When manufacturers want to make 3D-printed parts with complex geometries, they often turn to powder bed fusion (PBF) machines. These parts are notoriously hard to make (sometimes impossible) with traditional manufacturing methods. Let’s learn more about it.

What Are Powder Bed Fusion (PBF) Machines?

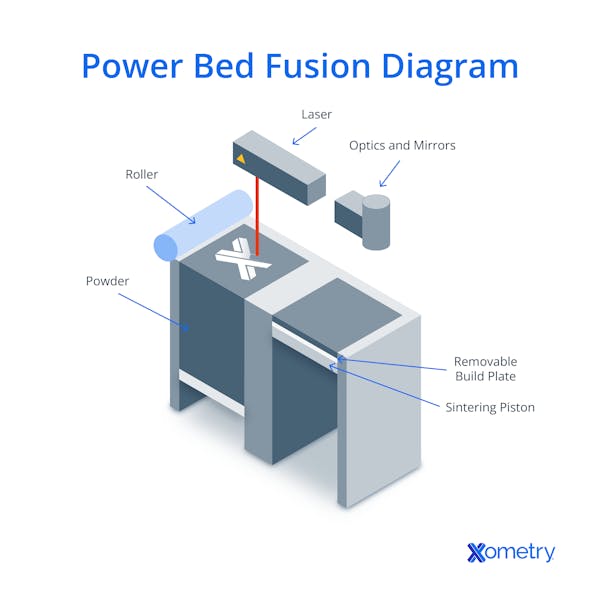

PBF machines are 3D printers that can create high-quality, intricate, and complex parts for various applications in many different industries. They work by melting and fusing layers of metal or plastic powders using a laser or an electron beam to build the part layer by layer from a bed of powder. It can make customized parts with specific properties, such as strength or heat resistance, that meet the specific needs of customers. You can see what one of these machines looks like in the below picture.

The great thing about PBF is that it generally keeps waste to a minimum, as any excess powder is collected and recycled after the part is complete. There’s also quick iteration on designs, allowing engineers to update CAD designs and reprint flawed parts. When it comes to complex parts with intricate internal geometries, PBF is the preferred 3D printing method. A complete part can be designed, manufactured, tested, re-designed, and printed again much faster than with other methods like metal casting or MIM. PBF machines can produce multiple parts simultaneously, which improves productivity and reduces the time required to manufacture parts.

PBF can work with a wide range of plastics and metals, and the parts made require minimal support structures during printing; the unused powder acts as support. For example, when making cooling channels inside turbine blades, the excess powder can simply be poured out. Having said that, PBF is a relatively slow process with a long print time due to the need for powder preheating, vacuum generation, and cooling-off periods. In addition, as they’re made one layer at a time, the structural properties of PBF parts aren’t typically as strong as those made using other processes. The surface quality will also depend on the grain size of the powder and can resemble manufacturing processes like sand casting and die casting.

You’ll also have to watch out for thermal distortion that can cause the shrinking and warping of fabricated parts, particularly if they’re made from a polymer. Another drawback for some could be the high cost; both the equipment and materials are expensive. While it is possible to find end-to-end systems under $100,000, prices typically start in the $150,000–$200,000 range, with high-end models sometimes costing over $1,000,000. It’s also an energy-guzzling process. The unused powder that remains after printing and is removed in post-processing should be recycled efficiently, though preheating can still affect some of the unused material.

How Do Powder Bed Fusion (PBF) Machines Work?

The steps in the PBF 3D printing process are as follows:

- A CAD model has to be created and sliced into layers. The 3D printer is programmed with the build sequence before printing begins.

- A thin, even layer of powder (typically 0.1 mm) is spread across the build platform.

- The powder bed is heated to a temperature slightly below the material’s melting point to reduce thermal stress.

- A high-powered laser or electron beam selectively melts the powder layer based on the digital model. The material solidifies as it cools.

- The build platform lowers by one layer thickness, and the process repeats until the part is fully formed.

- Once printing is complete, the part is removed from the powder bed, and any post-processing steps can begin.

What Are the Types of Powder Bed Fusion (PBF) Machines?

There are different types of PBF machines that can be used to print parts. There are two primary types of powder bed fusion (PBF) additive manufacturing techniques: laser beam (PBF-LB) and electron beam (PBF-EB). Each of these types has trademarked technologies associated with them. These are Direct metal laser sintering (DMLS), Selective laser sintering (SLS), Selective laser melting (SLM), and Electron beam melting (EBM). The processes are distinguished by the 3D printing materials used and the thermal source used to fuse the powders. PBF methods either use lasers or electron beams to fuse the powdered particles. Each of these methods is discussed separately in the following sections:

1. Direct Metal Laser Sintering (DMLS)

DMLS is a PBF additive manufacturing technique that uses a high-powered laser to selectively fuse metallic powders. The process is similar to SLS but uses metal powders instead of plastics. The laser beam melts and fuses the metal particles to form a solid part layer by layer. DMLS is commonly used in the aerospace and medical industries for the production of complex metal parts with high accuracy and desirable mechanical properties.

