Both titanium and tungsten are important materials in everything from the world of jewelry to industrial settings. Titanium has hypoallergenic qualities, in addition to being corrosion-resistant and lightweight, which makes it popular among Xometry aerospace customers. Tungsten, though, is exceptionally hard, scratch-resistant, and extremely dense, which makes it useful in other applications.

Though they can both look rather similar, they differ significantly in their weights and compositions. These differences will be discussed in this article, which will be especially useful if you want to choose between the two for things like rings. We’ll also look at some of their applications, advantages, and disadvantages.

What is Titanium?

Sometimes called Gregorite (from the Reverend William Gregor who discovered it in Cornwall, England, in 1971), Titanium (Ti) is a transition metal with a unique silvery-white exterior. It’s only found in nature as an oxide, and in its purest form of titanium, it’s already corrosion-resistant and strong. It’s also water resistant, but in the presence of concentrated acids, it will dissolve. For these reasons, titanium is pretty much used everywhere, from the aerospace to the medical sectors.

Titanium is most often CNC machined from stock into various components, but it is also possible to 3D print parts from it using our DMLS process. As it’s only found as an oxide in nature, titanium needs to be processed and refined into the usable forms we are familiar with. That’s where the Kroll method comes in, which involves extracting minerals like rutile, ilmenite, or sphene and purifying them.

Titanium concentrates are processed with carbon and chlorine gas to get impure titanium tetrachloride. Then the titanium tetrachloride is purified and distilled in order to separate the contaminants. The refined liquid is then combined with magnesium to create a sort of porous titanium sponge which is further treated in an arc furnace to turn it into a titanium alloy. Once you’ve checked the freshly made ingot, it will then be sent for further treatment to make it suitable for the intended application. It can later be laser cut into various shapes, which Xometry can help you with.

What Is Another Name for Titanium?

Gregorite is another term for titanium, and it bears the name of the Reverend William Gregor, who made the metal's discovery in Cornwall, England, in 1791. The term is historically significant, reflecting the early identification of the element.

What Is Titanium Made Of?

Titanium is found in minerals like ilmenite, rutile, and sphene, as well as titanates and certain ores. Commercially, it is produced by reducing titanium (IV) chloride with magnesium, showcasing a specific manufacturing process.

How Is Titanium Made?

Titanium is made using the Kroll method. It involves: extraction, purification, (metallic) sponge production, alloy synthesis, and shaping. Impure titanium tetrachloride is made by processing titanium concentrates with carbon and chlorine gas. Distillation is used in purification to separate contaminants. When the refined liquid and magnesium combine, a porous titanium sponge is created. Treatment in an arc furnace transforms these “sponges” into titanium alloys. After going through inspection, the resulting ingot can be treated further to create a variety of goods.

What Are the Different Types of Titanium?

The most commonly used titanium are six pure grades (1, 2, 3, 4, 7, 11) and four alloys which we explain more in the below table.

| Type | Description |

|---|---|

Type Ti 6Al-4V (Grade 5) | Description This is the strongest titanium alloy and is commonly used in aerospace, medical, and marine applications |

Type Ti 6Al-4V ELI (Grade 23) | Description Known as surgical titanium, Grade 23 is malleable and corrosion-resistant, and used in medical and dental |

Type Ti 3Al 2.5 (Grade 9) | Description Grade 9 has a high-temperature strength, and is used a lot in manufacturing, chemical, and marine |

Type Ti 5Al-2.5Sn (Grade 6) | Description Grade 6 is non-heat-treatable, but has impressive weldability, stability, and strength. It’s used for aircraft and airframe components |

What Are the Advantages of Titanium?

The advantages of titanium include:

- Forms a layer of titanium dioxide that protects it from rust and corrosion

- Is 100% recyclable, reducing waste

- Roughly half the weight of steel, but just as strong, it’s ideal for lightweight yet sturdy structures

- Has the highest strength-to-density ratio among metals, which is why it’s a hit in aerospace manufacturing

What Are the Disadvantages of Titanium?

The disadvantages of titanium include:

- It’s usually more expensive than other commonly used metals, like aluminum or steel

- It’s not the easiest to get, and can be hard to access. Might not work well for those who need a lot of it and quickly

- Titanium is not as easy to cast as iron or aluminum

- Its high melting temperature and reactivity makes titanium a more difficult metal to weld

Is Titanium Stronger Than Tungsten?

No, tungsten is stronger than titanium in terms of tensile strength. Tungsten boasts a tensile strength of 142,000 psi, significantly higher than titanium's 63,000 psi. Though titanium has a better mix of strength and toughness, tungsten is more brittle and prone to breaking under impact, therefore it's important to take into account all of the characteristics of both metals. Figure 2 shows two wedding rings made of Tungsten:

What is Tungsten?

