The term “milling” refers to the manufacturing process of using a circular cutting tool on the ends and sides of a material blank to make a finished part. That’s obviously just a very general summation; there are actually around 30 different types of milling operations, 15 of which (the most commonly used ones) we’ll go over in this article.

You’ll find that most milling types are self-explanatory with exactly what they do or how they work in their name, but here’s a little more info on each one.

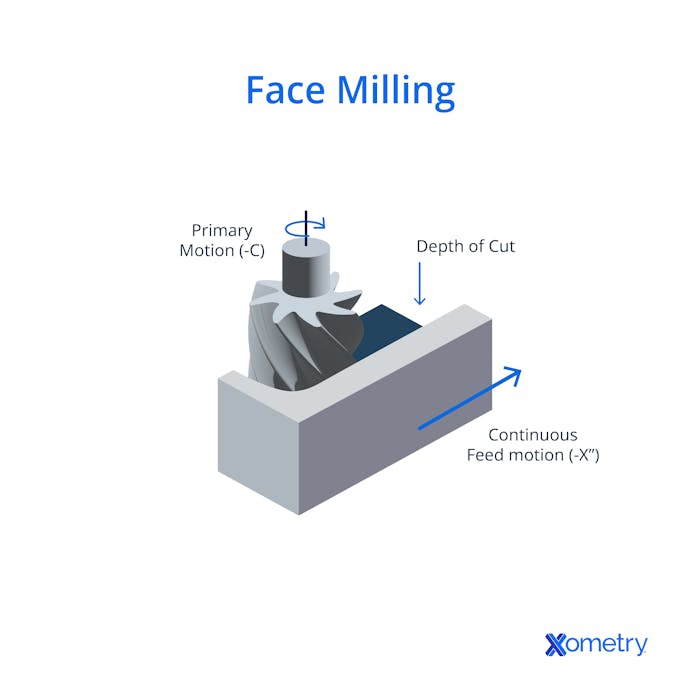

1. Face Milling

Face milling is beloved in the manufacturing world because it can be used to make accurate and smooth surfaces, even on larger pieces. It can make pockets and steps in metal by flattening the material and smoothing out the top. A face mill has cutting edges on its face, which is the part that looks like a disk, and these cutters work by shaving off material from a workpiece horizontally until it reaches the depth required (this will be preset by you). This image explains how it works:

2. Slot Milling

Slot milling makes slots (like grooves or trenches) in any size with a slot cutter which looks like a circular saw blade. This will cut into the sides of the materials to do the job, but you can also use an end mill that cuts on its side and face. It basically carves out a channel in the material, making things like the slot your keys go into (keyways) and other grooves, like this one:

A part made with slot milling

3. End Milling

The tool used in end milling has cutting edges on both its end and sides and can make things like slots, pockets, and contours. This method is very common because it is versatile. It’s a little like a drill bit that can cut straight down (plunging) but it can cut sideways, too. The below diagram will give you an idea of how it works.

4. Thread Milling

The spiraling threads you find on screws and bolts are made with thread milling. The tool has many cutting edges and is able to make threads in many different materials, in all different sizes, and can even tackle more complex designs. The thread milling cutting tool (which, by the way, is known for its durability and accuracy) rotates around the material along the thread path to cut the threads. Its capabilities are pretty much limited to making threads, but it does make them exceedingly well. Here’s a picture of a thread made by thread milling:

Thread milling.

5. Shoulder Milling

Shoulder milling removes material from the side of a workpiece (the “shoulder” or “sidewall”) with different cutting tools, like end mills, to make flat, 90-degree angles, like steps.

6. Side Milling

A side milling cutter or end mill is used in side milling to shave thin layers of material from the side of a workpiece. This is the way to go for flat or contoured surfaces. Xometry’s very own Aaron (our marketing SVP) explains more about this milling process in the below video.