2. Selective Laser Sintering (SLS)

SLS is a 3D printing technique that uses a high-powered laser to selectively fuse powdered polymer materials, typically plastics or nylon, into solid objects. It builds parts layer by layer, with each layer being fused by the laser. The unfused powder material supports the part during the build process, eliminating the need for support structures. SLS is widely used in prototyping, product design, and small-batch production.

3. Selective Laser Melting (SLM)

SLM and SLS share similarities in that both processes use a high-powered laser to provide heat, falling under the category of PBF-LB. However, SLM differs in that the laser fully melts the powder instead of just sintering it. This results in a denser and stronger final part. The process is commonly used with metal powders such as titanium and its alloys, aluminum alloys, and stainless steel. More uncommon metals such as tungsten can be processed, but their application tends to be more specialized. An inert atmosphere, usually argon, is employed in the build chamber to prevent oxidation or nitriding of the consolidated material. SLM is commonly used in aerospace, medical, and automotive industries for producing parts with high-quality mechanical properties and complex geometries.

4. Electron Beam Melting (EBM)

EBM is another powder bed fusion process that is used for creating metal parts. It uses a beam instead of a laser to melt and fuse metallic powders. Unlike laser-based techniques, an EBM printer operates like a small-scale particle accelerator by firing electrons at the powder bed under a vacuum to melt the metal material. The charged electrons can cause the powder particles to disperse, which is why each layer of material is typically pre-sintered before the 3D printing process begins. Additionally, the entire print bed is kept hot throughout the build. During the 3D printing process, parts are built inside the semi-sintered cake of powder, which provides support and often eliminates the need for additional support structures. It is worth noting that there is a variation of EBM that allows for parts to be sintered within the loose powder.

EBM is typically used for producing large and complex metal parts for aerospace and medical applications. EBM offers higher build speeds and less residual stress in parts than other PBF techniques, but the equipment is typically more expensive than other machines.

Powder bed fusion processes use a heat source to selectively fuse powder into a form layer by layer. It is particularly efficient at small batch production, as the entire powder bed can contain parts, which can stack on top of each other. It is also a support-free process, which improves the surface finish of down-facing surfaces. However, it can be more prone to warping.Christian Tsu-RaunTeam Lead, Manual Quoting

What Are the Benefits of Using Powder Bed Fusion (PBF) Machines for 3D Printing?

- Flexible

- Improved manufacturing times for parts with complex designs

- Reduced waste and, in turn, reduced costs and environmental impact

- Works with a range of materials

- Need minimal support structures during printing

What Are the Limitations of Using Powder Bed Fusion (PBF) Machines for 3D Printing?

- Long print time and slow process

- Weak structural properties

- Surface texture depends on the powder’s grain size

- Expensive machinery and powder

- Thermal distortion

- Uses a lot of energy

What Is the Manufacturing Process of Powder Bed Fusion (PBF)?

The manufacturing process of PBF involves the following steps:

- Design a CAD file and link it to the 3D printer. The design is sliced numerically into layers and the printing sequence is predetermined before the actual printing starts.

- Spread the powder across a build platform. A thin layer of powder is evenly distributed across the build area.

- Heat the entire build area to a temperature slightly below the melting point of the powder particles.

- Use a high-powered laser or electron beam to selectively melt the powder in specific areas, according to a pre-programmed pattern. The melted powder solidifies as it cools and forms a solid layer.

- The build platform is lowered by one layer of thickness, and the process repeats until the part is complete.

- Once the printing is finished, the parts are removed from the powder bed. They undergo various post-processing steps such as the removal of support structures, heat treatment, machining, or polishing.

How Is the Post Manufacture Process for PBF?

Post-processing of PBF-printed parts will be different for different materials used and the different methods used to print the part.

Metal PBF parts require heat treatment due to the internal stresses caused by the process. After heat treatment, support structures are removed and additional post-processing can proceed. Depending on customer requirements, there are several post-processing options available, including CNC machining and polishing.

Metal EBM parts are free-floating off the substrate and supported by semi-sintered powder during the build. Sacrificial supports may be added for heat control or post-processing. EBM parts require breaking out of the powder cake but do not necessarily require a heat treatment step due to elevated temperatures inside the printer.

