As a form of electrical discharge machining (EDM)—a process that shapes hard metals using electricity—sinker EDM is used to make detailed molds, dies, and complex parts that other tools struggle with. Whether you know it as sinker, plunge, ram, volume, or cavity EDM (yes, it goes by a lot of names), this is one method worth knowing about, especially if you need highly accurate parts.

What Is Sinker Electrical Discharge Machining?

A process that’s been around since 1770, sinker EDM uses spark erosion to produce parts through an electrode that creates cavities in metal workpieces. It’s a subtractive process that gets its name from the fact that the electrode actually sinks into the material, though there are machines available that work at other angles too, including horizontally.

This machining method is especially useful for making cavities that can’t be made using other methods like computer numerical control (CNC) milling. And the hardness of a material won’t affect the electrode’s performance, so you can use this method even on hardened steels for making injection molds. Another benefit of using this method is that it can be very accurate, as long as the electrode is properly machined. Unlike CNC machining, this process doesn’t expose the tool to loads that could distort it, which is why it can be controlled better. It also has the ability to produce irregular shapes, which are pretty much impossible to make using other methods.

No special tools are required, even with very hard materials. As long as the material is conductive, sinker EDM can work on it. Compared to CNC milling, this method is rather slow, and it’s also expensive to operate. The fact it’s limited to conductive materials might also be a con for some.

How Does Sinker EDM Work?

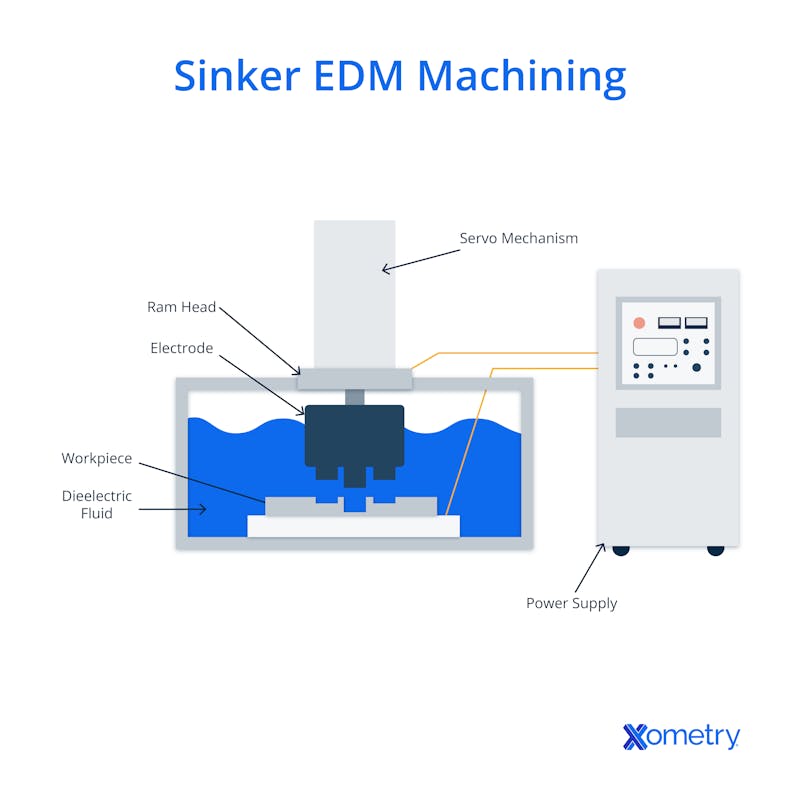

The electrode used in the process (usually made from graphite or copper) needs to have the same shape as the feature you’re trying to make. When the process starts, the electrode moves toward the material, which has been immersed in a dielectric fluid. Just as the electrode is about to touch the material's surface, a high-voltage spark—up to 12,000°C—jumps between them, melting away a bit of the workpiece (this is sometimes called “burning”).

The workpiece is immersed in dielectric fluid because the fluid serves as a coolant to manage high temperatures and acts as an insulator. This insulation prevents a continuous electrical current from passing between the part and electrode, ensuring sparks only form when the voltage is high enough. The dielectric fluid is constantly filtered to remove metal debris, and it’s cycled through a chiller to keep the temperature under control. Here’s a visual of the sinker machine and process.

Who Is the Pioneer of Electrical Discharge Machining?

The first documented analysis of the effect of spark erosion was made in 1770 by Joseph Priestley, an English physicist. A team of Soviet scientists named Dr. B. R. and Dr. N. I. Lazarenko took this research further in 1943 and invented the electrical discharge machining process. The first practical EDM machine was designed in 1952 by a company called Charmilles to remove broken taps.

