The laser technology sector has seen a rapid expansion in techniques, power output, and beam quality since the first working laser was demonstrated in 1960. The major types of technologies developed to produce coherent, collimated light beams are summarized below. Each of these laser types has given rise to variants, some of which have become important technologies in their own right.

Listed below are 11 different types of lasers:

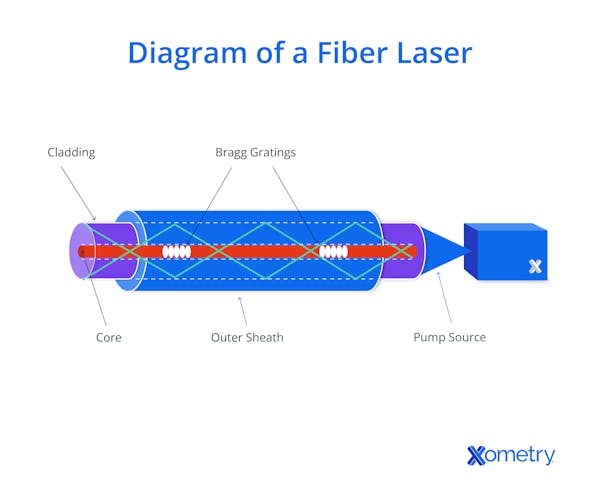

1. Fiber Lasers

Fiber lasers are a category of solid-state lasers that integrate an optical fiber as the lasing medium. They are known for their high power output, energy efficiency, and excellent beam quality. The lasing process takes place in the fiber medium, typically rare-earth-doped with erbium or ytterbium. Fiber lasers operate across a broad power range—from a few watts to several kilowatts—while maintaining high electrical efficiency. They create exceptionally efficient output energy from electrical power. This efficiency is achieved due to the distributed (i.e., not concentrated) gain medium (the fiber) and the resulting ability to lose heat. They produce excellent beam quality, characterized by narrow divergence and a near-Gaussian beam profile. This allows precise focusing, suiting applications requiring high precision and small area energy application. They’re compact and flexible in design. The fiber's flexibility allows for easy delivery of the radiation, suiting integrated applications and complex/flexible delivery paths.

Fiber lasers are stable and robust. A solid-state lasing medium and the absence of moving parts render them unaffected by the environment to a high degree and low maintenance. They enable wide wavelength selection, from infrared (IR) to ultraviolet (UV). The choice of the dopant defines the operating wavelength. Fiber lasers are applicable to most sectors: manufacturing, telecommunications, defense, medical, research, and spectroscopy.

To learn more, see our full guide on Fiber Lasers.

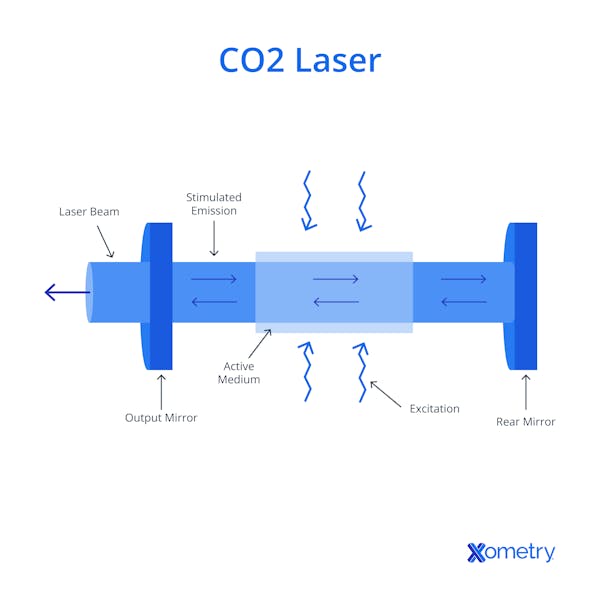

2. Gas Lasers

Gas lasers use a gas mixture as the active lasing medium. The lasing is typically initiated by an electrical arc, which triggers stimulated emission. Variations within the class are significant in their different capabilities in wavelength and power, though their structures and operations are similar. Helium-neon (HeNe) lasers employ a mixture of helium and neon as the active medium. They produce (visible) red light at 632.8 nanometers (nm) and are suited to low-power, eye-visible applications. Carbon dioxide (CO₂) lasers use a mixture of carbon dioxide, nitrogen, and helium as the active medium. They generate infrared (IR) light at a wavelength of 10.6 micrometers (μm). High power at low construction cost makes them widely used in industry for cutting. Argon-ion lasers use ionized argon as the active medium. They emit visible light at various wavelengths. They are used in display systems and research.

