You have most likely encountered the 18/8, 18/10, and 18/0 grades of stainless steel more than you realize. These steels are used in everything from the pipes that may have brought you the water for your morning coffee to the teaspoon you use to stir it with. Needless to say, these are very valuable materials in the world of manufacturing and are some of the most popular among Xometry customers.

For a quick overview of the differences between these three grades, we’ve outlined what each stainless steel grade consists of chemically, what it’s great (and not-so-good) at, and the ways in which Xometry’s services can be beneficial to processing stainless steel for your own business.

What is 18/8 Stainless Steel?

This kind of stainless steel is a member of the 300 grouping, and its most common and popular grade is 304. Its name basically gives away its composition—it’s got around 18% chromium and 8% nickel. Also included is roughly 67% iron, and a tiny trace of carbon (about 0.07%). It’s also part of the austenitic steel family, meaning they have better corrosion resistance than other families of stainless steel and can’t be hardened through heat treatments. That being said, it falters slightly in corrosion resistance when it comes to sitting in or being constantly exposed to saltwater.

This grade has an extra perk in that it’s food safe, meaning it can be made into cookware, like pots and pans, utensils and cutlery, and even those sleek stainless steel cooking worktops you find in restaurants. To make this grade, all the ingredients, including the alloying elements, have to be mixed together and then melted in an electric furnace. This part of the process takes around 8–12 hours. After that, it has to go through decarburization, which is basically getting rid of any carbon that has been left over, and this is done with argon or oxygen. It’s then poured into molds so that it can harden in the needed shape and size.

How Is 18/8 Stainless Steel Made?

To produce 18/8 stainless steel, manufacturers blend approximately 66.74% iron, 0.07% carbon, 18% chromium, and 8% nickel. The raw materials required for the formation of the stainless steel undergo melting in an electric furnace, a process lasting 8 to 12 hours. Excess carbon is eliminated through vacuum oxygen decarburization or argon oxygen decarburization. Stirring the molten steel ensures uniformity, followed by forming, heat treatment, cutting, shaping, and applying surface finishes. These steps collectively yield the desired 18/8 stainless steel composition, meeting specific mechanical and quality requirements.

What Are the Advantages of 18/8 Stainless Steel?

Here are the advantages of 18/8 Stainless Steel, also known as 304 stainless steel:

- Has good corrosion resistance in mild environments due to its 18% chromium content.

- The alloy's nickel content enhances its strength, making it durable and suitable for various applications.

- It offers a good balance between performance and cost, providing adequate strength and temperature resistance without being overly expensive.

- It has good weldability, which allows for easier fabrication and repair.

- It is safe for use in cookware and food preparation surfaces.

What Are the Disadvantages of 18/8 Stainless Steel?

The disadvantages of 18/8 stainless steel are:

- Despite its corrosion resistance, 18/8 stainless steel may tarnish over time, especially when exposed to harsh chemicals or acidic environments.

- Due to its vulnerability to chloride-induced corrosion, 18/8 stainless steel is not recommended for use in marine environments.

- It can only be hardened through cold working, which may limit its applicability in certain high-strength applications.

What is 18/10 Stainless Steel?

The numbers in 18/10 stainless steel’s name also describe its makeup; it’s got 10% nickel, and around the same amount of chromium as the other two (18%). With that extra bit of nickel, 18/10 steel is known for having slightly better rust and corrosion resistance, making it a great option for flatware, cooking utensils, and kitchen appliances. It can hold its own in high temperatures—earning it another point for use within the food and restaurant industries.

Just like 18/8, the scrap is melted down in a furnace and then decarburized. The only difference is that its ingredients have slightly different proportions, i.e. slightly more nickel. It’s then formed into the shape the manufacturer has in mind and finished in various ways to get the final product.

How Is 18/10 Stainless Steel Made?

When producing 18/10 stainless steel, scrap steel is melted in an electric arc furnace, which warms the steel to liquefaction using a current flowing between carbon electrodes. To obtain the low carbon content that characterizes stainless steel, the molten steel is subsequently transported to an Argon Oxygen Decarburization (AOD) vessel. The steel is then formed into slabs or billets after chromium and nickel have been added to achieve the appropriate compositions of 18% and 10%, respectively.

What Are the Advantages of 18/10 Stainless Steel?

The advantages of 18/10 stainless steel include:

- Even when used with acidic or corrosive foods, it maintains its integrity.

- The material has a shiny and aesthetically pleasing appearance.

- It's highly resistant to rust and staining due to its high chromium and nickel content.

- It's simple to clean and is dishwasher safe.

- It can withstand high temperatures without degrading, making it ideal for cookware.

What Are the Disadvantages of 18/10 Stainless Steel?

The disadvantages of 18/10 stainless steel include:

- It has a machinability rating of 48%, which means it’s less machinable compared to other metals like 1112 carbon steel, potentially increasing manufacturing costs and effort.