What Is Another Name for Sinker Electrical Discharge Machining?

Sinker Electrical Discharge Machining is known by many names such as plunge, ram, volume, or cavity EDM.

What Is Sinker EDM Used For?

Sinker EDM is primarily used to create blind holes or cavities in a part. These cavities often have complex shapes that are impossible to manufacture using conventional machining techniques like CNC milling. The hardness of the material does not affect the ability of the electrode to remove material whatsoever. This means that sinker EDM can be used to create cavities in hardened steels for injection mold making.

How Accurate Is Sinker EDM?

Sinker EDM is a very accurate machining process with tolerances that can be as low as +/- 0.004 mm provided optimal machining parameters are maintained. This high level of accuracy is due to the fact that the electrode is guided by a CNC (computer numerical control) machine that controls its movements with great precision. In addition, the electrode wears very evenly, which results in consistent dimensional accuracy. Some sinker EDM machines can even polish a part with a final surface roughness of 0.18 microns.

Who Manufactures Sinker EDM Machines?

There are many manufacturers of sinker EDM machines. Some of the most popular brands include: ONA, OFEK, Makino, Sodick, Mitsubishi Electric, and GF. Most of these manufacturers also produce wire EDM machines.

What Are the Advantages of Sinker EDM?

Some of the key advantages of sinker EDM are listed below:

- Accurate: Sinker EDM can produce features with extreme accuracy as long as the electrode is machined accurately. The sinker EDM process does not expose the tool to loads that can flex and distort it, as is the case with CNC machining; as such, features can be more precisely controlled.

- Blind Cavities: Sinker EDM can produce features with blind holes with irregular shapes like hexagonal holes, for example. Doing irregular shapes with a CNC machine would require very specialized tooling. In some cases, it is impossible to produce equivalent features using standard CNC machining.

- Simple Tooling: Unlike other machining processes, sinker EDM does not require a tool that is harder and tougher than the material being machined. As long as the metal is conductive it can be machined with sinker EDM. Tooling can be manufactured in-house out of copper or graphite using normal CNC machines.

What Are the Disadvantages of Sinker EDM?

Sinker EDM has many advantages, however, some downsides must be considered before making use of this technology. These disadvantages are listed below:

- Slow: The sinker EDM process removes very little material when compared to other machining technologies like CNC milling. This increased time means that the individual part cost is higher than if able to use other machining technologies. The increased time can be mitigated by pre-machining the part to get close to the final, desired dimensions.

- High Operating Costs: The high energy process of spark erosion used in Sinker EDM machines means that they use excessive amounts of electricity. Normal CNC machines consume considerably less energy.

- Limited to Conductive Material: Sinker EDM machines are limited to conductive materials and therefore cannot machine plastics or composites.

Frequently Asked Questions on Sinker EDM Machining

Exactly how accurate is this method?

Its tolerances can be as low as +/- 0.004 mm as long as everything is up to par. As well as being controlled by a CNC machine, the electrode wears evenly, so it stays consistent in terms of dimensional accuracy. Some of these machines can even polish a part, bringing its surface roughness to around 0.18 microns.

What Is the Difference Between Sinker EDM and Wire EDM?

A wire EDM machine uses a thin, electrically charged wire to cut complex, two-dimensional shapes through thick material. It doesn’t sink electrodes into the material like sinker EDM and it’s better for cutting through materials instead of making internal shapes within solid blocks.

What are the best sinker EDM machines?

There are several sinker EDM models on the market, including:

- GF Form P350: Great tool life management, can polish with a surface roughness of 0.12 microns

- Makino EDAF3: Dielectric tank underneath, automatic tool changer

- Mitsubishi SV12P: AI capabilities for up to 30% reduced machining time

Is Stainless Steel Suitable for Sinker EDM?

Yes, stainless steel is conductive and can therefore be machined using sinker EDM.

Is Sinker EDM Available at Xometry?

Yes, sinker EDM is available at Xometry. To learn more, contact a Xometry representative or make use of our online quoting tool.

How Xometry Can Help

If you have any further questions about this topic or anything else related to manufacturing, one of our representatives would be happy to assist you. In addition to offering sinker EDM machining services, Xometry has you covered with a huge variety of capabilities, from 3D printing to laser cutting, to powder coating and everything in between. Get started today by requesting a free, no-obligation quote.

Summary

Copyright and Trademark Notices

- MITSUBISHI is a trademark of MITSUBISHI CORPORATION.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.