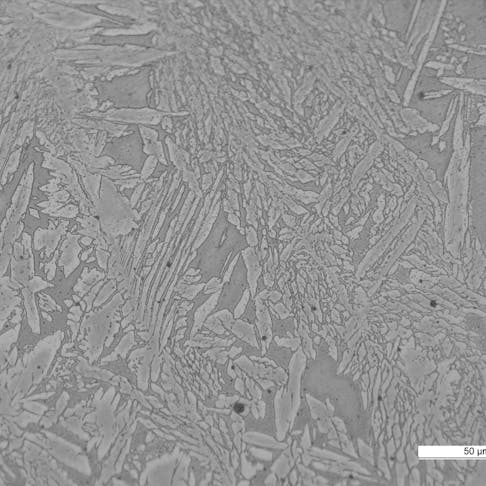

Super duplex steels play a vital role in a range of industries. These advanced stainless steel alloys are characterized by their unique composition and microstructure, and their excellent corrosion resistance properties. They find applications in demanding environments where durability and reliability are required. The microstructure of duplex stainless steel is a key factor that distinguishes it from other types of stainless steel and contributes to its exceptional properties. This microstructure is characterized by a dual-phase composition, typically consisting of roughly equal proportions of austenite and ferrite phases.

This article will discuss the versatile uses, alloy compositions, and outstanding properties of the super duplex family of stainless steels.

What Is Super Duplex Steel?

The super duplex stainless steels are a more highly alloyed, higher-performance subgroup of the duplex stainless steel family. The higher alloy content gives super duplex steels corrosion resistance better than that of standard austenitic stainless steels such as 316L. By looking at the exact levels of alloying elements, it is possible to calculate a “pitting resistance equivalence number (PREN), which predicts an alloy’s pitting corrosion resistance capabilities. The PREN number is calculated as the following:

PREN = %Cr + 3.3(%Mo + 0.5%W) + 16(%N)

The PREN of super duplex stainless steels is generally in the range of 38-45. It is much higher than the typical values of 25-36 for lean and duplex stainless steels and 23-32 for standard austenitic steels.

The super duplex steels are as corrosion resistant as the more expensive high-nickel/high-molybdenum “super austenitic” grades, particularly for resisting pitting corrosion, crevice corrosion, and stress corrosion cracking in acids, caustics, and chloride-rich environments like seawater. As a result, they may be used in industries such as the chemical, petrochemical, pulp, and paper sectors. They may replace both conventional and super-austenitic steels, nickel-based alloys.

How Is Super Duplex Steel Made?

Duplex steel undergoes a meticulous multi-stage manufacturing and forming process. Scrap steel and the intended main alloying additions are melted together in an electric arc furnace (EAF), where the raw materials are heated to a molten state. The molten steel is then transferred to an argon oxygen decarburization (AOD) converter. The steel then undergoes processes such as: decarburization, sulfur refining, and elimination of dissolved gasses. Alloying elements are also added to fine-tune the final chemical composition.

Following the AOD process, the molten steel is transported to a ladle furnace, where further refinement occurs. Once the steel has undergone these crucial steps, it is ready for casting. Depending on the intended application and production method, the molten steel can be cast into individual ingots or continuously cast blooms.

Subsequently, the solid steel ingots or blooms are reheated, forged, and rolled to achieve the desired thickness. To optimize the material's performance, the material undergoes solution annealing, ensuring a consistent internal structure. After annealing, quenching is performed to lock in the desired properties.

Finally, for a uniform and high-quality surface finish, the bars undergo mechanical “peeling” to remove the as-produced surface.

What Grade Is Super Duplex Steel?

There are several grades of super duplex stainless steel. The most common super duplex grades are 2507 and Z100. Other super duplex steels include 4501, UR 52N+, and 255.

What Are the Uses of Super Duplex Steels?

Super duplex stainless steel finds applications across various industries:

In the oil and gas sector, it's important for downhole tooling, wellhead, and subsea equipment, excelling in H2S-containing environments.

- A reliable choice for pollution control scrubbers.

- Marine applications such as propellers, shafts, rudders, and seals.

- For acid handling such as: sulfuric, nitric, and phosphoric acid.

- Water treatment, paper and pulp, pump shafts, and chemical and petrochemical applications.

- Used in components such as pumps, valves, pipework, and connectors across different industries.

What Is the Chemical Composition of Super Duplex Steel?

