There is an abundance of machining processes out there, all of which provide specific perks and unique results — and side milling is no different. Working on a vertical plane, you can create different slots and cuts with these machines. While it may seem like these are small details, they’re impactful when it comes to finished products that require smooth finishes and accurate slots to function as they’re supposed to.

Side milling has many different use cases and does differ from other milling methods you might be more familiar with. Below, we’ve given a brief rundown of how this particular type of milling works and how it might be most useful to your day-to-day workflow.

What Is Side Milling?

The most important distinction with this type of machining process is that the milling cutter works into the side of the workpiece, as its name would imply. The machine has a cutter that’s mounted onto an arbor, which will slice into the material that’s clamped down to the work table. Then, the edges or teeth on the cutter will cut into the object and create the shape or design you need. It’s a popular method that you can use in tandem with the likes of turning, drilling, and boring, too.

There are various materials you can use for side milling, including metals, plastics, and composites, which gives this machine versatility. If you’re trying to calculate feed rate, there are a few equations you can always rely on to get the right number:

First, get the RPM, which is:

RPM = (12 Surface Speed) / (Pi Tool Diameter) [revs/min]

Then you can get feed rate:

Feed Rate = RPM Chip Load Number of Teeth (Flutes) [in/min]

Remember that Pi = 3.14159

How Does Side Milling Differ From Other Milling Processes?

You might be curious about how side milling compares to other milling processes you’ll come across. The answer is relatively simple and present in the name: it cuts sideways. Because of how the cutter is positioned and what it’s meant to do, it stands out from milling machines that cut on different axes or from different directions, like in face milling, where you’d cut a workpiece from the top. It’s also built for the purpose of creating slots, contours, and designs into the sides of objects (whether on a vertical or horizontal plane) which not all other milling processes are capable of doing.

What Are the Different Types of Side Milling?

As you’ll find, there are two styles of side milling that involve different types of cutters, which you can learn below:

- Plain Cutters: Also called straight-tooth cutters, this type of side milling uses cutters with teeth lined up single file rather than staggered. It’s the right cutter to use if you’re doing all-purpose work, creating slots, or working on flat surfaces.

- Staggered-Tooth Cutters: Alternatively, you can use a staggered-tooth cutter, which features teeth that alternate along its circumference. This is particularly useful if you want to cut down on vibration or chatter and get a smoother finish overall. It is also a great type to use in heavy-duty operations or instances where surfaces are drastically uneven.

What Materials Can Be Machined Using Side Milling Techniques?

Side milling can be used to mill: metals, plastics, and composites.

What Tools and Equipment Are Required for Effective Side Milling?

To make the most of side milling, you’ll need a machine with several parts. The first is a milling machine, which is the main component that will power the cutter and allow it to move in the right direction. A side milling cutter is also necessary for making cuts into the side of an object. The arbor is also an important part because it’s the bridge between the milling machine and the specialized side cutter. You’ll also want to have some kind of clamps or vises on hand to hold your workpiece in place, as well as a cooling system to keep friction and chips at bay.

It’s worth pointing out that the type of material your cutter is made from will also make a difference in your finished product and how nice the finish is. For instance, a carbon tool steel cutter is great when it comes to abrasion resistance, but it loses hardness when it hits a certain temperature, making it a mediocre choice for materials that need to be cut at higher speeds. Carbide, on the other hand, is able to handle these temperatures and cut precisely and accurately, but these cutters may be more expensive.

How Does Side Milling Affect the Surface Finish of a Workpiece?

Side milling generally produces a good surface finish with light to medium machining marks. However, the ultimate quality of the surface finish depends on a variety of factors that contribute to the roughness profile parameter, Rz (peak-to-valley average). A study entitled "Factors Analysis Affecting the Roughness at Side Milling" highlights the multifaceted nature of this process. Factors such as: cutting conditions, workpiece material, cutting geometry, tool errors, and machine tool deviations collectively impact the surface profile of milled parts. The analysis emphasizes that the surface roughness is not solely influenced by one factor, but rather by a combination of these elements.