- Being non-magnetic may be a disadvantage in certain applications that require magnetic properties.

- The higher alloy content of 18/10 stainless steel contributes to its higher cost compared to other stainless.

- While highly resistant to corrosion, it can be susceptible to saltwater environments

What is 18/0 Stainless Steel?

This grade has no nickel in it — which is why there’s a zero in its name — but it does have the same amount of chromium as the other two grades. Its lack of nickel or molybdenum means it’s not as resistant to corrosion and oxidation. Perhaps balancing that out is its cost—it’s more affordable than the other two grades.

This steel is made just like the other two (melted in a furnace), just without any nickel. It’s then cast into whatever shape and size is needed, then. Once this is done, manufacturers will anneal it or put it through other processes to boost its benefits and improve its finish.

How Is 18/0 Stainless Steel Made?

To make 18/0 stainless steel, mix iron, carbon, and at least 10.5% chromium. These raw ingredients are melted together, cast into slabs, and hot rolled to the required thickness. Subsequently, the steel undergoes annealing to alleviate internal stresses and guarantee structural consistency. Ultimately, the steel goes through several finishing procedures like pickling, cutting, and polishing to attain the required level of surface quality.

What Are the Advantages of 18/0 Stainless Steel?

The advantages of 18/0 stainless steel are:

- This grade is more affordable than stainless steel alloys containing nickel. It is a budget-friendly option for applications that don’t require the additional corrosion resistance of austenitic stainless steel.

- Its affordability and resistance to rust make it a popular choice for everyday household items such as: utensils, flatware, and kitchen tools.

- Since no nickel is present in 18/0 stainless steel, it does not cause allergic reactions in individuals with nickel allergies. It's used in cutlery, kitchen tools, and medical devices where contact with skin is common. Its hypoallergenic nature ensures safety and comfort for sensitive users.

- t has some resistance to pitting due to its chromium resistance.

- 18/0 is magnetic, making it useful in applications where magnetism is relevant.

What Are the Disadvantages of 18/0 Stainless Steel?

The disadvantages of 18/0 stainless steel are:

- Compared to stainless steel alloys containing nickel, 18/0 stainless steel typically has lower corrosion resistance, making it more prone to corrosion damage over time.

- Welding can be challenging due to its efficient heat retention. Excess heat can cause warping or distortion during the welding process, and the high melting point of stainless steel can complicate joining with other metals.

- Has a more muted, grayish appearance compared to the brighter luster of 18/8 due to the absence of nickel.

- The nickel content in 18/8 stainless steel enhances its ductility, making it more malleable for intricate forming processes like wire drawing or deep drawing. In contrast, 18/0 stainless steel, lacking nickel, tends to be more brittle and can crack when subjected to similar forming operations.

How To Choose Between 18/8, 18/10, and 18/0 Stainless Steel?

You’ll want to think about the end purpose for the stainless steel you’ll be using and the environment it’ll be in, as well as the budget available for manufacturing and what specific characteristics are necessary. To help you decide, we’ve created the two tables below, which provide the strengths and weaknesses of each type of stainless steel, and their properties.

Table 1 highlights the differences among 18/8, 18/10, and 18/0 stainless steels:

| Type | Advantages | Disadvantages |

|---|---|---|

Type 18/8 | Advantages

| Disadvantages

|

Type 18/10 | Advantages

| Disadvantages

|

Type 18/0 | Advantages

| Disadvantages

|

Table 1: Comparing All Three Steels

| Property | 18/8 Stainless Steel | 18/10 Stainless Steel | 18/0 Stainless Steel |

|---|---|---|---|

Property Corrosion Resistance | 18/8 Stainless Steel Moderate | 18/10 Stainless Steel High | 18/0 Stainless Steel Low |

Property Nickel Content | 18/8 Stainless Steel 8-10.5% | 18/10 Stainless Steel 10-14% | 18/0 Stainless Steel 0% |

Property Chromium Content | 18/8 Stainless Steel 18-20% | 18/10 Stainless Steel 16-18% | 18/0 Stainless Steel 16-18% |

Property strength | 18/8 Stainless Steel Good | 18/10 Stainless Steel Excellent | 18/0 Stainless Steel Moderate |

Property Cost | 18/8 Stainless Steel Moderate | 18/10 Stainless Steel Higher | 18/0 Stainless Steel Lower |

Property Staining Susceptibility | 18/8 Stainless Steel Moderate | 18/10 Stainless Steel Low | 18/0 Stainless Steel High |

Table 2: Properties of 18/8, 18/10, and 18/0 Stainless Steels

Which Is More Corrosion Resistant: 18/8, 18/10, or 18/0 Stainless Steel?

Of the three stainless steel grades — 18/8, 18/10, and 18/0 — 18/10 have the highest corrosion resistance due to its higher nickel content along with the presence of molybdenum. This makes 18/10 stainless steel an excellent choice for applications requiring durability and resistance to rust. In terms of corrosion resistance, 18/8 stainless steel comes in second, while 18/0 stainless steel has the lowest corrosion resistance of the three, since it contains no nickel, unlike the others, and is, therefore, more prone to corrosion.

