New Additive Material Options

We are continuously updating and adding materials to the Xometry Instant Quoting Engine®, so that you can always find the right choice for your projects. Recently, we've added several new material options for our 3D printing processes. The latest materials include several high-performance and engineering-grade options, as well as some that customers have commonly requested. Learn more about each new offering below, including its characteristics and suitable applications. If you're looking to explore all the 3D printing materials we offer, check out our materials page.

Nylon 12, White

Bright White and Dyeable

Nylon 12, White provides the same robust mechanical properties and chemical resistance as standard grey MJF Nylon, but with a vibrant white base. This version is specifically intended for applications where high-contrast visibility or a clean, medical-grade aesthetic is desired. It can also be dyed for vibrantly colored parts.

- High strength and excellent long-term stability

- Clean, white aesthetic suitable for medical and consumer goods

- Robust and balanced material properties

- Ideal for functional prototypes, general use, white components

Nylon 12, Smooth

Premium Surface Finish

Nylon 12, Smooth is engineered with unique particle shapes and a narrow size distribution to produce parts that are significantly smoother directly from the printer. This material is a cost-effective choice for visible, end-use components that require fine detail and a clean, professional appearance. When combined with our vapor-smoothed finish, it's possible to achieve aesthetics that rival those of injection-molded components.

- Smoother surfaces directly from the printer compared to standard Nylon 12

- Excellent dimensional accuracy and fine detail for complex functional prototypes

- Can be combined with vapor smoothing to achieve a super smooth semi-gloss surface

- Best for cosmetic parts, consumer goods, high-visibility components

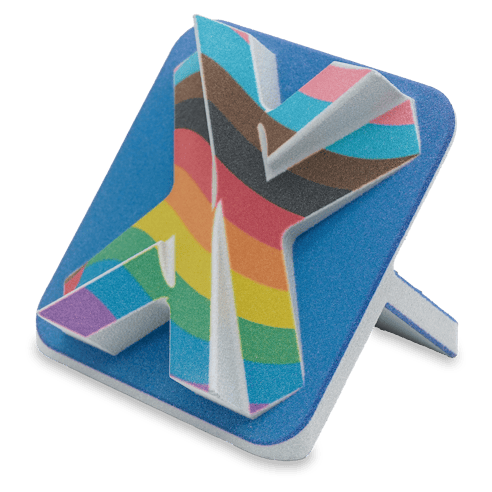

Nylon 12, Multi-Color (CB)

Full-Color Functional Components

Nylon 12, Multi-Color (CB) is specialized for producing full-color parts directly from the print bed. This material unlocks the ability to create complex multi-color assemblies where color-coding, branding, or photorealistic textures are essential to the part’s utility. It provides a significant advantage for users who require a versatile and functional material but need to eliminate the time and cost associated with secondary painting or labeling.

- Direct full-spectrum color printing

- High toughness and engineering-grade durability typical of Nylon 12

- Create multi-color components with realistic textures, graphics, or branding

- Use it for surgical planning models, color-coded assembly aids, and branded consumer goods

TPU 88A (M88A)

Durable and Flexible Elastomer

TPU 88A (M88A) is a high-performance elastomer engineered for parts that must combine flexibility with high tear strength and energy return. It is the ideal choice when an application demands "rubber-like" behavior, such as shock absorption or vibration dampening.

Note: Available by request.

- High elongation at break (up to 440% in X direction) and superior tear resistance

- Excellent shock absorption and energy return

- Passed testing according to ISO 10993-5 (cytotoxicity) and ISO 10993-10 (skin sensitization/irritation)

- Excellent for footwear, protective bumpers, grippers, and skin-safe wearables

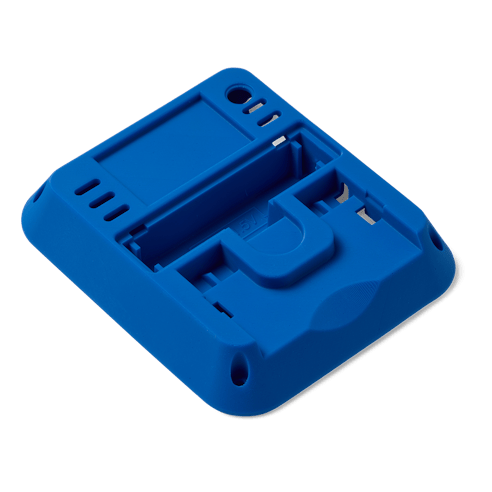

Formlabs Color Resin V5

Vibrantly Colored General-Purpose

This general-purpose rigid resin is available in a range of vibrant, production-ready colors. Great for color device housings and casings, and visual prototypes.

