Wood turning is a process that uses a lathe and hand tools to shape wooden parts that are symmetrical about a center axis. This process is somewhat similar to the potter’s wheel, on which users revolve clay around an axis to create items like bowls and vases. Unlike a potter’s wheel, on which one’s hands are used to shape parts, wood lathes require wood-turning tools for the operator to create parts.

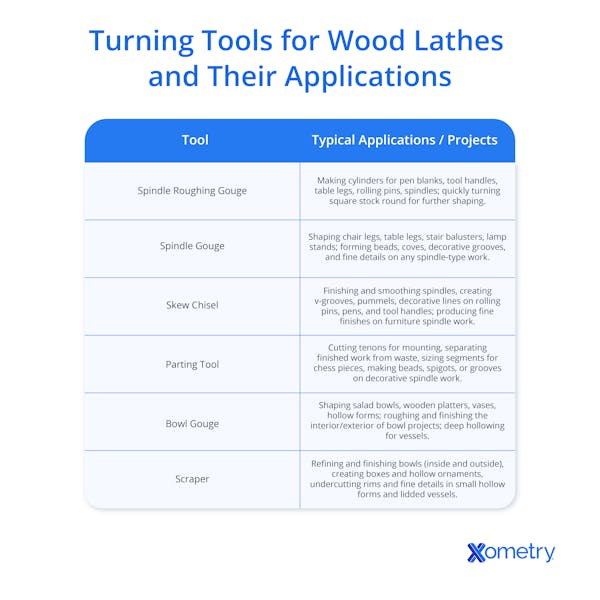

Wood lathe turning tools are hand tools that allow users to make different cuts to their workpieces. For example, spindle roughing gouges are used at the beginning of spindle work to round square stock, while parting tools are mainly used to cut narrow grooves, define diameters, and separate finished parts from waste. There are several types of handheld wood-turning tools, each designed for specific cuts or surface finishes. This article will review six different turning tools for wood lathes and a few best practices to follow when woodworking.

1. Spindle Roughing Gouge

A spindle roughing gouge is typically the first wood lathe turning tool used when starting a new project. For this particular tool, a wide U-shaped flute extends out from the grip. This tool allows users to quickly remove unwanted material and convert a square workpiece to a round one. By doing so, users can center their work on an axis running along the length of the workpiece. Spindle roughing gouges are often made from HSS (high-speed steel) and are available in different sizes, typically costing $20-$120.

2. Spindle Gouge

Spindle gouges (shallow fluted gouges) are wood lathe turning tools that have a noticeably smaller flute than roughing gouges. These tools are used to shape workpieces into desired shapes by creating features such as beads, coves, and ridges. The cutting edge of these tools is ground and beveled to obtain smooth surface finishes on workpieces. Spindle gouges come in a range of sizes, with typical prices from $10-$110.

3. Skew Chisel

Skew chisels have a flat blade and are used for “planing” or creating smooth surfaces on wooden workpieces. Additionally, the skew chisel is used to finely remove material to obtain desired thicknesses and make shallow curves, V-cuts, and pommels. This wood lathe turning tool is notorious for being difficult to handle and requires patience to use correctly.

It is recommended to keep the skew chisel’s bevel rubbing on the wood and present the cutting edge at a slight angle to the workpiece, while avoiding cutting with the corners. Using the corners can cause the workpiece to “catch,” which can be potentially dangerous. However, once familiar with the tool, the skew chisel is one of the most useful and versatile wood-turning tools. Skew chisels are available in different blade shapes and sizes, with typical prices from $10-$80 and premium versions up to $200.

4. Parting Tool

Parting tools are primarily used to cut narrow grooves, define diameters, and separate finished work from waste, though they can also add details such as fillets and spigots. Parting tools come in different sizes and styles, with prices typically ranging from $20-$100.

5. Bowl Gouge

Bowl gouges (deep-fluted gouges) are faceplate wood lathe turning tools that are ideal for shaping the interior and exterior curves of bowls and similar items. Bowl gouges have a long, deep-fluted blade (deeper than a spindle gouge). The tip of a bowl gouge is ground into different profiles, commonly a fingernail or swept-back grind, to suit various cutting styles. Bowl gouges are made in different sizes and shapes for specific applications, generally costing $20-$120.

6. Scraper

Scrapers are used for refining shapes and smoothing surfaces, though they do not cut as cleanly as gouges and can leave a less polished surface if not used carefully. There are several types of scrapers, including square-nose, round-nose, and specialized forms such as diamond-point or spear-point. Square-nose scrapers are used for finishing the outside of a bowl, while round-nose scrapers are used for finishing the inside of a bowl. While these are the two main types, there are other types for different applications. Scapers are useful because they can often reach areas that other wood-turning tools can’t reach. Scrapers typically cost between $15-$130.