7. Profile Milling

If you have to make complex shapes and profiles on a surface, profile milling will be your best friend. It uses a tool with multiple cutting edges to make curves and angles and also has a ball tip that moves around, smoothing everything out. It sometimes (but not always) uses multiple axes to make the cuts. Getting an axis to cooperate in manual milling is, putting it mildly, impossible, so the process often is used with CNC (computer numerical control) machines. Profile milling is used to make dies, molds, and other parts with more detailed surfaces, like this:

Profile milling

8. Saw Milling

Saw milling works with a large, thin, and round cutting tool that has lots of teeth (like a circular saw blade). This fairly quick and easy process is also known as “slitting” because it makes thin slits in a material. The blade of the tool can cut straight down in a vertical line or move along the surface for different types of cuts.

9. CAM Milling

CAM (computer-aided manufacturing) milling can make parts that most humans would find impossible to create by hand. It’s an automated process, with the cutting tool being controlled by a computer. Human effort is only needed to design the digital blueprint for the part with exact instructions on how to make it in the language that it can understand (don’t worry, there are tools for this) and then feeding it to the computer and switching it on.

10. Gear Milling

As you may have guessed, this milling method has been specifically designed to make gears and gear teeth (like the toothed wheels found in car engines or clocks). It’s done with gear hobbing cutters, or milling cutters, which remove material to make the gear teeth. For simple gears, manual machines are used, but for complex ones, manufacturers tend to go the CNC route.

11. Angle Milling

Angle milling makes beveled edges and angled features on parts. You can use specialized tools with this process, like tapered milling cutters that are cone-shaped or parallel-faced cutters that are flat but can be adjusted at a tilt to get the angle. To get the right tilt, you’d have to use a tilting arbor or four (or more) axis machine.

12. Form Milling

Form milling makes contoured and detailed shapes on a surface with either a specialized milling cutter in the exact shape or profile you want or generic cutting tools (the latter is a somewhat repetitive process, similar to profile milling). It’s used a lot in automotive, aerospace, and mold-making, and many times with a CNC machine.

13. Straddle Milling

Straddle milling involves mounting two milling cutters on an arbor and positioning them next to each other to create parallel slots, grooves, or surfaces on your chosen material. Because it has two cutting tools, it can essentially finish a piece in half the time. We see this process used often for keyway milling and machining flats on opposite sides of a shaft.

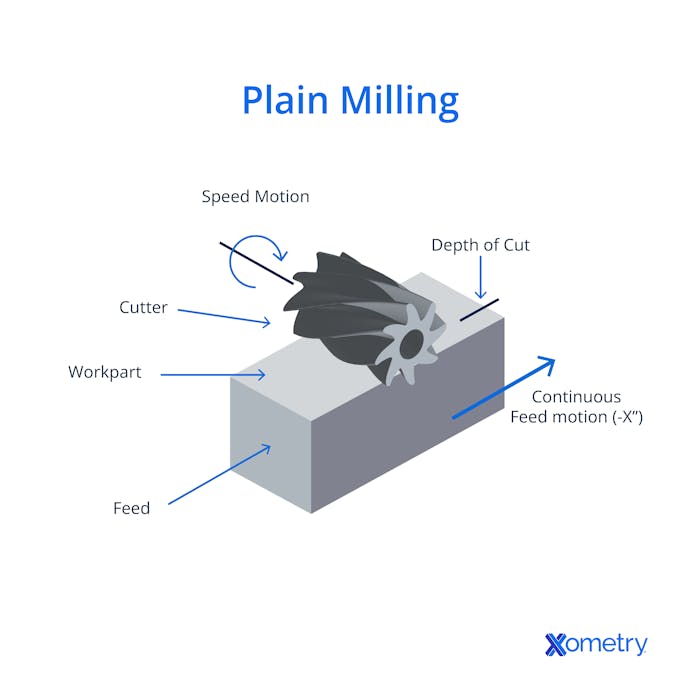

14. Plain Milling

It might not have a very interesting name, but plain milling is still a useful manufacturing method. It’s pretty basic, removing material from a surface using a flat, horizontal cutting tool, and it is used for making square or rectangular features. Here’s what that looks like:

15. Gang Milling

Gang milling is a little more aggressive, requiring you to mount several cutters on a single arbor. This allows you to cut multiple surfaces or features using a single pass. This is a good method to use if you want to keep productivity high and not have to spend lots of time setting up and handling several individual machines. It’s great for mass production of identical parts, but would be overkill for low-volume needs.

