As a process that can make complex, lightweight, yet durable plastic products, it’s little wonder why reaction injection molding (RIM) is so widely used for making parts for many industries, including automotive, electronics, marine, medical, aerospace, and consumer goods. Let’s learn more about it.

RIM parts are among the toughest large plastic components and can have very long functional life expectancies.

What is Reaction Injection Molding?

RIM is a manufacturing process for making single-part products with many complex features like ribs, bosses, curves, and undercuts. It offers design freedom and flexibility and produces parts with excellent strength-to-weight ratios. RIM can make parts with mixed large and small wall thicknesses, complex and large undercuts, foam core inserts, and very large moldings—features that are much harder to achieve with many other manufacturing methods (although sometimes very large parts could produce challenges in fill/cure processes).

RIM parts have excellent cosmetic finishes straight from the mold, though they can also be coated, painted, or textured if needed. Unless the detail is very fine (in which case it could be hard to reliably reproduce), RIM has no problem with complex designs. The parts are strong, resilient, and mechanically, chemically, and environmentally durable (as long as you’ve chosen the right material for the intended application).

RIM parts are among the toughest large plastic components and can have very long functional life expectancies. For example, aircraft interiors in commercial planes—which generally show cosmetic wear and tear but are still serviceable—are commonly kept in service for 5–15 years, depending on the policies of the airline. RIM car parts can be expected to last as long as the car does (sometimes longer), which is around 7–15 years.

Setup costs are high but significantly lower than injection molding. However, once production starts, per-part costs remain low. Large parts with integrated inserts can serve multiple purposes and be made from relatively low-cost materials. It’s quick, too! The only real qualm is that the tools used in the process aren’t as durable as they could be, so they are fairly easy to damage. Below are just a few of the parts that can be made via RIM.

How Does Reaction Injection Molding (RIM) Differ From Injection Molding?

RIM and injection molding are seemingly similar manufacturing processes used to produce plastic parts, but they differ in a range of highly significant aspects. RIM typically utilizes reactive liquid polymers, such as polyurethane, epoxy, or silicone, which chemically react in the cavity and solidify to form the final part. Injection molding, on the other hand, uses thermoplastic polymers that melt when heated and solidify upon cooling. Additionally, RIM operates at low pressure and temperature, below 10 MPa and typically 60–120 °C. Injection molding requires high pressures and temperatures, up to several hundred MPa and as high as 400 °C.

RIM molds are usually made of aluminum, non-hardened steel, and even composite materials such as glass-reinforced polyester (GRP). This renders them low-cost and quick to produce. Injection molding is considerably more costly (10–20x typically), as the molds are usually required to be more durable to tolerate considerably higher pressures and temperatures. Injection molding is ideal for high-volume production, with faster cycle times and the ability to produce large quantities of identical parts. RIM is better suited to lower-volume production or prototyping and is cost-effective for smaller production runs.

What Is the Importance of Reaction Injection Molding (RIM)?

RIM is a critically important manufacturing process in some fields. It offers several benefits and advantages in the production of plastic parts that are hard to achieve by any other means. The design flexibility that is possible with RIM enables the production of: mixed large and small wall thicknesses, complex and large undercuts, foam core inserts, and very large moldings, relative to other processes. The cross-linked materials suited to RIM generally produce parts with high strength-to-weight ratios. Low pressure/temperature processes allow RIM molds to be lower-cost and fast to build, compared with injection molding. RIM is a critically important process in various industries such as: automotive, aerospace, electronics, medical, and consumer goods. In these areas, RIM is an invaluable process for manufacturers seeking to create innovative, high-quality plastic parts.

