An aluminum alloy is a metal that consists of a large percentage of aluminum and small additions of other elements. Aluminum alloys are manufactured by combining these elements in their molten or liquid state. Aluminum alloy with a designation of 6061 indicates that the main alloy elements are magnesium and silicon. It may contain trace amounts of other elements such as copper, chromium, etc. The resultant effect of these additions compared to pure metal include improved corrosion resistance, workability, machinability, electrical conductivity, and strength.

This article will further discuss the alloy composition of 6061 aluminum alloy, its characteristics, properties, applications, trade names, and the factors to consider when choosing it.

What is an Aluminum Alloy?

An aluminum alloy is a blend of aluminum, as the main element, with other known elements. Aluminum alloys typically consist of aluminum and elements such as: magnesium, tin, chromium, copper, silicon, and manganese. These alloying elements are not necessarily combined in this order—and, it is not mandatory that all the elements should be present. Depending on the application, the specific alloying elements may be chosen and properly combined in quantifiable measures to form aluminum alloys. However, these metallic elements are combined with aluminum to the end that the new material formed will have improved strength, mechanical properties, durability, corrosion resistance, workability, etc. These metallic elements together with aluminum are mixed in their molten form to form a substance or material that is homogeneous after cooling takes place. Aside from the improved qualities, aluminum alloys are known to be cost-effective compared to pure aluminum because of its lower melting point. A lower melting point implies that lower heat energy will be consumed during subsequent manufacturing processes.

What Is the Alloy Composition of 6061 Aluminum?

The alloy composition of 6061 aluminum is aluminum (97.9 %), magnesium (1.0 %), silicon (0.6 %), copper (0.28 %), chromium (0.2 %), and a trace amount of other elements. A variety of aluminum alloys are available. Each of them is specified by a code number, such as the 6000 series, 7000 series, and 1000 series. Moreover, each digit of the number is representative of certain attributes that uniquely identify the aluminum alloys. In the case of 6061 aluminum, which is part of the 6000 series, the initial number 6 indicates that the primary alloying elements are magnesium and silicon. These elements are present in greater quantities than the other alloying elements.

The second digit emphasizes impurity control and that due attention should be given as the alloying elements are combined with the base aluminum element. Therefore, the number 0 in 6061 indicates that no special care is required to tighten controls. The third and fourth digits only identify the alloys within their series, without any particular meaning. However, this is not the case with the 1000 series, in which the last two digits represent the minimum additional purity above 99 %. For example, 1000 and 1050 indicate that the alloy would have 99 % and 99.5 % minimum aluminum, respectively.

What Are the Characteristics of 6061 Aluminum?

Some of the characteristics of 6061 aluminum include: good weldability, machinability, corrosion resistance, and workability. Generally, the corrosion resistance and strength are improved through tempering. Tempering is the process of enhancing the characteristics of metal by subjecting it to a high temperature. The alloy is heated to a temperature just below the melting point. Tempering strengthens the alloy by reducing its brittleness and internal stresses.

What Are the Material Properties of 6061 Aluminum?

Table 1 below highlights some material properties of 6061 aluminum. The material properties include but are not limited to, the mechanical properties, processing properties, and thermal properties:

| Material Properties | Value |

|---|---|

Material Properties Hardness, Vickers | Value 107 |

Material Properties Hardness, Rockwell A | Value 40 |

Material Properties Hardness, Rockwell B | Value 60 |

Material Properties Hardness, Knoop | Value 120 |

Material Properties Hardness, Brinell | Value 95 |

Material Properties Elongation at Break | Value 12% |

Material Properties Modulus of Elasticity | Value 10,000 ksi or 68.9 Gpa |

Material Properties Tensile stress | Value 42,000 psi or 290 Mpa |

Material Properties Yield stress | Value 35,000 psi or 241 Mpa |

Material Properties Ultimate Bearing Stress | Value 88,000 psi or 607 Mpa |

Material Properties Fatigue Stress | Value 14,000 psi or 96.5 Mpa |

Material Properties Poisson's Ratio | Value 0.33 |

Material Properties Shear stress | Value 30,000 psi or 207 Mpa |

Material Properties Shear modulus | Value 3770 ksi or 26 Gpa |

Material Properties Machinability | Value 50 % |

Material Properties Thermal Conductivity | Value 167 W/m-k |

Material Properties Specific Heat Capacity | Value 0.896 J/g-°C |

Material Properties Melting Point | Value 582–652 °C |

Material Properties Density | Value 2.7 g/cc |

Material Properties Artificial Aging Temperature | Value 160 °C |

Material Properties Solution Aging | Value 529 °C |

Where Is 6061 Aluminum Alloy Used?

