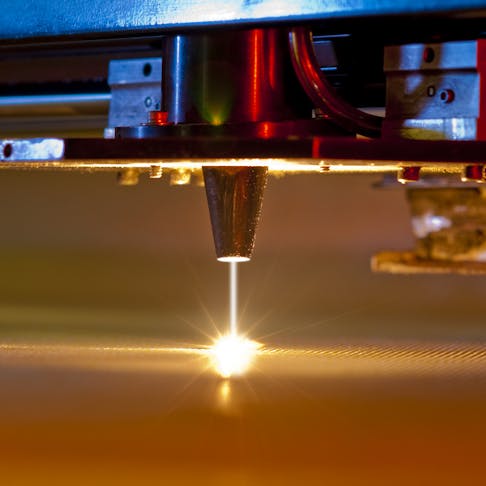

Laser cutting machines can engrave intricate patterns and designs onto parts or cut shapes that make whole components or products. From hobbyist and small commercial applications to large-scale manufacturing operations, the use of laser cutting machines is widespread.

The price of laser cutting machines depends on several factors, including laser type, power, worktable size, and the geometry and properties of the material to be cut. It makes sense that hobby laser cutting machines often lack many of the advanced features and capabilities found in industrial models. However, the vast number of options available on laser cutting machines means that a fabricator can find a suitable laser cutter for almost any application. This article will review the factors that impact the prices of laser cutting machines and identify the best machines for certain applications.

What Is a Laser Cutting Machine?

A laser cutting machine uses a laser beam to create intricate patterns and designs by heating the material to extreme temperatures. This is accomplished by burning, melting, or vaporizing the workpiece material. The cost of a laser cutter is related to its capabilities and the number and kinds of features it offers.

How Much Will a Laser Cutting Machine Cost You?

The price of laser cutting machines depends on four factors: the type of laser, available features, the machine size, and the properties of the workpiece material. The type of laser typically has the greatest impact on the price, primarily because of the cost of the laser optics.

The three main types of lasers used for cutting are CO2 lasers, diode lasers, and fiber lasers. CO2 lasers are the most common choice because they are versatile enough to both cut and engrave and can be used successfully on a variety of materials. The price ranges for these laser cutters can vary significantly depending on brand, wattage, included features, and regional market conditions. Table 1 below provides approximate price ranges for each type, intended as general guidelines rather than definitive figures.

| Type of Laser Cutting Machine | Price Range ($) |

|---|---|

Type of Laser Cutting Machine CO2 / Gas | Price Range ($) $500 to $1,000,000 |

Type of Laser Cutting Machine Diode | Price Range ($) $300 to $4,000 |

Type of Laser Cutting Machine Fiber | Price Range ($) $30,000 to $600,000 |

Table 1: Price Range of Different Types of Laser Cutting Machines

Do Different Types of Laser Cutting Machines Cost the Same?

No, different types of laser cutting machines do not cost the same amount. The prices of different types of laser cutting machines vary primarily based on the technology behind their optical systems.

What Are the Factors That Affect the Prices of Laser Cutting Machines?

The list below describes some of the factors that affect the prices of laser cutting machines:

- Type of Laser: The equipment used to generate the laser light beam in the three main types of laser cutting systems differ significantly in complexity and, consequently, price.

- Laser Power: As the rated power of the laser beam increases, the cost of the components to handle the higher energy levels increases.

- Workpiece Thickness: Cutting thicker material requires higher-power lasers. High-power lasers require heavier-duty components and are more expensive than low-power machines.

- Cutting Speed: Higher cutting speeds require more advanced (and expensive) motors to accurately drive the laser cutter head, thereby impacting the overall cost.

- Workpiece Material: Harder materials such as metals and highly reflective materials like stainless steel require specialized equipment for laser cutting to be successful.

- Worktable Size: Larger worktable size leads to higher prices due to the need for more raw materials and higher power equipment to build and operate larger machines.