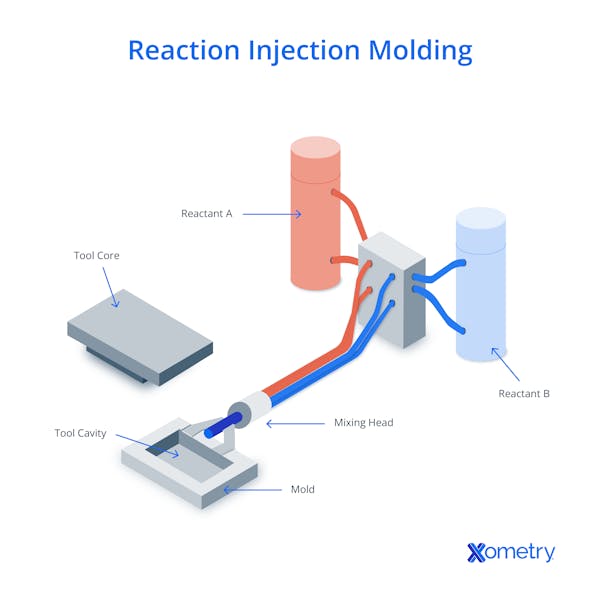

How Does Reaction Injection Molding (RIM) Work?

RIM uses the simultaneous injection of two or more reactive liquid components into a mold cavity. These liquid (monomer) components, typically a polyol (resin) and an isocyanate (hardener), are precisely metered, thoroughly homogenized, and mixed in a specialized mixing head, then injected into the cavity of a mold at low pressure (up to 10 MPa). The mold is typically made of two halves but could have more sections for undercuts and other more complex details. During and after injection, the liquid components will go through an exothermic reaction, which may include degassing/foaming.

In some cases, a monomer component contains dissolved gas that expands during polymerization, creating a closed-cell foam instead of a solid structure. The mixture then solidifies inside the cavity in a process that goes by relatively quickly—cycle times are commonly just 30–60 seconds long. The thickest part sections that it is practical to manufacture by RIM are generally reported as half an inch thick. Having said that, localized thickening and occasional parts are molded to thicknesses approaching 5 inches without major difficulties.

How Long Does It Take for the RIM Process To Complete?

Typical cycle times for RIM parts can range from 30 seconds to several minutes. This depends on material properties, section thicknesses, and the overall size of the part. Demolding can occur when polymerization is incomplete, so long as sufficient structural integrity is achieved and/or parts are carefully supported to retain shape and critical dimensions as the cure completes.

What Machine Is Used for Reaction Injection Molding (RIM)?

A RIM machine, or RIM press, consists of six key systems:

- A hopper or bin system for storing the pre-mixed chemicals.

- A metering and mixing system that precisely meters and homogenizes the liquid components in the correct ratio.

- An injection system (usually a hydraulic or electrically-driven piston) pumps the mixed liquid into the mold cavity.

- A heating system to keep the liquid components at the proper temperature.

- A mold clamping system (hydraulic, pneumatic, or mechanical screw) that aligns the mold halves, keeps the mold in place, and resists the injection pressure during the process.

- A PLC or CNC-type control system that monitors and regulates machine parameters, i.e., fluid volume/ratio, temperature, pressure, injection time, and mixing ratios.

Does RIM and Injection Molding (RIM) Use the Same Machine?

No, these two processes have no commonality of equipment or process, despite evident similarities in an overview of the methods. RIM machines are highly specialized equipment designed specifically for the RIM process, not suited to any other task. They are quite different from conventional injection molding machines and more closely related to epoxy resin mix/metering systems for potting applications.

What Are the 2 Types of Variations of Reaction Injection Molding (RIM)?

There are two main RIM variants: structural (SRIM) and reinforced (RRIM).

1. Structural Reaction Injection Molding (SRIM)

Structural Reaction Injection Molding (SRIM) is a variant of RIM that is ideally suited to producing large, structurally reinforced parts with high strength and stiffness. SRIM combines the benefits of RIM, such as design flexibility and cost-effective tooling, with the ability to incorporate structural reinforcement materials.

As is the case for RIM, the liquid components—typically a polyol and an isocyanate—are precisely metered and mixed. However, in SRIM, reinforcing materials such as glass fibers, carbon fibers, or other structural enhancers are introduced into the molding cavity before it is closed and injected. Otherwise, the process steps are essentially identical to RIM.

SRIM offers several advantages for the production of parts. The incorporation of reinforcing materials in SRIM results in parts with enhanced strength, stiffness, and resistance to deformation. SRIM also allows for the creation of lightweight parts by utilizing reinforcing materials that offer higher strength-to-weight ratios.