What Is Milling?

Metal milling is machining that involves the removal of material from a metal workpiece using a rotary cutting tool. Either the tool or the workpiece or both are moved to create profiles and complex shapes in the cut path.

In metal milling, the workpiece is typically secured to a worktable or fixture, and a cutting tool, such as an end mill, face mill, or drill, rotates at high speeds. The tool makes contact with the workpiece and, as it rotates, its cutting edges remove material, creating the desired features, profiles, and forms. The cutting tool, or part, or both can move along multiple axes, allowing for the creation of flat surfaces, contours, holes, threads, and intricate shapes.

Metal milling is widely used in industries such as: aerospace, automotive, manufacturing, and engineering. It offers the advantages of high precision, versatility, and the ability to work with a variety of metals, including steel, aluminum, brass, and titanium.

Machines used for milling are either multi-purpose and adaptable manual or CNC mills but can be special-purpose fixtures that are integrated into a production line.

What Is the Importance of Milling?

Milling plays a central and irreplaceable role in most manufacturing sectors due to its adaptability and expanding capability set. It allows for the production of precise and repeatable components, meeting tight tolerances and quality standards that can adapt to cost and functional needs. Milling offers the flexibility to create an almost unlimited range of parts with divergent shapes, sizes, and complexities, with few material limitations. It is efficient in reducing material waste, energy use, and processing time when compared with other manufacturing methods. The process can be used with virtually all metals, plastics, composites, ceramics, and many natural materials such as stone, wood, and bone. Milling enables the customization of parts, meeting specific design and engineering needs. Small design alterations during a production run generally involve minor programming alterations and can allow design tuning on the fly. CNC milling machines allow for automated and repeatable production, increasing productivity and consistency. CNC was the earliest form of digital manufacturing automation and remains central to the process. Milling is used for prototyping and product development, allowing for testing and refinement of designs. The benefit of “real” material components at prototype is that full-force and long-duration testing is easier and more precisely reflects the mass-produced product.

What Are the Uses of Milling?

Milling machining is central to the delivery of single, moderate-volume, and mass-production components across essentially all sectors of industry. For example, milling is central to the creation of critical components like: aircraft frames, engine parts, landing gear, engine blocks, transmission components, and chassis parts. It allows fast processing and is extensively used for finishing operations on sand, die, and investment cast components. Milling is used in the precision manufacture of implants, prostheses, and surgical instruments, often using exotic materials and always requiring high precision. The high-volume manufacturing and precision machining of printed circuit boards (PCBs) and connector components is also generally performed on special classes of CNC mills.

How To Choose a Type of Milling?

Selecting the appropriate type of milling process for machining components depends on various factors. For example, for simple components with flat surfaces or straight features, plain milling will often serve well. Complex components with intricate shapes may require more specialized processes like profile milling or form milling. Tight tolerances and high-grade surface finishes are best achieved with precision milling processes such as finish milling or surface milling. This involves fine cuts and low feed rates and results in longer processing times and higher costs.

Consideration of the type of material greatly affects equipment, cutting tool selection, and cutting parameters. Harder materials generally benefit from climb milling for reduced tool wear. For low-volume or prototype production, flexibility and setup simplicity may be prioritized, favoring manual or CNC milling.

What Is the Most Popular Type of Milling?

The most prevalent type of milling for machining parts is by 3+ axis CNC processing. The overwhelming majority of tasks only require 3 or 3 ½ axis machines, which are the most common type. CNC milling has become dominant in fourth-generation manufacturing, due to its numerous advantages.