What Is a Turning Tool?

A woodturning tool is a hand tool used with a lathe to remove material from a rotating wooden workpiece. Some tools are used for spindle turning, where cuts are made on work held between centers along the axis to create cylindrical parts. Others are used for faceplate turning, where work is mounted on a faceplate or chuck to shape bowls and other hollow forms. Each wood lathe turning tool will have a handle and a protruding blade. A wide range of tools, their various subtypes, and blade materials are available on the market. Higher-end tools, often made from quality high-speed steel or carbide, hold their edge longer and allow smoother, more controlled cuts.

What Are the Applications of Turning Tools?

Turning tools can be used to make spindle parts – or cylindrical parts that are symmetrical about the axis of rotation. Some examples of spindle parts include table legs, baseball bats, fence spindles, chairs, and lamps. Turning tools can also be used for faceplate work, where parts are mounted to the headstock using a faceplate or chuck. This setup allows hollowing operations to form bowls, cups, vases, and other similar items.

How to Choose the Best Wood Turning Tool for Beginners

For beginners, it is advisable to choose well-made tools, such as those made from high-speed steel, since they hold an edge longer and make learning easier. The list below shows some general steps toward choosing the best turning tool for beginners:

- Become acquainted with using both spindle roughing gouges and spindle gouges. Choose a roughing gouge around ¾″ wide, made from HSS, and a smaller spindle gouge in the ¼″–½″ range to practice shaping beads and coves. These two tools will help beginners get a feel for how to grip the turning tool and how to remove material from the workpiece.

- Choose tools with slightly longer handles, which provide better leverage and stability, helping beginners maintain control.

- Once comfortable, practice with other tools such as chisels and parting tools for spindle work, and bowl gouges or scrapers for basic faceplate projects.

How to Identify a Wood Turning Tool

Wood lathe turning tools are easily identifiable by their shape and blade. The list below shows how to identify wood-turning tools:

- Gouges have a round cross-section with a fluted channel, while chisels, parting tools, and scrapers are typically made from flat bar stock.

- Gouges are distinguishable based on the size of their flute. Spindle roughing gouges have wide, shallow flutes; spindle gouges have narrower, shallow U-shaped flutes; and bowl gouges have deeper, more open flutes suited for heavier cuts.

- Chisels, parting tools, and scrapers are distinguishable based on the shape of their blades. Chisels, such as skew chisels, have a flat blade ground at an angle to form a sharp edge, sometimes skewed to create a pointed tip. Parting tools are narrow and pointed, typically ground with beveled sides that form a V-shaped cutting edge. Scrapers resemble flat bars with different nose profiles (square, round, diamond, etc.), each suited for specific finishing tasks.

How to Use a Wood Turning Tool

Different wood lathe turning tools have various uses and therefore require different techniques and grips. The list below shows the steps on how to use a wood-turning tool:

- Position your hands so there is no way they can contact the workpiece. Use your dominant hand to guide the handle of the tool and your other hand to steady the blade on the tool rest. Maintain tool presentation so the cutting edge meets the wood at a controlled angle, with the bevel supporting the cut.

- Ensure the turning tool is always contacting the tool rest. Minimize the distance between the rest and the workpiece to about ¼ inch.

- Ensure the bevel of the cutting tool is rubbing on the wood just behind the cutting edge during the cut. This will help prevent removing too much material at once and also help prevent the tool from “catching” the workpiece.

- Cut with the grain, not against it. For faceplate work such as bowls, cuts usually start from the rim toward the center, following the grain. For spindle work, cuts typically follow the grain direction, from larger diameters toward smaller ones. Cutting against the grain, sometimes called cutting “uphill,” makes it much harder to control the tool.

Is it Easy to Use Turning Tools?

Basic turning techniques can be learned fairly quickly, but tool control takes practice, and mastering the craft requires many hours at the lathe. However, becoming a master at the craft will take hundreds of hours of practice. When first starting to learn wood turning, it’s important to first learn the basics (lathe speeds, cut angles, hand grips, etc.), what the different cutting tools are and what they’re used for, and how to use those tools. With time, wood-turning skills can become second nature.

Summary

This article presented six wood lathe turning tools, explained what they are, and discussed how each is used. To learn more about turning tools, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including CNC machining and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry��’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.