- Deep, vibrant colors

- High resolution, dimensionally accurate parts

- Useful for color-coded components for assemblies, jigs, fixtures, and general use

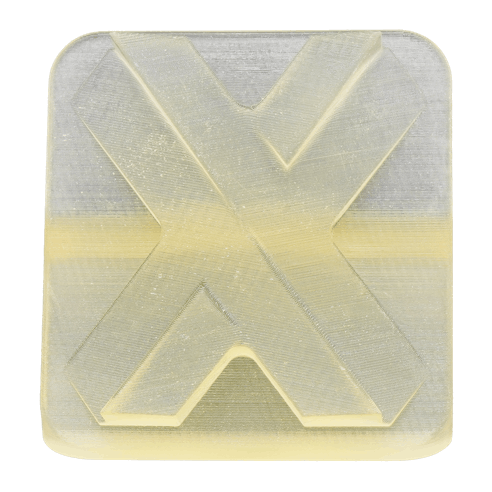

Formlabs Tough 1000

Highly Ductile HDPE-Like

A ductile, impact-resistant resin designed to simulate the strength and utility of high-density polyethylene (HDPE) with exceptional fatigue resistance and a low-friction surface. It's an excellent choice for components with compliant mechanisms that need to withstand repeated flexing or require low friction.

- Complaint, up to 180% elongation at break

- Highly impact-resistant and tough, comparable to HDPE

- Enables parts with low-friction surfaces

- Great for ball joints, gears, impact-resistant enclosures, and compliant mechanisms

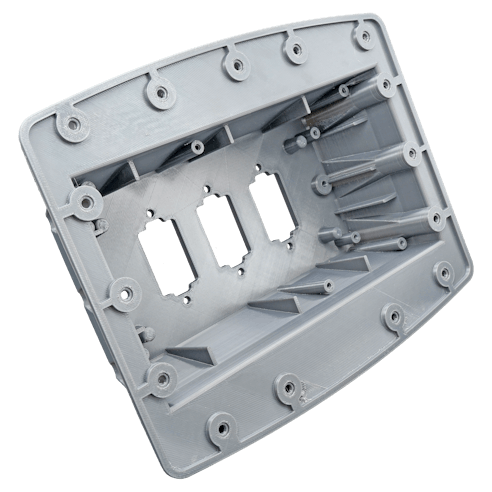

Accura SL 5530

High-Temperature Resin

Engineered to maintain its structural rigidity in environments that would cause standard resins to soften or fail. Excels in applications that undergo significant thermal stress, such as high-heat fluid testing or electrical housing enclosures.

- High stiffness and dimensional accuracy at elevated temperatures

- Resistant to water and automotive fluids

- Translucent amber appearance for fluid flow or internal component visibility

- Can be used for under-the-hood automotive testing, electrical connectors, and hot-air ducting prototypes

PETG

Versatile and Impact-Resistant

PETG, our newest general-purpose option that has been frequently requested, is now available for autoquoting! It serves as the perfect "bridge" material between PLA and ABS, offering a significant upgrade in durability and chemical resistance without a massive jump in cost.

- Excellent impact resistance and durability

- Superior chemical and moisture resistance over PLA

- Available in a variety of colors

- Ideal for protective enclosures, functional prototypes, and fixtures

Nylon 6 CF

Light-weight and Stiff

This composite utilizes carbon fiber chop reinforcement to create incredibly strong, stiff, and lightweight parts. It's highly suited for printing light-weight fixtures, clamps, and structural components that require improved performance and heat resistance.