The chemical composition (by weight percentage) and the pitting resistance equivalent number (PREN) of several different super duplex stainless steels are given in Table 1 below:

| Name | 255/SD50 | 2507 | Z100 | UR52N+ | 4501 |

|---|---|---|---|---|---|

Name UNS | 255/SD50 S32550 | 2507 S32750

S39275 | Z100 S32760 | UR52N+ S32520

S32550 | 4501 S32760 |

Name EN No. | 255/SD50 1.4507 | 2507 1.441 | Z100 1.4501 | UR52N+ 1.4507 | 4501 1.4501 |

Name C (max.) | 255/SD50 0.04 | 2507 0.03 | Z100 0.03 | UR52N+ 0.03 | 4501 0.03 |

Name Mn | 255/SD50 1.5 | 2507 1.2 | Z100 1 | UR52N+ 1.5 | 4501 1 |

Name Si | 255/SD50 1 | 2507 0.8 | Z100 1 | UR52N+ 0.8 | 4501 1 |

Name Cr | 255/SD50 24.0-27.0 | 2507 24.0-26.0 | Z100 24.0-26.0 | UR52N+ 24.0-26.0 | 4501 24.0-26.0 |

Name Ni | 255/SD50 4.5-6.5 | 2507 6.0-8.0 | Z100 6.0-8.0 | UR52N+ 5.5-8.0 | 4501 6.0-8.0 |

Name Mo | 255/SD50 2.9-3.9 | 2507 3.0-5.0 | Z100 3.0-4.0 | UR52N+ 3.0-5.0 | 4501 3.0-4.0 |

Name N | 255/SD50 0.10-0.25 | 2507 0.24-0.32 | Z100 0.20-0.30 | UR52N+ 0.2-0.35 | 4501 0.20-0.30 |

Name Cu | 255/SD50 1.5-2.5 | 2507 0.5 | Z100 0.50-1.00 | UR52N+ 0.5-3.0 | 4501 0.05-1.0 |

Name Other | 255/SD50 - | 2507 - | Z100 W 0.5-1.0 | UR52N+ P(max.) 0.035

S(max.) 0.020 | 4501 P (max.) 0.03

S(max.) 0.010

W 0.5-1.0 |

Name PREN | 255/SD50 38-41 | 2507 40-43 | Z100 40-43 | UR52N+ >40 | 4501 40-43 |

Table Credit: https://www.imoa.info/molybdenum-uses/molybdenum-grade-stainless-steels/duplex-stainless-steel.php

What Is the Carbon Content of Super Duplex Steels?

The carbon content of super duplex stainless steels, and duplex stainless steels in general, is typically below 0.04%.

What Are the Properties of Super Duplex Steels?

The physical and mechanical properties of several super duplex stainless steels are listed in Table 2 below:

| Property | 255 | 2507 | Z100 | UR52N+ | 4501 |

|---|---|---|---|---|---|

Property Density (g/cm3) | 255 7.81 | 2507 7.8 | Z100 7.8 | UR52N+ 7.81 | 4501 7.8 |

Property Modulus of Elasticity (GPa) | 255 200 | 2507 200 | Z100 - | UR52N+ 205 | 4501 200 |

Property Elongation (%) | 255 16 | 2507 15 | Z100 25 | UR52N+ 25 | 4501 25 |

Property Tensile Strength (MPa) | 255 790 | 2507 795 | Z100 750 | UR52N+ 770 | 4501 805 |

Property Proof Stress 0.2% (MPa) | 255 570-600 | 2507 550 | Z100 550 | UR52N+ 550 | 4501 - |

Property Hardness (HB) | 255 <270 | 2507 310 | Z100 270 | UR52N+ 310 | 4501 290 |

What Are the Machinability Ratings of Super Duplex Stainless Steel?

The machinability of super duplex stainless steels is rated at 10-30% of the machinability of the plain carbon steel SAE 1112. Both duplex and super duplex grades combine a high level of strength and toughness with a low level of impurities such as sulfur which can facilitate machining by acting as "chip breakers." The super duplex stainless steels work harden more easily than other types of stainless steels during machining. The surface left behind by the passage of the tool is thus harder after the first pass, elevating the risk of tool damage and wear.

In machining super duplex stainless steels, it is critical to provide sufficient coolant to the interface of tool and workpiece to prevent heat damage to the tool. The recommended cut depth per pass is designed to remove the work-hardened layer from the previous pass while maintaining the desired machining quality.

Is Super Duplex Steel Magnetic?

Yes, super duplex steel is magnetic. Super duplex stainless steel microstructure is a blend of both austenitic and ferritic grains. While austenitic microstructures are non-magnetic, ferritic microstructures exhibit magnetic properties. Consequently, super duplex grades are also categorized as magnetic due to the presence of these ferritic components in their composition.

