As a manufacturing technique, molding has been around for thousands of years. Two of the oldest molding processes that are still used today are blow molding and rotational molding. In this article (and the video below), we explain them in more detail and cover how they differ and what they each do best.

What is Blow Molding?

Blow molding is a plastic hollow-part forming process used to make products with simpler designs and thin walls. It’s an ancient technique that first emerged in the form of glassblowing around 1700 BCE in Syria. Later refinements allowed glassblowers to create bottles. The more modern blow molding process matured in the 1930s when the first automatic blow molding machine was introduced by the Plax Corporation.

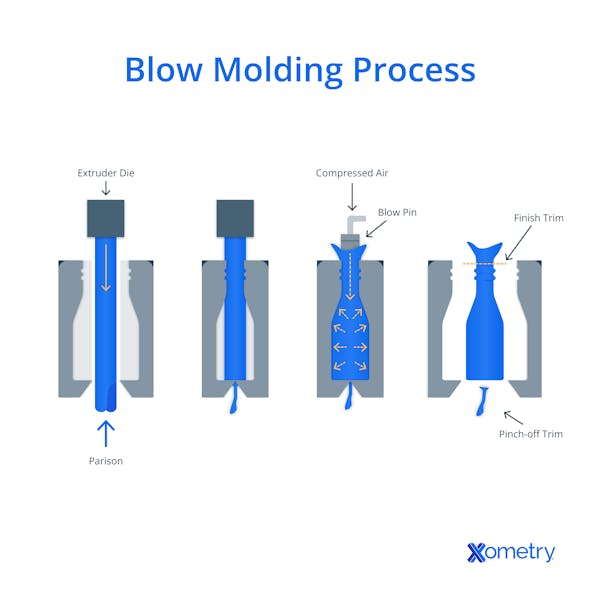

Most modern blow molding deals with thermoplastics. The procedure, shown in the diagram below, involves a hollow plastic parison (also known as a preform) being placed at the mouth of a mold cavity and heated until properly malleable. Pressurized gas is then forced into the parison’s open end until it expands to match the mold cavity’s shape. The product then gets cooled and crystalized so it doesn’t deform while being removed from the mold.

This method is ideal for large-scale production thanks to how quickly it can make parts—70 of them in just an hour. It can make thin, lightweight parts with parting line integrity (no visible hems or seams from the mold), and you can control the wall thickness. Though this fully automated approach is best known for soda and water bottles, it also finds uses in engineered gas tanks and electrical enclosures.

It’s preferred over rotational molding for its cost-efficiency in high-output industrial settings, especially at rates higher than 3,000 units per year. Further adding to its cost-efficiency is the mold itself, which lasts a very long time. Having said that, the tooling cost is quite high, and low-volume production quantities work out more expensive. As far as aesthetics, this isn’t typically the method you’d want to use if you need parts with super attractive finishes.

What is Rotational Molding?

Also known as rotomolding, rotational molding is a high-heat, low-pressure thermoforming process used to make hollow plastic parts. A type of rotational molding was used in ancient Egypt to make ceramics, but an upgraded version was introduced in the U.S. around 1945 for plastics. This wasn’t met with open arms, though, due to its snail-like pace. The plastic powders have since had several upgrades so that they flow more easily and evenly, making the process today much faster (thankfully).

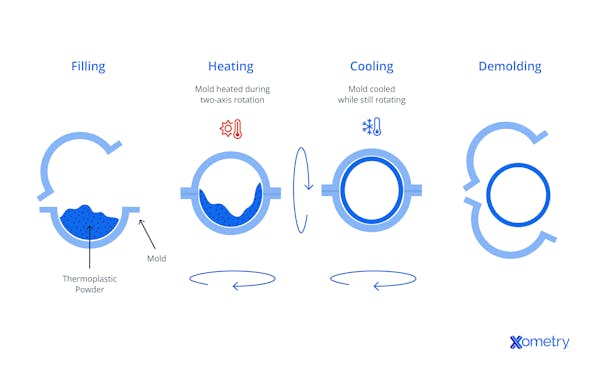

In the process, which you can see in the above picture, a hollow mold is filled with powdered plastic resin and spun before being transferred to an oven, where the resin melts and coats the mold’s walls. The mold keeps on spinning until the resin cools and hardens into the final desired shape. The mold can then be opened so you can take the part out.

