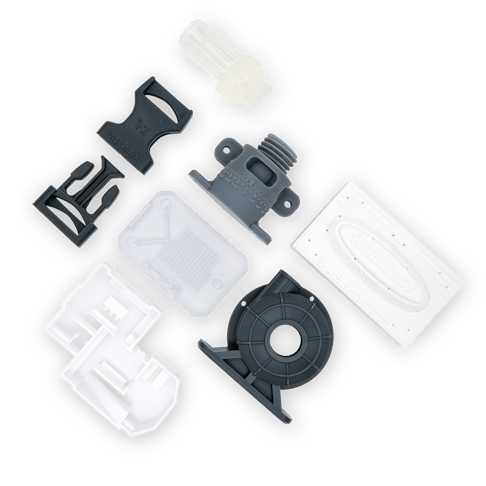

New Formlabs Materials

We are proud to offer Formlabs SLA resins on Xometry’s Instant Quoting Engine®. Formlabs is a key innovator in stereolithography (SLA) 3D printing, offering a versatile portfolio of low-cost engineered materials with professional results, meeting various engineering and design needs. From general prototyping to demanding functional applications, their materials empower users to create high-resolution parts with specific mechanical, thermal, and visual properties.

These materials run on the Form 4 and 4L platforms to achieve consistent and repeatable results. This guide provides a concise overview of eight key Formlabs SLA resins, highlighting their characteristics, benefits, and ideal use cases to help you select the optimal material for your next project.

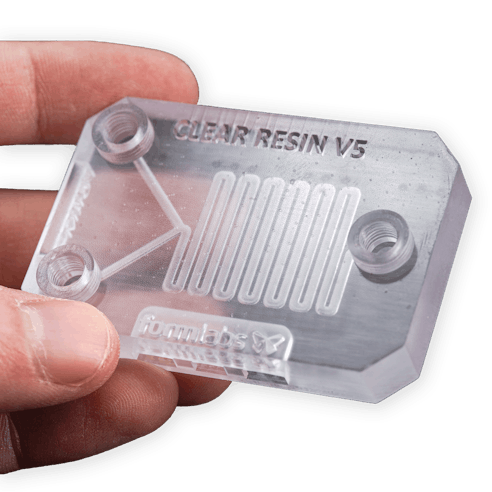

Formlabs Clear Resin V5

Colorless and Cosmetic

Clear Resin V5 is a colorless material offering an optimal balance of print speed, accuracy, and high transparency.

- Exceptional optical clarity and color neutrality

- Produces stiff, strong parts with a smooth surface finish

- Ideal for transparent enclosures, optical components, and lighting

- Suitable for showcasing internal features and fluidic devices (<1% moisture absorption)

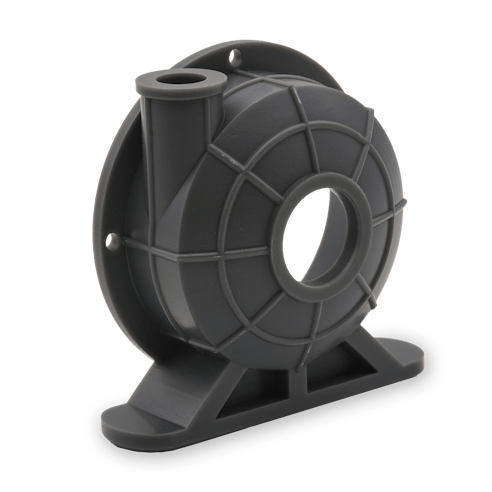

Formlabs Tough 1500 Resin V2

Resilient and Rugged

A dark grey, resilient engineering resin that balances stiffness and compliance, offering toughness comparable to polypropylene.

- Excellent balance of stiffness and ductility for impact resistance

- High fracture toughness for durable parts in demanding applications (155% elongation at break)

- Ideal for impact-resistant jigs and fixtures (Izod Notched 45 J/m)

- Ideal for prostheses, insoles, sports goods, snap fits, and living hinges

- Creates rugged enclosures and prototypes with snap-fits or living hinges

Formlabs ESD Resin

Static-Dissipative Protection

A dark black, rugged engineering resin for ESD-safe parts, essential for protecting sensitive electronics in manufacturing environments.

- Static-dissipative (surface resistivity 10⁵ - 10⁸ Ω/sq); protects sensitive electronics from electrostatic discharge

- Used for anti-static prototypes, jigs, and electronics manufacturing fixtures

- Ideal for enclosures, housings, fixtures, and tooling

- Creates protective housings for sensitive electronic components

Formlabs Grey Resin V5

General Purpose and Smooth

A versatile grey, general-purpose material delivering a strong balance of accuracy, excellent finish, and robust mechanical properties.

- Smooth, opaque matte surface ideal for detailed presentation models

- Good all-around mechanical properties for general prototyping needs

- Suitable for form/fit prototypes and detailed concept models

Formlabs High Temp Resin

Extreme Heat Resistance

A translucent engineering resin offering the highest heat resistance in the Formlabs portfolio, with a Heat Deflection Temperature (HDT) of 238°C @ 0.45 MPa.

- Exceptional thermal stability (HDT 238°C) for high-heat applications

- Produces detailed, precise parts that maintain integrity at high temperatures

- Ideal for hot air, gas, and fluid flow components

- Suitable for heat-resistant mounts, housings, fixtures, molds, and inserts

Formlabs Rigid 10K Resin

Ultra-Stiff and Strong

An off-white, highly glass-filled material, representing the stiffest material in Formlabs' engineering portfolio, ideal for industrial parts requiring high rigidity and resistance to significant loads without bending.

- Extremely high stiffness (~10 GPa) for minimal deflection under load

- Offers high heat and chemical resistance with a smooth matte finish

- Suitable for short-run injection molds, press tooling, and inserts

- Used for demanding industrial components and aerodynamic test models

Formlabs Tough 2000 Resin

Strong and Sturdy

The strongest and stiffest grey material within Formlabs' Tough and Durable family, engineered for rugged prototyping of parts that must resist bending.

- Offers ABS-like strength and stiffness characteristics

- Produces strong, sturdy parts that maintain their form under stress

- Ideal for strong, stiff functional prototypes that resist deformation

- Suitable for sturdy jigs and fixtures needing high rigidity and durability

Formlabs White Resin V5

Bright and Clean

A bright white general-purpose material that blends high accuracy, a smooth matte finish, and solid mechanical properties.

- Bright white, opaque, smooth matte surface for aesthetics or painting

- Good all-around properties for general prototyping applications

- Suitable for form/fit prototypes and detailed presentation models

- Used for medical or anatomical models and jigs/fixtures needing a clean white look

Making Your Formlabs SLA Selection

Choosing the correct Formlabs SLA resin is critical for achieving optimal results for your specific project. Consider the primary functional requirements: Is optical clarity essential (Clear Resin V5)? Do you need parts that can withstand impacts (Tough 1500 or 2000 Resin)? Are you creating components that demand extreme stiffness (Rigid 10K Resin) or must perform under high temperatures (High Temp Resin)? ESD Resin provides a targeted solution for specialized needs, such as static dissipation in electronics applications. Grey or White Resin V5 offers excellent surface finishes and well-balanced properties for general visual models and initial prototypes.

These Formlabs Resins complement Xometry’s extensive photopolymer offerings. To check out Xometry’s resins, download datasheets, or our design guides, go to our Stereolithography (SLA) Capabilities page.

Want to see how all Xometry’s SLA materials stack up? Check out our guide to navigating stereolithography resins by application.