When perusing the alloys available to you for manufacturing, it’s sometimes difficult to keep things straight between materials that look and behave similarly. Two metallic materials that often come to mind are bronze and brass, which are both machined, processed, and found in similar places but bring different properties to the table—which we’re going to explore more in depth below.

What Is Bronze?

Bronze is one of the many alloys out there, but it’s made up of a specific mix of copper and tin, as well as smaller concentrations of other elements, like phosphorus, silicon, zinc, arsenic, aluminum, and manganese. Bronze provides a nice blend of good corrosion resistance, low metal-to-metal friction, and decent ductility.

Bronze usually has a metallic finish in a reddish-brown hue, which you can see an example of in the picture below.

This alloy is no stranger to oxidation, however, and you may find bronze products or structures that are deeper brown and have a greenish-blue patina developing.

Advantages and Disadvantages

There are a few perks to working with bronze:

- Bronze tends to have better corrosion resistance when you compare it to brass—even when it’s exposed to seawater.

- It’s hard and durable, especially more so than copper and iron on their own.

- Its fatigue resistance is better than many steel types out there.

That said, there are also some downsides to be aware of with bronze:

- Bronze is hard, therefore it’s a little more difficult to work with than brass or copper.

- It’s susceptible to bronze disease, which is a type of corrosion that ruins the material and isn’t possible to reverse.

- It doesn’t have the best resistance to ammonia, cyanides, and ferritic compounds.

- It tends to oxidize much more easily than copper.

- It’s usually more expensive than brass.

What Is Brass?

Brass is also an alloy, like bronze, but rather than having tin in its composition, it has a mix of copper and zinc. You’ll also find various other elements and metals in the makeup of brass, including silicon, iron, aluminum, and manganese, which will impact its color and properties. As an example, if you have more zinc in your brass, you’ll get a material with better ductility and strength, whereas if you have extra manganese, the brass will have improved corrosion resistance. To boost its workability, sometimes lead is added.

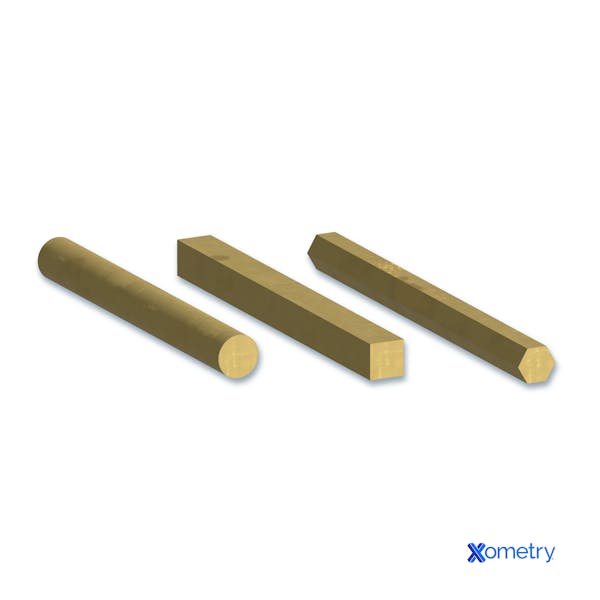

Brass usually has a yellow or golden hue—which you can see in the photo of brass rods below—but it’ll depend on what concentrations of elements are present. More zinc, and you’ll get a silvery finish, and more copper will give your brass a reddish tone.

Brass rods

Advantages and Disadvantages

You’ll find that brass has its own advantages as a material:

- Brass has better workability, machinability, and malleability when you compare it to bronze.

- Brass is also antibacterial, which can be useful in specific sectors.

- It usually has a gold color that’s more aesthetically pleasing than other metals and alloys.

You’ll also want to note the disadvantages that usually come with using brass:

- Brass can crack when it’s exposed to harsh chemicals like ammonia.

- It’s prone to tarnishing more so than some other materials.

- Brass has a slightly lower melting point than bronze (900 °C compared to 950 °C).

How They Are Made

The processes for making brass and bronze are relatively similar — the main difference you’ll spot lies in their concentrations of elements and what metals are added. For bronze, you’ll see about 88% copper and about 12% tin mixed together. For brass, you’ll see around 55–95% copper and a range of 5% to 45% zinc. Once the mixture is just right, manufacturers will melt them down, then cast them into molds. The molds will cool and harden, then will be moved on for processing where they’ll get prepped and ready for all kinds of applications.

Cost-wise, you’ll find that bronze is more expensive than brass since tin has a higher price than zinc. Copper also tends to be expensive, and since bronze has more copper than brass, this puts its price higher. You’ll find that making and purchasing bronze can be up to four times more expensive than brass.

Properties of Bronze and Brass

This table will give you a quick rundown of how bronze and brass compare when it comes to how they look and their properties and uses.

| Property | Bronze | Brass |

|---|---|---|

Property Color | Bronze Reddish-brown | Brass Goldish |

Property Alloying elements | Bronze Copper and tin | Brass Copper and Zinc |

Property Melting point | Bronze 950 °C | Brass 900 °C |

Property Corrosion resistance | Bronze Excellent (even in saltwater) | Brass Good |

Property Brittle/ductile | Bronze More brittle | Brass More ductile |

Property Magnetic | Bronze No | Brass No |

Property Applications | Bronze Instruments and parts like bells, cymbals, guitar strings, and architectural decorations, outdoor sculptures, bearings, bushings, springs, precision-grade machine parts, and submerged bearings and ship propellers. | Brass Instruments like saxophones, French horns, harmonicas, trumpets, and tubas, jewelry, coins, statues, decorative items, gears, bearings, locks, doorknobs, and valves. |

Bronze vs. Brass Properties

Does copper turn to bronze?

No, although there is copper in bronze’s composition, bronze also has other elements that make it an alloy. So, overtime, you won’t find that copper turns into bronze—only if tin and other element traces are added to the mix.

Are bronze and brass weldable?

Yes, you can weld both bronze and brass, but because of how well they conduct heat, it can be tricky. We recommend using a tip that’s larger (about one size bigger) than one you’d use for welding steel of a similar thickness, as this will make it easier.

Is bronze or brass more malleable?

Brass tends to be more malleable than bronze. Because bronze has tin in its makeup, it tends to have more hardness than its counterpart.

Are bronze and brass magnetic?

No, neither bronze nor brass are magnetic. That’s because they’re made up of metals and elements that aren’t magnetic, like copper, zinc, and tin. Sometimes nickel gets added to a bronze mixture, which gives it a slight magnetic pull, but overall these materials aren’t.

How Xometry Can Help

We’re very familiar with working with bronze and brass here at Xometry, and you can grab a free quote on our website for services that cater to both, too. You’ll find solutions, including bronze CNC machining, brass laser cutting, and brass CNC machining.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.