Two incredibly versatile methods of manufacturing are molding and casting—but what makes them different from each other? While they may sound similar, both processes are unique in materials, process, and results, and are specified for different applications. Both are also used throughout modern industry, making choosing one over the other confusing. While there is no “best” method per se, this article aims to show which method—injection molding or casting—is the right manufacturing process for your existing capacity and which provides the quality of the necessary parts for your intended production line.

What is Casting?

Casting is a group of manufacturing processes in which liquid material (usually molten metal, plastic, or other liquefied substances) fills engineered hollow cavities known as molds, and then solidifies into the shape of the molds. This process dates back nearly 6000 years, when early creators used simple two-piece ceramic molds and low-melting-point alloys to pour jewelry, weapons, statues, and more. However, modern casting implements engineered dies, sand casts, or other types of casting techniques to create highly detailed parts. It is difficult to explain the process further without speaking on specific casting methods—see the sections below to see how casting works in modern industry as a reliable and resilient manufacturing method.

Types of Casting

Below are the most common types of casting techniques used in modern industry and their general descriptions. Not all manufacturing methods are presented here; only the most common techniques are included, encompassing many other specific or proprietary methods.

Die Casting

Die casting implements reusable metal molds known as “dies” and molten metal to create tight-tolerance, high-accuracy, and complex metal parts. The dies are machined out of tool steel and typically last between 20,000 and 500,000 castings per die, depending on the material and design. A molten casting metal (aluminum, zinc, copper, and other non-ferrous metals) is forced into a pair of clamped, lubricated die halves under extreme pressure, where the metal will conform to the die’s shape. Though highly expensive to produce, die casting machines can produce some of the most complex and dimensionally accurate cast metal parts available. Some dies contain water-cooled channels, runners, sprue holes, guide pins, cores, ejector pins, and other high-level accessories to ensure consistent quality castings. Die casting part quality is exceptional and is most useful for small to medium-sized parts with complex geometries for automotive parts, mechanical assemblies, and other industrial applications.

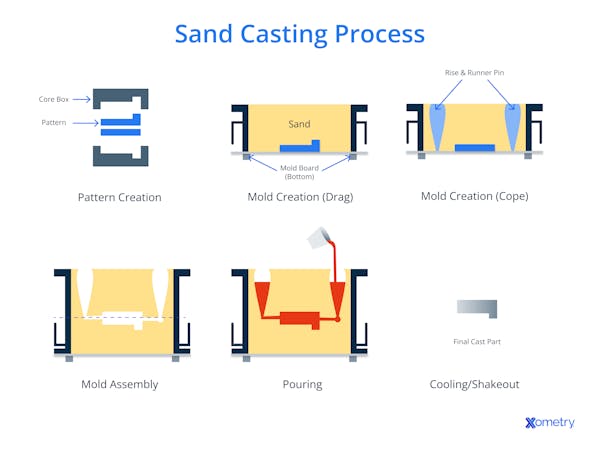

Sand Casting

One of the easiest, oldest, and most common casting methods, sand casting is both reasonable and highly effective. Sand casting uses molds made of (unsurprisingly) sand, where molten metal is then poured into the molds and solidifies into the mold’s shape. Sand is used because it retains heat, reduces cost, and allows for nearly infinite mold shapes if manufactured correctly. Sand is also more forgiving than dies and ceramic molds, meaning it can accommodate thermal shrinkage during cooling with reduced risk of cracking. The above image shows the entire process of sand casting, but notice how there is no theoretical limit to sand mold sizes; one of the most beneficial aspects of sand casting is its use in casting massive, complex parts. Sand casting also allows for nearly any metal or alloy if it melts and can be poured. Though best for short production runs, sand casting is a cheap, versatile, and highly adaptable casting method.

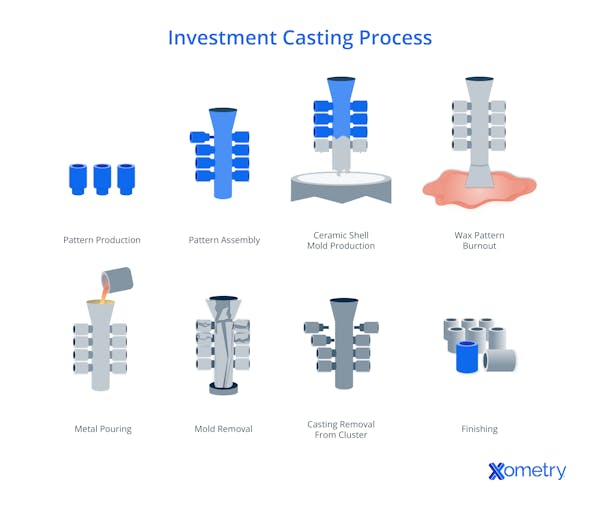

Investment Casting

Investment casting (also known as lost-wax casting) uses disposable wax patterns and ceramic shells to create molds used for casting metal parts. The wax patterns are formed by a lower-temperature casting process, where hot wax is poured into master molds and then removed and cleaned. This wax pattern is dipped in a refractory material (usually fine ceramic silica with binders) multiple times until a hard and thick shell forms. Once hardened, the mold is inverted and heated so that the wax melts out, leaving the hollow ceramic shell. Molten metal is poured into replace the wax, and then the shell is broken off once the metal is solidified. Investment casting leads to highly accurate, thin-walled, and high-surface finish casts that require little cleaning. While generally more expensive than sand and plaster casting, investment casting works best in high-output, small-scale applications where thin sections and low tolerances are specified.

