Injection molding is only possible thanks to the plastic injection molding machines. Plastic injection molding machines combine material feeding, melting, injection, and ejection in one condensed space and allow for the mass production of products. This article will discuss the different types of molding machines, their major components, common uses, where to buy them, their costs, and how to maintain them.

What Are the Different Types of Molding Machines?

Injection molding machines (also known as injection presses) are generally categorized based on their drive system, or based on what powers their major components. The three basic types of drive systems are electrical, hydraulic, and hybrid drives, each of which is suited to unique injection molding applications. Below is a brief explanation of these drive types, their main advantages/disadvantages, cost, and general applications.

1. Hydraulic Injection Molding Machines

Hydraulic injection molding machines became the dominant design starting in the 1950s, replacing earlier mechanical presses that had existed since the early 1900s. They utilize hydraulic drives to clamp the injection mold halves together and push molten plastic into the mold cavity. They consume hydraulic fluid and need constant energy input to pump and cool their hydraulic systems.

Because hydraulic machines are an established technology, they are the least expensive, most rugged, and easiest to source and repair. Hydraulics can provide very high clamping forces, often in the range of 3-4 tons per square inch, making them ideal for larger molds.

However, injection molding machines are generally less energy efficient because their pumps run continuously, but they do not inherently require higher molding temperatures than other machine types. Both hydraulic pumps and coolant need continuous power input and require additional infrastructure to support them. Also, these types of machines can be problematic as they carry the risk of hydraulic fluid leaks, and they produce more noise than other injection molding machines.

Hydraulic machines are typically less expensive than all-electric models, ranging from about $3,000 to over $100,000 depending on size. They also require significant maintenance and infrastructure support, which can add substantial yearly costs in addition to operator wages. They can last up to 7-10 years with proper maintenance, but their hydraulic systems make them prone to frequent issues that can shorten their lifespan with improper care. These types of drive systems are mainly for larger, thick-walled applications such as those found in the automotive industry.

2. Electric Injection Molding Machines

All-electric injection molding machines were first introduced in Japan in the early 1980s as an alternative to hydraulic models. They use digitally controlled servo motors for precise independent control of movements such as injection, screw rotation, clamping, and ejection.

Servo motors can idle when not in use, reducing power consumption by as much as 50–70% compared to hydraulic models with continuously running pumps. All-electric machines simplify operation by eliminating hydraulic oil and related components, making them cleaner and easier to run, though repairs can be more complex than for hydraulic machines. All-electric machines are ideal for cleanroom applications needing high accuracy and a clean, quiet, and energy-efficient machine.

Electric injection molding machines do have some disadvantages. The main disadvantages are higher upfront cost and potentially more complex, specialized repairs; however, modern all-electric machines can match hydraulic models in clamping force.

Electric injection molding machines' prices depend on size and features, but generally hover around $5,000 to $200,000+, depending on the needed size. All-electric machines will last on average 20+ years with proper maintenance and are mainly specified in cleanroom applications for the production of small to medium-sized parts for medical, biochemical, and pharmaceutical products.

FREE Injection Molding Design Guide

3. Hybrid Injection Molding Machine

Hybrid injection molding machines combine features of both hydraulic and all-electric designs.

Hybrid injection molding machines combine the benefits of hydraulic and electric machines to create a powerful, accurate, and energy-efficient system. They implement servo motor pumps for the hydraulic fluid and circulating oil for hydraulic pressure, but they allow for power, emission, noise, and energy adjustments. They also have a servo motor-based reciprocating screw that saves energy costs compared to fully hydraulic models that expend a significant amount of energy on screw recovery.

The advantages of hybrid injection molding machines include improved energy efficiency, reliability, responsiveness, and controllability, with pricing and maintenance requirements that typically fall between hydraulic and all-electric models. Because of their efficiencies, they exhibit faster ROIs than other types while still providing great clamping forces and precision.

The main disadvantages of hybrid machines are their greater design complexity and the need for technicians familiar with both hydraulic and all-electric systems. Hybrid injection molding parts may not be readily available. Repairs to hybrid machines will require technicians to be familiar with both electric and hydraulic injection molding machines.

Another challenge with hybrid machines is that their design varies significantly by manufacturer, so performance and efficiency can differ depending on the model. For example, some hybrid models that use a hydraulic screw drive instead of an electric screw drive will not be as efficient as electric models and will experience many of the same downsides as hydraulic injection molding machines, despite having some servo control.

