Sheet metal forming is a process used in many industries to make metal parts from thin metal sheets. It’s actually one of Xometry's most popular manufacturing methods. Our customers use the Xometry Instant Quoting Engine® to get automatic quotes on everything from simple brackets to aircraft parts and sheet metal assemblies. In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons.

What is Sheet Metal Forming?

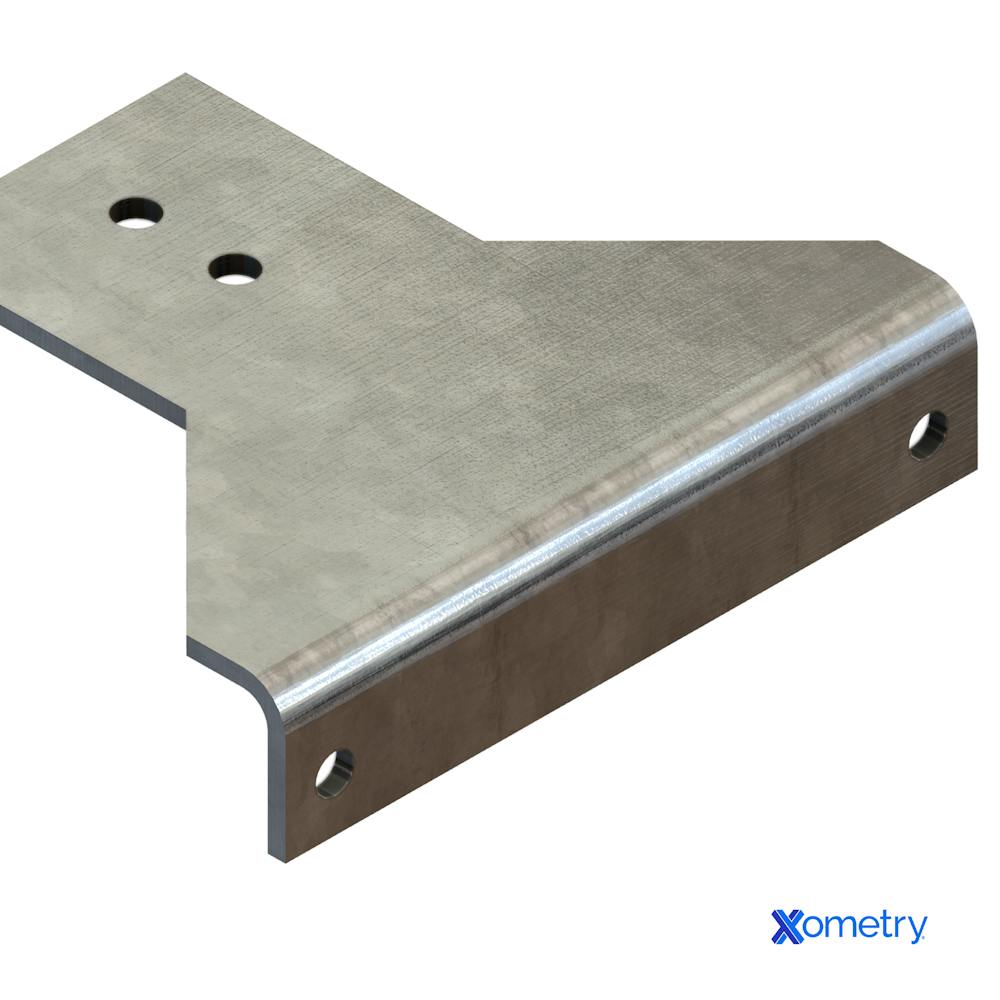

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different processes and equipment, which we’ll cover a little further down. The material then goes through any necessary finishing steps, like surface treatment, deburring, or welding.

The reason for this process’s popularity is that sheet metal is both tough and malleable, making it easy to manufacture different parts that, despite being bendy and lightweight, are still strong and durable. It’s not limited to just food and drinks cans, however; almost anything can be made using sheet metal forming, including appliances, furniture, structural components, and HVAC systems. In fact, if you take a look around you right now, it's likely you'll come across some product that incorporates sheet metal into its design.

Depending on the type of metal used, the number of processing steps needed to achieve the final form, and the complexity of the design, steel metal forming is also relatively inexpensive compared to similar processes, like forging and metal stamping. Simple designs in standard sizes can be particularly cost-effective.

Sheet Metal Forming Equipment

The relevant tools and equipment needed to form sheet metal will depend on what you want to make. For example, if you need specially shaped holes, cutting with punches and dies would be best. Shearing tools are also useful for cutting off small unwanted slithers in a straight line. Rollers are used to make cone or cylinder-shaped items, and to bend the metal you’ll need something like a press brake.