6061 aluminum alloy is used as a manufacturing material in the automotive industry and is also used in the fabrication of motorcycles, scuba tanks, yachts, bicycle frames, and electrical fittings. Moreover, the foil wrapper in food containers is sometimes made with 6061 aluminum alloy. It is also well suited to the construction of aluminum cans. Manufacturing of roofing sheets or roof structures is also recognizably among its use cases.

How Strong Is 6061 Aluminum?

6061 aluminum strength depends on the tempered grade, including 6061-O, 6061-T4, and 6061-T6. With 6061-T6, for example, the parameters for measuring how strong it is depends on the yield and tensile strengths. The yield strength of a material measures its allowable stress limit when force is applied to it. When the force exerted is above this value, permanent deformation will take place and the material is unable to return to its original shape. On the other hand, the tensile stress of a material is the maximum stress above which it will fail and break. That said, the yield stress of 6061-T6 aluminum is at least 35,000 psi or 241 Mpa. While its tensile stress is a value upwards of 42000 psi or 290 Mpa.

How Do I Identify My Grade of Aluminum?

The grade of an aluminum alloy can be ascertained by looking at the numerical designation. Different grades are available in the market. Among them are 3003, 1100, and 6061. The grade determines which application the metal is well suited to—as well as the price point. For example, when comparing 6061 with 1100 it is clear that they are fundamentally aluminum alloys. However, 1100 is less expensive than 6061 and is not applicable in situations that involve high temperatures. Therefore, it cannot be used to manufacture cooking utensils such as pots.

Common FAQs About 6061 Aluminum Alloy

What Is the Operating Temperature Range for 6061 Aluminum?

The operating temperature range can be described in terms of the hot working, annealing, and aging temperature range. 6061 aluminum is hot worked at a temperature range of 260–372 °C. Annealing can be conducted at a temperature of 413 °C for a period of 2–3 hrs. Afterward, the metal is cooled at a controlled temperature of 10 °C per hr until 260 °C is reached. Another operating temperature is the aging temperature. Aging of 6061 aluminum can be conducted at a temperature of 160 °C for a period of 8 hrs before it is cooled in the air.

Is 6061 Aluminum Good for Welding?

Yes, 6061 aluminum is routinely welded, provided the correct filler material is used. The use of suitable filler material is crucial to avoid one of the welding difficulties that is inherently associated with 6061 aluminum—solidification cracking. For best results, the right filler material must be chosen; commonly this is 4043 or 5356 aluminum alloy. To avoid cracking, 6061 filler material should never be used to weld 6061 aluminum alloy.

What Are the Things To Consider When Choosing an Aluminum Grade?

The things to consider when choosing an aluminum grade are listed below:

- Corrosion resistance

- Weldability

- Workability

- Strength

- End-use application

- Heat treatment

- Machinability

Aluminum alloys come in a variety of shapes and grades. The selected aluminum grade depends to a large extent on the end-use application. When the end-use is defined, it will be easier to rank the attributes or characteristics of each grade. The grade that matches the desired attribute can be chosen. For example, if a project requires an alloy that has good weldability without putting so much emphasis on strength, alloy 1100 is a good option. The reason is that it has good weldability but is not suited to high-strength applications.

Summary

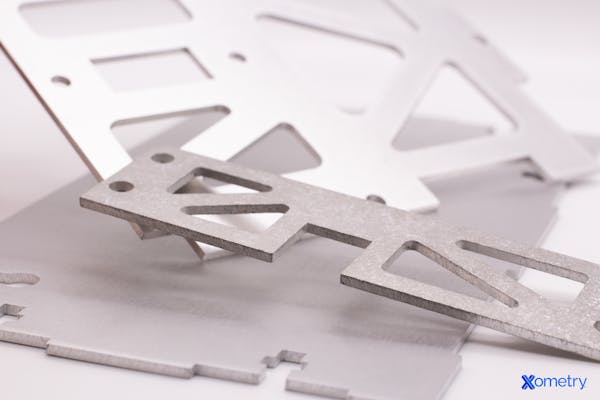

Xometry provides a wide range of manufacturing capabilities including CNC machining, 3D printing, injection molding, laser cutting, and sheet metal fabrication. Get your instant quote today.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.