Is Super Duplex Steel Durable?

Super duplex steel has the potential to be durable when used appropriately. It offers exceptional strength and corrosion resistance, making it suitable for use in demanding environments, including those with corrosive substances such as: acids, seawater, and chemicals.

Does Super Duplex Stainless Steel Rust?

Yes, super duplex stainless steel, although having a high level of rust, corrosion, and pitting corrosion resistance, is not impervious to rust. This steel is, however, less prone to rust than other types of stainless steel. It contains a significant amount of chromium, which forms a protective oxide layer on its surface. This oxide layer acts as a barrier, preventing the steel from rusting when exposed to oxygen and moisture. Super duplex steel's excellent corrosion resistance makes it suitable for use in environments with corrosive substances, such as seawater, acids, and chemicals, where it maintains its integrity.

What Are the Thermal Properties of Super Duplex Steel?

The thermal properties of some common super duplex steels are outlined in Table 3:

| Property | 255 | 2507 | Z100 | UR52N+ | 4501 |

|---|---|---|---|---|---|

Property Thermal Conductivity (W/m·K) | 255 14.2 | 2507 19 | Z100 15 | UR52N+ 17 | 4501 15 |

Property Thermal Expansion (m/m·K) | 255 12.8-13.8 to 300 °C | 2507 14.5 to 300 °C | Z100 12.8-13.3 to 200 °C | UR52N+ 13.5 to 200 °C | 4501 13-14 to 300 °C |

Property Specific Heat 0-100°C

(J/kg·K) | 255 475 | 2507 460 | Z100 500 | UR52N+ 450 | 4501 500 |

What Are the Commonly Available Forms of Super Duplex Stainless Steels?

The most commonly available forms of super duplex stainless steel material include:

Sheet

Super duplex stainless steel sheets are flat, thin pieces typically used in various applications where corrosion resistance and strength are required. They are versatile and can be cut or shaped to suit specific project needs. Super duplex stainless steel sheets are used in a variety of applications, including chemical processing, oil and gas structures, marine components, desalination equipment, aerospace parts, power generation, architectural elements, water treatment, food and beverage industry equipment, mining, and renewable energy systems, owing to their exceptional corrosion resistance and strength.

Bar

Super duplex stainless steel bar stock consists of solid, long pieces, often cylindrical in cross-section. It is used in the manufacture of components and structures where high strength and corrosion resistance are essential, such as: boat shafts, fasteners, and supports.

Plate

Super duplex stainless steel plate is thicker than sheet stock. They are commonly used in structural and industrial applications where corrosion resistance, strength, and durability are critical, such as in pressure vessels and tanks.

Pipes

Super duplex stainless steel pipes are tubular structures made from the material. They are designed for transporting liquids and gasses in corrosive environments, making them a popular choice in the oil and gas industry, as well as in chemical processing.

Tubes

Super duplex stainless steel tubes are similar to pipes but are smaller in diameter. They are commonly used in heat exchangers, condensers, and high-pressure applications where resistance to corrosion and high-stress conditions is crucial.

What Are the Equivalents of Super Duplex Steel?

The equivalents of some common super duplex steels are given in Table 4:

| Grade | UNS No | Euronorm No. | Euronorm Name |

|---|---|---|---|

Grade 255 | UNS No S32550 | Euronorm No. 1.4507 | Euronorm Name X2CrNiMoCuN 25-6-3 |

Grade 2507 | UNS No S32750 | Euronorm No. 1.441 | Euronorm Name X2CrNiMoN25-7-4 |

Grade Z100 | UNS No S32760 | Euronorm No. 1.4501 | Euronorm Name X2CrNiMoCuWN25-7-4 |

Grade UR52N+ | UNS No S32520 | Euronorm No. 1.4507 | Euronorm Name X2CrNiMoCuN25-6-3 |

Grade 4501 | UNS No S32760

S39276 | Euronorm No. 1.4501 | Euronorm Name X2CrNiMoCuWN25-7-4 |

What Are the Advantages of Using Super Duplex Steels?

Super duplex stainless steels offer a wide range of advantages, including:

- Has exceptional strength, providing structural integrity and durability in demanding applications.

- Exhibits high resistance to pitting and crevice corrosion, ensuring longevity even in aggressive environments.

- Highly resistant to stress corrosion cracking, corrosion fatigue, and erosion, making it reliable in critical conditions.

- Excels in chloride resistance, crucial in environments with chloride-containing substances.