What is Injection Molding?

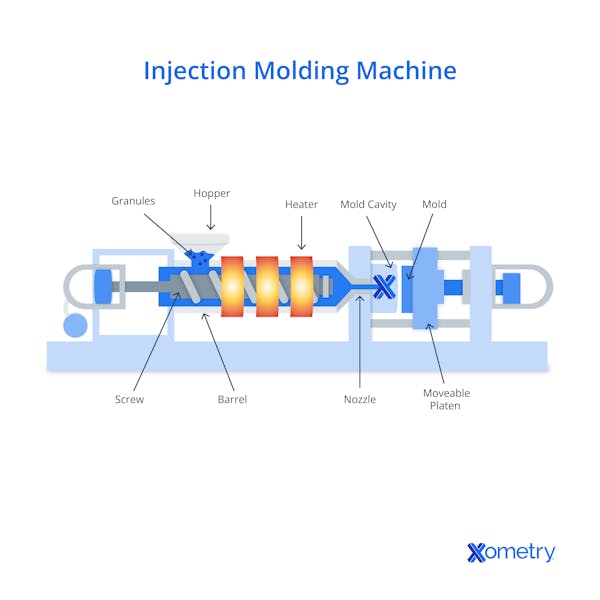

Injection molding is a manufacturing process where molten material (typically thermoplastics or thermosets) is injected into molds under high pressure. The mold is contained within a specialized injection molding machine, which heats, injects, cools, and ejects the part rapidly. The most common injection molding process is known as plastic injection molding, where plastic raw material is molded into many cost-effective plastic parts (depicted below):

As you can see above, solid plastic granules are conveyed and heated via the injection machine, where it is forced under pressure into the mold cavities. Injection molding tools are similar to the dies in die casting, but they are typically used for producing thinner-walled plastic parts and are subject to different design considerations. Once solidified, the platen opens, releasing the two mold halves and the finished part, where the process is ready to mold another part with minimal or no cleanup necessary. The high volume production of injection molding machines is truly impressive—one machine can easily create thousands to tens of thousands of parts in a workday, depending upon complexity. Though initially expensive and typically used for thin-walled parts, injection molding provides excellent surface finishes, high production rates, and requires little labor post-molding. Its throughput and low material costs make injection molding perfect for mass production applications like plastic packaging, production-grade plastic parts, urethane casting, and more.

Types of Injection Molding

Just like casting, there are also different types of injection molding techniques; however, they differ less in process and more in materials. Below is a brief list of common injection molding techniques and how they differ from the traditional definition stated in the previous section.

Powder Injection Molding

Metal, ceramic, or other powdered material is mixed with a binder and fed into an injection molding machine, resulting in a part that can be debound and sintered into a final part. Powder injection molding allows for the high-output production of metal or ceramic parts.

Co-injection Molding

Two different materials are extruded through a coinjection nozzle, allowing for more versatility in manufacturing. A core of material can be surrounded by a second skin material, enhancing strength, durability, and parts quality.

Fusible Core Injection Molding

A core is first molded or cast from a low-melting-point metal in the shape of the hollow cavity for the part. It is then injected with plastic in an injection molding machine, and the part/core assembly is then submerged in a heated bath to melt the inside core, leaving the finished part behind. This is most useful for more durable thermosets and finds applications in the automotive industry for intake manifold production.

These are not the only types of injection molding available, but they show how they mostly differ in material specification and not in the manufacturing process.

Injection Molding vs. Casting

It should be clear from the above sections that injection molding and casting are unique processes from each other, both in material and application. It is difficult to say which is the “best” process in all situations, but this section will attempt to show where the advantages and disadvantages of both processes exist. Below is a table that explains the basic pros and cons of each type of manufacturing process:

| Pros | Cons | |

|---|---|---|

Pros Injection Molding | Cons

|

|

Pros Casting | Cons

|

|

In general, injection molding is best for thermoplastics, thermosets, and other low-viscosity materials, while casting is best for metals, thermosets, and ceramic/glass materials. Die casting, investment casting, and injection molding all involve high tooling costs, with injection molding often being more expensive due to complex mold designs and high-precision requirements. If looking to create high complexity, accurate, and aesthetic parts, casting is easily the winner, but injection molding will always win regarding volume. The choice will come down to material selection, production volume, parts quality, and everyday life considerations such as manufacturing space. Luckily, there are many options in both casting and injection molding that will satisfy your requirements, providing high-quality products in a variety of materials and shapes.

Summary

This article presented a brief comparison between injection molding and casting. Though similar in some ways, both processes are called for in different manufacturing lines and should be carefully considered before choosing any one option. Your time, finances, and desired quality will all inform which process is most effective, and while no “best” method truly exists one will surely add more value at a justifiable cost.

Xometry can help with all of your injection molding projects. Visit our plastic injection molding capabilities page to get a free, no-obligation quote or to learn more about our material capabilities, finishes, and injection mold classes. Also, be sure to review our Ultimate Guide to Injection Molding, where you can learn more about optimizing your design for the injection molding process.

Disclaimer:

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.