to a specific thread type. But it's handy to have a thread mill in your toolbox to hit non-standard threads to hit thread offsets that may not be achievable with a standard tap.Greg PaulsenDirector, Applications Engineering

How Does Tapping Work?

Tapping begins with the preparation stage, in which a hole of the appropriate size is drilled into the material. The size of the hole must be sufficient to accommodate the tap while leaving room for the creation of threads. The hole's dimensions are critical to ensure a proper fit for the threads. Next, the tap is perfectly aligned with the prepared hole. Cutting fluid or lubricant is then applied to both the tap and the hole. Lubrication serves several purposes, including reducing friction and heat generation during the tapping operation. With the hole prepared, aligned, and lubricated, the tap is inserted into the hole. The tap is then rotated clockwise (for normal, right-hand threads) while being fed into the material. As it rotates, the tap's cutting edges engage with the material, gradually cutting and forming the threads. It's important to periodically reverse the tap's rotation to break the chips created during the cutting process. This prevents the chips from clogging the hole and interfering with the threading process.

After the tapping process is complete, the workpiece undergoes a clean-up phase. This involves removing any remaining chips or debris from the hole, as well as cleaning away any residual cutting fluid or lubricant.

How Is Tapping Used in Manufacturing?

Thread tapping is used to create interior threads in holes. One of the most common applications of tapping is in the production of threaded holes and nuts that receive threaded fasteners, such as screws and bolts. These components are essential for assembling machinery, structures, and consumer products.

Furthermore, thread tapping plays a crucial role in industries such as: automotive, aerospace, electronics, medical, and construction. Thread tapping is utilized in the automotive sector to establish internal threads in transmission housings, engine blocks, suspension components, brake systems, and other vehicle parts. The aerospace industry also relies on thread tapping to manufacture threads in critical aircraft components, including landing gear, engine parts, and structural elements. Additionally, thread tapping is essential in the electronics industry for creating threads that accommodate fasteners and screws in a variety of devices, such as smartphones, computers, and consumer electronics. Finally, in the medical field, thread tapping is used to make threads in surgical instruments and medical equipment.

What Are the Advantages of Tapping?

Tapping is a speedy process, especially if you’re looking to make lots of threads in a short amount of time. It can make deep threads in tough materials like steel and is the way to go if you need to make very small threads.

What Are the Disadvantages of Tapping?

However, if you want to make different hole sizes with tapping, you’ll need many tools on hand. Also, once the thread is cut, it’s hard to change its size. Tapping is also not suitable for making external threads, although it’s great for internal ones.

How To Choose Between Thread Milling and Tapping?

Selecting between thread milling and tapping depends on various factors. The decision should be based on the specific needs of your machining application. Generally, it is best to use tapping when you need to make multiple holes with little variations in size. Some key considerations to help you weigh the two options are: speed, power, size, tool life, flexibility, thread fit, thread quality, blind holes, and chip control.

For example, tapping generally offers a slight speed advantage over thread milling. For typical workpiece materials and thread depths, tapping can be faster, taking around 4–5 seconds to create a 1/4"-20 thread, while thread milling may take roughly twice that time. However, for large production quantities, thread milling can become more efficient. Taps also require substantial torque, especially when dealing with larger threads. Machining centers, particularly those with geared heads, are needed for threads beyond approximately 3/4" in diameter. In contrast, thread milling has no inherent size limitations and can handle various thread sizes effortlessly.

Thread milling's versatility can be limited by extremely tiny threads, such as those found in wristwatches and certain medical devices. If these miniature threads extend beyond a few diameters, taps might be the preferred choice due to their wider availability. Thread milling also has the advantage of longer tool life, thanks to the use of carbide tools compared to most taps, which are made of high-speed steel (HSS). When taps wear and break inside a hole, workpiece damage or scrapping is more likely. Thread mills are more predictable, making it more likely to salvage the workpiece if breakage occurs during operation. Taps can also only create threads based on manufacturer specifications, requiring a different tap for each variation in thread size and pitch. Whereas, thread milling offers the flexibility to adjust thread size and pitch through CNC machine tool programming.

Basically, if you need to make a lot of threads quickly, particularly small or deep ones, go for tapping, which is usually faster. It’s also more economical if you only need to make a few threads in standard sizes – so it’s good if you’re on a tight budget. If you need to adjust thread sizes, and work with various materials, large or custom threads, thread milling will be the method for you. It’s adaptable, and the tools also last much longer.