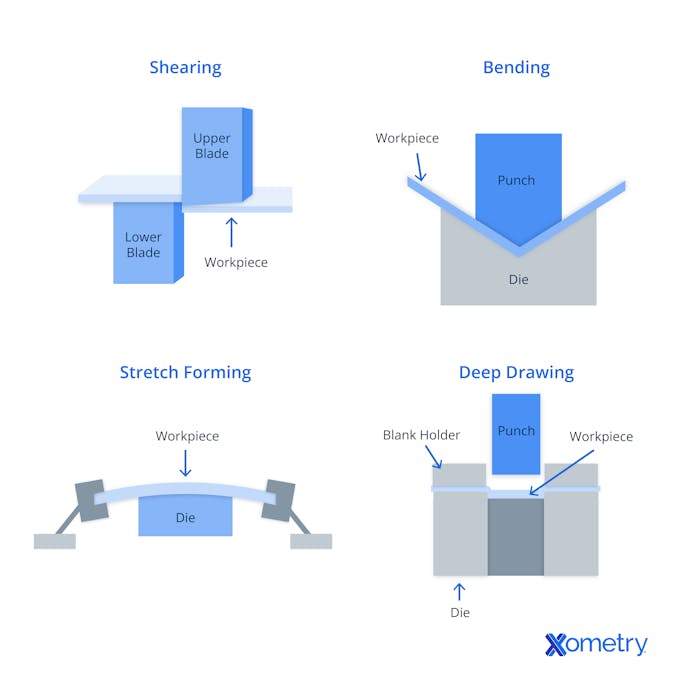

Sheet Metal Forming Processes

Let’s talk a little more about sheet metal forming’s various processes as each one is better-suited for making different items.

Laser Cutting

Before metal sheets get formed, many times the initial flat patterns are laser cut first. Laser cutting uses a high-powered laser to cut shapes into flat metal sheets. It’s one of the most precise methods and can make a plethora of shapes, patterns, and holes. To start laser cutting sheet metal, a blank sheet is attached to the cutter’s bed, and then the laser itself does all the hard work. The machine’s laser beam is controlled by a CNC (computer numerical control) system so that highly accurate and clean cuts can be made. The system can also pre-program different patterns and repeat them again and again.

There is very minimal post-processing needed with this method, and hardly any waste. It is commonly used in automotive, aerospace, and electronics. At Xometry we offer sheet cutting as a standalone service and offer many metals like steel, stainless steel, aluminum, and copper. A potential downside of this method is its high initial cost—the machinery is quite pricey. This is why many customers turn to Xometry for their laser cutting needs. Visit our sheet cutting services page to learn more about what we offer in this area.

Bending

One of the most commonly utilized sheet metal forming processes at Xometry is bending. Bending sheet metal requires the use of specialized but fairly simple bending tools, like press brakes. The sheet metal bending process is quick, accurate, and one of the most inexpensive. The process is used to (as the name suggests) make bends and curves on the metal sheet in a straight line. With press brakes, the metal is put or clamped into place and then bent to the required angle.

This sheet metal forming process is often used for vehicle body parts, enclosures, and electrical components. It can be performed on most compatible sheet metal forming materials, like stainless steel, brass, aluminum, and galvanized steel. It does have some limitations, however; the metal needs to have the same thickness throughout, and thicker materials will understandably be much harder to bend.

Curling

This process adds a hollow circular roll to the edge of the sheet metal it’s working on to smooth them out, improve safety when handling, and add strength. During curling, the sheets are fed into machines that slowly roll or bend the edges into smooth, rounded shapes. Some curled features require specialized tooling, and machinery might be required for complex shapes or tight rolls.

Depending on their thickness and how ductile they are, most metals can be put through the curling process, including steel, aluminum, and brass. The process is used in HVAC, appliance manufacturing, and architecture for edges on panels, trim, or housings.

Ironing

Ironing is used to make sheet metal parts smoother and ensure they have an even thickness. This is done by pushing the part through one or more metal-shaping dies that press it, slowly making it thinner and longer without changing its shape too much.

It’s great for products that need the same thickness throughout, like soda cans, and ideal for bendy and stretchy metals like steel and aluminum. The method needs specialized tools and machinery and can’t be used for parts that need drastic shape changes.

Hydroforming

This process uses high-pressure fluid to shape sheet metal and can also handle more complex shapes. The blank sheet is held in place over a die, which is in the shape of the final product. The sheet and hydraulic chamber are sealed off, and fluid is pumped directly into the chamber at high speed. As the hydraulic pressure builds up, the fluid presses the metal against the die, forcing it to conform to the shape of the die. It’s suitable for aluminum, stainless steel, brass, and other ductile metals and is commonly used in automotive, medical, and aerospace.

Hydroforming can create shapes with even thickness and very little waste. It’s also one of the more affordable sheet metal forming methods for creating complex pieces in high quantities. Hydroforming equipment, though, is expensive to buy and the forming dies can require a higher upfront investment.