Considering the high price of industrial laser cutting machines, outsourcing usually makes more sense unless fabrication is your core business. While low-cost desktop machines are available, they come with limitations in power, speed, and material capability, which can make them impractical for most production needs.Audrius Zidonis, Principal Engineer at Zidonis EngineeringNote from the Editor

What Are the Types of Laser Cutting Machines?

There are three main types of laser cutting machines. Each of these machines has its own set of advantages and disadvantages for cutting different kinds of materials. The list below describes which type of machine works best for which material:

1. Laser Cutting Machines for Steel

High-power (0.5-12 kW) fiber lasers are the most efficient machines for cutting steel, especially uncoated or reflective types. This is because the wavelength of the light produced by fiber lasers (~1060 nm) is efficiently absorbed by steel, while the wavelength of a CO2 laser, for example, at 10,600 nm, is mostly reflected. Fiber lasers, followed by CO2 lasers, are the best laser cutting machines for steel. The price of a fiber laser that can cut steel ranges from $30,000 to $600,000, while the price of a CO2 laser with steel-cutting capabilities ranges from $10,000 to $200,000.

2. Laser Cutting Machines for Metals

The best laser cutting machines for metals are fiber lasers, followed by CO2 lasers. The type of laser cutter most suitable for a metal application depends on factors such as the specific metal and its reflectivity, the metal's melting and vaporization temperatures, and the workpiece's thickness. The type of metal and its reflectivity determines whether a fiber or CO2 laser is better for cutting. This is because metals readily reflect long red and infrared wavelengths that are commonly emitted by CO2 lasers. Metals absorb shorter blue, violet, and ultraviolet wavelengths from fiber lasers. The melting and vaporization temperatures and the thickness of the workpiece determine the minimum power required for cutting, as more power and energy density are required to cut through thicker materials. The price of a fiber laser cutter ranges from $30,000 to $600,000, while the price of a CO2 laser system can vary from $10,000 to $200,000.

3. Laser Cutting Machines for Fabrics

CO2 laser cutters and diode laser cutters are the best machines for processing fabrics since they are both efficient and cost-effective compared to fiber lasers. High-power lasers aren’t needed to cut fabrics, unlike metals, since fabrics are extraordinarily thin and don’t require much power to vaporize. A 40W CO2 or diode laser can cut and engrave fabrics such as polyester, cotton, wool, and leather with ease. A CO2 laser cutting machine for fabric costs between $500 and $4,000, while diode lasers for fabric-cutting cost $300 to $1,000.

4. Laser Cutting Machines for Paper

CO2 laser cutters and diode laser cutters are the best options for laser cutting paper. As with laser cutting of fabrics, a powerful laser isn’t required to achieve cuts and engravings on paper products such as cards and invitations. The power needed to cut paper is less than the power needed to cut fabrics. It is minuscule compared to the power needed to cut metals. CO2 lasers for paper cutting cost between $500 and $4,000, while the price of diode laser cutting machines is between $300 and $1,000.

5. Laser Cutting Machines for Wood

CO2 and diode laser cutters are the two best types of laser cutters for wood. This is because wood, like fabric and paper, doesn’t require high power to be vaporized for a laser to cut through. The price of laser cutting machines for wood ranges from $500 to $4,000 for CO2 lasers and is generally between $300 and $1,000 for diode lasers.

6. Laser Cutting Machines for Acrylic

CO2 lasers are the best laser cutters for acrylic. These lasers offer greater efficiency and cut quality because acrylics readily absorb the red and infrared wavelengths produced by CO2 lasers. With higher laser powers like CO2 lasers, cut efficiency is increased, and quality is improved. Diode lasers can also cut acrylic. They are a good alternative but may require multiple passes depending on the acrylic's thickness. Laser cutting machines for acrylic cost between $500 and $4,000 for CO2 lasers, and between $300 and $1,000 for diode lasers.

7. Laser Cutting Machines for Invitations

The best laser cutting machines for invitations are diode lasers. Invitations for various ceremonies and events are commonly made from paper and similar materials. High-power lasers are not required to create elaborate and intricate designs for invitations. Diode lasers can create beautiful invitations with ease. The price of diode laser cutting machines ranges between $300 and $1,000.

