Casting is one of the oldest manufacturing methods known to man, going back around 7,000 years — give or take. The reason it’s still popular today is that it’s simple, efficient, and cost-effective, and it can be used with many different materials. Read on to learn about all things casting.

What is Casting?

Casting is an age-old manufacturing process in which different materials are melted down and poured into molds to set. Engineers and manufacturers use casting to make complex and detailed parts. It reduces production times and costs and simplifies assembly processes because extensive welding or joining isn’t needed—the parts basically come out of the molds ready to go.

Although better suited to small quantities, casting is also successfully used for bulk production and can even make extra-large castings that weigh several tons. In the case of certain metals, like some cast irons, complex alloys, and ceramics, casting is the only processing method available as these materials can’t be mechanically processed.

Casting is often confused with injection molding, but this is a very different process. Both methods use molds but injection molding (as the name suggests) injects the melted material into a mold and uses high pressure to set it. Casting, on the other hand, just uses good old gravity.

There are various casting techniques, and different materials can be used with each one. The process can take anywhere from a few hours to a few days, depending on the material, the casting type, the size of the part, and the number of pieces you want to make.

How Does Casting Differ From Injection Molding?

Casting and injection molding are two distinct manufacturing processes. Injection molding involves injecting molten material into a mold under high pressure to create a solid object. In contrast, casting commonly utilizes the force of gravity to pour the molten material into the mold cavity. These processes differ in their mechanisms and applications, providing unique solutions for various manufacturing needs.

What Is the Importance of Casting in Manufacturing?

The importance of casting in manufacturing is that it allows for the production of complex and intricate metal components cost-effectively. Casting reduces the number of individual parts required, as multiple pieces can be cast as a single unit. This simplifies assembly processes, streamlines inventory management, and reduces overall costs. By eliminating the need for extensive welding or joining, casting enhances efficiency and productivity in manufacturing operations.

What Are the Different Types of Casting?

There are around 14 different types of casting, but below we look at five of the most popular ones.

- Sand Casting: Sand casting is one of the oldest types known and has its roots in metal casting. It creates molds with different types of sand (dry/resin) and can even make large parts from ferrous and non-ferrous metals.

- Investment Casting: This is another super old method that uses wax patterns coated with a heat-resistant material to make the mold. It can make smooth and complex designs with thin walls.

- Plaster Casting: This process uses gypsum (think: drywall), water, and a strengthening material like lime or cement, and is able to make complex shapes with smooth finishes. It’s one of the more expensive types and isn’t compatible with a wide range of materials.

- Die Casting: This casting method involves feeding the liquid metal at high speed and under high pressure into a reusable mold. Methods include gravity die casting, high- and low-pressure die casting, and squeeze die casting. It’s one of the more accurate methods, making it a hit with Xometry die-casting customers.

