Materials capable of adapting to different environments and applications become a handy go-to in the back pockets of manufacturers, and 410 stainless steel is definitely one such example. Thanks to its easy machinability and relatively low cost—along with a few other helpful properties—410 has risen among the ranks of useful stainless steels. Here’s what you should know about it.

What Is 410 Stainless Steel?

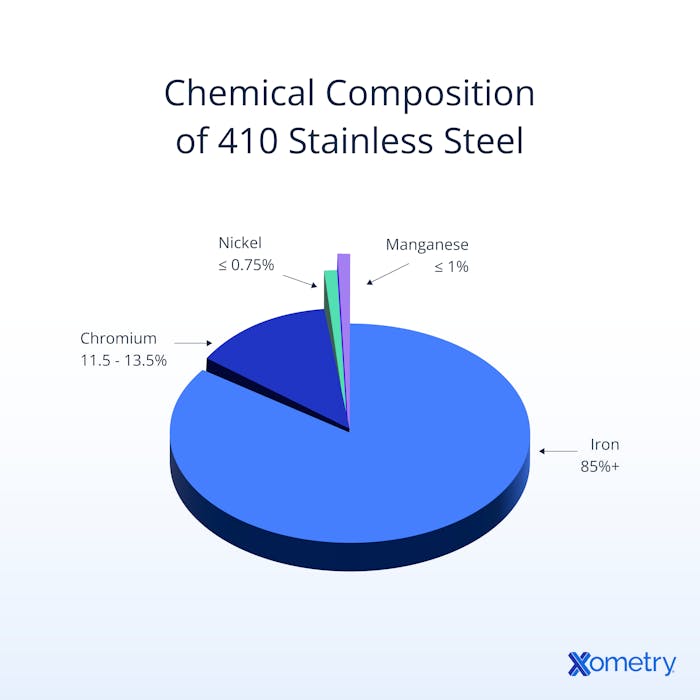

You’ll find this popular steel neatly categorized under the family of steels with martensitic structures. Its composition will vary slightly, but it’s usually made up of iron chromium, magnesium, and nickel, then around 0.08 to 0.15% of carbon, 1.0% or less of silicon, 0.03% or less of sulfur, and 0.04% or less of phosphorus. You can see the breakdown in the pie chart below.

Because 410 brings a decent corrosion resistance and good hardness to the table, it’s found in everything from your standard pair of kitchen scissors to heavy-duty steam turbine blades. You can also harden it, which can’t be said for other kinds of martensitic steels.

What Is 410 Stainless Steel Used For?

410 stainless steel has wide applications across most product sectors, specifically for its good corrosion resistance, hardness, high strength, and heat resistance. Some examples are listed below:

- It is particularly well suited to making knife blades, scissors, and other kitchen utensils.

- The material finds various industrial applications such as valves, pumps, pipe fittings, and parts for petroleum refining and chemical processing equipment.

- It is used in firearm barrels and other components.

- It is also utilized extensively for fasteners, screws, bolts, nuts, and other hardware/fixing applicationS.

- It is suitable for steam turbine blades in direct force and power generation applications.

- It is suited to forming springs, spring and Belleville washers, and other components that use its high elastic modulus and strength.

How Is 410 Stainless Steel Made?

With the help of an electric arc furnace, the components of this stainless steel are melted and formed into whichever format the manufacturer has in mind. Here’s how the process works on a more granular level:

- First, the raw bits needed to make 410 steel are poured into an electric arc furnace or an induction furnace—these usually include chromium, carbon, and other alloying elements. Higher grades will usually have this done under a vacuum. The melting process cuts out contaminants and oxides, creating a floating slag that’ll be removed.

- Once it’s melted down, the mixture will be poured into casts to form some kind of ingot or billet.

- After they’ve formed and cooled, the maker will reheat those ingots to get them to a place where they can be turned into different shapes. This’ll be done through forging, rolling, or extrusion.

- Then, these shapes will go through annealing to lessen internal stresses and boost their ductility and workability.