Ultimately, whether the surface finish is good enough depends on the parameters of the side milling process and the application that the part is to be used for.

How Is Side Milling Different From Thread Milling in Terms of Procedure?

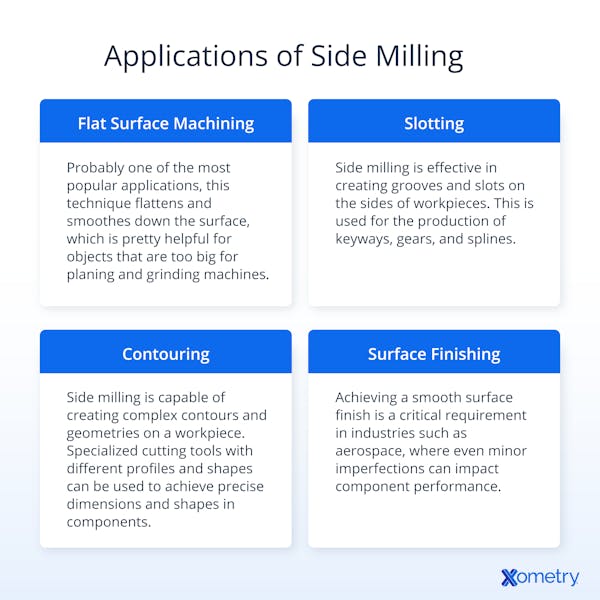

Side milling and thread milling are two different milling processes with different purposes and procedures. Side milling is primarily employed for surface machining, aiming to create flat surfaces or contours on the sides of a workpiece. In this process, a side milling cutter, mounted horizontally on an arbor, moves perpendicular to the workpiece surface, removing material from the side to achieve the desired flat vertical surfaces or contours.

Thread milling, on the other hand, is used to cut threads, whether internal or external, on a workpiece. The procedure involves the use of a thread milling cutter with a unique design featuring multiple cutting edges. Unlike side milling, the thread milling cutter follows a helical path to gradually generate threads on the workpiece.

How Is Side Milling Different From Plain Milling in Terms of Procedure?

The primary distinction between side milling and plain milling lies in the orientation of the cutting tool and the resulting surface features. Side milling is used to make flat surfaces perpendicular to the cutter arbor axis, or to create slots, ledges, or other contours. In contrast, plain milling is focused on creating a flat, horizontal surface parallel to the axis of rotation of the milling cutter. The procedure utilizes a plain milling cutter, typically mounted on an arbor. The workpiece is secured on the milling machine table, and the cutter, aligned with the axis of rotation, removes material by rotating on its axis to produce a flat, horizontal surface. If you're using a narrow cutter, you can cut deeper into the material compared to using a wide cutter. The choice of cutter depends on the size and shape of what you're working on. If you have a big area to mill, a wide cutter is good because it means you need fewer passes. When you're removing a lot of metal, start with a rough cutter and then switch to a finer one for a smoother finish. For the initial rough cuts, it's better to go at a slower cutting speed with a fast table feed. When you're finishing up, speed up the cutting but slow down the table feed for a polished look.

What Are the Advantages of Side Milling in Industrial Production?

Here are some of the benefits you’ll reap when working with side milling machines:

- Various textured finishes: A side milling machine can produce a wide range of surface features, such as flat vertical surfaces, slots, and intricate contours.

- Ideal for slots and grooves: When you need these types of cuts on a workpiece, side milling is the way to go.

- Range of cutter types: You can purchase cutters in plenty of sizes, types, and materials so you can really cater to the kind of work you’re doing and the specific materials you’re machining.

- Quality and accuracy: Side milling machines can give you precise and accurate finishes where other machining processes might not be able to.

What Are the Disadvantages of the Side Milling Process?

There are also a few downsides of side milling to take note of:

- Only machines the sides: As its name says, this machine is built for carving into the side of an object and not other surface areas.