Excimer lasers use a blend of noble gases as an active medium: argon, krypton, and xenon, with fluorine or chlorine. They produce ultraviolet (UV) light at selected wavelengths defined by the gas mixture. They are widely used in medical and industrial applications. Krypton-ion lasers use ionized krypton as the active medium. They emit visible light in the red and green spectra. These lasers are used in scientific research and display technologies. Nitrogen lasers use nitrogen (N2) as the active medium. They produce pulsed UV and are used in research, spectroscopy, and laser fluorescence.

3. Excimer Lasers

Excimer lasers are an example of a subcategory morphed into a standalone classification. They are a type of gas laser, but their properties differ in key regards from general gas lasers, and they have characteristics that make them optimal for a number of applications. They can deliver ultraviolet (UV) emission at a relatively low cost, which is an unusual and useful feature. Some examples of excimer lasers are those available with 193 nm emissions (argon fluoride, ArF), 248 nm (krypton fluoride, KrF), and 308 nm (xenon chloride, XeCl).

Excimer lasers operate exclusively in pulsed mode, offering high peak power and short pulse durations. This makes them suitable for precise material ablation and micro-material processing applications. They are known for their strong photoablation effects, as the high-energy UV photons break chemical bonds in target materials, removing atoms in a controlled and precise manner. This property makes excimer lasers particularly valuable in semiconductor fabrication (microlithography), LASIK eye surgery, and dermatology.

4. Semiconductor Lasers (Diode Lasers)

Semiconductor lasers or diode lasers use a p-n junction arrangement as the active medium. They are compact in size, have high efficiency, and are versatile. Semiconductor lasers are structurally simple, as they are directly electrically pumped (i.e., not laser, arc, or flash-tube-initiated). Applying a forward bias current to the junction triggers the emission of laser light, as holes and electrons meet at the junction and are canceled out with the emission of a coherent photon. Diode lasers are extremely compact, often measuring only a few millimeters, which allows for easy integration into devices and laser arrays. This is particularly useful for fiber-optic comms applications and for portable devices. They have high electrical efficiency, using only slightly more electrical power than they emit as laser radiation, making them suitable for battery-powered devices. Their class output across various types covers various wavelengths, defined by semiconductor dopants, bandgap, and amplifier structure: infrared, visible, and ultraviolet. This equips the class for most applications. These lasers are also used as efficient pump sources for other types of lasers, such as Nd:YAG, providing a compact alternative to xenon flash-tube pumping.

5. Dye Lasers

Dye lasers are a class that uses organic dye solutions as the active medium. They offer great tunability across the visible and near-infrared spectrum. Dye lasers can generate high-energy pulses of short duration. A typical xenon discharge tube exciting a dye laser will deliver intense bursts of light. This is ideal for time-resolved spectroscopy, photochemistry, and laser-induced breakdown spectroscopy. They are highly wavelength tunable across a broad spectral range by changing the dye solution or adjusting the optical amplification cavity. This results in a wide range of wavelength radiation, from UV to NIR (near-infrared). Dye molecules result in a wide gain bandwidth, generating ultrashort pulses of femtosecond or picosecond durations. This makes them suited to research and medical applications, allowing very precise control of energy levels.

6. Solid-State Lasers

Solid-state lasers use a solid, generally doped crystalline material as the active medium. They have advantages and are heavily used in several fields. Solid-state lasers are capable of producing high-power output in continuous wave (CW) or pulsed mode at high efficiency. They cover a wide range of emission wavelengths (IR to visible UV) depending on the dopants. Examples are neodymium-doped yttrium aluminum garnet (Nd:YAG) lasers, erbium-doped fiber lasers, and titanium-sapphire lasers. They typically produce beams with excellent spatial and temporal coherence, enabling close focus, limited divergence, and low beam distortion.

