Compression testing is a key part of manufacturing and quality control. A material’s compressive strength is a critical parameter for many applications, particularly in structural building components.

Compressive strength is important in many wider applications, from cardboard boxes to lipsticks, and these can be tested in different ways. Listed below are the steps on how to test an item’s compressive strength.

1. Select the Test Material

Select the material to be tested. Testing procedures depend on the material type and expected properties. For example, you evaluate ABS plastic differently from carbon steel. Follow the procedures that best fit your material type and test article.

2. Prepare the Material

Most international standards prescribe a specific geometry for material test samples. These defined shapes and sizes generate standardized and relevant results even when using different testing rigs. Therefore, before testing, you need to form your material into the proper shape. Metals, for example, are usually machined for the task while concrete is cast in cubes.

3. Set Up the Testing Equipment

Compression testing is usually accomplished using a universal testing machine. It consists of a table, a load frame, and upper and lower crossheads. It includes measuring instruments such as a load cell and extensometer. The “universal” moniker comes from its ability to evaluate multiple different material properties, including tensile strength and puncture force. It also evaluates shear, bending, and fatigue properties.

The size and type of machine will depend on the item you’re testing. Plastics require far less compressive force than metals or concrete. The machine’s fixtures (platen, load cell, and other accessories) need to be selected and fitted according to the sample’s material and shape.

4. Preload the Material

Place the standardized material sample on the compression platen. You must align your sample properly to ensure that the force is applied evenly across its surface. Stress concentrations that are caused by the test setup rather than the sample will skew the results.

5. Define the Test Parameters

Input the test parameters into the universal testing machine’s software. These can be dictated by the testing standard or determined by experience. The parameters can include details such as the maximum load to be applied, the platen’s speed of travel, the maximum travel length, and the strain rate.

6. Start the Compression Test

You can now start the compression test. The upper platen will begin to move downward towards the lower one. This movement is slow and controlled. The operator should observe to make sure the sample is correctly aligned when the upper platen makes contact.

7. Monitor the Test

Remain and supervise the compression testing as it progresses. Take note of any problems that arise or if the part fails prematurely. Improper tests may need to be discarded or repeated, but detecting them often demands careful observation. Also, if anything goes wrong for any reason, you will be able to stop the test immediately.

8. Determine the Compressive Strength

The universal testing machine will output a stress vs strain plot. This plot depicts results such as the compressive strength — the highest stress experienced by the sample during the test. The plot also helps identify material behavior, such as elastic vs. plastic deformation.

9. Analyze the Results

Other parameters can be read from the graph of stress vs strain, such as the modulus of elasticity and the yield stress (the stress at which plastic deformation begins). These measurements, together with the compressive strength, can be compared with international and internal standards. In this way, the data acts as a quality control method, ensuring that the samples under test meet specifications and alerting you to potential failures or inadequate quality-control trends.

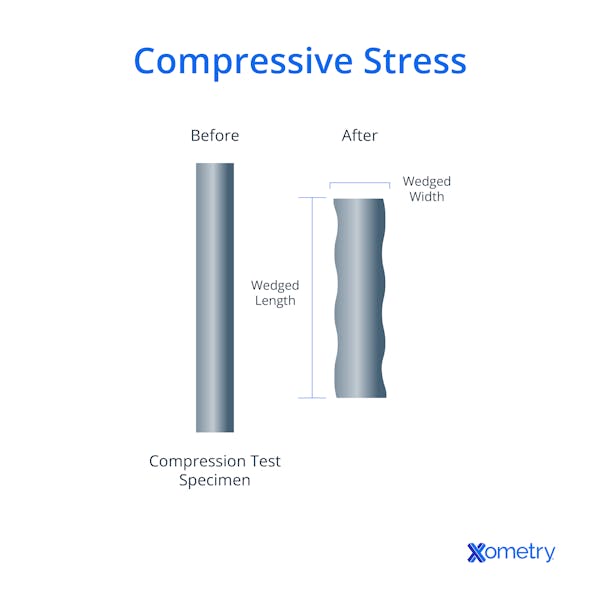

What Is a Compression Test?