2. Reinforced Reaction Injection Molding (RRIM)

Reinforced Reaction Injection Molding (RRIM) is another variant of RIM that involves the incorporation of mold-inserted short-strand reinforcing materials such as glass fiber and carbon fiber into the mixing process. This is done to increase the strength, durability, and impact resilience of RIM parts.

In RRIM, the liquid components used in RIM—typically a polyol and an isocyanate—are mixed with reinforcing agents such as glass fibers, mineral fillers, or other reinforcing materials. The reinforcing agents are added to the mixture to improve the mechanical strength and impact resistance of the final part.

The process only differs from RIM in the material preparation. The liquid components—polyol and isocyanate—are accurately measured and mixed, as in RIM. Reinforcing agents are only then introduced into the mixture, to achieve uniform distribution of the reinforcing materials.

RRIM offers enhanced mechanical properties, including increased strength, impact resistance, and stiffness, compared with RIM. The process is used in the same range of industries and applications as RIM and SRIM, mainly when greater component strength, stiffness, or resilience are advantageous.

What Are the Materials Used in Reaction Injection Molding?

The common materials used in RIM are listed below:

1. Polyamides

The use of reactive polymerized precursors that form nylon materials is increasing in RIM applications. Nyrim® is an example of a nylon 6 which is elastomer-modified. It has very low viscosity during processing which results in high-molecular-weight nylon in the cured state. Varying from 7–40% elastomer allows these materials to replace advanced TPEs at lower cost, with higher strength, and with the various advantages of the RIM process.

RIM polyamides offer a beneficial stiffness/toughness balance even at low temperatures, with great fatigue and abrasion properties and good paintability. Most interestingly, RIM polyamides are thermoplastic once molded. They can be introduced into the normal recycling channels, unlike the bulk of RIM-capable materials.

2. Fiber Composites

Fiber composites are commonly used materials in RIM. Pre-formed mats of reinforcer materials such as glass fiber and carbon fiber are pre-positioned into the mold before injection. The low-viscosity precursor materials are then injected into the cavity and completely encapsulate the reinforcement components, integrating them into a composite structure.

3. Polyurethanes

Polyurethanes are among the most commonly used materials in RIM processes, due to excellent general properties and versatility. They offer a wide range of characteristics that make them suitable for various applications in RIM.

Polyurethanes, as a material family, exhibit a broad spectrum of material properties that can be tailored to specific application requirements. They can be formulated to have varying levels of hardness, flexibility, impact resistance, chemical resistance, and thermal stability. Polyurethanes can deliver high-quality surface finishes and aesthetic appearances and are easily colored, painted, or textured to meet design requirements.

Can Silicone Be Used in Reaction Injection Molding?

Yes, silicone can be used in all RIM-derived processes. Silicone RIM, also known as Liquid Silicone Rubber (LSR) injection molding, is a variant of RIM that specifically utilizes silicone-based materials. Silicone RIM offers several advantages and unique properties compared to other materials. These unique properties include: excellent resistance to high and low temperatures, excellent elongation tolerance and flexibility, good electrical insulation, excellent resistance to a wide range of chemicals, and good biocompatibility.

Silicone RIM shares similarities with other RIM processes, but requires specific equipment and processes designed for handling silicone-based materials. Injection pressures are lower than for general RIM processes and tool design requires careful attention to flow and venting, to ensure quality parts.

Can Polyester Be Used in Reaction Injection Molding?

Yes, polyester can be used in various RIM processes. Low-cost polyester-based materials offer certain advantages and properties that make them suitable for specific applications in RIM. Polyester-based materials allow properties to be tailored to meet application requirements. Properties such as strength, impact resistance, chemical resistance, dimensional stability, and heat resistance can be optimized by formulation and additives. These materials offer good durability and resistance to wear, making them suitable for applications in which parts are subjected to mechanical stress, abrasion, and cyclic/repeated loading.

Polyester RIM may require specific equipment and processing parameters to achieve optimal results, but many generic RIM systems can handle the necessary protocols with good results.

What Are the Typical Industrial Applications of the RIM Process?

RIM manufacturing finds wide and increasing applications in industrial applications. Some examples are listed below:

- Automotive: Body kits, body panels, spoilers, instrument panels, and door panels.