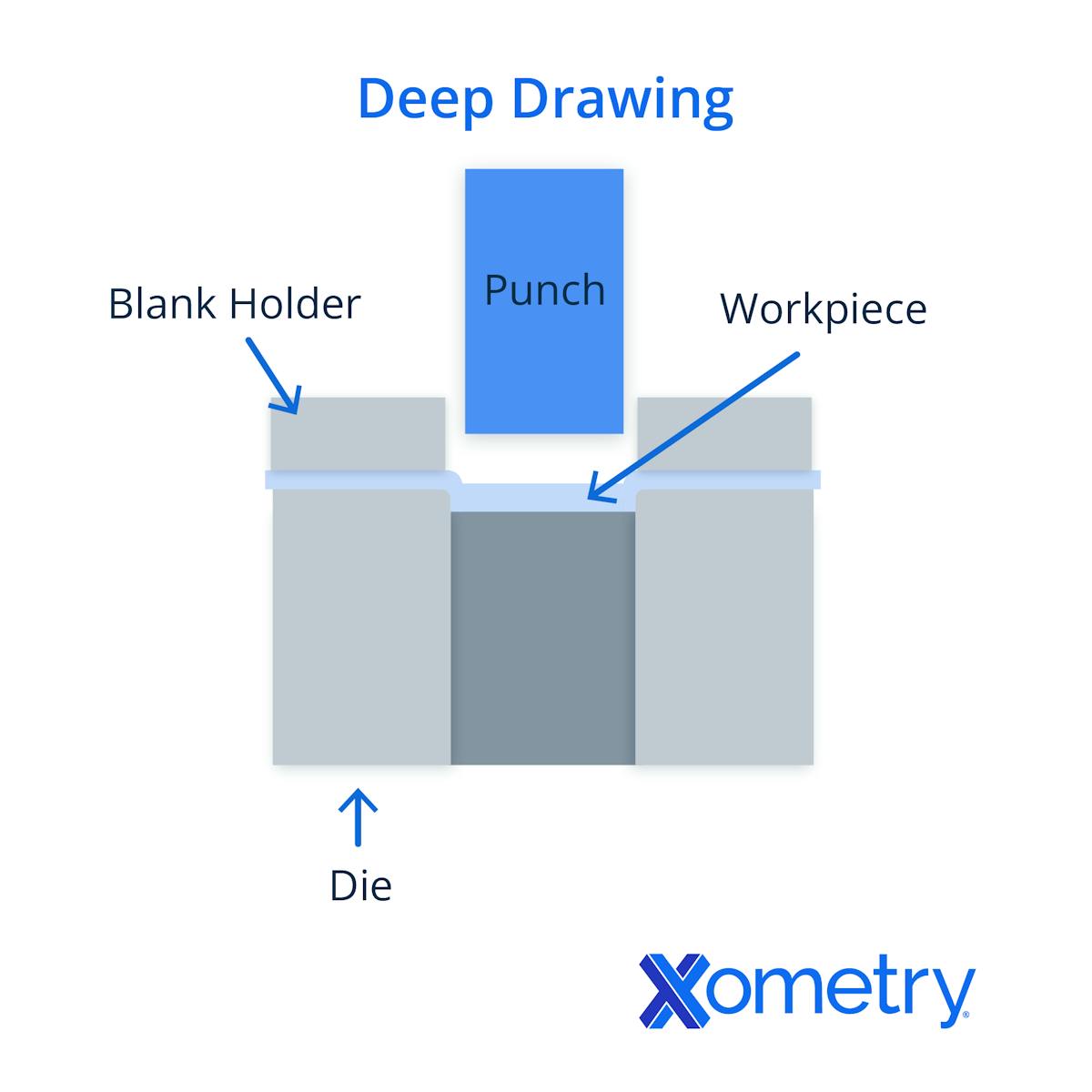

Deep Drawing

For intricate and hollow cylindrical shapes like cooking pots, beverage cans, and car door panels, many manufacturers turn to deep drawing. The process involves the sheet metal being placed over a die, then pressed with a punch into an open cavity, causing the material to undergo plastic deformation. The process allows for precisely made complex shapes and designs with deeper features.

Materials common in deep drawing include malleable metals like aluminum, copper, brass, and stainless steel. Minimal manual labor is needed with this method, and it’s cost-effective for high-volume production.

Shearing

Shearing is used to cut sheet metal along a straight line, which is helpful when either cutting the material into smaller pieces or trimming its edges. A shearing machine has two blades that slide past each other, like giant scissors, to cut the metal. A sheet has to be placed on the machine, clamped into place, and then its upper blade is lowered onto the material to make the cut. This is one of the most widely used processes for sheet metal forming, mainly because it’s convenient, quick, produces minimal waste, and reduces costs when making high volumes.