Tungsten (W), also known as Wolfram, is a strong, silvery-white metal that was discovered in 1783 by Spanish chemists Juan José and Fausto Elhuyar. It’s refractory, meaning it's highly wear- and heat-resistant. This rare metal is mostly found in compounds with other elements. If pure tungsten were to be coarsely powdered, it could ignite on its own and catch fire. Steel is often alloyed with tungsten to increase its hardness and strength, and quite often, lightbulb filaments will be made from tungsten. Other common items that might be made from it include the cutting tools our shops utilize for machining parts, jewelry, and radiation shielding.

Just like titanium, you won’t be able to find any tungsten in its pure form in nature. To get it, it has to be extracted and produced from minerals; wolframite and scheelite are the two main sources. To get to these minerals, a couple of mining methods are used; surface mining (removing the rock and soil above the mineral), and underground mining (via shafts and tunnels). The ores are crushed and cleaned, then treated with alkali to make tungsten trioxide (WO3). Carbon or hydrogen gas is then used to heat the compound and produce tungsten metal with carbon dioxide or water vapor.

What Is Another Name for Tungsten?

Tungsten is also known as Wolfram. This other name is often used in a variety of settings, mirroring how the element was originally identified by the term wolfram.

What Is Tungsten Made Of?

Tungsten is not found in its pure form in nature but is primarily sourced from minerals like wolframite and scheelite. Wolframite is a solid solution of ferberite and hübnerite, containing iron, manganese, and tungstate. Scheelite, another source, is composed of calcium tungstate. These minerals serve as the main raw materials for extracting tungsten.

How Is Tungsten Made?

Tungsten is primarily extracted from the minerals wolframite and scheelite, which are obtained through surface and underground mining. While underground mining uses shafts and tunnels, surface mining removes the rock and soil that is above the required minerals. The ores are crushed and cleaned, then treated with alkali to create tungsten trioxide (WO3). This compound is then heated with carbon or hydrogen gas to produce tungsten metal along with carbon dioxide or water vapor. Juan Jose and Fausto Elhuyar devised the production process.

What Are the Different Types of Tungsten?

If you’ve ever come across tungsten, it’s highly likely it was tungsten carbide. This is the most popular type and is used in many tools, thanks to its strength and chemical resistance. There are lots of other types, too, like cemented carbide, heavy metal tungsten alloys, pure tungsten, and alloyed tungsten. Cobalt-alloyed cemented carbide is popular among Xometry customers for equipment like industrial pumps, cutting tools, and mining equipment. Tungsten is often used in its pure form in electrical applications, and tungsten-based chemicals can often be found in things like ceramics and pigments.

What Are the Advantages of Tungsten?

The advantages of tungsten include:

- It’s ideal for racing car ballast, alloys, and other compact yet weighty applications

- Helps tools remain stable in extreme heat conditions

- Perfect for corrosive environments like marine applications

- Very high melting point

- Can be used in X-ray targets, radiation shielding, and electronic components

What Are the Disadvantages of Tungsten?

The disadvantages of tungsten include:

- It’s difficult to cut, drill, and weld

- Pricier than zinc alloy, stainless steel, and titanium

- Its high melting point can complicate the fabrication process

- It can crack or shatter on impact

- Rings made from tungsten can’t be resized

Is Tungsten Stronger Than Titanium?

Yes, tungsten is stronger than titanium. Tungsten has a higher hardness scale rating (8.5 to 9) compared to titanium (6), making it more scratch-resistant. The drawback of tungsten's strength is that the metal is extremely brittle and is prone to breaking or shattering under pressure. Titanium is less hard than steel, but because of its greater malleability, it offers considerable flexibility and is less likely to break when dropped.

How To Choose Between Titanium and Tungsten?