While CNC milling is prevalent, it's important to note that manual milling for small-scale or specialized applications is still widely used. Also, more specialized milling techniques like gear milling or thread milling, are still used when the specific requirements of a part call for them.

What Is the Cheapest Type of Milling Operation?

The cheapest milling operation for making parts typically involves manual milling using conventional milling machines. Manual milling relies on skilled operators to control the machine's movements and tool engagement.

It is cost-effective because it requires a relatively low initial investment compared to CNC milling machines, which are considerably more expensive. This approach is suitable for small-scale production, prototyping, and repair tasks. The choice between manual and CNC milling depends on factors like: part complexity, production volume, and budget constraints.

What Is the Most Expensive Type of Milling Operation?

The most expensive milling operation for making parts typically involves processes that require advanced equipment, tooling, and operator/programmer expertise. For example, utilizing high-spindle-speed machining centers with advanced tooling and cutting strategies for precision and speed can increase machine charges. It is utilized by 30 to 50% but increases throughput to a lesser degree, increasing overall costs. A job that costs $100 manufactured with normal spindle speeds is liable to be around 10-30% more expensive when performed on equipment that supports higher spindle speeds, as throughput is barely altered but equipment costs are increased.

On the other hand, increasingly complex applications in aerospace and medical industries commonly require machines with five or more degrees of freedom for complex, multi-sided machining. Multi-axis machines typically require charge-out at two to three times the rate, but the reduction in additional setups will generally more than compensate for this. Overall, a complex task will generally cost 20 to 70% less when performed on higher-capability equipment, despite higher machine costs. Simple tasks are similarly higher by 2 or more times, through poor exploitation of machine capabilities.

Utilizing the most advanced types of machine and exotic techniques in the tool path can also deliver extremely tight tolerances and high-quality surface finishes. This is common for optical and semiconductor applications. This adds a multiplier of 2 to 3 times, compared with more ordinary precision-level machining of an otherwise identical part. Finally, working with exotic or optical materials, superalloys, ceramics, and composites raises the cost of tooling and expertise, making the process expensive. Exotic materials can increase costs by multiples of 10 to 100 times and more, as material costs can completely overwhelm machine costs even after additional machining difficulty is factored in.

What Type of Milling Operation Is Most Accurate?

The most accurate general milling operation for making parts is typically precision CNC milling, particularly when combined with advanced machining techniques and equipment. The use of higher-precision equipment, more advanced and esoteric tool path planning, and extremely precise cutters can elevate precision and repeatability considerably.

For industries like: aerospace, medical devices, and optics, in which tight tolerances are critical, precision CNC milling is the only practical choice.

What Milling Cutter Has Helical Flutes on Its Surface?

Helical flute cutters have flutes (cutting edges) that spiral around the tool's axis in a helix form. Helical end mills and side cutters efficiently evacuate chips from the cutting area and are particularly useful in applications in which chip removal and improved surface finish are essential. In particular, the helical form reduces the adhesion and buildup of cuttings behind the tool edge. It also encourages a degree of chip flow along the cutting edge, making them self-clear. The recruitment of cuttings onto the tool has the greatest and most immediate impact on the surface finish, as the cuttings score the freshly cut face.

Helical end mills are available in various configurations, including: square end mills, ball nose end mills, and corner radius end mills, making them versatile for varied milling operations and materials.

Is CNC a Type of Milling Operation?

Not specifically. CNC has come to mean a broad family of machining processes, any of which can be controlled by a computer numerical control system and a G-code program. The overwhelming majority of broad capability machining centers are 3+ axis CNC mills.

Summary

To make things super simple, here’s a useful cut-out-and-keep, quick-reference guide on the different milling types.

How Xometry Can Help

Xometry provides a wide range of manufacturing capabilities, including all the types of milling mentioned in this article, as well as 3D printing, laser cutting, CNC machining, and much more. If you want to learn more about machining or request a free no-obligation quote, reach out to a Xometry representative today.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.