The manufacturing, construction, and auto industries all use it for shearable materials, like steel, aluminum, and stainless steel. The process does sometimes cause the edges to deform or burr, especially when working with thicker materials which some shearing machines might particularly struggle with. For more complex shapes, you’ll have to add in an additional forming process, as this one only does straight-line cuts.

Punching

Just like your average paper hole punch, this sheet metal forming method makes holes, slots, or specific shapes by punching the unwanted material out. The metal sheet is held in place against a die, which is in the shape of the final cut-out. A punch is driven down into the sheet metal, pushing it into the die, which shears off the material precisely along the edges of the die, producing the completed cut-out in the material. This automated process is quick, efficient, and ideal for high-volume production of enclosures, brackets, panels, and many other products.

While it can be used with various different metals, some machines might not be able to punch through thicker materials. The more advanced and capable machines are pricey, and you’ll still have to do a bit of post-processing, especially for more complex designs.

Compatible Materials for Sheet Metal Forming

There are mainly six sheet metal materials that are used in manufacturing and suitable for sheet metal forming. At Xometry, we offer instant quoting on sheet metal forming for these materials and more.

Stainless steel: This material is super strong, has good malleability, and is corrosion resistant, making it very common in medical, and food and beverage.

Aluminum: Another option with excellent corrosion resistance and malleability is aluminum. This lightweight metal also has thermal and electrical conductivity, and an impressive strength-to-weight ratio. It’s used in everything from household and industrial appliances, aerospace components, and power lines.

Hot-rolled steel: Used in construction and for things like automotive chassis and railroad tracks, hot-rolled steel is a cost-effective material that’s fairly easy to form, although it’s not designed for parts that need extreme precision.

Cold-rolled steel: There are a few more steps to forming this material than hot-rolled steel but this just makes it stronger. It’s used in home appliances, structural components, and aerospace parts.

Galvanized steel: This is a durable and affordable metal with good corrosion resistance. It’s often used in roofing, air conditioning, refrigeration, and industrial machinery.

Copper: This extremely malleable material has good electrical and thermal conductivity which is why it’s so often found in electrical applications.

We often form sheet materials 0.6mm to 6.35mm thick, but depending on the design and the type of metal, we can support other gauges.

Advantages of Sheet Metal Forming

Despite the multitude of different processes available, many industries time and time again turn to sheet metal forming for their manufacturing needs. This versatile method is less expensive than some other manufacturing methods, like casting or forging. The process is flexible, allowing for many different designs and applications.

As the metal sheets used are typically very thin, the parts are lightweight with great strength-to-weight ratio. Sheet metal forming offers malleability, precision (both in the forming processes and parts created), and can be formed with lots of different metals, such as the ones we've outlined in the section above. The created parts are strong, durable, weather-resistant, high load-bearing, and long-lasting. Another reason companies love sheet metal forming is because they’re able to produce items in small batches—ideal for rapid prototyping.

Disadvantages of Sheet Metal Forming

Sheet metal forming might not be ideal in certain circumstances. For instance, it’s not the best for making parts with highly complex designs, and a more detailed product could end up taking much longer and costing a lot more. To start making products yourself using sheet metal forming, you’ll need to make a hefty initial investment for all the equipment and tools needed (unless you let Xometry handle things for you). Also, the process often requires numerous manual steps, making it quite labor-intensive.

For certain less malleable materials, you’ll have to look for another manufacturing method, as sheet metal forming is not suitable for these types of metals. For example, tool steel is a hard and brittle material that’s not ductile or malleable. If you were to put it through metal forming, it would simply crack or break in a non-usable condition.

Applications of Sheet Metal Forming

Sheet metal forming’s disadvantages aren’t enough to dissuade countless industries from avidly using it—its pros far outweigh the cons. In aerospace, sheet metal forming is used often for fuselages and the structural components in aircraft and spacecraft. The automotive industry also uses it for structural parts like body panels and chassis components.

Housings and enclosures for medical equipment and devices are often made via sheet metal forming as this process meets the industry’s strict standards and regulations. The process is used a whole lot in construction for things like beams, columns, brackets, long-lasting and weather-resistant roofing sheets, and ductwork for HVAC systems. In household appliances, you’ll find many parts, like enclosures and frames, that are made via sheet metal forming. If you use a desktop computer with a tower, you're likely to find it's comprised of metal sheet cut and bent panels.

How Can Xometry Help

Sheet metal cutting and forming is one of Xometry's core offerings. We serve a multitude of industries and customers, from aerospace and automotive to medical and more. We can bend and shape various materials like aluminum, stainless steel, and even titanium, among others. Best of all, you can get instant pricing and lead times for custom parts when you use the Xometry Instant Quoting Engine®. Get started today by uploading CAD files of your bent or cut designs and get an instant quote!

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.