Centrifugal casting is a unique and versatile manufacturing process that has proven to be cost-effective for producing complex shapes with minimal machining and reduced overall manufacturing costs compared to traditional methods such as forging or fabrication (e.g., stamping). It is particularly well-suited for components like bushings, rings, engine cylinder liners, large-diameter pipes, and a variety of other cylindrical or symmetrical parts.

This article will examine the centrifugal casting process, outlining its advantages, disadvantages, and the diverse range of applications for which it is commonly used.

What Is Centrifugal Casting?

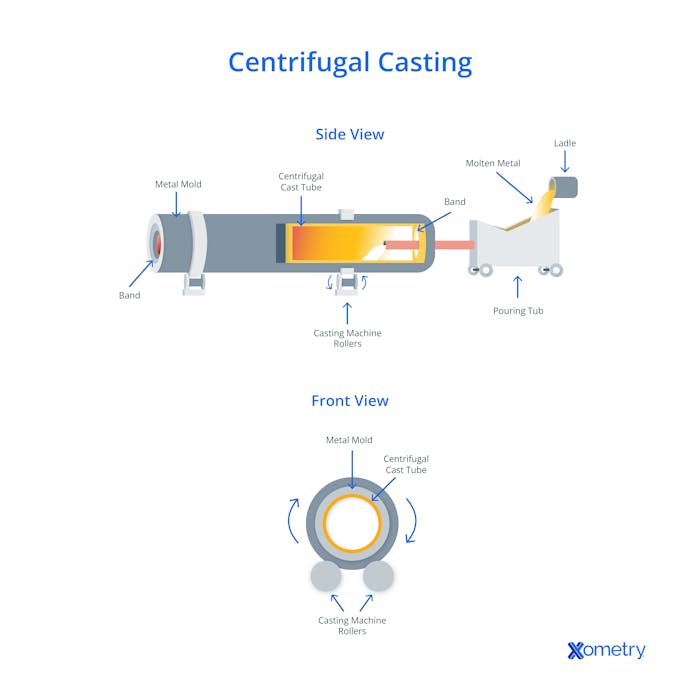

Centrifugal casting is a manufacturing process used to create cylindrical components with a central axis of rotation. This technique involves rotating a mold around a central axis at speeds typically ranging from 300 to 3000 rpm while pouring molten material into the mold. The centrifugal force generated by the rotation spreads the molten material against the inner surface of the mold, resulting in the desired shape of the finished product. This method is often employed for producing large pipes, cylinder liners, and hollow cylindrical components cast from a variety of materials, including metals, concrete, and glass. While centrifugal casting maintains tight dimensional tolerances on the outer surface, the inner diameter is typically cast slightly undersized, allowing for subsequent machining to achieve the precise inner diameter required.

Schematic of the centrifugal casting process

What Is the Origin of Centrifugal Casting?

The initial patent for centrifugal casting was granted to Anthony Ekhardt, an Englishman, in 1809. Within a few years, additional patents were issued in Germany and the United States. However, progress in perfecting the technique remained slow and inconsistent for more than a century. A significant turning point in the method's evolution took place in the aftermath of World War I, particularly in the casting of pipes. During this period, centrifugal casting of pipes became a viable and competitive manufacturing approach.

Before the widespread adoption of centrifugal casting for pipes, pipes were typically made using labor-intensive methods such as wrought iron or steel welding, clay shaping and firing, wooden stave construction, and cast iron casting. These methods had limitations in terms of seam strength, corrosion resistance, and variability in size and shape. Centrifugal casting became competitive with these traditional methods in the early 20th century. This marked a significant advancement in pipe manufacturing.

What Is Another Term for Centrifugal Casting?

Variations and specific applications within the centrifugal casting process have led to the use of alternative terms such as "spin casting" and "rotocasting." The term spin casting is commonly used to describe certain adaptations of centrifugal casting, particularly those that involve rubber molds and are employed in industries such as jewelry manufacturing, small component production, and the use of low-melting-point alloys.

Rotocasting may also refer to process variants related to centrifugal casting in specific contexts, although it is less frequently used in conventional metal casting terminology. In some cases, rotocasting is used interchangeably with rotational molding, a distinct process typically applied to plastics.

These alternate terms are generally used to distinguish subtypes or specialized adaptations of the centrifugal casting process, depending on the materials, mold types, and industry-specific applications involved.

What Is the Importance of Centrifugal Casting in Manufacturing?

Centrifugal casting is important for its ability to yield components characterized by high material integrity and soundness. The centrifugal forces that distribute the molten metal to the walls of the mold achieve a uniform material distribution around the circumference of the part. It also reduces porosity, which improves the mechanical properties of the resulting casting.

