Used on 3D-printed polymers to even out their surfaces and give them an overall nicer aesthetic, acetone vapor smoothing is especially useful in FDM (fused deposition modeling) where bumpy surface finishes are common. This article will cover how exactly it works, the process, and what materials you can use it with.

What is Acetone Vapor Smoothing?

Acetone vapor smoothing is one of the post-manufacturing processes used to get rid of surface imperfections on 3D-printed parts that are fresh off the machine. The way it leaves a glossy and smooth finish is by breaking down the outermost layer of a compatible material (like ABS, ASA, PMMA, HIPS, PC, and any other plastic that can be dissolved by acetone—it doesn’t really do much for PLA, Nylon, PETG, or TPU). It’s a quick and easy method, and can be used on complex parts that other methods tend to struggle with as they can’t evenly remove the layers. It’s also time- and cost-efficient because it works on all areas of the part equally, instead of focusing on each area individually. This also evenly spreads out the material’s strength.

We mentioned in the intro that the method is used a lot in FDM printed parts. This is because they’re known for being a tad unstable—basically, depending on which direction they’re loaded in, their mechanical properties change. But with acetone vapor smoothing, that becomes less of an issue. The technical reason is that the smoothing creates more bonds in the z-axis and decreases strength in the x- and y-axes.

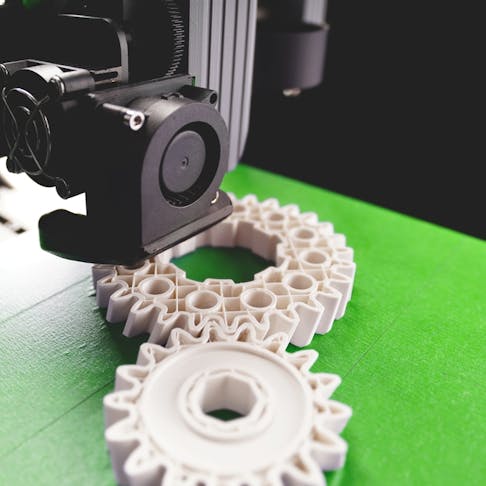

The image below shows our 3D-printed logo after having been vapor smoothed.

Which Types of 3D Printing Materials Are Compatible With Acetone Vapor Smoothing?

Acetone vapor smoothing works on any material that can be dissolved by acetone. Some filament types that don’t respond the same way to acetone may be damaged by the process or may remain completely unaffected. The five most common 3D printed materials which benefit from acetone vapor smoothing are:

- ABS (acrylonitrile butadiene styrene)

- ASA (acrylonitrile styrene acrylate)

- PMMA (polymethyl methacrylate)

- HIPS (high-impact polystyrene)

- PC (polycarbonate)

To use these materials, check out Xometry's 3D Printing Services for your needs.

How Does Acetone Vapor Smoothing Work?

So if you’re interested in doing some acetone vapor smoothing of your own, you can follow these steps:

1. Preparation

To prepare, using a clean file, sand your 3D printed model and take off any majorly coarse surfaces, including those with supports. Then, you’ll need to figure out the best way to place the part in a container so the vapor can cover all the necessary surfaces at the same time and the lid closes fully. Usually, you can only do the front and sides in one go. Another important tip is to make sure the part has a base to rest on that won’t dissolve in acetone. Metal foil usually works well.

2. Acetone Vapor Generation

The easiest way to make the vapor is by pouring acetone into a see-through and non-reactive container (like glass), then covering it—without sealing so the acetone can evaporate quickly. If you want to make the most of the process, a helpful tip is to soak a paper towel in acetone and put it inside the container, not touching the part when it goes in.

3. Object Suspension

Put the part inside the container, but make sure it doesn’t touch the liquid acetone or the soaked paper towel. If it does touch either of these, that contact point will dissolve much faster.

4. Vapor Exposure

Leave the part in the container and monitor it continuously. There is no set timeframe or method of calculating how long the part might need to be in the container. This will depend on several variables including: the rate of acetone evaporation, the size of the container, the size of the part, and the initial surface roughness.

5. Smoothing Process

Leave the part in the container and let it do its thing, but keep an eye on it. There isn’t a way to calculate how long each part has to stay in there, so you’ll have to play it by ear—or eye. The size of the container, the amount of acetone, the size of the model, and several other things all have a bearing on how long it will take. You don’t want to let it sit for too long because it could start losing the detail—when the part looks smooth enough, you’re good to go.

6. Ventilation and Drying

The last step involves carefully removing the part (not letting it touch the paper towels), and setting it down in a well-ventilated area to dry, which can take anywhere from a few hours to a couple of days.

What Are the Advantages of Acetone Vapor Smoothing in 3D Printing?