- After this, you or the manufacturer can choose from a few different finishing processes, including more annealing or heat treatment, hot rolling, or cold rolling.

- Lastly, grinding, polishing, and other surface treatments are popular in order to get the steel in shape for the application it’s being made for.

410 is complicated to machine versus other stainless steels. Some challenges include work hardening, higher toughness compared to 304/316, material can stick to the tool and cause rough finishes/bad tool wear, and surface properties altering as heat builds from machining. Best practices would be to machine in the annealed condition, use new HSS or Carbide cutting tools, plenty of coolant, higher feed rate with a decent depth of cut to make it through any work-hardened layer.Kurt PokopacSolutions Engineer

What Is the Carbon Content of 410 Stainless Steel?

410 stainless steels have around 0.1% carbon content. It has a higher carbon content than some mild steels, contributing to higher strength and reduced ductility. The general range of 0.08–0.15% is much less than that of medium-carbon steels which have 0.30-0.60% carbon.

What Are the Properties of 410 Stainless Steel?

The following table will give you a good understanding of some of the physical, thermal, chemical, and structural properties of 410 stainless steel.

| Property | Value |

|---|---|

Property Density | Value 7.8 g/cc |

Property Yield Strength | Value 1,225 MPa at a strain of 0.2% |

Property Ultimate Tensile Strength | Value 1,525 MPa |

Property Hardness | Value 126–192 Brinell hardness (annealed) or 201–255 Brinell hardness (hardened and tempered) |

Property Bulk Modulus | Value 200 GPa |

Property Melting Point | Value 1,480–1,530 °C |

Property Corrosion Resistance | Value Good corrosion resistance in milder environments, including chemical-laden ones and water. Pitting, corrosion, and staining happen in salt water conditions and acidic environments. |

Property Magnetism | Value Magnetic thanks to its martensitic structure and a permeability of 700–1,000. |

Property Thermal Conductivity | Value Low, 24–27 W/mK |

Property Coefficient of Thermal Expansion | Value 9.9 to 11.0 x 10-6/°C between 0–100 °C |

Property Minimum and Maximum Service Temperature | Value -70 °C (min), 400–580 °C (max) |

Property Machinability Rating | Value Moderately so at 55% for a 12% chromium alloy, but it will strongly depend on the steel’s specific carbon content and how it is heat treated. |

Property Applications | Value Scissors, knife blades, kitchen utensils, valves, pumps, pipe fittings, petroleum refining/processing equipment, firearm barrels, fasteners, screws, bolts, nuts, steam turbine blades, springs, and Belleville washers. |

410 Stainless Steel Properties

Is 410 Stainless Steel Magnetic?

Yes, 410 stainless steel is magnetic as it is made from martensite. It is highly attracted to magnets and carries magnetic flux very well, with a field permeability of 700–1,000.

Machinability Rating of 410 Stainless Steel

410 stainless steel is generally considered to be moderately machinable, at 55% for a 12% chromium alloy. The ease with which a material can be machined or shaped using various cutting processes is affected by the carbon content of the steel and by its work-hardened or quench-hardened/temper state. It is classified as a harder material to machine than the austenitic stainless steel grades 304 or 316. Higher carbon content contributes to its increased hardness, which results in tool wear and poorer chip formation. It's worth noting that the machinability of 410 stainless steel is heavily influenced by its heat treatment condition. It is recommended to consult with tool manufacturers and experienced machine operators for the best practices.

What Are the Thermal Properties of 410 Stainless Steel?

The thermal conductivity of 410 stainless steel is relatively low, ranging from 24 to 27 W/mK at room temperature. Its CTE is in the range of 9.9 to 11.0 x 10-6/°C between 0–100 °C. The specific heat of 410 stainless steel is approximately 460 J/kgK. 410 stainless steel has a maximum service temperature of between 400 and 580 °C after which the material’s mechanical properties degrade rapidly. The minimum service temperature is around -70 °C due to carbon content causing embrittlement at lower temperatures.