An essential aspect that sets centrifugal casting apart is its specific focus on producing rotationally symmetric stock materials in standard sizes. Centrifugal casting primarily produces components that are further refined through machining. This approach not only minimizes material waste but also streamlines production cycles, contributing to cost efficiency.

How Does Centrifugal Casting Work?

Centrifugal casting works by introducing molten metal into a heated rotating mold. The mold's rotation can be either vertically or horizontally aligned, depending on the desired configuration of the final part. Centrifugal (or, more accurately, centripetal) force due to the rapid rotation of the mold distributes the molten metal onto the walls of the mold at pressures that can reach nearly 100 times the force of gravity. The controlled solidification advances from the outer diameter toward the bore. During controlled solidification, the denser components, with greater momentum, move towards the wall, displacing less dense elements and impurities.

Additionally, the rapid rotation prevents the less dense components from being flung as far outward, resulting in their concentration towards the inner diameter. After the casting has solidified, the part is extracted from the mold. Any remaining impurities within the inner diameter are then removed by machining. This results in a nearly flawless structure, free from cavities, defects, and gas and shrinkage porosity.

What Makes Centrifugal Casting Stand Out Among All Types of Casting?

Centrifugal casting's uniquely valuable features include the production of fully dense castings with good mechanical properties; the ability to process parts ranging from the small to the very large; the range of materials that can be cast, including not just most metals, but also concrete, ceramics and glass; and the ability to cast one layer of material inside another (for example, concrete-lined cast iron pipe). Unlike most casting methods, which rely on gravity or applied pressure to fill a mold, centrifugal casting spins the mold while liquid metal is poured into it, and the rotational forces fill the mold. This distinctive approach eliminates the need for gating systems and risers.

To learn more, see our guide on Types of Casting Processes.

What Are the Steps in the Centrifugal Casting Process?

The process is further explained in the following list of steps:

1. Prepare the Mold

The inner surface of the mold is coated with refractory material, typically between 1-1.15 mm in thickness. In true centrifugal casting, this coating process involves preheating the mold and then applying the ceramic slurry while the mold is spinning. Following this application, the coated mold undergoes a drying and curing process, ensuring the refractory coating adheres securely to the mold surface. Cleaning the mold surface before applying the refractory coating remains a crucial step to remove any contaminants or debris that could affect the surface finish and integrity of the cast part.

2. Pour the Molten Metal Into the Mold

The casting metal is heated beyond its melting point and poured directly into the mold through a spout, without the need for a gating system.

3. Pour the Molten Metal Into the Mold

The mold is either rotated while the molten metal is being poured into it or is set into rotation after the pouring is completed. The rotation rate generally falls between 300 and 3000 rpm, depending on the project specifics.

4. Centrifugal Forces Distribute the Molten Metal

The centrifugal forces generated by the rotation of the mold cause the molten metal to be pushed toward the outer wall of the mold cavity.

5. Maintain Mold Rotation Until Molten Metal Solidifies

The mold continues to spin after pouring is finished, allowing the part to cool and solidify completely. The rotation helps maintain a uniform material distribution around the inner circumference of the mold.

6. Remove Solidified Casting From Mold

Once the casting is solid and the desired part hardness is achieved, the mold is removed and opened to extract the finalized solidified casting. The specifics of the process can vary based on the type of centrifugal casting being performed, such as true centrifugal casting or semi-centrifugal casting.

What Are the Three Different Types of Centrifugal Casting?

There are three variations of centrifugal casting. These are listed and discussed below:

1. Centrifuging

Centrifuging or centrifuge casting requires positioning mold cavities of varying shapes at a specified distance from the spin axis. Under the influence of centrifugal forces, molten metal is propelled into the mold cavities through the sprue and runner. Similar to true centrifugal casting, the properties of the castings can vary as a function of their distance from the spin axis. This technique helps create smaller components, such as jewelry, miniature bushings, and sleeves.

The mold's design incorporates cavities surrounding a central sprue and interconnected by runners. Molten metal is carefully introduced to the sprue, and it then flows through the runners to fill each mold cavity. The molten material can be poured into a mold that is either already rotating or stationary at the outset of the casting process. The pouring ceases once the required molten metal volume for the castings, along with the necessary runner and sprue quantities, has been delivered. Rotation is maintained post-pouring to ensure complete distribution within the cavities during the solidification phase. The operator (or the control system) halts the mold’s rotation once the castings have solidified adequately, allowing for the extraction of components from the mold.