Solid-state lasers are renowned for stability and reliability, as the solid-state medium is robust and less susceptible to environment, vibrations, and misalignments. Q-Switching (rapid modulation) and mode-locking (rapid, ultrashort bursts) enable them to produce short-duration, high-intensity laser pulses. This is useful in applications such as laser marking, lidar systems, laser ranging, and ultrafast spectroscopy. Many solid-state lasers can be directly pumped using laser diodes, enabling simplified designs and improved power efficiency.

7. Chemical Lasers

Chemical lasers generate laser light from a chemical reaction excitation source. Violent exothermic chemical reactions between two or more initial chemicals produce a population inversion (of electrons in the excited state), resulting in stimulated emission for very high outputs. High output is possible, often in the megawatt range, from compact sources. This intensity makes chemical lasers valuable for military systems, laser-induced plasma, and high-energy physics. They can be operated in CW or pulsed mode. Pulse-mode chemical lasers are often used in military and defense applications, including directed-energy weapons and laser-based missile defense systems.

The chemical oxygen-iodine laser (COIL) is a specific type used primarily in research and development. It operates by reacting chlorine gas and hydrogen peroxide to produce energetic oxygen and iodine molecules, which undergo stimulated emission. COIL lasers have been studied for potential applications in cutting and welding, materials processing, and space propulsion systems. This class of laser was popular in military development in the 1970s, but they’ve largely been supplanted by technically more complex but less violent and more easily contained devices. Chemical lasers have severe limitations, including the requirement for violent chemical reactants, structure complexity, and the need for specialized handling and safety measures of the reactive agents involved.

8. Metal-Vapor Lasers

Metal-vapor lasers excite metal vapor as the active medium to generate laser light. They operate by exciting metal atoms or ions to higher energy levels, which then undergo stimulated emission to produce coherent laser radiation. Metal-vapor lasers have uniquely useful properties, such as the ability to emit in the extreme UV spectrum. These lasers use a vaporized metal as the active medium. Common metals used include copper, gold, silver, and mercury. The metal vapor is typically created by heating a metal sample to its vaporization temperature using another laser type. They primarily emit in the visible and UV spectra, depending on the metal used. Copper-vapor lasers emit green light at around 510 nm, while gold-vapor lasers emit yellow light at around 628 nm.

Metal vapor lasers are capable of producing high energy emissions, delivering intense radiation with high overall efficiency. They are ideal for applications that require high-energy output. These devices can generate short pulses in the nanosecond range. This property is particularly useful in applications that require precise temporal control, such as laser-induced breakdown spectroscopy and time-resolved spectroscopy. They have been used in various industrial and scientific applications. Copper-vapor lasers, for example, are employed in laser marking, laser engraving, holography, and scientific research. Gold-vapor lasers have been utilized in medical treatments, dermatology, and photochemical processes. The extreme UV lasers used in the highest resolution lithography processes are metal-vapor based, using tin vapor to produce laser light at near X-ray frequencies. This short-wavelength light has allowed higher-resolution imaging to reduce microprocessor feature sizes and allow a higher density of components on a single wafer.

Metal-vapor lasers can produce laser beams with high beam quality, characterized by a well-defined focus, low divergence, and good spatial coherence. They are excited using various methods: electrical discharge, laser excitation, and electron-beam excitation, among others.

9. Free Electron Lasers (FELs)

FELs generate laser light by passing a high-energy electron beam through a magnetic undulator, causing the electrons to emit coherent radiation. The free electrons originate from a linear accelerator, and their energy level determines the wavelength of the resultant radiation. FELs can cover a broad range of wavelengths, from the infrared to the X-ray region, because of the precise control of electron energy levels. This wide tunability makes FELs versatile for a wide range of applications. Through self-amplified spontaneous emission (SASE), they amplify the radiation. The effect on the electron beam of an oscillating magnetic field causes the electrons to emit radiation. This stimulates further emission, leading to amplification.