A compression test is a controlled and measured application of compressive force to a standardized sample of material. It measures how the material deforms under pressure and determines properties, such as strength, elasticity, and ductility. The test is performed using a universal testing machine, which applies force through a moving platen while measuring the resulting stress and strain.

What Is the Purpose of a Compression Test?

Compression tests are meant to measure certain material properties. It reveals information such as the ultimate compressive strength, the modulus of elasticity, and yield stress (the stress at which the material begins to deform plastically).

What Are the Applications of Compression Tests?

Compression tests are used wherever an element’s strength under compression is a critical property. Some applications of compression tests are listed below:

1. Aerospace and Automotive Industry

Aerospace engineers need the results of compressive tests so they can be certain of their materials’ integrity under pressure. Whole components can also undergo compression testing to evaluate their failure points. Similarly, the compressive strength of structural components in vehicles is critical. This has a significant impact on passenger safety, and the design of crumple zones is meant to absorb the impact.

2. Construction Industry

Concrete samples regularly get tested for their compressive strength. That strength is critical to the safety and structural integrity of buildings, bridges, and other structures. Compressive strength tests on concrete are foundational to the quality control measures employed during planning and construction. Other building materials such as bricks also undergo compressive strength testing.

3. Cosmetics Industry

Compression testing is used in the cosmetics industry in a number of ways. Products such as lipstick are tested for the force they’ll absorb before deformation. The packaging for creams and lotions is tested for the squeezing force required to dispense them. Some powders, such as eyeliners, are also compacted before being sold, and the compacting force requires testing.

4. Electrical and Electronics Industry

Many components used in the electrical and electronics industry need to reliably withstand compressive forces. These include not only interfaces such as LCD screens and keypads but also components that get crimped, such as connectors and insulation.

5. Medical Device Industry

Medical devices such as syringes and needles regularly experience compression. There are also devices that use compression to release pre-metered doses, as is the case with inhalers and pen injectors. Each of these items, therefore, needs to undergo compressive testing to ensure that they will function reliably each time.

6. Packaging Industry

A common application of compression testing is the crush test, which determines the maximum weight a container can withstand during storage and transport. This ensures that products remain protected and packaging does not collapse under pressure.

7. Paper and Board Industry

Materials like corrugated cardboard and laminated boards are tested for their resistance to crushing and bending forces. Unlike packaging tests, which focus on structural integrity in shipping, these tests help manufacturers optimize raw material composition, durability, and production processes for various paper-based products.

8. Plastics, Rubber, and Elastomers Industry

Many elastomers and rubbers are employed to absorb compressive forces. Compressive strength is, therefore, a vital element of their engineering. Plastics range from inexpensive, low-performance options to high-end engineering materials. Compression testing helps engineers find plastics with the right balance between cost and capability.

9. Safety, Health, Fitness, and Leisure Industry

Various sports equipment undergoes compression testing. This is particularly relevant for items such as balls (tennis, golf, etc) that need to bounce predictably and repeatedly.

What Are the Types of Compression Test Equipment?

Compression test equipment can be classified in a number of ways, but it’s generally organized based on the maximum force the machine is designed to deliver. Other aspects follow from this. Examples are listed below:

- Light Duty (<5 kN): This compression testing equipment is typically used on plastics, elastomers, and packaging materials. The test rig is bench-mounted, uses electric servo motors to apply an accurate force, and typically has a single-column load frame.

- Medium Duty (approximate range of 5-100 kN): This testing equipment is used for stiffer materials, harder plastics, and more robust packaging units. It is usually still bench-mounted but has a dual-column load frame. Older models may still use hydraulics to apply force, but newer electric servo motors generally give the machine more precise control.