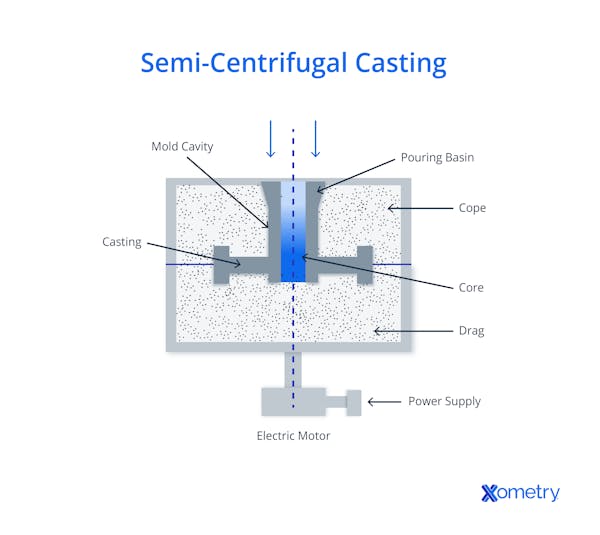

2. Semi-Centrifugal Casting

Semi-centrifugal casting is a technique that utilizes centrifugal force to create solid castings, as opposed to the tubular shapes produced by true centrifugal casting. In the illustrated example of the semi-centrifugal casting in Figure 2 below, the molds are configured with a riser located at the rotation axis to facilitate the flow of molten metal.

A disposable or permanent mold is arranged around a central sprue, where molten metal is poured. This molten material then flows into a rotating mold under the influence of the centrifugal force induced by the rotation. Pouring is stopped once the mold and sprue have been filled. Rotation persists post-pouring. The ongoing rotation ensures that the parts of the casting furthest from the axis of rotation remain fully dense throughout the solidification phase. Once the castings have fully solidified, the equipment discontinues rotation, allowing for the extraction of the finished cast pieces.

This method is used to craft various components, including pulleys, spoked wheels, gear blanks, nozzles, and brass bushings. Parts made by semi-centrifugal casting display higher density in their outer regions than at the central axis. This process finds particular application in fabricating items such as spoked wheels, which exhibit rotational symmetry, thereby eliminating the need for a central casting region. This removal of the center section concurrently eliminates the lowest-density part of the cast.

3. True Centrifugal Casting

In the true centrifugal casting process, molten metal is introduced into a rotating mold. The mold's rotation can be either vertical or horizontal, with horizontal rotation being more popular. Horizontal-axis centrifugal casting is primarily used for producing tubular components such as bushings, tubes, pipes, and rings. The molds employed are typically constructed from materials such as iron, steel, or graphite, and a refractory lining is applied to them to extend their operational life. The mold surfaces are designed to accommodate a variety of external pipe profiles.

The working principle of true centrifugal casting involves the direct pouring of molten metal into the mold without the need for gating mechanisms. The spinning mold imparts an initial tangential motion to particles of molten material resting on its surface. These particles tend to move tangentially due to their inertia, but the centripetal force exerted by the mold redirects them inward, preventing them from being expelled from the mold and compelling them to adhere to the inner wall of the cavity. Following the completion of the pour, the mold continues to rotate until the part has solidified sufficiently. Once the casting has set, the mold is removed and opened, and the finished part is extracted for subsequent processing. Products generated by true centrifugal casting are fully dense, particularly in the outer sections where the centrifugal force is highest.

The advantages of this method include: high density, superior mechanical strength, adequate outer surface finish, and a fine-grained structure in the castings. Nonetheless, some drawbacks of centrifugal casting include potential inaccuracies in the inner surface diameter, limitations in producing highly complex hollow parts, substantial initial investment requirements, and challenges associated with casting minimal inside diameters, particularly in terms of operational safety factors and reduced effectiveness of the centrifugal process at smaller sizes.

What Metals Can Be Centrifugally Cast?

The metals commonly used in centrifugal casting include:

1. Stainless Steel

Stainless steel is a widely used material in centrifugal casting due to its excellent corrosion resistance, mechanical strength, and long-term durability. It is suitable for both true centrifugal casting and semi-centrifugal casting, depending on the part geometry and application requirements. Stainless steel is extensively used in industries such as chemical processing, food and beverage production, and aerospace, where high performance under corrosive or high-stress conditions is essential. To learn more, see our guide on Stainless Steel Material.

2. Nickel Alloys

Nickel alloys are highly regarded for their exceptional high-temperature and corrosion resistance properties, making them indispensable in critical applications within the aerospace industry, petrochemical processing, and power generation equipment. Nickel alloys are commonly utilized in true centrifugal casting to ensure precise material properties for demanding applications. To learn more, see our guide on Nickel Alloy.