FELs can produce remarkably high peak powers and femtosecond pulses. This makes them suited to studying nonlinear phenomena, high-intensity interactions, and investigations of ultrafast dynamics. The intense and tunable X-ray beams emitted are ideal for image technologies, such as X-ray diffraction, X-ray microscopy, and X-ray spectroscopy, in various fields of fundamental research. A sub-category is free electron laser oscillators (FELOs). These use resonant optical cavities to improve spectral purity and generate stable, narrowband beams. They are used in high-resolution spectroscopy and precision metrology.

10. Neodymium Lasers (Nd)

Nd lasers are a subcategory of solid-state lasers that use neodymium-doped crystals (e.g., Nd:YAG) as the lasing medium. Neodymium lasers are constructed to emit a variety of spectra by varying the host crystal. Most Nd lasers produce 1.064 µm (IR). The introduction of a frequency doubler or a parametric oscillator can retune the beam to green, blue, and ultraviolet radiation. They deliver high-energy radiation with high efficiency, ideal for roles such as laser cutting, welding, and laser marking. Nd lasers can be operated in CW or pulsed mode. CW operation is suited to material processing, and pulsed Nd lasers are used in applications that require precise temporal control, such as laser-induced breakdown spectroscopy, range finding, and laser ablation.

Neodymium lasers are compact, long-lived, and robust, making them suitable for various applications: industrial integration, research laboratories, and portable applications. They are used in medical intervention in dermatology and ophthalmology for procedures such as tattoo removal, skin resurfacing, hair removal, and treatment of vascular lesions. Neodymium lasers are often used as the pump source for other laser types.

11. Pulsed Lasers

Pulsed lasers are defined by their operational mode rather than their underlying laser technology. Any laser that is of a type that can emit in short, intense pulses rather than a continuous beam is adopted into this class. These lasers supply high-energy bursts of light with precise temporal control. Pulsed lasers fit a wide range of applications, including research, materials processing, spectroscopy, imaging, medicine, and defense. Generating intense and precisely timed pulses of light facilitates various fields.

Pulses can be as short as a few femtoseconds or a much longer duration. This is dependent on the application needs, the excitation methods, and the laser technology. Short pulses allow complex uses in material analysis, spectroscopy, and atomic-level manipulation.

How To Choose the Types of Laser for Your Needs

Choosing the optimal laser type for your application can be complex. Many laser technologies have overlapping capabilities, and factors such as equipment cost, operational expenses, and expected lifespan further complicate the decision. Listed below are some of the factors to consider when choosing the type of laser:

- Application: Clearly defining the intended function—such as cutting, welding, engraving, spectroscopy, or medical treatment—will help eliminate unsuitable laser types early in the selection process.

- Power Requirements: Determine the power level required based on material thickness and throughput needs. For example, cutting thin (0.2 mm) steel may only require 20–50 watts, while cutting thick (50 mm) steel may demand several kilowatts. Power requirements vary significantly with depth and speed.

- Wavelength: After determining power needs, select a laser wavelength that matches the material properties. Metals, plastics, ceramics, and composites absorb different wavelengths to varying degrees. For instance, gold and copper absorb shorter wavelengths (e.g., green or UV) better than infrared.

- Pulse Duration: Pulse durations range from femtoseconds to continuous-wave. Pulsed lasers are preferred for precision tasks (e.g., laser engraving, medical procedures), while CW lasers are suited to steady processes like welding or high-speed cutting.

- Beam Quality: Applications like cutting, drilling, or precision welding benefit from a tightly focused, high-quality beam with low divergence (e.g., near-Gaussian profile). For tasks like optical communication, beam quality is less critical.

- Environmental Factors: Evaluate the operating environment—temperature fluctuations, dust, vibration, and humidity can affect laser stability and alignment. Some lasers, like fiber types, are more tolerant than others.

- Budget: Cost should be evaluated after filtering options based on performance needs. Once suitable laser types are identified, consider the upfront cost, maintenance, and operational expenses.

- Safety Considerations: Always review laser safety class (Class 1 to Class 4), interlocks, shielding, and required PPE. Even low-power lasers can damage eyes or ignite materials under the right conditions.

What Type of Laser Is Used for Laser Cutting?