It can make large parts with double walls and an open design, and not much secondary processing is necessary because it doesn’t have any weld lines or seams (as opposed to blow molding). There’s cheaper tooling due to the low pressures involved, and it’s more efficient at lower production volumes of less than 3,000 pieces a year—great for startups and small businesses.

With rotational molding, you get a lot more versatility, design flexibility, and stronger products that are much more durable than those made with blow molding. Rotomolded parts do, however, have thicker walls which uses more material and makes them heavier, and the final product could also end up with voids. This method is pretty labor-intensive, and doesn’t offer good control over the thickness of the walls. The tools also need regular maintenance or replacement.

| Attribute | Blow Molding | Rotational Molding |

|---|---|---|

Attribute Versatility | Blow Molding Low | Rotational Molding High |

Attribute Design flexibility | Blow Molding Low | Rotational Molding High |

Attribute Cycle time | Blow Molding Fast, less than a minute | Rotational Molding Slower, 30 minutes or more |

Attribute Production rate | Blow Molding 70 parts per hour | Rotational Molding 2 parts per hour |

Attribute Part weight | Blow Molding Light (0.1–5 pounds) | Rotational Molding Heavy (varies could be 50 pounds or more) |

Attribute Part size | Blow Molding Medium to small (around 1–5 gallons) | Rotational Molding Small to very large (can reach 20–300 gallons, sometimes more) |

Attribute Part porosity | Blow Molding Low | Rotational Molding High |

Attribute Shape complexity | Blow Molding Limited to simple shapes without undercuts | Rotational Molding High, can make intricate, hollow shapes, multi-compartment designs, and undercuts |

Attribute Wall thickness control | Blow Molding Good, uniform | Rotational Molding Less control, more variation |

Attribute Need for secondary processes | Blow Molding Minimal, sometimes needs trimming and finishing | Rotational Molding Moderate, typically needs trimming and finishing |

Attribute Startup costs | Blow Molding Higher, $200,000 for lifetime | Rotational Molding Lower, $150,000 per year |

Attribute Long-term costs | Blow Molding Can save up to 40%, especially for high-output production of over 3,000 units a year | Rotational Molding Higher per part for lower volumes |

Attribute Piece cost | Blow Molding Approx. $22 | Rotational Molding Approx. $35 |

Attribute Mold durability | Blow Molding High | Rotational Molding Low |

Attribute Compatible materials | Blow Molding LDPE, HDPE, PP, PET, and PVC | Rotational Molding LDPE, LLDPE, HDPE, and PEX |

Attribute Applications | Blow Molding Bottles, containers, toys, oil tanks | Rotational Molding Large tanks, coolers, kayaks, playground equipment |

Blow Molding vs. Rotational Molding

FAQs on Blow Molding and Rotational Molding

Are there any alternatives to blow molding and rotational molding?

There are a couple of alternatives to both these molding techniques. Thermoforming is a popular option that heats a plastic sheet until it is fully pliable, then it’s shaped around a single-sided mold and left to cool. Thermoforming is similar to both blow molding and rotomolding in that all three processes involve heating the plastic. The other option gaining a lot of traction in recent years for its ease of use and affordability is vacuum forming, where a plastic sheet is heated and then pulled against the mold via suction.

What method is more affordable?

This will all boil down to how many products you need to make. While blow molding has higher initial startup costs than rotomolding, it can churn out 70 pieces an hour, and works out cheaper (around 40%) in high-volume production. For low production demands of less than 3,000 units a year, rotomolding will be more cost-effective as it has a lower initial startup cost.

How Xometry Can Help

We’ve got a bunch of molding services here at Xometry, including custom blow molding, insert molding, prototype molding, overmolding, and injection molding. You can get started today by uploading your designs to the Xometry Instant Quoting Engine®!

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.