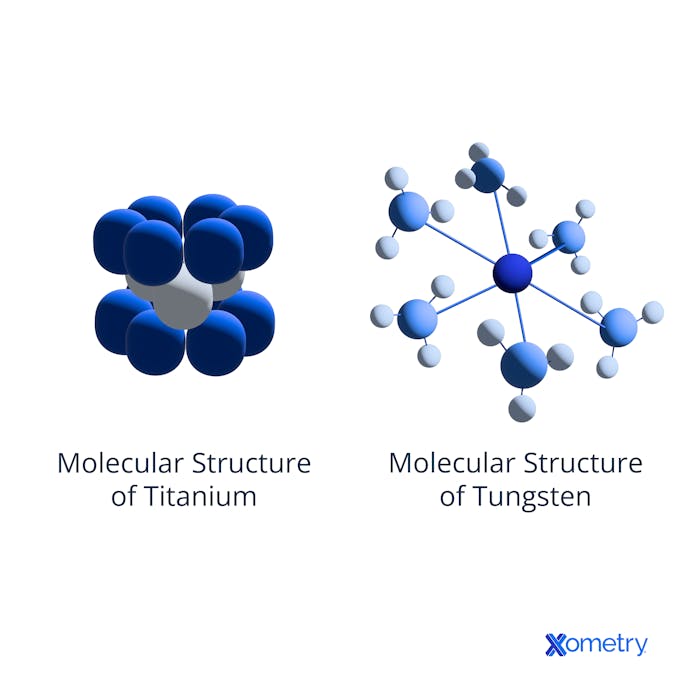

Xometry customers often ask whether titanium or tungsten would be better suited to their projects. Once we collect all the important information, such as their precise needs, preferences, part geometry, and their part's intended function, we are in a better position to advise them. For instance, for customers who want to make a strong and scratch-resistant item, we recommend tungsten. If impact resistance isn’t a concern, this is a good choice, but if it could get knocked about a bit, perhaps it won’t be suitable, as tungsten tends to be brittle. In this instance, titanium could be a good compromise as it’s strong (albeit not as much as tungsten), corrosion-resistant, and lightweight. Tungsten's 142,000 psi tensile strength is stronger than titanium's 63,000 psi, but titanium has a better mix of strength and lightweightness. The image below shows the molecular structures of titanium and tungsten.

How To Identify Titanium and Tungsten?

Tungsten and titanium are two different metals with special qualities. One way to recognize titanium is by gauging how lightweight it is; titanium has a low density. On the other hand, tungsten is almost four times as dense as titanium (and more than twice the density of steel). One of the most important things to consider when differentiating between these metals is weight, with titanium being regarded as a relatively low-density metal and tungsten being quite the opposite.

What Are the Applications of Titanium and Tungsten?

Titanium and tungsten are two metals that are relatively useful and find relevance in several applications. Titanium’s applications are listed below:

- Titanium's strength-to-weight ratio excels in aerospace components, reducing aircraft weight without compromising integrity.

- Its biocompatibility and corrosion-resistance make it pivotal in medical implants.

- It enhances sports gear and boasts a modern aesthetic in jewelry design.

Tungsten applications are listed below:

- Tungsten's high melting point allows for the illumination of lightbulbs.

- It can also function as a cutting tool as a result of its hardness.

- Contribute to microelectronics and radiation shielding in electronics.

- It proves desirable in jewelry making.

Titanium is a popular metal for use in aerospace and medicine because of its lightweight nature and ability to withstand corrosion. Strong tools and electronics employ tungsten because of its high density and hardness, which allow it to withstand harsh environments.

How Can Xometry Assist You With Your Titanium or Tungsten Needs?

Xometry offers comprehensive manufacturing solutions for titanium or tungsten needs. With a focus on on-demand precise manufacturing, Xometry offers a range of services including design, CNC machining, milling, turning, 3D printing, injection molding, sheet metal fabrication, and urethane casting. They are a one-stop solution for a variety of industrial needs because of their broad range of capabilities.

Frequently Asked Questions About Titanium and Tungsten

Is It Possible To Perform Arc Welding on Titanium and Tungsten?

Yes, arc welding is possible on both titanium and tungsten. The most widely used welding methods for titanium and related alloys are gas metal arc (GMA or MIG) and gas tungsten arc (GTA or TIG). These techniques are ideal for welding these materials in a variety of applications because they provide exact control.

Are Titanium and Tungsten Both Scratch-Resistant?

Yes, both titanium and tungsten are scratch-resistant. Titanium is approximately three times as strong and scratch-resistant as gold. Tungsten, being the stronger of the two metals, is even more scratch-resistant, making it a durable choice for jewelry and other applications in which resistance to scratches is essential.

Do Titanium and Tungsten Resist Cracking?

Yes, titanium is more resistant to cracking compared to tungsten. Titanium resists breaking better than other metals because it is softer and easier to bend. Though tungsten is strong, it can also be brittle, increasing the possibility that it will fracture under extreme pressure or force.

How Much Do Titanium and Tungsten Cost?

Tungsten costs $3.25 per pound, while titanium costs $0.35 per pound. Despite the seemingly low cost per pound, it's important to note that the pricing for these metals is often influenced by various factors, including form, purity, and processing, so direct comparisons based solely on weight may not fully reflect the overall cost.

Is Titanium Suitable for Shipbuilding?

Yes, titanium is suitable for shipbuilding. Its high strength, corrosion resistance, and lightweight properties contribute to improved fuel efficiency and durability, making it an excellent choice for maritime applications.

How Xometry Can Help

Xometry offers comprehensive manufacturing solutions for titanium or tungsten needs and makes quoting super easy. With a focus on on-demand precise manufacturing, Xometry offers a range of services, including CNC machining processes like milling and turning. For titanium, we also offer sheet cutting and bending services. If you have any questions on either titanium or tungsten, want tips on how to best use this material, or know exactly what you want and need a free quote, a Xometry representative is waiting to hear from you!

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.