When compared to CNC (computer numerical control) mills, CNC routers are a low-cost option that make creating custom parts easy and accessible. These routers have been designed specifically to carve out complex shapes from soft materials like wood, plastic, foam, sift metals, and sometimes even steel. Let’s have a closer look at how a CNC router works, its various components, what it can and can’t do, and which software to use with it.

What is a CNC Router?

A CNC router can be controlled by a computer—it’s like a traditional router with a modern-day upgrade. To control it, the machine’s servo motors are fed a set of instructions in a language they can understand: G-code. The instructions tell the machine exactly how and where to move and, once it has read them, the router gets to work moving a high-speed rotating cutting tool to make the carvings. The process falls under the subtractive manufacturing category as it removes material to make parts, unlike 3D printing, a.k.a. additive manufacturing, which adds layers.

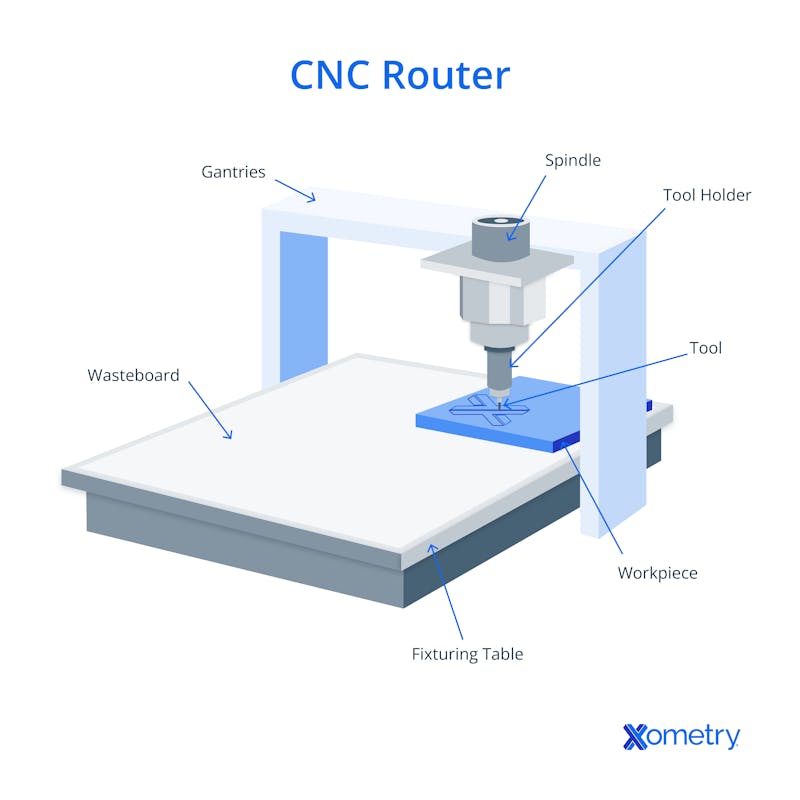

These routers typically have a gantry-style construction (with a horizontal support beam or structure) where the spindle (the main cutting tool) will move in two directions—left and right along the x-axis, and back and forth on the y-axis—to cut or carve material in the right shape and design. Depending on the material you’re working with and the shape you want the CNC router to carve, there are different cutting tools available. These can be manually swapped out, but some of the more advanced models feature an automatic tool changer so you don’t have to physically get involved.

Unlike standard CNC mills, these routers don’t have much range of motion up and down (along the z-axis), so won’t be able to make deeper cuts or holes on tall parts or very thick materials without struggling or making mistakes. They can be used to engrave lettering onto harder materials like granite, though. In general, CNC routers are best for use on flatter and softer materials (think: MDF, plywood, acrylic, and polyurethane foam/sheet), and metals like brass and aluminum.

CNC routers are used a lot in woodworking to make everything from cupboard doors to 3D sculptures. They can create wooden patterns for sand molds used in metal casting and cut foam into custom shapes to be used in packaging. The advertising industry uses CNC routers to engrave custom signs and lettering on wood or plastic for various promotional products.

Parts of a CNC Router

A CNC router machine has four main components that all work together to make the part: the bed, the controller, the motors, and the spindle/router. Below you’ll find a little more information on each of these components.

Bed: This is where you’ll put the material that you want to cut. Some beds have multiple holes or attachment points to make it easier to mount clamping hardware so that the workpiece can stay in place during cutting.

Controller: This part houses all the electronics, including the stepper or servo motors, that control the machine’s speed and how and where it cuts.

Motors: The stepper or servo motors operate each of the three motion axes. Steppers are usually found on cheaper hobbyist routers, whereas servos, which are found on more expensive machines, are used in professional-grade models because they offer more precision. There’s also a separate high-speed motor that rotates the cutting tool.

Spindle/Router: This is what holds and rotates the cutting tool at the set speed. It’s usually mounted on the gantry above the bed and moves as needed along the axes.

The below diagram shows the different parts of a CNC router.

How Xometry Can Help

Need help with CNC routing or any other manufacturing service? Xometry provides a wide range of capabilities including CNC machining, 3D printing, injection molding, laser cutting, and sheet metal fabrication. Get your instant quote — for free and with zero obligation — today.

Xometry provides a wide range of manufacturing capabilities including CNC machining, 3D printing, injection molding, laser cutting, and sheet metal fabrication. Get your instant quote today.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.