Acetone vapor smoothing is a good option for several reasons. The advantages are discussed below:

1. Surface Quality

Acetone vapor smoothing improves the surface quality of printed parts. Naturally, 3D-printed parts have rough surfaces because they are made in layers. Acetone vapor smoothing is an effective process of reducing surface roughness and improving surface quality, mainly for aesthetic purposes.

2. Time and Cost-Efficiency

Compared to other post-processing methods that use sandpaper, heat guns, or filler material, acetone vapor smoothing is quicker and cheaper. Those other methods concentrate effects on only one area at a time, so they’re more labor-intensive in general. The acetone vapor, by contrast, affects all areas of the model equally. Thus, acetone vapor smoothing can actually boost your productivity.

3. Smoothing Complex Geometries

Acetone vapor smoothing has advantages over other methods because it can reduce the surface roughness of complex geometries evenly. Other methods have trouble adding or removing an even layer of material, especially over complex geometry.

4. Strength and Integrity

Prior to acetone vapor smoothing, FDM prints are very anisotropic. This means that their mechanical properties differ when loaded in different directions, and it’s considered a major problem with FDM 3D printing. The vapor smoothing, however, helps to even that directionality out, putting the parts closer to isotropy. In short, the acetone vapor smoothing creates more bonds in the z-axis (perpendicular to the print bed) but decreases strength in the x-axis and y-axis (parallel to the print bed). Such can be advantageous if your item is likely to see z-axis loads.

How Does Acetone Vapor Smoothing Affect the Thickness or Material of the 3D-Printed Object?

Acetone vapor smoothing has no effect on the overall thickness of the 3D-printed object. The process only smoothes the item’s surfaces. This does not reduce the thickness or overall geometric parameters of the finished product.

What Are the Best Methods for Applying Acetone Vapor Smoothing to 3D-Printed Objects?

The best method for applying acetone vapor smoothing depends on several factors, including the time required to complete the process and the size of the part. In general, there are three prominent methods used to apply acetone vapor to 3D-printed objects:

- One method is to apply acetone using a paintbrush. However, this takes more manual work and is less likely than other methods to give you a completely even and glossy finish.

- The second method is submerging the part in the acetone. This process, however, generates unpredictable results.

- The third method is to use an acetone steam bath where the acetone is either heated gently to create vapor or allowed to evaporate naturally. This final method is considered the best way to create an even, glossy finish.

Can 3D-Printed Edges Be Improved With Acetone Vapor Smoothing?

Yes, any edge of a 3D-printed part, as long as it’s printed in a material susceptible to acetone, can be improved using acetone vapor smoothing. Parts with large layer heights see the greatest benefits. Parts with smaller layer heights or which are printed via different 3D printing techniques will receive less benefit but are still likely to come out smoother than before.

Is Acetone Vapor Smoothing Better for Certain 3D-Printed Materials?

Yes, some materials benefit from acetone vapor smoothing while others do not. The viable materials are: ABS, ASA, PMMA, HIPS, and polycarbonate. On the other hand, some will be degraded by exposure to acetone while others will be entirely unaffected. Examples of materials that do not benefit from this post-processing include: PLA, PETG, Nylon, and TPU.

What Are the Differences Between 3D Printing Post-Processing Methods and Acetone Vapor Smoothing?

Acetone vapor smoothing is a form of 3D printing post-processing. Others include the likes of: sanding, sandblasting, using XTC-3D, using 3D gloop, using Polymaker Polysmooth PVB filament, chemical smoothing, and using a heat gun. These post-processing methods differ in application and target materials. For example, Polymaker Polysmooth and chemical smoothing are similar to acetone vapor smoothing as they all use a chemical reaction to dissolve and smooth the outer layer. The difference is that Polymaker Polysmooth uses a patented filament and chemical exclusive to that filament, and chemical smoothing uses a different chemical such as ethyl acetate to smooth PLA.

Sanding and sandblasting also differ from acetone vapor smoothing. They are purely abrasive techniques that erode the high ridges of the part, leaving a smooth surface. XTC-3D and 3D gloop, meanwhile, use a filler material to build up the outer surface and give it a smooth and glossy appearance.

What Are the Differences Between Acetone Vapor Smoothing and Vapor Smoothing PLA?

Acetone vapor smoothing and chemical smoothing of PLA are the same methods in principle. They both partially dissolve the surface layers of the material. However, PLA (polylactic acid) plastic responds to ethyl acetate rather than acetone. Acetone won’t create the proper effect on PLA and ethyl acetate won’t do the trick on ABS and other plastics that respond to acetone. To learn more, see our full guide on Vapor Smoothing PLA.

How Xometry Can Help

If you have any questions on any 3D printing processes—anything from making the parts to smoothing out their surfaces—feel free to reach out to one of our representatives who will be more than happy to assist you. We also have a large catalog of manufacturing services like CNC machining, and laser cutting. You can get started today quickly and easily by uploading your designs and requesting a free no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.