Which Is the Most Durable: 18/8, 18/10, or 18/0 Stainless Steel?

The durability of stainless steel varies based on its composition. Here's a brief comparison:

- 18/8 Stainless Steel (304): Known for good weldability and excellent corrosion resistance. It has a tensile strength of 515 MPa and yield strength of 205 MPa.

- 18/10 Stainless Steel: Similar to 18/8 but with slightly more nickel, enhancing its corrosion resistance and making it a bit more durable. It has a yield strength of 200 Mpa and 500-700 Mpa.

- 18/0 Stainless Steel: Contains no nickel, which makes it less corrosion-resistant and less durable than 18/8 and 18/10.

Are 18/8, 18/10, and 18/0 Stainless Steels Weldable?

Yes, 18/8, 18/10, and 18/0 stainless steel are all weldable. 18/8 stainless steel, composed of 18% chromium and 8% nickel, is strong, weldable, ductile, and easy to fabricate. Arc welding techniques including TIG (tungsten inert gas), MIG (metal inert gas), MMA (manual metal arc), and SA (submerge arc) apply to both 18/8 and 18/10 stainless steel, which has 10% nickel and 18% chromium. Despite not having nickel, 18/0 stainless steel is nevertheless weldable with conventional welding methods, though not as easily.

Are 18/8, 18/10, and 18/0 Stainless Steels Magnetic?

It depends. 18/0 stainless steel, also known as 430 stainless steel, contains chromium but not nickel, resulting in a ferritic microstructure which is ferromagnetic. Nickel-containing stainless steels such as 18/8 and 18/10 are austenitic. This microstructure is not generally magnetic. 18/8 stainless steel can become mildly magnetic through cold-working processes. Magnetic properties are crucial for various applications, influencing the suitability of stainless steel for specific uses and industries.

Are 18/8, 18/10, and 18/0 Stainless Steels Good for Cookware?

Yes, 18/8, 18/10, and 18/0 stainless steels are all suitable for cookware, but each has different characteristics. The 18/8 and 18/10 stainless steels are especially suitable because of their higher nickel content, which offers better durability and corrosion resistance. This makes them perfect for cookware that comes into contact with acidic foods. For basic cookware applications, 18/0 stainless steel is still suitable, although it does not contain nickel and may be more prone to corrosion.

Do 18/8, 18/10, and 18/0 Stainless Steels Contain Lead?

No, 18/8, 18/10, and 18/0 stainless steels do not contain lead. Stainless steel is primarily composed of iron, chromium, and nickel (in varying proportions), with additional elements such as carbon and manganese. Lead is not a component of stainless steel alloys. Therefore, cookware made from these stainless steel grades is safe for food preparation and consumption, as it does not leach lead into food.

How Much Do 18/8, 18/10, and 18/0 Stainless Steels Cost?

The prices of 18/8, 18/10, and 18/0 stainless steels vary according to the product form, market demand, and composition of the alloy. Generally, 18/10 stainless steel is the most expensive due to its higher nickel content and molybdenum, which results in superior corrosion resistance. 18/8 stainless steel typically falls in the mid-range in terms of cost, while 18/0 stainless steel is the most affordable option due to its lack of nickel and slightly lower corrosion resistance performance.

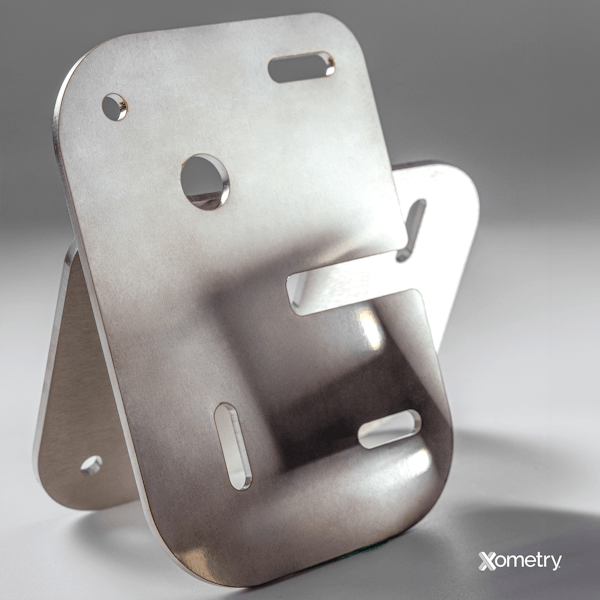

How Can Xometry Help

At Xometry, we offer many different grades of stainless steel, including popular choices like grades 304 and 316. Best of all, you can an instant quote for custom-made parts in these materials through the various manufacturing processes we offer, including CNC machining, sheet metal fabrication, sheet cutting, and more!

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.