- External feature focus: If you’re looking for a process to machine internal parts, skip the side milling machine and opt for another service like end milling.

- Not ideal for thin workpieces: With the force that comes from these machines, you may find that thinner boards and surfaces will bend, warp, or deflect under the pressure.

What Factors Influence the Quality and Precision of Side Milling Operations?

When you’re side milling, it’s worth being aware of the specific details that can impact how the final piece looks and functions. Here are a few factors to keep your eye on:

- The feed rate and how deeply you cut

- The design of the tool, including the number of teeth, chip formation, and helix angle

- What the cutting tool is made out of

- How accurate and well-aligned the spindle is on the milling machine

- How stiff the tool is

- How hard your workpiece is and the type of material it’s made out of

- The speed of your cutting tool and how quickly it moves across and into the workpiece

- How well-trained and skilled you are as a milling machine operator

How Does the Choice of Cutting Tool Material Impact Side Milling?

The choice of cutting tool material in side the milling process impacts: tool performance, tool life, machining efficiency, and product impact. Different tool materials are chosen to maximize performance under specific sets of machining conditions. For example, plain carbon tool steel maintains a cutting edge due to its high abrasion resistance but loses hardness above 250 °C. It is an appropriate choice for low-speed machining of materials such as aluminum and magnesium.

Harder materials like carbide offer greater durability and wear resistance, enhancing tool life and maintaining cutting performance during side milling operations. These tools remain hard even at temperatures up to 1000 °C. They are also able to withstand high-speed cutting operations.

Can Side Milling Be Used To Create Complex Shapes and Profiles?

Yes, side milling can be used to create complex shapes and profiles. This is achieved through the use of specialized cutters to create contours and complex profiles.

What Safety Precautions Should Be Taken During Side Milling?

To make sure your side milling operation is safe, follow these guidelines:

- Wear personal protective equipment, including hearing protection, work gloves, and safety glasses, and make sure your team or milling machine operators do the same.

- Make sure the guards are down and work properly so there are no accidents or injuries that happen with moving parts.

- Uses vises or clamps to keep your workpiece in place and prevent sliding, errors, and serious injuries.

- Inspect your side milling machines every time before you use them and always keep them well maintained.

- Train your team and ensure people are always up to speed with safety requirements, emergency procedures, and proper operation protocol for this type of machine.

- Make sure every person that uses a side milling machine and the people surrounding them know where the emergency stop buttons are.

How Do You Calculate the Correct Feed and Speed for Side Milling?

The correct feed and speed for side milling can be calculated using the following equations:

RPM = (12 Surface Speed) / (PI Tool Diameter) [revs/min]

Feed Rate = RPM Chip Load Number of Teeth (Flutes) [in/min]

Where PI is a constant (3.14159).

What Are the Common Challenges and Solutions in Side Milling?

Side milling isn’t too convoluted of a machining operation, but it can be difficult and cause a few tricky problems. Below are the most common issues that arise and what you can do to solve them:

- Jerky or inconsistent chip evacuation: The best way to ensure a smooth chip evacuation is to buy a side milling cutter with specialty chip breakers and monitor the coolant flow. Feed rates can also impact this.

- Excessive vibration or chatter: You can lower the radial engagement angle or use shorter tool holders to stop annoying vibrations or chatter that are affecting the look and finish of your products.

- Premature or overtly quick tool wear: This can be down to feed rate and tool speed or something as obvious as lower-quality tools that aren’t built to last for a long time. Try to only purchase high-quality parts and cutters if possible and adjust speeds and rates for the type of material you’re milling.

- Tool breakage: This can happen when feed rates are too quick or if you use too long of tools. Make sure your alignment is correct, slow down your feed rate, and use shorter tools to prevent this.

- Workpiece deformation: This usually happens when you’re machining a piece that is too thin. Try to side mill materials with thicker diameters and reserve the thinnest pieces for other machines if possible. If this isn’t doable, slow down your feed rate and give the workpiece ample support while you mill it.