3. Copper

Copper and its alloys are celebrated for their superb thermal and electrical conductivity. This makes them essential materials in electrical components, plumbing systems, and various engineering applications. Copper alloys are versatile and frequently employed in both true centrifugal casting and semi-centrifugal casting, depending on the part's complexity and required conductivity. To learn more, see our guide on Copper Physical Properties.

4. Cast Iron

Cast iron, including variants like gray iron and ductile iron, is a trusted choice for heavy-duty applications. It is often used in the manufacturing of pipes, rolls, and automotive components. Cast iron is particularly well-suited for true centrifugal casting, where high material density and strength are essential.

5. Aluminum

Aluminum alloys are lightweight and have good corrosion resistance, making them invaluable in weight-sensitive industries like automotive and aerospace. Aluminum alloys can be employed in a variety of centrifugal casting methods, including true centrifugal casting, semi-centrifugal casting, and centrifuging, depending on the specific application requirements.

To learn more, see our guide on the Properties of Aluminum.

6. Steel

Various types of steel, including carbon steel and alloy steel, can be centrifugally cast. They offer a balance of strength and versatility and are used in a wide range of applications across industries like manufacturing and construction. Steel can be used effectively in both true centrifugal casting and semi-centrifugal casting, tailored to meet the complexity and material properties needed for specific components.

To learn more, see our guide on Steel Properties.

Can Magnesium Be Used as a Casting Metal for Centrifugal Casting?

No, magnesium is not well-suited for centrifugal casting; however, its alloys (e.g., aluminum-magnesium alloys) are often used.

What Are Some Applications of Centrifugal Casting?

Centrifugal casting produces a substantial array of components suitable for both industrial and consumer goods. For instance, this technique is applied in casting, such as cylinder liners, gearbox components, and various other parts. Centrifugal casting’s utility extends further to crafting sinker bars and furnace tubes crucial in petrochemical plants, as well as fabricating intricate medical implants like hip replacements and dental crowns. Centrifugal casting is also the technology of choice for hydraulic wear rings, military and defense components, jet engine compressor cases, and other high-reliability applications.

What Industries Use Centrifugally Cast Products?

Centrifugal casting finds diverse applications across multiple industries due to its unique advantages and capabilities. For example, centrifugal casting serves the automotive sector by producing a variety of critical components, including cylinder liners, pistons, pipes, tubes, and cylinders, made from various metals and alloys. The aerospace industry relies on centrifugal casting to create components that meet rigorous standards, such as rocket nozzles for aerospace propulsion systems. The method is employed in the production of reaction vessels, columns, and other chemical processing equipment. The resulting components exhibit excellent corrosion resistance and structural integrity. Centrifugal casting is also applied in creating high-quality jewelry pieces and ornamental items. It allows for intricate designs and ensures the proper filling of fine details.

What Is the Quality Level of Centrifugally Cast Products?

Centrifugal casting is renowned for producing high-quality components. These components reach full density and are free from oxides, gas porosity, and any other nonmetallic inclusions.

Are Centrifugally Cast Products Heat Resistant?

Yes, when the alloy used to make a centrifugal casting is heat-resistant, then the cast product will be heat-resistant. But the level of heat resistance depends on various factors, including the type of metal used and the casting process parameters. Metals used in centrifugal castings, such as cast irons, a range of steel alloys, and non-ferrous metals such as bronze, can possess excellent heat-resistant properties.

What Are the Advantages of Centrifugal Casting?

Centrifugal casting offers several advantages, including:

- The rapid cooling produced by mold rotation promotes the development of a fine and uniform grain structure, which improves the mechanical properties and structural integrity of the final part.

- Centrifugal force pushes molten metal outward while forcing impurities, inclusions, and gases toward the center of the casting, where they can later be machined away to produce a cleaner, defect-free component.

- The controlled, directional solidification minimizes common casting defects such as porosity, shrinkage cavities, gas pockets, and segregation, resulting in higher-quality castings.

- The process enables even material distribution throughout the mold, reducing anisotropy and resulting in more uniform properties across the entire component.

- Thin-walled sections—as small as 2.5 mm—can be produced with reduced risk of defects, though this advantage applies primarily to semi-centrifugal casting and centrifuging.

- The process can reproduce fine surface details, making it well-suited for manufacturing complex or decorative components such as jewelry; this is particularly true for centrifuge casting and semi-centrifugal casting.

- A wide range of materials can be used, including iron, steel, stainless steel, aluminum, copper, nickel, and magnesium alloys, as well as non-metallic materials such as cement, concrete, glass, and ceramics.

