Both of these methods are types of 3D printing. SLS stands for selective laser sintering, and FDM stands for fused deposition modeling. They share a number of similarities. For instance, they’re both used in lower-volume production and rapid prototyping, both use thermoplastic materials, and they’re great for making proofs of concept. But they’re quite different in other areas. In this article, we’ll look at how they differ and when you might want to use either one.

SLS Definition and Comparison to FDM

Developed in the mid-1980s at the University of Texas in Austin and funded by the U.S. Department of Defense, SLS has become one of the most standard methods of 3D printing, with many companies using the same basic technology to manufacture and sell their own machines. These printers usually use a CO₂ laser that selectively sinters and bonds together thermoplastic polymer powder—usually nylon or something similar. When each layer is finished, the print bed will go down, another batch of powder is applied, and the process starts again. When the part is finally complete, it needs to cool down—which could take up to 12 hours—and be cleaned with compressed air or some other form of blasting media.

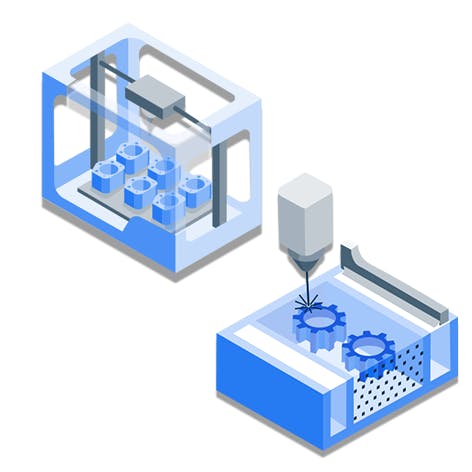

SLS tends to work out more expensive than FDM, but its parts come out with higher resolutions, amazing mechanical properties, and accurate complex designs. We have an article on SLS which you can check out to find out more. The image below shows one of our SLS 3D printing stations here at Xometry:

SLS has lots going for it. For instance, aside from being good at making prototypes, it can make parts for end-users too. Also, parts don’t need support structures during printing, the process is quick, and unsintered powder can be reused and recycled. On the downside though, SLS printers are usually only used in industrial settings, so getting hold of one could take a while. What’s more, they have a moderately limited selection of materials (mainly polyamides), and some parts with large, flat surfaces and small holes could warp or be over-sintered.

What are the Advantages of SLS Compared to FDM?

Listed below are the advantages of SLS vs. FDM:

- Excellent mechanical properties make SLS parts great for both end-users and as prototypes.

- Complex geometries are simple with SLS since no supports are needed.

- SLS quickly completes small-to-medium-sized batch production.

- SLS allows the recycling and reuse of unsintered powder.

What are the Disadvantages of SLS Compared to FDM?

Listed below are the disadvantages of SLS vs. FDM:

- Long lead times for SLS printers since only industrial-scale SLS printers are widely available.

- SLS often produces grainy surface finishes which may require post-processing.

- Warping and oversintering can occur on large flat surfaces and small holes of SLS-printed parts.

FDM Definition and Comparison to SLS

The most traditional form of 3D printing today, FDM was developed in the late 1980s, and once its patents expired in 2009, companies jumped at the opportunity to make their own. Since then, it’s become a staple in the 3D printing space and even found in many homes.

Like SLS, FDM uses thermoplastics, but in the form of a filament that’s poured out onto the print bed through a hot nozzle. When each layer is printed and cooled down, the nozzle gets started on the next, until eventually the part is complete. FDM is way cheaper than SLS and is the perfect starting point, even for hobbyists. To learn more, head on over to our article on FDM printing. This is one of our industrial FDM 3D printers here at Xometry:

FDM printers are generally easy to use, which is why many hobbyists love using them as a starting point. You can even get hold of rather large FDM machines, which allow you to print parts up to a few feet wide. On the flip side, though, they don’t have as high a print resolution as SLS printers do, so don’t expect perfection on small or detailed parts. They can also be quite slow, and the prints will require support structures during printing. Matthew Schmidt, a Senior Solutions Engineer here at Xometry, says, "SLS and FDM process are common in the respect that they both utilize real thermoplastic feedstock, however, the deposition process is much different. Selective Laser Sintering (SLS) provides a more dense, homogenous and isotropic part due to its laser melting process, but only from a limited number of Nylon derived materials. FDM on the other hand has a less dense, but unique contour and raster extrusion deposition process that can accommodate many different thermoplastics in different colors."

What are the Advantages of FDM Compared to SLS?

Listed below are the advantages of FDM vs. SLS:

- Lower costs make FDM a great point of entry for smaller manufacturers.

- Simple and user-friendly technologies and displays make FDM easy to use.

- Some FDM machines are very large, making large parts possible.

What are the Disadvantages of FDM Compared to SLS?

Listed below are the disadvantages of FDM vs. SLS:

- The lower resolution makes FDM less desirable for small and/or detailed parts.

- Slower print times mean FDM isn’t ideal for large production runs.

