Laser cutting aluminum uses a tightly focused and collimated beam of light radiation to heat and melt a small spot on the surface of the material, with minimal vaporization. This melted material is then blown away with a gas stream, exposing deeper material, which is similarly removed. By this means, a path is cut as the laser advances through the depth of the cut and progresses along the line of the cut, to extract a CAD-designed component from a flat or formed sheet, an extruded section, or a tube, depending on the need.

This article will explain the laser cutting process for aluminum, its significance, and key optimization strategies.

What Is Laser Cutting Aluminum?

Laser cutting aluminum is a manufacturing process that uses a high-powered and tightly focused laser beam. It is used to precisely cut aluminum sheets or plates to match CAD-specified shapes or patterns. It is a critically important method for metal fabrication, offering major advantages over more traditional cutting techniques. Laser cutting aluminum is common in various industries, including aerospace, automotive, electronics, signage, and architectural applications. It offers a precise and efficient method for cutting aluminum with high quality and consistency.

What Is the Importance of Laser Cutting Aluminum?

The laser cutting of aluminum holds significant importance in virtually all manufacturing sectors. It offers both versatility and cost-effectiveness. The laser cutting of aluminum is primarily suited to flat parts and can accommodate a wide spectrum of thicknesses and alloys, although cutting formed parts often requires specialized equipment. The materials wastage from laser cutting is also very low. Additionally, laser-cut parts produced by a good setup and appropriate equipment require minimal or no post-processing to produce an acceptable finish on the cut faces. This ultimately removes the need for additional manufacturing stages.

How Does Laser Cutting Aluminum Work?

The process uses a high-powered laser beam to melt and vaporize the material, creating a precise and clean cut. The applied beam is focused on a small spot, and its energy is transferred to the target material, heating it very rapidly. Thicker materials require the molten material to be blown out of the active cut region using a gas or air assist.

How To Laser Cut Aluminum?

The specific details of the laser cutting process vary according to the type and power of the laser machine used and the specific operational parameters optimized by the operator. In general, the laser cutting process involves the following steps:

- Prepare the material by cleaning the surface and ensuring it is securely positioned on the cutting table.

- Set up the cutting parameters such as laser power, CNC-controlled feed speed and path, assist-gas type and pressure, and nozzle position. This involves trial and iteration of settings.

- Direct the focused laser beam onto the aluminum surface, rapidly heating and melting the material, with little to no vaporization. Simultaneously, assist gas such as nitrogen is directed through a nozzle to blow away the molten metal and clear the kerf or cut path.

- The assist gas clears the molten material from the kerf and may contribute to localized cooling, though its primary role is to aid material ejection and maintain cut quality.

How Effective Is Laser Cutting in Cutting Aluminum?

The process is highly effective, offering numerous advantages over traditional methods and enabling precise extraction of parts from sheet aluminum and, with the appropriate equipment, from formed parts. For more information, see our guide on Aluminum Properties.

What Type of Laser Can Cut Aluminum?

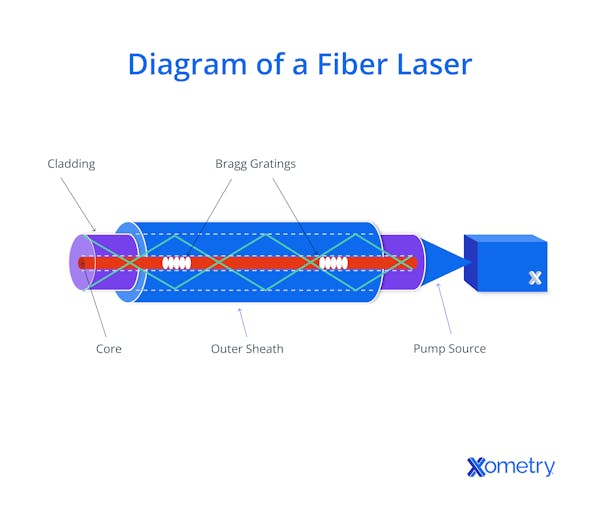

Aluminum can be cut using several types of lasers, with fiber and CO₂ systems being the most commonly used. Both of these types offer specific advantages and are suitable for different applications and thickness ranges. Fiber lasers use solid-state laser diodes to generate the beam, which is then transmitted via optical fibers to the cutting head. They are known for their high power density, excellent beam quality, and elevated energy efficiency. Fiber lasers are effective for aluminum cutting in the range of 0.5 to 15 mm, with specialized high-power systems capable of cutting up to around 25 mm. As such, fiber lasers represent key equipment in the precise and fast cutting of aluminum for applications in automotive, aerospace, electronics, and signage usage, among others.

