Ductile failure is a critical consideration in the design of components subjected to tensile loading. Engineers typically design parts so that the expected maximum stress remains within the elastic limit of the material—below its yield point—to avoid permanent deformation. However, if stress exceeds this limit, the material begins to deform plastically and may ultimately experience ductile fracture.

In ductile failure, the part undergoes significant plastic deformation, often visible as a localized reduction in cross-sectional area (necking), before it fractures. This behavior contrasts with brittle failure, which occurs with little or no plastic deformation and minimal warning.

This article will explain what ductile failure is, how it initiates and progresses, what it looks like, its common causes, and strategies to prevent it in structural design.

What Is Ductile Failure?

Ductile failure refers to the process of a material fracturing after plastically deforming past its yield limit. This is in contrast to brittle failure, where the material barely deforms before fracturing. Materials that deform in a ductile manner have a distinctive failure mode compared to brittle failure.

In a typical stress-strain curve, once stress increases beyond this limit to the material’s yield point, it begins to deform plastically. In some materials, a distinct upper and lower yield point may be observed; the lower yield point marks the onset of uniform plastic deformation. From A to B, the material undergoes strain hardening, where it can withstand increasing stress due to dislocation interactions despite continued plastic deformation. The maximum stress at Point B is the ultimate tensile strength (UTS). Beyond Point B, localized reduction in cross-sectional area occurs, a phenomenon called necking, and the stress the material can sustain decreases until fracture occurs at Point C.

It should be noted that necking typically develops after uniform plastic deformation and is not present during the early stages of ductile failure. A higher degree of elongation before failure means the material is more ductile. However, some degree of strain hardening occurs in most metals before they reach the necking stage.

Highly ductile materials often lack a sharply defined yield point. For these materials, yield strength is commonly determined using the 0.2% offset method, in which a line parallel to the elastic region of the curve is drawn from a strain value of 0.2% until it intersects the curve. This intersection marks the yield point.

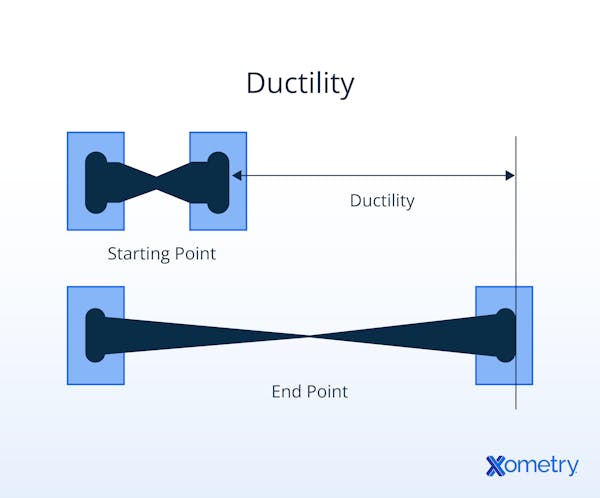

A material’s level of ductility can be determined by the proportional reduction in cross-sectional area at the fracture plane after failure. Materials such as aluminum and gold, which exhibit a large reduction in area before breaking, are considered highly ductile.

What Does “Ductile” Mean?

The word ductile originates from the Latin ductilis, meaning "malleable," "flexible," or "capable of being led." In materials science, ductility refers to a material's ability to undergo significant plastic deformation before fracturing. This property allows materials to be drawn into wires, formed into complex shapes, or absorb energy under load without failing suddenly.

For more information, see our guide on Ductility.

What Happens When Ductile Failure Occurs?

Ductile failure is a multi-step process that, for the purpose of clarity, will be limited to tensile ductile failure. First, the part must be loaded in tension such that the stress developed begins to exceed the elastic limit (or yield point) of the material. This is when the material will start to deform plastically. This process is called necking and refers to the reduction in the cross-sectional area of the part. Eventually, the applied stress becomes stronger than the bonds between atoms that hold the material together. The weakest parts of the material are internal defects where the metallic crystals are not lined up for optimum strength, such as at pre-existing pores or voids, or inclusions or contaminants such as slag or metal carbides. Next, these voids will coalesce, which means they will grow and join with nearby voids to form larger voids. Once the voids have joined up to create sufficiently large discontinuities, a crack will begin to propagate outward from the initiation point until the material ultimately separates on a macro level and fails.

What Does Ductile Failure Look Like?

Ductile fracture is characterized by a noticeable reduction in the cross-sectional area of the part near the fracture plane, a result of localized plastic deformation. This narrowing, known as necking, creates a distinctive profile in the failure region. In highly ductile materials, the necking zone often tapers to a sharper point before fracture, while in less ductile materials, the transition is more gradual.

Understanding ductile failure is key to designing reliable components and structures. By recognizing how plastic deformation initiates and progresses to fracture, engineers can better predict failure modes and implement strategies such as safety factors, proper material selection, and geometry optimization. Ductile failure, while offering warning signs before complete fracture, still poses serious risks if not adequately accounted for. Incorporating thorough analysis of stresses, defects, and environmental effects into design helps ensure components remain functional and safe throughout their service life.Mahder Tewolde, Ph.D., PENote from the Editor

What Are the Causes of Ductile Failure?