Plastic parts, on the other hand, are removed from the bed of unfused powder, and excess material is removed with a bead blast, resulting in a consistent surface finish. SLS parts are left as-is once the bead blast is completed, but they are good candidates for additional dyeing if color is desired.

How Do PBF Machines Differ From Other Types of 3D Printers?

PBF machines differ from other types of 3D printers in several ways. The most significant difference is how they build parts layer by layer using powdered materials. PBF machines use a high-powered laser or electron beam to selectively fuse metal or plastic powders, while other 3D printers may use extrusion or photopolymerization methods. PBF machines are also capable of producing highly complex and intricate parts with a high degree of precision and accuracy. Additionally, PBF machines are capable of producing functional plastic parts with exceptional mechanical properties, surpassing those achievable by any other 3D printing technology. However, they often require post-processing to achieve the desired surface finish and may have limitations in terms of the size and geometry of the parts they can produce. What’s more, PBF machines tend to be more expensive and require more specialized knowledge and training to operate.

What Materials Can Be Used With PBF Machines?

PBF 3D printers support a wide range of materials, which are listed below:

Plastics

- Nylon (including glass and mineral-filled)

- Polypropylene

- Polyetheretherketone (PEEK)

- Polyetherketoneketone (PEKK)

- TPU

Metals

- Aluminum and light alloys

- Chrome-cobalt alloys

- Precious metals (gold, silver)

- Copper and alloys (bronze, brass)

- Inconel®

- Steel (mild, alloy, and stainless steel 316 L and 17-4PH)

- Titanium and alloys

- Nickel and alloys

What Are the Common Applications of PBF Machines in Different Industries?

- Aerospace (turbine blades, fuel nozzles, guide vanes)

- Medical (custom-made orthopedic parts, titanium alloy cranial/acetabular implants, artificial hip joints)

- Automotive (prototyping, brake pads with cooling ducts for motorsports)

- Military aircraft components

How Has the Development of PBF Machines Impacted the Manufacturing Industry?

The development of powder bed fusion (PBF) machines has revolutionized the manufacturing industry in various ways. One of the most significant impacts is the increased design freedom it provides. PBF machines allow for the creation of complex and intricate geometries that would be difficult or impossible to produce using traditional manufacturing methods.

Another key impact of PBF machines is faster prototyping, which has significantly reduced the time and cost required to develop new products. With rapid prototyping, manufacturers can quickly test their design concepts and make improvements before finalizing the production design.

PBF machines have also contributed to reducing waste in manufacturing. By using only the material required to create a part, PBF machines reduce waste and lower the cost of materials. This not only benefits the environment but also the bottom line of manufacturers. In terms of efficiency, PBF machines can produce multiple parts simultaneously, which improves productivity and reduces the time required to manufacture parts. Finally, PBF machines enable the production of customized parts with specific properties, such as strength, durability, and heat resistance. This has led to the development of new products with unique features that meet the specific needs of customers.

How Much Are the PBF Machines Compared to DED?

The cost of PBF machines and DED (directed energy deposition) machines can vary depending on several factors such as the manufacturer, the model, the size, and the features. However, in general, PBF machines tend to be more expensive than DED machines. PBF machines use more advanced technology and are capable of producing parts with higher precision and better surface finish.

What Safety Measures Should Be Followed Operating PBF Machines?

Staying safe while making parts with PBF, just like with most manufacturing processes, should be a priority. Here are some things to consider relating to safety.

- PBF machines emit fumes and fine dust—make sure you’re working in a properly ventilated area to minimize inhalation risks.

- Wear PPE, including gloves, safety glasses, and respirators, when handling powders and operating the machine.

- Avoid touching heated components or printed parts until they have cooled, and be cautious of sharp edges, especially with metal prints.

- High temperatures and sparks pose fire hazards, so keep a fire extinguisher nearby and remove flammable materials from the area.

- Metal powders can be hazardous—handle them carefully and use protective equipment to avoid inhalation or skin contact.

- Regular inspections and maintenance will help prevent malfunctions and ensure safe operation.

Post-Processing for PBF

Post-processing methods for PBF-printed parts vary based on the material and manufacturing process used. Metal PBF parts made via DMLS or SLM typically need heat treatment to relieve internal stresses caused by the printing process. After heat treatment, support structures are removed, followed by additional post-processing like CNC machining, polishing, or surface treatments.

Metal parts made with EBM, unlike laser-based metal PBF methods, are supported by a semi-sintered powder cake rather than a solid substrate. They must be extracted from the powder bed, but they generally don’t need heat treatment, as the high build temperatures keep residual stress to a minimum. Sacrificial supports may be added for heat control or post-processing. Plastic SLS parts are removed from the powder bed and cleaned to remove excess material, often using bead blasting for a uniform finish. These can be left as-is or dyed for color customization.