How To Heat Treat 410 Stainless Steel

Manufacturers typically heat treat 410 stainless steel through hot quenching and tempering to harden, strengthen, and toughen it. The process usually involves preheating the material to a temperature between 760–815 °C, and then when it’s hot, it gets quickly quenched in oil, water, or air. This freezes the steel’s microstructure when it has a fine crystallinity. Once this is done, it’ll often get tempered to reduce internal stress—and the temperature this is done at will determine how hard and ductile it remains.

- Preheat the material to 760–815 °C.

- Once heated, quickly quench in oil, water, or for lesser effect air. This freezes the hot microstructure of the steel, maintaining the fine crystallinity present in the heated material. Oil quenching provides a slower cooling rate compared to water, reducing the risk of cracking or distortion but reducing the hardness. For maximum hardness, the more rapid cooling of water quenching is necessary. More complex parts and parts with very variable cross-sections can distort the quenching effect, as relative cooling rates affect thermal contraction. Parts with internal defects—more common in forgings or castings—can also fracture during quenching. Air quenching is the slowest cooling option and is only suited to smaller parts. This can result in limited hardening, as the cooling time is such that greater crystal growth occurs.

- After quenching, the stainless steel is typically brittle and liable to have internal residual stresses. Tempering relieves internal stresses and improves the toughness, elastic limit, and ductility of the material. The tempering temperatures are between 150–370 °C depending on the degree of temper required—on items as diverse as springs to blade edges, for example. The tempering temperature determines the degree of hardness retained—lower tempering temperatures result in more hardness and higher temperatures in more toughness. Using a tempering furnace, hold the steel at the selected temperature for a sufficient time to allow for complete tempering. The time depends on the thickness of the component and the required characteristics. After the tempering period has passed, allow the part to air cool.

What Are the Common Forms of 410 Stainless Steel Material?

There are a few formats that are most typically found when you’re sourcing or making 410 stainless steel, and we’ve put a small explanation of shapes and finishing processes below:

Sheet

This is a flat-profile sheet material that often has a thickness between 0.5 to 3.5 mm and can come as a hot-rolled or cold-rolled variation, the latter usually being stiffer.

Bar

You can find bars in a few distinct shapes, including round, hexagonal, rectangular, or other customized dimensions. They can also go through hot and cold rolling, depending how hard you need it to be.

Plate

This type looks pretty similar to a sheet, but is usually thicker (though there isn’t a standard definition between when steel becomes a plate rather than a sheet). Typically plates are around 2 to 3 mm, but it’s a guide rather than a strict requirement.

Hot Rolled

This is a sizing process that gets ingots or billets into the thickness that manufacturers need for additional processing.

Cold Rolled

After sizing happens during hot rolling, steel can be cold rolled which gives it a nicer surface finish and more precise thickness. This process also work-hardens it slightly.

Annealed

Stainless steel that’s gone through annealing means that it hasn’t been hot- or cold-rolled and instead cooled from red hot to the stage it’s in now. This gives the material a better chance to grow its crystal structure without as many internal stresses.

Cold Drawn

Steel that goes through this will be cold-pulled through a die for better dimensions and work hardening. This process improves its strength and hardness, but reduces its ductility (and it can be brittle after).

| Country/Organizational Body | Equivalent Grade |

|---|---|

Country/Organizational Body Japan | Equivalent Grade JIS SUS 410 |

Country/Organizational Body AISI | Equivalent Grade AISI 416 / AISI 420 (close grade) |

Country/Organizational Body Europe | Equivalent Grade X12Cr13 (1.4006) |

Country/Organizational Body UNS | Equivalent Grade S41000 |

Country/Organizational Body EN | Equivalent Grade 1.4006 |

What Are the Advantages of Using 410 Stainless Steel?

Using 410 stainless steel brings various advantages to suit particular applications.

- Provides good corrosion resistance in mildly corrosive environments, normal atmospheric conditions, non-salt water, and most chemicals/solvents.

- It offers relatively high tensile strength and hardness when compared to other stainless steel grades.