- Demonstrates excellent resistance to sulfide stress corrosion, which is particularly vital in "sour service" applications. "Sour service" refers to environments where the presence of hydrogen sulfide (H2S) gas, often found in oil and gas production, can lead to corrosion-related issues

- Formable and weldable, allowing for versatility in manufacturing and construction processes

- Has a high toughness, making it suitable for applications where sudden impacts or dynamic loads may occur

What Are the Disadvantages of Using Super Duplex Steel?

The potential disadvantages of super duplex steels are listed below:

- Is generally more expensive than standard austenitic or ferritic stainless steels due to its higher alloy content. This cost factor can be a limitation for some projects.

- The potential for the precipitation of embrittling phases in certain temperature ranges, which can reduce the material's toughness and impact resistance.

- Its high strength and work hardening tendencies make it challenging to machine and form. This can lead to difficulties in manufacturing components, especially on-site, and may require specialized tooling and machinery.

- Exhibits a DBTT (Ductile to Brittle Transition Temperature), which, while relatively low at about -50°C, can still be a limitation in certain applications, particularly those involving sub-zero temperatures.

Is Super Duplex Steel Better Than 316 Stainless Steel?

It depends. Super duplex steel offers distinct advantages, particularly in terms of strength and corrosion resistance. It is significantly stronger than 316 stainless steel. Super duplex steel excels in aggressive environments, providing excellent resistance to pitting and crevice corrosion, and stress corrosion cracking. These characteristics make it a preferred choice for industries such as oil and gas. However, its higher alloy content and lower availability result in a higher cost.

T316 stainless steel, on the other hand, is a cost-effective option for applications in marine or mildly corrosive environments where extreme strength is not essential. Moreover, 316 stainless steel is easily weldable and widely available. Ultimately, your selection should align with your project's specific needs, budget constraints, and the environmental conditions to which the material will be exposed.

To learn more, see our guide on 316 Stainless Steel Properties.

Is Super Duplex Stainless Steel Expensive?

Yes. Super duplex stainless steel commands a higher price than duplex stainless steel. This is primarily due to its increased nickel and molybdenum contents. Super duplex stainless is stronger than duplex steel, and demonstrates remarkably low corrosion rate in corrosive settings, notably in marine and petrochemical industry applications, outlasting duplex steel.

What Is the Difference Between Duplex and Super Duplex Stainless Steels?

Duplex and super duplex stainless steels are both families of stainless steel alloys known for their exceptional corrosion resistance and high strength. Duplex stainless steels comprise a family of alloys known for their remarkable corrosion resistance and high strength. It is characterized by a unique two-phase microstructure consisting of both austenite and ferrite phases. Within this family, there are several categories based on their pitting corrosion resistance, often measured by the PREN (Pitting Resistance Equivalent Number) value.

Lean duplex stainless steels feature a reduced level of alloying elements and have lower PREN values. They are suitable for applications where corrosion resistance requirements are moderate. Standard duplex stainless steels strike a balance between corrosion resistance and strength and are characterized by a moderate PREN value.

Super duplex stainless steels, on the other hand, occupy a middle ground with PREN values typically falling between 38 and 45. They boast higher levels of key alloying elements such as chromium, nickel, and molybdenum, offering superior resistance to pitting and crevice corrosion. Additionally, the inclusion of nitrogen enhances structural integrity and mechanical properties, making them well-suited for highly corrosive environments, including those containing acids and caustic solutions.

Hyper duplex stainless steels represent a specialized subset of duplex alloys with even higher PREN values, typically exceeding 45. Engineered for the most demanding applications, hyper duplex steels feature exceptionally elevated levels of chromium, nickel, molybdenum, and nitrogen. It provides unparalleled resistance to a wide range of corrosive agents, including harsh acids and seawater.

To learn more, see our guide on Duplex Steel.

What Is the Difference Between Super Duplex Steel and 304 Stainless Steel?

Super duplex stainless steel has a unique combination of strength and corrosion resistance. In contrast, 304 stainless steel, an austenitic alloy, provides good formability but is less robust in corrosive environments. Super duplex stainless steels typically contain higher chromium (24-28%), moderate nickel (up to 9%), molybdenum (up to 5%), and nitrogen (up to 8%) levels, while 304 stainless steel features lower chromium (18-20%), higher nickel (8-10.5%), no molybdenum, and no added nitrogen. Super duplex stainless steels excel in highly corrosive settings, such as offshore oil and gas equipment, whereas 304 stainless steel is more commonly used in milder environments such as food handling and other general-purpose applications.

To learn more, see our guide on Properties of 304 Stainless Steel.

Summary

This article presented super duplex steel, explained it, and discussed its various applications and compositions. To learn more about super duplex steel, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.