CO₂ lasers are traditionally the most commonly used lasers in laser cutting applications. They are favored for their relatively low equipment cost, high power output, narrow beam width, and strong absorption in organic materials like wood, acrylic, and plastics. The high wattages available enable rapid and efficient cutting of the bulk of materials. The beam is absorbed by many metals, non-metals, and organic substances at 10.6 µm emission. Their narrow beam diameter and good coherence allow for precise focusing and clean cutting, especially on non-metallic materials. Processing speed is optimal in many applications, allowing for high throughput.

However, CO₂ lasers struggle with highly reflective metals (e.g., copper, brass, aluminum) due to poor absorption at the 10.6 µm wavelength, requiring higher initial power to start cutting. This can lead to the need for much higher initiation power. Once melting has commenced, the absorption property alters, and cutting can proceed.

Fiber lasers and Nd:YAG lasers are better suited for cutting reflective or precious metals, as their shorter wavelengths are more efficiently absorbed.

Can a Fiber Laser Be Used for Laser Cutting?

Yes, fiber lasers are widely used in laser cutting applications, especially for metals. They offer excellent beam quality, high power density, and energy efficiency, making them ideal for precision and high-speed cutting.

What Type of Laser Is Usually Utilized for Laser Engraving?

CO₂ lasers are most commonly used for laser engraving, particularly on organic materials like wood, leather, glass, and acrylic. Fiber and diode lasers are also used for engraving metals and plastics, depending on the material. This classification of laser offers a good balance between device cost, beam quality, power, and power modulation that renders them adapted to the delicate control required in laser engraving. Other laser classes, such as fiber and diode lasers, can also be appropriate for specialist tasks, depending on the material and processing requirements.

What Type of Laser Is Frequently Employed for Laser Welding?

Fiber lasers are the dominant choice for laser welding today due to their high beam quality, controllable power, and adaptability. Their excellent focusability allows deep and narrow welds in metals. These make them most amenable out of the available options. Fiber lasers offer improved performance, energy efficiency, and versatility. Their high radiant energy power, superior beam quality, and flexibility of control are advantageous in precise and efficient laser welding.

Which Laser Type Is Utilized for Laser Ablation?

Laser ablation often uses solid-state lasers such as Nd:YAG for their precision, pulse control, and short wavelengths. Excimer lasers are also used when UV wavelengths or extremely short pulses are required. Their wavelength, power, beam performance, and durability suit ablation roles. While Nd:YAG lasers are extensively utilized in ablation tasks, other classes, such as excimer lasers, are suited to specific applications that require ultrashort pulses or particular wavelength requirements.

What Type of Laser Is Commonly Used for Plasma Cutting?

Plasma cutting does not use lasers. It is a distinct thermal cutting process that uses ionized gas to melt and cut conductive materials. Fiber lasers, however, are used in laser cutting—often confused with plasma cutting due to similar applications. Their combination of high power capability, beneficial beam quality, advantageous processing speed, and flexible delivery (via optical fiber) are all advantages in this field.

What Type of Laser Is the Most Powerful?

High-energy lasers (HELs), a term used to describe any laser system capable of delivering very high power (often for defense applications), and free electron lasers (FELs) are among the most powerful laser systems, capable of delivering megawatt to gigawatt-level outputs. These are used in advanced defense and research systems. In commercial settings, high-power CO₂ and fiber lasers (up to 100+ kW) are the most powerful options.

What Is the Most Commonly Used Type of Laser?

For industrial materials processing, CO₂ and fiber lasers are the most commonly used. In consumer devices, diode lasers dominate due to their small size, efficiency, and integration into pointers, printers, sensors, and communications. In absolute numbers, the laser pointer and related devices are very widespread. They usually use either diode lasers or diode laser-pumped solid-state lasers. Diode lasers are also used in fiber-optic devices and most laser printers. They are increasingly used as initiator optical sources for larger and more complex devices. This makes diode lasers the most widely used type of laser by unit volume.

Is a CO₂ Laser a Gas Laser?

Yes, a CO₂ laser is a molecular gas laser. It operates by electrically exciting a gas mixture—typically CO₂, nitrogen, and helium—which emits infrared light at 10.6 µm through energy transitions in CO₂ molecules.

Summary

This article presented the different types of lasers, explained each of them, and discussed their various applications. To learn more about lasers and their applications, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including sheet cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.