Hybrid models are generally priced between hydraulic and all-electric machines, depending on size and application. Also, there will be lower maintenance costs associated with these machines, leading to a faster ROI than either all-electric or hydraulic machines. Hybrid injection molding machines can easily last as long (or longer) than other injection molding machine designs with proper care. Their applications involve high-volume parts for the medical industry, heavy industrial products, varying wall-thickness parts, and other applications, both small and large.

“As a design engineer, I see injection molding machines not just as equipment but as part of the design process itself. The choice between hydraulic, electric, or hybrid directly influences part quality, tolerances, and even the freedom we have when creating new designs.”Audrius Zidonis, Principal Engineer at Zidonis EngineeringNote from the Editor

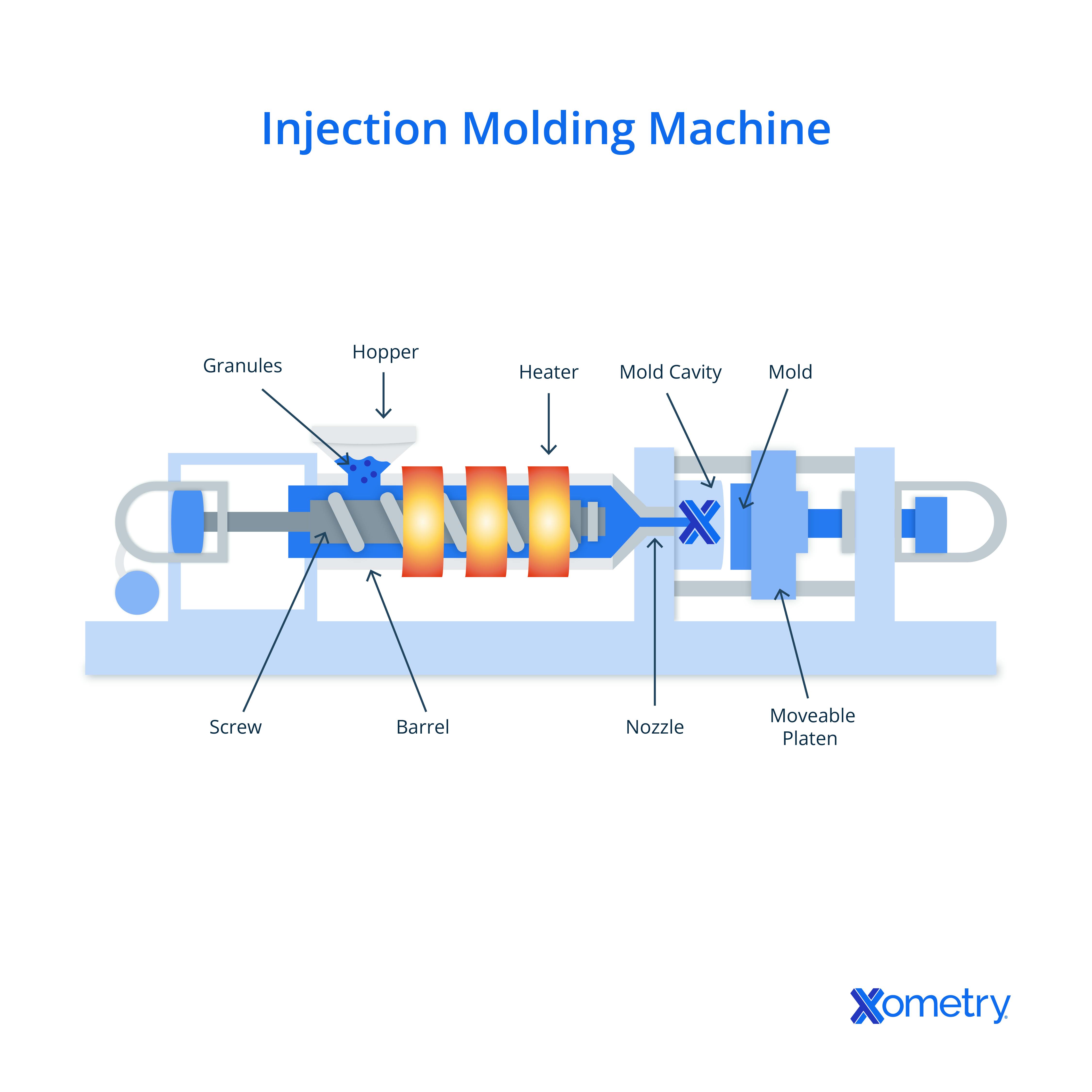

Below is a list of common parts found in a typical injection molding machine. Model-specific variations are not included to keep the summary general.

