Grade 434 stainless steel is one of many ferritic stainless steel grades available. It is valued for its strength, and corrosion resistance, but also for its low coefficient of thermal expansion and magnetic properties all balanced with cost-effectiveness. Due to its numerous desirable properties and affordable cost compared to other stainless steels, 434 stainless steel is often used in the automotive, food packaging and processing, power generation, and chemical processing industries.

SAE 434, like other steel alloys, is made by melting raw iron ore, removing impurities, and then adding the necessary concentrations of alloying elements. SAE 434 has a chemical composition of 16-18% chromium, 1% each of molybdenum, silicon, and manganese, 0.12% carbon, and other elements. This article will shed light on the alloy’s uses, advantages, and disadvantages by examining the composition and properties of 434 stainless steel.

What Is 434 Stainless Steel?

Type 434 is a ferritic stainless steel. This means that its as-annealed microstructure consists of ferrite and spheroidal carbides. Ferrite is the form of iron-based alloys that solidify with a body-centered cubic (BCC) crystal lattice. It is not heat-treatable to increase strength. Like other stainless steels, 434 steel is characterized by its corrosion resistance and strength. These traits mean 434 stainless steel is a mid-range ferritic stainless steel that strikes a good balance between cost and corrosion resistance for applications that are not excessively demanding. This enables 434 stainless steel to be used in low to moderately demanding corrosive environments and in various industrial and high-temperature applications. For more information, see our guide on the material properties of carbon steel.

What Is 434 Stainless Steel Used For?

Type 434 stainless steel’s unique blend of properties makes it great for applications across a variety of industries at a reasonable cost. The material is often used in applications that demand corrosion resistance, thermal stability, chemical stability, and high strength. For instance, in the automotive industry, 434 stainless steel is often used in exhaust systems because of its corrosion resistance and thermal stability. This helps extend the life of a car’s exhaust components. Another common use of 434 stainless steel is in food processing equipment, where the material is often used in storage containers and mixing tanks. Type 434 steel’s chemical stability makes it a great choice for acidic foods and for routine cleaning from various chemicals.

How Is 434 Stainless Steel Made?

The production of 434 stainless steel starts with the creation of pig iron from iron ore by using a blast furnace or electric furnace. Pig iron is iron that has excess carbon and other impurities removed by way of oxygen that is injected into the molten iron. When the desired carbon concentration is obtained in the pig iron, 434 stainless steel alloying elements like chromium, molybdenum, silicon, manganese, and others are added to the melt. Next, the molten 434 stainless steel alloy is cast into various shapes like ingots, billets, and bars and then allowed to naturally cool to the ambient temperature. Additional forming processes like extrusion or rolling are used to create additional shapes such as sheets, plates, and more.

What Is the Chemical Composition of 434 Stainless Steel?

434 stainless steel consists primarily of iron (81%), chromium (16-18%), molybdenum (1%), manganese (1%), silicon (1%), and carbon (0.12%). The full chemical composition of 434 stainless steel is shown in Table 1 below:

| Element | Chemical Composition (%) |

|---|---|

Element Chromium | Chemical Composition (%) 16-18 |

Element Molybdenum | Chemical Composition (%) 1 |

Element Manganese | Chemical Composition (%) 1 |

Element Silicon | Chemical Composition (%) 1 |

Element Carbon | Chemical Composition (%) 0.12 |

Element Phosphorus | Chemical Composition (%) 0.04 |

Element Sulfur | Chemical Composition (%) 0.03 |

Element Iron | Chemical Composition (%) Remainder |

What Is the Carbon Content of 434 Stainless Steel?

The carbon content of 434 stainless steel is 0.12% which is higher than other stainless alloys containing chromium. Its higher carbon content makes it harder than other stainless alloys but also less ductile.

What Are the Properties of 434 Stainless Steel?