How Has Technological Advancement Improved Side Milling Techniques?

There have been a few advancements in milling as a whole, which are not necessarily just applicable to side milling. Some of these technological advancements include:

- Chip Slitter End Mills For Deep Cavity Machining: Cutting-edge chip splitter technology incorporates strategically placed chip gashes along the flute of end mills. These chip splitters effectively split chips in half, facilitating the efficient clearance of material and ensuring clean cuts. This innovative solution not only prevents bird nesting but also significantly reduces the risk of tool breakage. End mills equipped with this design excel in various machining applications, including: deep cavities, side milling, shoulder milling, and helical milling. The active control over chip size makes these cutting tools particularly well-suited for mold builders seeking optimal performance and reliability.

- CNC Machining: Computer numerical control (CNC) technology has revolutionized milling processes, including side milling. CNC machines allow for precise control over tool paths, speeds, and feeds. This results in higher accuracy and repeatability in side milling operations. CNC milling technology has undergone remarkable advancements, with five key developments standing out. Firstly, there's a significant boost in processing power, enabling faster and more precise machining cycles. Advanced controls offer greater flexibility and improved user interfaces. Precision has increased through enhancements in machine components. Multi-axis capabilities, especially 4 and 5-axis milling, have become more common, allowing for more complex machining in a single setup. Lastly, automation integration is now feasible, leading to improved productivity and the potential for unattended operation.

- Micromilling: Micromilling is a specialized milling technique that makes use of small-diameter cutting tools to achieve unparalleled precision on a miniature scale. The use of sub-millimeter end mills enables the creation of intricate features and fine surface finishes. Micromilling is particularly valuable in industries requiring precision at small scales, such as: electronics, medical devices, and aerospace. This technique brings a new level of detail to side milling applications, allowing for the machining of tiny slots, grooves, and features with high accuracy.

- IoT Integration for Smart Milling: A noteworthy recent advancement in milling applications is the integration of the Internet of Things (IoT) technology. IoT brings a new dimension to milling processes by facilitating connectivity and data exchange between CNC milling machines and various sensors, devices, and computer systems. This interconnected ecosystem enables real-time monitoring, analysis, and optimization of milling operations. Through sensors embedded in the milling equipment, data on factors such as temperature, vibration, tool condition, and machine status are continuously collected. This data is then transmitted and analyzed, allowing operators and manufacturers to make informed decisions for process optimization and predictive maintenance. IoT integration in milling applications enhances overall efficiency, reduces downtime, and contributes to the development of smart, adaptive machining systems.

What Are Ways Can Side Milling Be Integrated With CNC Technology?

Integrating side milling with CNC (Computer Numerical Control) technology offers a streamlined and precise approach to machining operations. CNC technology allows for the automation of side milling processes by programming the CNC machine to follow specific toolpaths and parameters. This integration eliminates the variability associated with manual operation. CNC systems provide unparalleled control over cutting speeds, feed rates, and tool movements, ensuring accuracy and repeatability in milling tasks.

Frequently Asked Questions About Side Milling

Is Side Milling a Common Manufacturing Process?

Yes, side milling is a fairly common manufacturing process that is used whenever the side of a workpiece needs to be machined to have flat or contoured surfaces or it can be used for other specific features like slots and grooves.

What Is the Difference Between Side Milling and Saw Milling?

Side milling and saw milling differ in purpose and in the type of cutting tool used to perform the two operations. Side milling is a machining process where milling cutters are used to create flat surfaces or slots on the side of a workpiece. Saw milling is a machining process where a thin cutting tool, known as a slitting tool, is used to cut narrow slots in a workpiece or part a workpiece in two.

How Xometry Can Help

Xometry provides a wide range of manufacturing capabilities that are applicable for aerospace, automotive, medical, and construction industries, among many others. Whether you’re interested in CNC milling or something completely different, you can get your instant quote today.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.