How Does PBF Contribute to Additive Manufacturing?

PBF contributes to additive manufacturing in several ways. First, it enables the production of complex geometries that would be difficult or impossible to create using traditional manufacturing methods. Second, it allows for the creation of customized parts with specific properties, such as strength or heat resistance. Third, it can produce parts more quickly and with less waste than traditional manufacturing methods. Finally, it has the potential to reduce the cost of manufacturing, particularly for low-volume, high-value products.

Are PBF Machines Expensive?

Yes, PBF machines are quite expensive. While it is possible to find end-to-end systems below $100,000, prices typically start in the $150,000–$200,000 range. High-end PBF machines can cost over $1,000,000. The cost of these systems is dependent on the size, capabilities, and features of the machine. The cost of PBF machines does, however, decrease over time as the technology becomes more widespread and new manufacturers enter the market. Additionally, the potential cost savings and efficiencies gained from using PBF machines for certain applications can justify the investment for some businesses.

Do PBF Machines Produce Higher-Quality Solutions than DED (Directed Energy Deposition) Machines?

PBF machines and DED (directed energy deposition) machines have different strengths and weaknesses, so it's difficult to make a blanket statement about which produces higher-quality solutions. PBF machines are generally better suited for producing high-precision parts with fine details, better surface finishes, and excellent mechanical properties. The powder bed fusion process allows for intricate geometries and precise control over the material distribution, resulting in parts with excellent dimensional accuracy and surface finish, although post-processing is sometimes required. PBF machines can also produce parts in a wide range of materials, including metals, ceramics, and plastics.

On the other hand, DED machines are better suited for producing large parts with complex geometries, such as aerospace components or industrial molds. DED machines are typically faster than PBF machines and can handle larger part sizes, but they may not have the same level of precision or surface finish.

Frequently Asked Questions About Powder Bed Fusing Machines

What’s the difference between PBF and DED machines?

PBF machines and DED (directed energy deposition) machines have different strengths and weaknesses, so it's difficult to make a blanket statement about which produces higher-quality solutions. PBF machines are generally better suited for producing high-precision parts with fine details, better surface finishes, and excellent mechanical properties. The powder bed fusion process allows for intricate geometries and precise control over the material distribution, resulting in parts with excellent dimensional accuracy and surface finish, although post-processing is sometimes required. PBF machines can also produce parts in a wide range of materials, including metals, ceramics, and plastics.

On the other hand, DED machines are better suited for producing large parts with complex geometries, such as aerospace components or industrial molds. DED machines are typically faster than PBF machines and can handle larger part sizes, but they may not have the same level of precision or surface finish. The cost of PBF and DED machines can vary depending on several factors, such as the manufacturer, the model, the size, and the features. However, in general, PBF machines tend to be more expensive than DED machines. PBF machines use more advanced technology and are capable of producing parts with higher precision and better surface finish.

How do PBF machines differ from other types of 3D printers?

PBF machines differ from other types of 3D printers in several ways, the main one being how they build parts layer by layer using powdered materials as opposed to filament or resin. While PBF machines use a high-powered laser or electron beam to selectively fuse the material, other 3D printers may use extrusion or photopolymerization methods. PBF machines are more precise and can make functional plastic parts with excellent mechanical properties—better than any other 3D printing technology. However, they often require post-processing to achieve the desired surface finish and may have limitations in terms of size and geometry. PBF machines also tend to be more expensive and require more specialized knowledge and training to operate.

What’s the best material to use with PBF machines?

This will depend on what you need to make and other factors, such as your budget. Each material has its unique properties, strengths, and weaknesses that can affect the printing process. Metals need high temperatures and energy to melt and solidify the material, which can increase printing time and cost. Polymers require lower temperatures and less energy than metals, which could mean faster printing times and lower costs. But it’s worth noting that polymers could have lower-quality mechanical properties than metals and can be more susceptible to warping and deformation. Again, the best material for your project will be based on what properties you need and how much you’ve got to spend.

Why is PBF good for prototyping?

PBF machines allow for faster prototyping, significantly reducing the time and cost required to develop new products. With rapid prototyping, manufacturers can quickly test their design concepts and make improvements before finalizing the production design.

How Xometry Can Help

If you have any questions about PBF machines, or you need help with a specific project, you can reach out to one of our representatives who would be happy to assist. Xometry also offers lots of related manufacturing services including laser cutting, CNC machining, and of course, 3D printing. You can get started today by uploading your designs to the Xometry Instant Quoting Engine®!

Copyright/Trademark

- Inconel® is a registered trademark of Special Metals Corporation

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.