Some properties of 434 stainless steel are shown in Table 2 below.

| Property | Value |

|---|---|

Property Density | Value 7.80 cm³ |

Property Yield Strength | Value 205 MPa |

Property Ultimate Tensile Strength | Value 450 MPa |

Property Elongation | Value 22% |

Property Hardness | Value 89 HRB (converted from Brinell hardness) |

Property Electrical Resistivity | Value 60 μΩ*cm |

Property Magnetism | Value Yes |

Is 434 Stainless Steel Magnetic?

Yes, 434 stainless steel is magnetic. This is because it is largely composed of a magnetic phase called ferrite. Ferrite is magnetic due to the arrangement of its atoms in a body-centered cubic (BCC) crystal lattice.

Machinability Rating of 434 Stainless Steel

434 stainless steel machinability rating ranges between 40-75%. Compared to austenitic stainless steels (machinability rating of 30-80%), 434 is more machineable but less machineable when compared to martensitic stainless steels (machinability rating of 40-100%).

What Are the Thermal Properties of 434 Stainless Steel?

Some of the thermal properties of 434 stainless steel are shown in Table 3 below:

| Property | Value |

|---|---|

Property Melting point (liquidus) | Value 1510°C |

Property Thermal conductivity | Value 26.1 (@100°C) - 26.3 (@500°C) W/mK |

Property Thermal expansion coefficient | Value 10.4 (@100°C) - 11.4 (@538°C) µm/m°C |

What Are the Common Forms of 434 Stainless Steel Material?

SAE 434, like other steel alloys and metals, is available in various shapes that are suitable for different applications. The common forms of 434 stainless steel are listed below:

Bar

Type 434 stainless steel bars are made by the continuous casting of the molten alloy or by extruding or rolling and extruding 434 ingots. Bars can be square, rectangular, circular, hollow tubes, or hexagonal-shaped. Additionally, bars may be strengthened by cold rolling since cold rolling alters the microstructure of the material and force the atoms in the steel to dislocate. If desired, annealing and hot-rolling can be used after cold-working to soften the material and restore it to its original material properties. SAE 434 bars are ideal for making parts from machining.

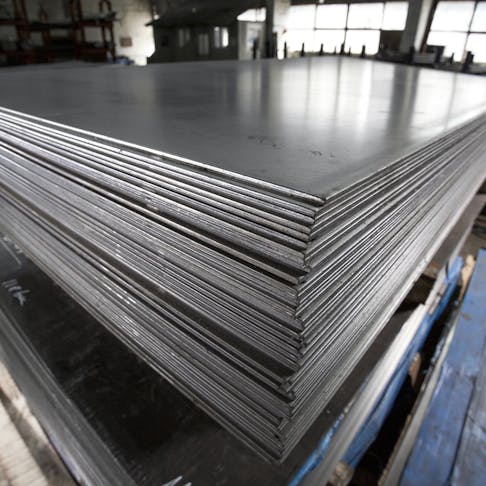

Plate

SAE 434 stainless steel plate is made by hot rolling or cold rolling the material by passing it through several rollers to achieve the desired thickness and dimensions. SAE 434 plate thickness ranges from 6 to 25 mm. Welding and plasma cutting are often used to process 434 plates into parts or assemblies.

Sheet

Type 434 stainless sheets are similar to plates but thinner. Like plates, sheets are made by either hot rolling or cold rolling until the desired thickness and dimensions are obtained. The thickness of 434 stainless steel sheets ranges anywhere from 0.1 to 6 mm. Sheets are highly flexible and ideal for lighter applications that aren’t particularly load-demanding.

Hot Rolled

Hot rolling is a forming process that entails heating metal above its recrystallization temperature and plastically deforming it by rolling the metal between two rollers. The cross-sectional area of the metal decreases due to the rolling process which causes atoms in the microstructure to move around. Hot-rolled 434 steel is available in plates, sheets, and rectangular and round bars.

Annealed

Annealing is a heat treatment process used to make materials more ductile and less hard. The process involves heating and holding 434 stainless steel at a temperature higher than its recrystallization temperature. After heating, the metal is cooled to room temperature. Annealing causes atoms in the microstructure to rearrange and reduces the number of dislocations. As the metal cools, recrystallization occurs.