- Heavy Duty (>100 kN): Heavy-duty compression testing equipment is used for materials with high compressive strengths, like metals and some ceramics. This equipment is floor-mounted, significantly larger and heavier than the lighter-duty machines. The load frame has two columns, and the force is usually applied by hydraulics to achieve forces of up to 2,000 kN.

What Are the Common Compression Testing Results?

Compression testing can illuminate multiple material properties. The most common are listed below:

- Compressive Strength: This is the maximum stress that the sample experienced during the compression test. It is taken from the stress vs strain graph.

- Modulus of Elasticity: Also referred to as Young’s modulus, this is a measure of the stiffness or rigidity of the material. It is the ratio between stress and strain — illustrated as the gradient of the graph of stress vs strain — in the elastic portion of its deformation. Young’s modulus can be calculated for compression as well as tension.

- Yield Stress: This is the stress at which the material begins to deform plastically (irreversibly) rather than elastically.

What Are the Types of Compression Testing?

Compression tests come in three different categories. The types are listed below:

- Top Load/Crush: This is the simplest type of compression test where the load is applied directly to the top of the sample. This demonstrates the material’s compressive strength. This type of test is also carried out on everything from concrete to packaging materials to measure their resistance to crushing.

- Flexure/Bend: This type of compression test uses two lower supports to hold the ends of the test article. A load from above is then applied between those supports, causing the part to bend. The deflection of the sample is measured according to the load applied, and this gives valuable information about the specimen’s stiffness and bending strength.

- Spring Testing: This type of compression testing is applied to springs. They’re compressed so the test equipment can measure various properties. The spring starts at rest, gets extended, and is then slowly compressed until all coils are touching. This type of compression testing demonstrates a solid height, maximum load, and spring rate of the spring.

What Are the Benefits of Compression Tests?

Compression testing can be used in a number of beneficial ways. Some of its benefits are listed below:

- Can be used for quality control in manufacturing. Compression tests allow key parameters of the product to be tested across batches to ensure consistent quality.

- If carried out with the necessary quality controls and according to defined standards, the results are repeatable and accurate.

- Allow the design of components (such as packing cartons) to be optimized. Adjustments can be made to a design to reduce weight or save on material costs, while still ensuring that it meets the necessary specifications for compressive strength.

What Are the Challenges of Compression Tests?

Compressive testing does have some limitations, which can make the tests challenging. A few are listed below:

- If you fail to place the sample in the ideal spot on the platen, you may get imperfect measurements.

- Samples must be prepared to a specific geometry, which can be hard to do with some materials.

- The results of the compression testing can be affected by environmental factors such as temperature.

- Compression testing can be time-consuming.

Are Compression Tests Accurate?

Yes, compression tests are accurate if conducted properly. International standards guide testing methods, ensuring that results are comparable regardless of where the tests are performed or which brand of equipment is used. However, there are some factors that may decrease the accuracy of compression tests, such as temperature variability, poor alignment on the platens, and worn or uncalibrated equipment. But if you are disciplined in your inspections and certifications, you can have confidence in your compression tests.

Can Compression Tests Determine the Tensile Strength of Materials?

No, a compression test cannot reliably determine the tensile strength of a material. For example, while concrete exhibits high compressive strength, its tensile strength is significantly lower — a disparity that highlights the distinct behaviors of materials under different types of loads. Although some materials may have both high compressive and tensile strengths, the mechanisms of deformation under compression differ markedly from those under tension, so one test cannot substitute for the other. For more information, see our guide on the Tensile Strength of a Material.

What Is the Difference Between a Compression Test and a Tension Test?

The difference between a compression test and a tension test is the direction of the applied load. For both tests, it acts perpendicular to the material’s surface. In compression testing, it is applied inward, towards the center of the sample to compress it while a tensile test applies it outward, stretching the material. As previously mentioned, although some materials may exhibit similar strengths under both compression and tension, many materials behave differently depending on the type of load applied.

Summary

This article presented how to do a compression step, explained each step, and discussed the various applications of these tests. To learn more about compression tests, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.