- The elimination of gating systems and risers reduces material waste and manufacturing costs. However, sprues and runners may still be used in semi-centrifugal or centrifuge casting to help control defects.

- The method supports a wide range of part sizes, from small precision components to large cylindrical parts up to 6 meters in diameter and 15 meters in length.

- The process enables the production of two-layered or composite castings, where different materials can be combined to achieve tailored performance characteristics.

- Internal stresses are minimized due to the uniform thermal gradients and controlled solidification during rotation, resulting in round parts that are dimensionally stable.

- Less dense substances—including oxides, sulfides, and trapped gas—are separated and concentrated near the bore, where they are later removed, improving the quality of the final product.

- Because the material solidifies from the outside in, mid-wall defects common in gravity casting are avoided, leading to castings that are free of shrinkage cavities and internal voids.

What Are the Disadvantages of Centrifugal Casting?

Centrifugal casting has several drawbacks that render it incompatible with certain applications, such as:

- The dimensions of the inner wall in centrifugal casting are typically less precise than those of the outer wall, due to the concentration of impurities and less controlled solidification near the bore.

- While centrifugal casting accommodates a wide range of sizes, it is generally unsuitable for producing hollow parts with complex internal geometries, as the process does not allow for intricate internal mold features.

- Achieving a smooth surface finish can be more challenging than other casting methods, and additional post-processing, such as machining or polishing, is often necessary to meet surface quality specifications.

- Vertical centrifugal casting is generally limited to a maximum length-to-diameter ratio of approximately 2:1; exceeding this ratio can lead to uneven metal distribution, which may compromise quality and increase material usage and cost.

- Producing castings with irregularly shaped outer diameters is possible, but it often requires costly custom molds made of metal or graphite, potentially offsetting cost savings achieved through reduced post-processing.

- Casting components with minimal inside diameters presents operational challenges, as the benefits of centrifugal force decrease at smaller scales, and mold rotation speeds are limited by safety constraints.

- High-quality results depend heavily on multiple factors, including equipment capability, mold design, use of chills, effective feeding systems, and adherence to good foundry practices; inconsistencies in any of these areas can lead to substandard castings.

- Although centrifugal castings can have various outer shapes—such as elliptical, hexagonal, or fluted profiles—the inner bore produced by the true centrifugal casting process is inherently restricted to a circular cross-section due to the nature of rotation-based solidification.

Frequently Asked Questions About Centrifugal Casting

How Much Does Centrifugal Casting Cost?

Centrifugal casting, also known as spin casting, is often regarded as a cost-effective method, with a total investment requirement typically not exceeding $20,000. This stands in stark contrast to investment casting, which is more expensive (usually millions).

Is Centrifugal Casting the Same as Investment Casting?

No, centrifugal casting and investment casting are two distinct processes. Both investment casting and centrifugal casting can produce high-quality, near-net-shape parts. A key difference between the two methods lies in the use of molds: investment casting utilizes disposable ceramic molds that are broken away after the part has cooled, whereas centrifugal casting employs durable metal or graphite molds that can be reused multiple times. Centrifugal casting is also unique in that it relies on centrifugal force to distribute the molten metal during the casting process.

In investment casting, the process begins with the creation of a wax pattern that is a replica of the final part. This wax pattern is coated with layers of ceramic material to form a shell, which becomes the “investment” or “lost-wax” mold. The term "investment casting" comes from this step, where the wax pattern is invested—or surrounded—by ceramic slurry. Investment casting is well-known for its ability to produce parts with intricate geometries and fine surface details, and is often regarded as a premium casting process for precision applications.

What Is the Difference Between Centrifugal Casting and Sand Casting?

The primary difference between true centrifugal casting and sand casting is that true centrifugal casting utilizes expendable molds made of sand, whereas true centrifugal casting employs permanent, metal molds. Some differences are listed below:

- Centrifugal casting involves the rotation of a mold at high speeds while molten metal is poured into it. In contrast, sand casting relies on a mold made from a mixture of sand and binders to shape the molten metal. This mold, formed around a pattern resembling the final object, accommodates the poured metal, which solidifies within the mold. Once the casting has hardened, the sand mold is broken apart to reveal the final product.

- Centrifugal casting typically utilizes permanent molds made from robust materials, such as steel, cast iron, or graphite. Sand casting is a versatile and applicable process to a wide range of casting sizes and shapes. Its applications encompass a broad spectrum of items, including engine blocks, machinery parts, and artistic sculptures, making it well-suited for both intricate and larger-scale castings.

Summary

This article presented centrifugal casting, explained it, and discussed its various applications and advantages. To learn more about centrifugal casting, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including casting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.