Cold Drawn

Cold drawn is a form of cold working and is both a forming and strengthening process that involves permanently deforming a material at room temperature. Cold drawing is often completed after annealing and is accomplished by forcing the material through an extrusion die. The dislocation of atoms in the microstructure at room temperature affects the material’s crystal lattice structure and leads to increased strength and higher hardness.

What Are the Equivalents of 434 Stainless Steel?

Different countries and regions of the world use different nomenclature and standards for stainless steel alloys. Table 4 below shows the stainless steel equivalents of 434 steel based on the country or region in which the steel is used.

| Country or Region | Equivalent Grade |

|---|---|

Country or Region USA | Equivalent Grade AISI 434 |

Country or Region Germany | Equivalent Grade DIN 1.4113 |

Country or Region France | Equivalent Grade AFNOR Z 8 CD 17.01 |

Country or Region Italy | Equivalent Grade UNI X 8 CrMo 17 |

Country or Region Japan | Equivalent Grade JIS SUS 434 |

What Are the Advantages of Using 434 Stainless Steel?

The advantages of 434 stainless steel are listed below:

- It exhibits great corrosion resistance.

- It has high strength compared to other materials like 1090 mild steel or A36 steel.

- It exhibits little expansion compared to austenitic stainless steel due to its low coefficient of thermal expansion.

- It is chemically stable which means it does not readily react with solvents and cleaning agents. This makes 434 stainless steel easy to clean.

- Unlike other commonly used stainless steel grades like 304 or 316, 434 stainless steel is magnetic. This makes 434 stainless steel great for applications where magnetic properties are desirable such as solenoids, fuel injectors, motors, and more.

What Are the Disadvantages of Using 434 Stainless Steel?

Type 434 stainless steel disadvantages are listed below:

- It is more expensive than carbon steel and other metals like aluminum due to its alloying elements and higher production costs.

- It has a low thermal conductivity compared to materials like copper and aluminum but has higher thermal conductivity compared to other stainless steels. This makes the material a non-ideal material choice for applications that require rapid heat transfer.

What Is the Difference Between 434 Stainless Steel and 304 Stainless Steel?

The primary differences between 434 stainless steel and 304 stainless steel are their compositions, and consequently, their properties. Grade 434 is a ferritic stainless steel, while 304 is austenitic-type stainless steel. This means 434 stainless steel has a ferritic microstructure due to its lower chromium and nickel concentrations, while 304 stainless steel is austenitic. As a result, 434 stainless steel is magnetic while 304 stainless steel is not. Additionally, 434 stainless steel has a lower chromium and nickel concentration than 304 stainless steel. The lower chromium concentration and higher carbon content in 434 stainless steel make it less corrosion-resistant, but stronger than 304 stainless steel.

What Is the Difference Between 434 Stainless Steel and 316 Stainless Steel?

Like the differences between 434 stainless steel and 304 stainless steel, the differences between the properties of 434 and 316 are entirely attributed to their chemical compositions. 434 stainless steel is a ferritic stainless steel while 316 stainless steel, like 304, is an austenitic stainless steel. This means 434 stainless steel is magnetic, while 316 stainless steel is not. While 434 and 316 have similar chromium concentrations, 316 is considered more corrosion-resistant due to its higher nickel and molybdenum concentrations.

What Is the Difference Between 434 Stainless Steel and 201 Stainless Steel?

Type 201 stainless steel, like 304 and 316, is austenitic stainless steel. This means that 201 stainless steel is not magnetic, unlike 434, which is a ferritic stainless steel. While 434 and 201 have similar chromium concentrations and corrosion resistance properties, 434 stainless steel is harder and stronger than 201 stainless. This is because 434 stainless has a higher carbon concentration and molybdenum in its structure.

Summary

This article presented 434 stainless steel, explained it, and discussed its composition and properties. To learn more about 434 stainless steel, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.