Under the right conditions, any material can fail, and ductile failure occurs when those conditions allow significant plastic deformation before fracture. Some of the factors that contribute to ductile failure are listed below:

1. Stress Level

Parts are typically designed so that the stresses they experience remain well below the yield strength, often with a built-in safety factor. If the applied stress in a tensile load exceeds the yield strength, the material begins to deform plastically. This initiates the first stage of ductile failure, with deformation continuing until the fracture strength is reached and the part breaks.

2. Type of Loading

Ductile failure is most often observed under tensile loading, where the applied force stretches the material. The loading rate, which is the speed at which the load is applied, can also influence ductile failure behavior. In some cases, higher loading rates may increase the material’s apparent fracture toughness. Although most components are designed to withstand more than the expected load, unforeseen or extreme tensile stresses can still trigger ductile failure.

3. Pre-Existing Cracks or Defects

Cracks, voids, or other defects weaken a material locally, creating stress concentrations in those regions. When the applied load is sufficient, these high-stress zones can yield first, initiating crack propagation. Most ductile failures occur by this mechanism, beginning with microscopic void formation and coalescence, followed by crack growth that ultimately leads to fracture.

4. Material Properties

Preventing ductile failure requires designing parts so that stress concentrations remain well below the yield strength of the material. Some materials, such as medium-carbon steel, have a sharply defined yield point that is easily identifiable on a stress-strain curve. Highly ductile materials like aluminum do not exhibit a distinct yield point. Instead, their yield strength is defined using the 0.2% offset method, which identifies the stress corresponding to 0.2% permanent strain. For such materials, this 0.2% offset yield strength is effectively treated as the yield stress in design calculations.

5. Temperature and Environmental Effects

Temperature has a significant influence on the tensile behavior of materials. Elevated temperatures reduce a material’s yield strength, allowing ductile failure to occur at much lower loads. Conversely, reducing the temperature can cause an otherwise ductile material to fracture in a brittle manner. The temperature at which this shift occurs is known as the ductile-to-brittle transition temperature (DBTT). At high temperatures and sustained loads, materials may also experience creep, a time-dependent deformation that can occur even below the room-temperature yield strength. Environmental factors such as corrosion can further affect failure behavior. Certain corrosive agents can cause embrittlement, leading a material that is normally ductile to fail in a brittle mode.

How Can Ductile Failure Be Prevented?

Ductile failure can be prevented by careful engineering design. Every component and system must be designed so that the applied loads it will experience in its service environment do not exceed the material's yield point in that environment. To eliminate failure, the load must be reduced, the cross-sectional area must be increased, or a different material must be selected.

Since stress is defined as force divided by cross-sectional area, reducing the force or increasing the area will lower the stress and reduce the risk of failure. Choosing materials with higher yield strengths ensures that operational loads remain within the elastic range.

It is standard engineering practice to design parts to withstand a safety factor above the maximum expected load. Safety factors account for uncertainties such as material variability, environmental conditions, and unforeseen loading scenarios. In many industries, acceptable safety factors are regulated and cannot be chosen arbitrarily by the designer.

How Can Parts That Fail By Ductile Fracture Be Repaired?

A component is considered to have experienced ductile failure when it has undergone sufficient plastic deformation that can no longer perform its intended function, regardless of whether complete fracture has occurred. Repair is generally possible only by removing the deformed section and replacing it or by replacing the entire component.

This type of failure often indicates a potential design flaw: either the service loads were higher than anticipated, or a material with insufficient strength was selected. In either case, a comprehensive failure analysis—including material characterization, load history review, and potential environmental effects—should be conducted. The findings should inform a redesign of the part or the selection of more suitable materials to prevent recurrence.

What Are the Ductile Material Examples?

The vast majority of metals used in engineering applications are ductile. Listed below are some common examples of ductile materials:

- Aluminum: High ductility, especially in annealed form; widely used in structural, automotive, and aerospace applications.

- Low-carbon steel: Very ductile and tough; commonly used in construction and fabrication.

- Zinc: Moderately ductile, especially at elevated temperatures; often used in galvanizing and die casting.

- Medium-carbon steel: Lower ductility than low-carbon steel but still capable of substantial plastic deformation.

- Copper: Extremely ductile and malleable; ideal for electrical wiring and heat exchangers.

- Gold: One of the most ductile and malleable metals known; used in electronics and decorative applications.

What Are the Types of Ductile Failure?

There are two general types of ductile failure, differentiated by the level of ductility of a material. These are listed below:

- Significant Necking: This refers to the situation where a highly ductile material experiences a tensile load that results in significant necking (or reduction in cross-sectional area) until failure. These materials will have a significant amount of permanent deformation before ultimately failing.

- Cup-and-Cone: This failure mode occurs when a material with a relatively lower degree of ductility fails. This ductile failure mode is caused by void nucleation and coalescence, which ultimately causes crack growth and failure.

What Is the Difference Between Ductile Failure and Brittle Failure?

Ductile failure occurs when a material is loaded beyond its yield strength and begins to plastically deform for a period before ultimately failing. Brittle materials experience little or no plastic deformation before breaking. Their ultimate tensile strength and yield strength are close together. Because of the lack of plastic deformation, a brittle material gives no visual indication that it is about to fail.

Most materials fail because they exhibit some combination of ductile and brittle behavior, and both strain rate and temperature can change the behavior of the material from ductile to brittle or vice versa.

For more information, see our guide on Brittle Failure.

Summary

This article presented ductile failure, explained what it is, and discussed how to manage and prevent it. To learn more about ductile failure, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.