- Exceptional stiffness and tensile strength

- High strength-to-weight ratio

- Excellent thermal and fatigue resistance

- Improved aesthetics over other FDM materials

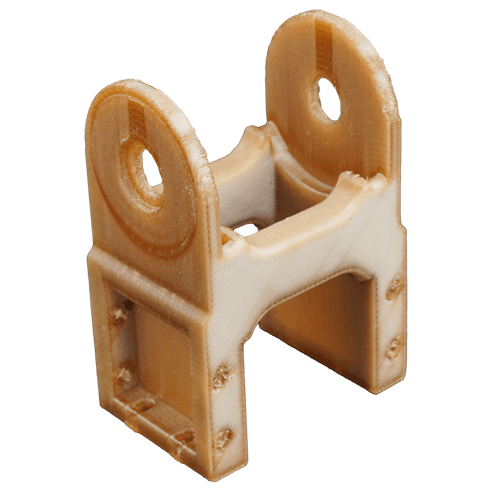

Stratasys ABS CF-10

Rigid and Dimensionally Stable

By combining the reliability of ABS with 10% carbon fiber reinforcement, ABS-CF10 achieves a 50% increase in stiffness over standard ABS. It's a great choice where increased stiffness and weight reduction are desired.

- 50% stiffer and 15% stronger than standard ABS

- High-dimensional accuracy for large parts

- More consistent matte appearance and layer stacking

- Ideal for jigs, fixtures, end effectors, and manufacturing tools

Stratasys Antero 800NA

Chemical-Resistant Aerospace PEKK

A PEKK-based thermoplastic engineered for the most extreme environments, including the vacuum of space and exposure to caustic jet fuels, making it a viable solution for mission-critical hardware that requires ultra-low outgassing and unmatched thermal stability.

- Ultra-low outgassing properties

- Exceptional resistance to fuels, oils, and acids

- High heat deflection and flame retardancy

- Used for spacecraft hardware, engine bay components, and chemical processing equipment

Stratasys Antero 840CN03

High-Strength Static Dissipative (ESD)

Provides the extreme environmental resistance of the PEKK family with the added benefit of inherent electrostatic discharge protection, making it our highest-tier ESD material.

- Consistent Electrostatic Dissipative (ESD) properties

- Maintains strength in extreme heat and cold

- Superior chemical and wear resistance

- Ideal for satellite electronics housings, semiconductor test sockets, and avionics tooling

Stratasys VICTREX AM 200

High-Integrity Optimized PEEK

A PEEK-based material optimized for 3D printing for enhanced melt and interlayer bonding. By providing superior Z-axis strength, this material ensures that printed components possess the mechanical integrity and wear resistance of molded PEEK.

- Optimized for high Z-axis (interlayer) strength

- Outstanding wear and abrasion resistance

- Excellent mechanical performance at elevated temperatures

- Applications include load-bearing aerospace parts, medical devices, and high-wear bushings

Stratasys ULTEM 1010 CG

Certified Food-Safe and Autoclavable

ULTEM 1010 offers the highest heat resistance and tensile strength in our FDM lineup. The Certified Grade (CG) version is accompanied by documentation for food contact (NSF 51) and biocompatibility (ISO 10993/USP Class VI) compliance, qualifying it for use with the food and medical industries.

- Highest heat deflection temperature (216 °C @ 66psi)

- Exceptional tensile strength and rigidity

- NSF 51 food-safety and ISO 10993 biocompatibility certifications

- Suitable for sterilizable surgical guides, food-production tooling, and high-heat tooling

Ready to Start Your Project?

Whether you're looking to add color to your prints with Nylon 12, Multi-Color, need the rugged durability of Antero, or the extreme detail of Accura SL 5530, getting started is simple. You can upload your 3D designs to the Xometry Instant Quoting Engine® to receive instant pricing, lead times, and manufacturability feedback on these high-performance materials and many others.

If you are still deciding on the right fit for your application, visit our comprehensive 3D Printing Materials Page to compare our full suite of polymers, metals, and resins.