- Hopper: The hopper is essentially a large funnel that accepts stock material and feeds it into the machine.

- Barrel: The barrel contains the reciprocating screw and is the outer housing of the machine. The barrel is wrapped in heater bands and is tasked with containing the material and the heating portion of the cycle.

- Reciprocating Screw: This rotating screw conveys plastic pellets forward, melts them through shear and external heating, and then moves backward to accumulate the shot before moving forward again to inject the molten plastic into the mold.

- Heaters: The heaters supply thermal energy through the barrel, converting solid plastic pellets into molten plastic as they are pushed by the reciprocating screw. Heaters allow for precise temperature control and are usually staggered in temperature for gradual heating.

- Nozzle: The nozzle dispenses molten plastic from the barrel into the mold cavity. The nozzle usually sits within a depression in the mold known as the injection mold bushing. It is heated to ensure that the plastic does not lose temperature before entering the mold.

- Mold: The mold contains the mold cavity and additional supporting features like ejector pins, runner channels, cooling channels, vents, etc. Molds are commonly separated into two halves: the stationary side (closer to the barrel) and the mold core (on the moving platen), but can also come in more sections depending on the specific machine being considered.

- Mold Cavity: The mold cavity is a negative of the desired part shape, where molten plastic fills and cools before ejection. Gates, runners, and sprues are part of the mold design but are not part of the cavity itself.

- Movable Platen: The platen is part of the clamping unit, clamps the mold together, and releases the mold core when revealing the finished part. This component is either hydraulically or electrically driven and ensures that no material escapes the mold when injection occurs.

Frequently Asked Questions About Injection Molding Maintenance

What Is the Most Common Use of Plastic Injection Molding Machines?

Plastic injection molding machines allow for the mass production of plastic parts. They can produce thousands of parts per day, depending on the machine size, cycle time, and part design, with high repeatability and consistency. Their use is only limited by the size of the machine and the imagination of the designers. Injection molding is so widespread that nearly every household in the US has contact with dozens of molded items, if not more.

Where Can I Buy a Plastic Injection Molding Machine?

Suppliers like Alibaba, Amazon, and other retailers offer options for desktop-scale machines. For high-volume industrial systems, it is best to purchase directly from manufacturers. There are also extensive aftermarket sources for used injection molding machines; however, these involve the risks associated with any aftermarket purchase and may require maintenance/repair.

Are Plastic Injection Molding Machines Expensive?

Yes, injection molding machines are one of the most expensive parts of the process, but molds themselves are often the single highest cost item.

Injection molding machine prices vary widely: small desktop units can cost as little as $2,000-5,000, while large industrial machines typically start around $50,000 and can exceed $200,000. Also, these prices do not include the facility upgrades, skilled worker costs, maintenance fees, and monitoring equipment needed for such a system. This massive overhead incentivizes companies to outsource their injection molding to dedicated companies with existing infrastructure. Only those companies with a core need for injection molding and a developed, high-volume product would consider purchasing an injection molding machine; otherwise, the investment is not recommended.

Are Plastic Injection Molding Machines Easy To Maintain?

It depends on the model, but in general, injection molding machines require significant maintenance. Regular maintenance includes daily visual checks to catch early problems and scheduled preventive inspections, often performed monthly or quarterly depending on machine usage. A dedicated full maintenance day is required annually to identify issues, perform adjustments, and replace aging parts.

Parts that need an especially keen eye are oil filters (regardless of indicator status), valves, safeties, hoses, machine cylinders, power lines, lubrication points, nozzle alignment, and control modules. Finally, injection molding machines can be temperamental with seasonal changes, so be extra vigilant during transitional months and extreme temperature days. A lack of preventative maintenance will stall the machine and reduce profitability. Regular checks decrease downtime and extend the machine’s lifespan, ensuring more value from the investment.

For more information, see our guide on the Major Components of a Plastic Injection Molding Machine.

Summary

This article presented a review of the plastic injection molding machine and how it works. We hope this article helped readers understand this amazing piece of machinery, its types, and other vital pieces of information for those interested in injection molding machines or the process of injection molding.

About Xometry

Xometry offers a full range of injection molding capabilities to help with your production needs. Visit our website to explore the full range of our capabilities or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.