- Electronics: Enclosures, housings, and structural components.

- Marine: Fenders, engine housings, seating, storage bins.

- Medical: Equipment enclosures, device housings, and patient comfort components.

- Aerospace: Interior and exterior components, panels, and ducts.

- Consumer Goods: Furniture, appliances, tool handles, and sporting equipment.

What Are the Examples of Reaction Injection Molding Products?

Some examples of RIM products are listed below:

- Dashboards and instrument panels.

- Interior trims.

- Armrests.

- Overhead storage compartments.

- Cabin panels.

- Orthopedic aids.

- Insulation panels.

How Long Do Reaction Injection Molding Products Last?

RIM parts are among the toughest large plastic components and can have very long functional life expectancies. For example, aircraft interiors in commercial planes are commonly kept in service for 5–15 years, depending on the policies of the airline. Generally, such interiors show cosmetic wear and tear but remain serviceable for long periods. Private and light aircraft interiors can also have a much longer service life. Automotive parts made by RIM can be expected to serve for the functional life of the vehicle, generally 7–15 years depending on the market region, but potentially much longer.

What Are the Advantages of Reaction Injection Molding?

RIM offers various advantages, including:

- High strength and resilience.

- The complexity of parts is only limited by fine detail.

- Flexibility and rigidity can be specified by material selection and design.

- Parts tend to be lower in weight than alternative processes can achieve.

- Tooling costs are low compared with, for example, injection molding.

- Part costs can be low, as large parts with integrated inserts can serve multiple roles and be made from relatively low-cost materials.

- Cosmetic finishes are good to excellent straight from the mold. Most materials offered in RIM-related variant processes accept surface finishing/coating/painting.

What Are the Disadvantages of Reaction Injection Molding?

The disadvantages of RIM are listed below:

- The range of material options is limited but growing.

- Fine features can be hard to reliably reproduce.

- Tools are of low robustness, so they are relatively easy to damage.

- Very large parts can produce challenges in fill/cure processes.

- Many of the material options produce volatile organic compound (VOC) pollutants.

Frequently Asked Questions on Reaction Injection Molding

RIM vs. injection molding—what’s the difference?

While both RIM and injection molding are used to make plastic parts, they differ quite a bit in materials, process conditions, and applications. RIM uses liquid reactive polymers (e.g., polyurethane, epoxy, silicone) that chemically solidify, while injection molding uses melted thermoplastics that harden upon cooling. RIM operates at low pressure (<10 MPa) and moderate temperatures (60–120°C), but injection molding needs high pressure (up to several hundred MPa) and high temperatures (up to 400°C).

In addition, RIM molds are made from aluminum or composites, which are cheaper and faster to make. Injection molding, on the other hand, requires more durable, expensive molds to withstand extreme pressures and temperatures. These typically cost 10–20 times more. That said, injection molding is great for high-volume, fast-cycle production, while RIM is better for low-volume runs, prototyping, and complex designs.

Does RIM and injection molding use the same equipment?

No, RIM and injection molding use entirely different equipment. RIM machines are highly specialized equipment designed specifically for the RIM process, and aren’t suited to any other task. They are quite different from conventional injection molding machines and more closely related to epoxy resin mix/metering systems for potting applications.

Are RIM Products Thick?

It depends. The thickest sections that it is practical to manufacture by RIM are generally reported as ½ inch thick. Although localized thickening and occasional parts are molded to thicknesses approaching 5 inches without major difficulties.

Are RIM Products Durable?

Yes. RIM products are mechanically, chemically, and environmentally durable when the materials are appropriately selected for the expected application and the usage does not exceed reasonable force.

Is Reaction Injection Molding Expensive?

It depends. There are high costs associated with establishing RIM production, but overall the part and tooling costs are low compared with injection molding. The tools are lightweight and parts can be made of relatively low-cost materials for many applications.

How Xometry Can Help

For any more information or personalized advice on reaction injection molding or similar processes, reach out to one of our representatives. Xometry provides a wide range of manufacturing capabilities including CNC machining, 3D printing, injection molding, laser cutting, and sheet metal fabrication. You can get started today by uploading your designs to the Xometry Instant Quoting Engine®!

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.