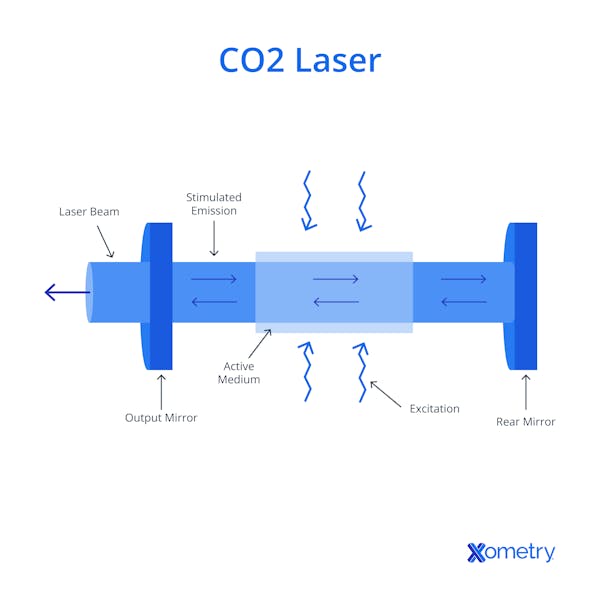

CO₂ lasers use a gas mixture of carbon dioxide, nitrogen, and helium, excited by electrical discharge to produce laser light. They are relatively economical to buy and suitable for a wide range of materials, including aluminum. This is despite the strong reflection characteristic of aluminum that coincides with the laser emission frequency. CO₂ lasers can cut thicker aluminum (above 6 mm), but their effectiveness is limited by aluminum's high reflectivity at CO₂ wavelengths (10.6 µm), often requiring special optics or coatings and higher power levels.

For more information, see our guide on CO2 lasers and How a Fiber Laser Works.

Can Plasma Cutters Cut Aluminum?

Yes, plasma cutters can cut aluminum effectively and quickly, especially at thicknesses where laser systems may be limited or cost-prohibitive. Plasma cutting is a versatile and widely used method for cutting various metals, including aluminum. Plasma cutting utilizes a high-velocity jet of ionized gas (plasma) to melt and remove the metal, creating a clean and precise cut. However, compared to laser cutting, plasma cutting may result in a wider heat-affected zone and considerably rougher (cut) edges. This does not prevent plasma cutting of aluminum from being a cost-effective solution in some sectors.

What Is the Role of Speed and Power in Laser Cutting Aluminum?

Speed and power are the defining parameters when laser cutting aluminum. Their impact on equipment cost, processing time, and finished part quality is critically important. The cutting speed directly affects the amount of heat input into the material. Slower cutting speeds allow time for more heat to be absorbed, potentially leading to a larger heat-affected zone and increased risk of material distortion. The intensity of the laser beam at the cut point is influenced by beam quality, collimation, focal equipment setup/quality, and the overall power of the laser. Higher power improves the cut depth and speed at which material can be processed. This directly drives the thickness capacity and productivity of the equipment.

Laser power affects the quality of the cut. Higher power levels allow for faster cutting speeds, but if not matched to material thickness and cutting parameters, they can cause a wider kerf, poor edge quality, and material splattering. Additionally, aluminum is highly reflective, particularly at the emission frequency of CO₂ lasers. To effectively cut aluminum when experiencing such reflection, laser systems require higher net energy levels to initiate melting. For more information, see our guide on Speed and Power.

What Is the Recommended Speed for Laser Cutting Aluminum?

The recommended cutting speed for laser cutting aluminum is highly variable and depends heavily on several factors. This includes the thickness of the material, laser power, beam quality, and the specifics of the cutting system being used. For example, a thin aluminum sheet (up to 3 mm) benefits from higher cutting speeds, provided the laser power is sufficient to allow it. Cutting speeds for thin aluminum (up to 3 mm) generally range from 1,000–3,000 mm/min, depending on laser power and material properties.

Medium-thickness material (3–6 mm) needs cutting speeds that may range from 500–1,500 mm/min. Heavy-gauge aluminum plates (above 6 mm) require slower cutting speeds unless the laser power exceeds 6–10 kW, which can enable higher throughput at these thicknesses. Faster cutting at these high powers and thicknesses prevents full penetration/clearance and can cause splattering. Cutting speeds in the range of 200–800 mm/min are commonly used for heavy aluminum plates.

How Much Power Is Needed for Laser Cutting Aluminum?

The power required for cutting aluminum depends on several factors, including material thickness, desired cutting speed, and the cutter’s specifications. The power needed can range from a few hundred watts to several kilowatts. For example, thin aluminum sheets (up to 3 mm or 0.12 inches) require a laser power of at least 500 W for a 3 mm sheet and pro-rata for thinner material. Medium-weight aluminum (3 mm to 6 mm or 0.12 to 0.24 inches) needs power in the range of 1–3 kW for good results. Heavy-gauge plates (above 6 mm or 0.24 inches and up to 100 mm or 4 inches) generally require 3,000–8,000 watts or more, depending on the cut quality desired. Cutting aluminum thicker than ~25 mm is uncommon and requires specialized equipment. For more information, see our guide on Power for Laser Cutting.