8. Laser Cutting Machines for Plastic

The best laser cutting machine for most plastics is the CO2 laser. The wavelengths from CO2 lasers are readily absorbed by most plastics, which makes laser cutting a highly efficient process. The price of CO2 laser cutting machines for plastic can range between $500 and $4,000 for hobbyist and small business use, though not all plastics are safe to cut due to potential toxic fumes. Costs can rise to as much as $200,000 for a laser cutter designed for industrial use.

What Are the Cheapest Laser Cutting Machines That Can Cut All Materials?

CO2 lasers are among the most versatile types of laser cutters, capable of cutting and engraving a wide range of non-metal materials such as wood, acrylic, leather, and paper. While they cannot cut metals, they can often engrave coated or anodized metal surfaces. Below are some of the most affordable CO2 laser cutting machines currently available (prices approximate as of 2025):

- Monport LightBurn: The Monport 40W CO2 laser engraver is priced at approximately $650. It is ideal for engraving and cutting non-metal materials like wood, leather, acrylic, and paper. While it cannot cut metal, it can engrave on certain coated or anodized metals. Attempting to cut metal may damage the machine.

- OMTech MF1220-50: This 50W CO2 laser cutter, priced at around $2,000, is suitable for a wide variety of materials, including wood, acrylic, leather, and some plastics. It can engrave coated metals but is not designed to cut through metal. With a spacious work area, it is well-suited for small business or advanced hobbyist applications. Note: Avoid materials like PVC, which emit hazardous fumes when lasered.

- FLUX Beamo: Priced at approximately $1,700, the FLUX Beamo is a compact 30W CO2 laser cutter that supports cutting and engraving of materials such as wood, acrylic, leather, and cardboard. It is not intended for cutting metal but can engrave some coated metal surfaces.

What Are the Best Laser Cutting Machines That Are Worth Buying?

The following laser cutting machines are considered among the best in terms of performance and user experience. While they come at a higher price point, they offer excellent build quality, ease of use, and software integration. Prices are approximate as of 2025:

- Glowforge Pro: The Glowforge Pro is equipped with a 45W CO2 laser tube, not 800W. It is capable of cutting and engraving a variety of non-metal materials, including wood, acrylic, leather, and fabric. While it can engrave certain coated metals, it does not have the power to cut through metal materials. Price is $6,000.

- Glowforge Basic: The Glowforge Basic features a 40W CO2 laser and costs about $2,500. It is designed for cutting and engraving common materials like paper, cardboard, wood, leather, and some plastics. Similar to the Pro, it can engrave coated metals but is not suitable for metal cutting. Its simplicity and plug-and-play setup make it an excellent option for hobbyists and small-scale creators.

- FLUX BeamBox Pro: Priced at around $3,000, the FLUX BeamBox Pro is a 50W desktop CO2 laser cutter ideal for small businesses and advanced hobbyists. It handles materials such as wood, acrylic, leather, cardboard, and paper with ease. While it can engrave certain coated metals, it is not designed to cut metal. Its spacious work area, touchscreen controls, and user-friendly software interface make it a strong contender in the mid-range desktop laser market.

Is It Worth Buying an Expensive Laser Cutting Machine?

Whether it is worth buying an expensive laser cutting machine depends on a lot of factors. Unless you have large volumes of parts that must be laser cut or are consistently cutting metal to fabricate parts, there is no need to buy an expensive laser cutting machine. Cheaper laser cutting machines have the capability to perform many of the same tasks as the more expensive machines can do but at a slower pace. Cheaper machines often have lower power compared to more expensive machines and usually have smaller workspaces. However, expensive laser machines may be more reliable and have better builds. Consider the product volumes and the materials used in your laser cutting operation to help you pick a suitable machine.

Summary

Xometry provides a wide range of manufacturing capabilities, including sheet cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.