- Due to its hardness, 410 stainless steel offers excellent wear resistance.

- It has good heat resistance, allowing it to maintain its mechanical properties at moderately elevated temperatures.

- While 410 stainless steel is only a moderately machinable material, with the appropriate tools and techniques good results can be achieved.

- It is relatively low cost, compared to most other stainless steel grades, because of its lower alloy content.

- 410 stainless steel responds well to heat treatment. This allows great adaptation of mechanical properties, according to application.

What Are the Disadvantages of Using 410 Stainless Steel?

While 410 stainless steel offers several advantages, there are also some disadvantages to consider.

- While 410 stainless steel exhibits good corrosion resistance in mildly corrosive environments, it is unsuited to aggressive or highly corrosive environments. It suffers from pitting corrosion and chloride ion-related stress corrosion cracking (SCC).

- It suffers from relatively poor weldability, compared to other stainless steel grades. With appropriate pre- and post-weld treatments, good results can be achieved by skilled personnel.

- 410 stainless steel becomes increasingly brittle as the temperature falls, with lowered toughness and impact resistance in sub-zero or cryogenic environments.

- While 410 stainless steel has good heat resistance, it is not as resistant to scaling and oxidation as some other stainless steel grades.

- It suffers from limited formability, compared to the austenitic stainless steels, so it is poorly suited to forming complex shapes.

- 410 Stainless steel is a magnetic material, which can be a limitation in sensing and medical applications.

What Is the Difference Between 410 Stainless Steel and 304 Stainless Steel?

410 stainless steel and 304 stainless steel have distinct differences in composition, properties, and applications. 410 stainless steel is martensitic, containing 11.5–13.5% chromium, which provides corrosion resistance, and minimal to zero nickel (0–0.75%). It also contains small amounts of carbon, manganese, phosphorus, and sulfur. 304 stainless steel, on the other hand, is an austenitic stainless steel containing 18–20% chromium and 8–10.5% nickel. It has a lower carbon content (max 0.08%) compared to 410 stainless steel, with trace amounts of manganese, silicon, phosphorus, and sulfur.

410 stainless steel provides good corrosion resistance, but only in mild or non-corrosive environments, such as atmospheric conditions and non-salt water. It is very susceptible to pitting and fracture corrosion in moderate chloride environments. 304 stainless steel has excellent corrosion resistance in a wide range of environments, including corrosive chemicals, acids, and saltwater. It is highly resistant to corrosion and staining. 410 stainless steel has high strength, impact resistance, and hardness which can all be improved by traditional heat treatment methods. 304 stainless steel offers lower strength and hardness compared to 410 alloys but has higher ductility and toughness, better elongation at break, and less brittle behavior than 410 stainless steel.

What Is the Difference Between 410 Stainless Steel and 18/8 Stainless Steel?

"18/8 stainless steel" is not a precise stainless steel grade, but a commonly used descriptor referring to a stainless steel alloy that contains approximately 18% chromium and 8% nickel. This alloy is most similar to AISI 304 stainless steel.

What Is the Difference Between 410 Stainless Steel and A2 Stainless Steel?

410 stainless steel and A2 stainless steel differ in their composition, mechanical properties, and applications. 410 stainless steel is formed from martensite crystalline structures and consists of 11.5–13.5% chromium, traces of nickel (0–0.75%), and the remainder primarily iron. It contains low levels of carbon, manganese, phosphorus, and sulfur and no measurable quantity of molybdenum. A2, on the other hand, is a group of austenitic stainless steels that include AISI 304 and closely related alloys. A2 stainless steel contains around 17–19% chromium, 8–10.5% nickel, and 2–3% molybdenum. It also contains small amounts of carbon, manganese, phosphorus, sulfur, and silicon.

How Xometry Can Help

We’re no stranger to working with various stainless steel materials here at Xometry, including 410. Some of the related services we offer that you can get a free quote for through our website include stainless steel 3D printing, stainless steel laser cutting, and stainless steel sheet metal fabrication.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.