How do Thread Milling and Tapping Differ in the Cutting Process?

The primary distinction between tapping and thread milling lies in their approach to creating threads. Tapping employs a tap specifically designed to cut a predetermined thread, while thread milling relies on the controlled movement of the tool to define the thread. Consequently, tapping is exclusively used to cut threads on the inner surface, whereas a thread milling cutter can be employed for both inner and outer surface threading.

What Is the Accuracy of Thread Milling?

The accuracy of thread milling is typically quite high. Thread milling allows for precise control over thread dimensions and profiles, making it well-suited for applications that require tight tolerances and accurate threads. The CNC machines equipped with thread milling cutters can provide consistent and accurate results, ensuring that threads meet the desired specifications.

What Is the Size of the Thread Mill?

The size of a thread mill can vary widely depending on the specific application and requirements. Thread mills come in various sizes to accommodate different thread dimensions and hole sizes. They can range from small, compact thread mills for threading small holes to larger, more robust thread mills for machining larger threads. The size of the thread mill is typically determined by factors such as the thread pitch, diameter, and depth, as well as the material being machined and the machine's capabilities.

How do Thread Milling and Tapping Differ in Applications?

Thread milling is particularly suited for machining thin-walled parts, asymmetric or non-rotating components, and materials that generate high cutting forces, where chip evacuation might be problematic. It also excels in reducing tool inventory, accommodating unstable component setups, and customizing threads. Furthermore, it efficiently handles large threaded holes. In contrast, tapping shines when speed is of the essence, standard thread sizes are required, and deep threads need to be produced, especially in tougher materials. Tapping is also economical for small threads like those in wristwatches and medical devices. The choice between thread milling and tapping depends on specific application requirements and considerations.

How Flexible Are Thread Milling and Tapping?

Thread milling shines in terms of flexibility. When dealing with tapped threads that fall out of tolerance, the usual solution is to acquire a different "H-size" tap with minor size adjustments available in increments of 0.0005" larger or smaller. Thread milling simplifies this process by allowing for straightforward offset adjustment to bring threads back to specification, eliminating the need for multiple tap sizes. Moreover, traditional taps are designed to produce a single size and type of thread and often feature material-specific geometries. In contrast, thread mills excel in versatility. A full-profile 16-pitch thread mill can effectively cut any 16-pitch thread, and the same principle applies to 20-pitch thread mills and so on, as long as the thread fits within the hole dimensions. Single-plane thread mills can accommodate a wide range of thread sizes and pitches simply by modifying the machining program. This adaptability makes thread milling an excellent choice when precision, customization, and efficient thread adjustments are essential.

What Is the Typical Life Span of Thread Mills and Taps?

The life span of thread mills and taps in manufacturing can vary depending on several key factors. In general, thread mills tend to have a longer life span compared to taps. High-quality thread mills, often made of durable materials like carbide, can last for thousands of holes or more before requiring replacement. Proper maintenance, such as keeping the tool clean and well-maintained, can further extend their lifespan. On the other hand, taps have a comparatively shorter life span. The longevity of taps depends on factors like their material (e.g., high-speed steel or carbide), the hardness of the workpiece material, and the specific cutting conditions. Taps may last from several dozen to a few hundred holes before showing signs of wear or reduced cutting performance, particularly in demanding materials like stainless steel or hardened steel. Regular monitoring of tool condition and adherence to recommended cutting speeds, feeds, and lubrication practices are essential to maximizing the life span of both thread mills and taps in manufacturing operations.

Are Thread Milling and Tapping Common Methods Used in Milling Processes?

Yes, both thread milling and tapping are common methods used in milling processes. These methods provide precision and reliability in producing threads for fasteners, components, and various parts. Thread milling is known for its versatility and ability to create a wide range of threads, offering flexibility in manufacturing. Tapping, on the other hand, is favored for its speed and efficiency, making it a practical choice for high-volume production.

How Xometry Can Help

If you’ve decided which thread-making method is right for you, or if you are still stuck and want some help in the matter, our experts are on hand to help you out. Reach out to one of our reps or get a free, no-obligation quote for any of your manufacturing needs.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.