- Many FDM parts tend to warp and shrink.

| Attribute | SLS | FDM |

|---|---|---|

Attribute Good resolution quality | SLS TRUE | FDM FALSE |

Attribute Easy to use technology | SLS FALSE | FDM TRUE |

Attribute Use for proof-of-concept prototypes | SLS TRUE | FDM TRUE |

Attribute Large print volume | SLS FALSE | FDM TRUE |

Attribute Use for functional prototypes and parts | SLS TRUE | FDM FALSE |

Attribute Need for supports | SLS FALSE | FDM TRUE |

Attribute Complex geometries | SLS TRUE | FDM FALSE |

Attribute Costly | SLS TRUE | FDM FALSE |

SLS vs. FDM Comparison

If your project requires complex and/or functional prototypes, SLS may be the better option. It is also recommended for use in mass-production situations. FDM, however, is better for simple proof-of-concept prototypes and can be a good point of entry into AM due to its relatively low cost.

SLS vs. FDM: Technology Comparison

Technology, in this case, refers to the equipment and tools used to produce a 3D-printed part. SLS systems have more complex technologies and processes than FDM (high-powered lasers, thermoplastic powders, and sintering). If you want simplicity, FDM would be the better option in terms of technology.

SLS vs. FDM: Material Comparison

Material has a big impact on the quality and surface finish of the part. SLS uses engineering thermoplastics such as Nylon 11 and Nylon 12. FDM uses standard thermoplastics such as PLA, ABS, and others.

SLS vs. FDM: Product Applications Comparison

The types of products you can create using SLS vs. FDM depend on their geometry and complexity as well as the material properties of the thermoplastic you select. When complexity isn't the goal, FDM is the better option.

SLS vs. FDM: Print Volume Comparison

SLS printers are smaller (up to 300 x 300 x 300 mm worth of printing volume) than FDM ones (up to 300 x 300 x 600 mm). If you need larger parts, FDM is the better option.

SLS vs. FDM: Surface Finish Comparison

The surface finishes of SLS parts serve some applications well even without post-processing (though others will require additional cleaning or finishing). FDM parts can appear rough because of the layers of filament used to form the part. This is what prevents FDM printers from reaching the same resolution as SLS.

SLS vs. FDM Cost Comparison

SLS systems are more expensive than FDM systems because of the complex technologies and materials involved. SLS systems start around $10,000 and can go as high as $100,000. Desktop FDM systems go for a few hundred dollars while industrial FDM printers start around $15,000.

What are the Similarities Between SLS and FDM?

SLS and FDM exhibit some commonalities:

- Both SLS and FDM use thermoplastic materials to form parts.

- Both SLS and FDM are excellent for basic prototyping and proofs-of-concept.

- Both SLS and FDM can rapidly produce parts but cannot mass-produce them.

What are the Other Comparisons for SLS Besides FDM?

A few other technologies bear similarities to SLS:

- SLS vs. MJF: MJF is comparable to SLS since both build up layers by fusing powder. However, the MJF machine uses an inkjet-style print head to apply a fusing agent to the sections of powder it needs to solidify. The whole space is then hit by infrared light to fuse the treated powder. MJF can also print much faster than SLS since entire layers are heated at once.

What are the Other Comparisons for FDM Besides SLS?

A similar alternative to FDM is the FFF process:

FDM vs. FFF: FFF (fused filament fabrication) uses the same process as FDM. It uses a heated nozzle or extruder to apply layers of filaments to a flat printing bed. FFF, however, does not have FDM's heated chamber that helps control temperature.

Frequently Asked Questions on SLS and FDM

What are the Mutual Alternatives to SLS and FDM?

Of course. Some of the most suitable alternatives are SLA (stereolithography) and DLP (digital light processing). Both of these use photopolymers, which are special resins that are cured using a UV laser in SLA machines, and a light projection in DLP machines. They both work layer-by-layer until the part is built and cured.

What’s the difference between SLS and MJF?

MJF stands for multi-jet fusion, and similar to SLS, it fuses powder to build up each layer. But unlike SLS, it uses an inkjet-style print head to deposit the fusing agent onto the sections of powder it needs to harden. It then projects infrared light onto the entire area to bond the treated powder together, and because of this, MJF is way faster than SLS. You can check out our article on SLS vs. MJF to find out more.

What’s the difference between FDM and FFF?

FDM is often compared to (FFF), which stands for fused filament fabrication. It uses the same process as FDM in that a heated nozzle or extruder will deposit layers of filament onto the print bed. But, unlike FDM, FFF doesn’t have a heated chamber that helps control the temperature. Why not read our article on FDM vs. FFF to learn more about this comparison?

How Xometry Can Help

We’ve covered a lot in this article, but if you still have any questions relating to these methods or general 3D printing, one of our representatives would be happy to help you. Xometry also offers a plethora of manufacturing services in addition to 3D printing, like CNC machining, laser cutting, and powder coating, to name just a few. You can request a free, no-obligation quote today to get started.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.