What Is the Best Grade of Aluminum for Laser Cutting?

Various aluminum grades are processed by laser cutting because of their favorable characteristics. Common aluminum grades for laser cutting include 5052, 5083, 6061, and 7075. While 5052 and 5083 offer excellent weldability and laser cut well, 6061 and especially 7075 can be more difficult due to their higher strength and tendency to produce rougher edges. However, 7075 aluminum requires higher laser power levels and slower cutting speeds due to its high strength and hardness.

What Size of Aluminum Can Be Laser Cut?

The maximum sheet size that can be laser cut depends on the machine’s bed dimensions. Common industrial aluminum sheet sizes include 4 ft × 8 ft (1.2 m × 2.4 m) and 5 ft × 10 ft (1.5 m × 3 m), and many industrial lasers are designed to accommodate these. Most larger industrial machines are built to accommodate such stock, although some are larger still. Many machines used in large-scale production are set up to work with rolls of sheet, allowing a less disrupted process as the roll can be pulled through for a new cut batch. Desktop machines range in sheet capacities from a few inches diagonal, with approximately an A4-size sheet being widely accommodated.

What Are the Benefits of Laser Cutting Aluminum?

Laser cutting aluminum offers several benefits, making it a popular choice for various applications. These benefits include:

- It delivers exceptional accuracy and precision.

- It can process aluminum sheets up to the bed size or X-Y axis limits. Cutting formed parts may require specialized equipment, such as 5-axis or tube lasers.

- It is fast and cost-effective and enables high-speed cutting with minimal setup time and material waste.

- The highly localized heating helps minimize the heat-affected zone (HAZ), reducing the distortion risk. However, some thermal effects may still occur, especially in thin sections.

- Delivers clean cuts with minimal burrs when parameters are optimized, often reducing or eliminating the need for post-processing.

- Highly amenable to being integrated into automated production lines, increasing productivity, and reducing labor costs.

As a mechanical engineer, I see laser cutting as a powerful tool when the design is aligned with the process. Considering edge quality, thermal effects, and cut tolerances early in the design stage ensures the part performs as intended and avoids costly revisions.Audrius Zidonis, Principal Engineer at Zidonis EngineeringNote from the Editor

What Are the Challenges of Laser Cutting Aluminum?

While laser cutting aluminum offers numerous advantages, there are also challenges in the process. These are listed below:

- Aluminum is a highly reflective material, particularly in its polished state and particularly at the wavelength of key equipment such as CO₂ lasers. This causes a proportion of the energy to scatter rather than be absorbed, reducing cutting effectiveness.

- The high thermal conductivity of aluminum results in rapid heat dissipation, which increases the risk of incomplete cutting and makes it harder to maintain a focused thermal profile.

- The oxide layer (and anodizing) of aluminum can influence the cutting process, having different optical properties from the bulk metal.

- Laser cutting is suitable for a wide range of material thicknesses. However, cutting very heavy-gauge plates may require higher laser power levels and slower cutting speeds, because of the heat dissipation into the bulk.

- Material warping and distortion can be an issue, especially for thin and delicate aluminum parts.

- Laser cutting can leave surface discoloration or oxidation, especially when using oxygen as the assist gas. Nitrogen helps prevent this.

Frequently Asked Questions About Laser Cutting Aluminum

Is Laser Cutting Aluminum Expensive?

No, laser cutting aluminum is not expensive on a per-part basis in high-volume operations. However, it does involve high capital expenditure (CAPEX) for equipment and setup. When properly utilized, laser cutting offers high throughput and efficiency. In many applications, processing costs are lower than raw material costs, especially when parts are simple and batch sizes are large.

Is Laser Cutting Aluminum Safe?

Yes, laser cutting aluminum is safe when proper safety protocols are followed. Industrial laser systems use high-powered radiation that poses risks to the eyes and skin. These hazards are managed through enclosures, interlocks, warning signage, PPE (such as protective eyewear), and fire prevention systems. Safety compliance ensures that laser cutting is a controlled and low-risk process in manufacturing environments.

Can a 10 mm Thickness of Aluminum Be Laser Cut?

Yes, a 10 mm sheet of aluminum can be cut with good results using fiber lasers rated between 3–6 kW. Lower power systems (1–2 kW) may struggle with throughput or edge quality at this thickness.

Summary

This article presented laser cutting aluminum, explained it, and discussed its various applications. To learn more about laser cutting aluminum, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including laser cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.