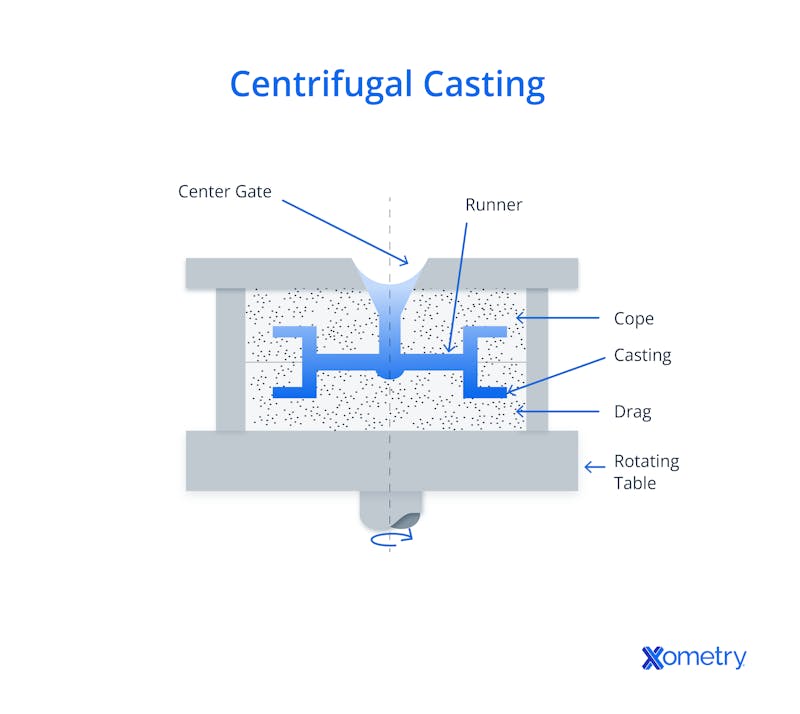

- Centrifugal Casting: Used to make long, cylindrical parts, centrifugal casting uses molten metal slowly put into a spinning mold. It can be done with water-cooled molds or pressure casting for irregularly shaped parts.

How Does Casting in Manufacturing Work?

Casting in manufacturing involves the process of pouring molten material into a mold to create the desired shape. The molten material solidifies and takes the shape of the mold, forming the final product. The mold can be made from various materials, such as: sand, plaster, or metal, depending on the casting method. After solidification, the casting is removed from the mold, cleaned, and further processed as needed.

What Is the Process of Casting?

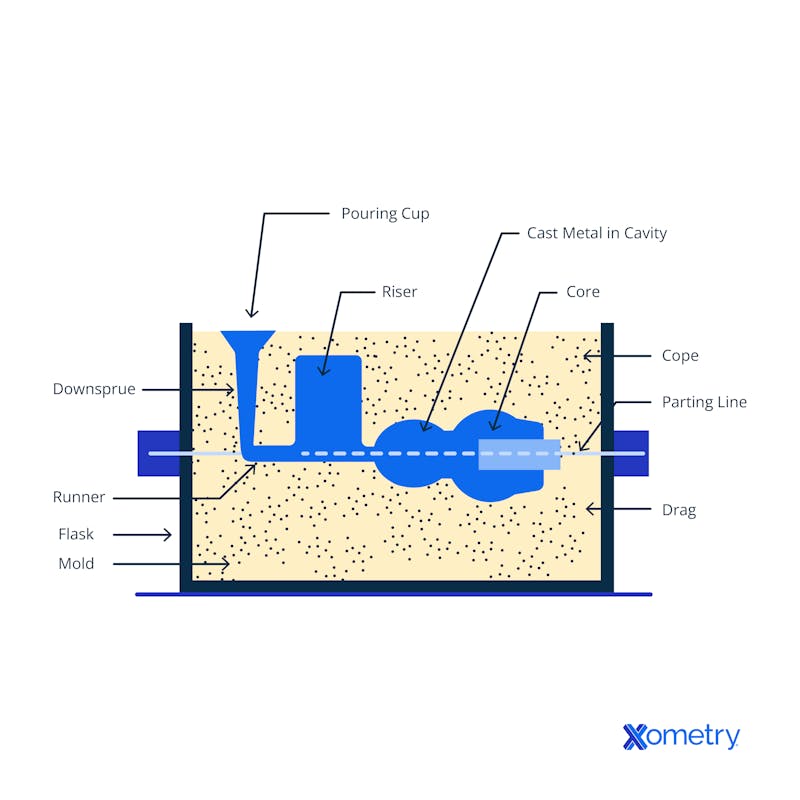

The general premise of casting is putting a melted material into a mold, waiting for it to set, and then taking it out when it’s ready. There are, of course, a few extra steps to the process, which can be different for each casting type. In sand casting, the mold pattern is put in the sand mixture until it hardens to make the mold. When the sand has taken shape, the mold pattern is removed and the mold is ready for use. You’ll then have to melt the metal and pour it into the mold cavity via a gating system.

Metal, like steel or iron, is heated until molten before being poured into the mold cavity through the gating system. It’s then left to cool in the mold, with cooling times differing depending on the metal used. When solidified, the mold is removed, and the newly formed metal casting is revealed. The piece will then undergo processing, cleaning, and any other necessary treatments. Sand cast mold patterns are typically reusable, but the sand molds will need to be remade for each casting.

Casting is a scalable alternative to custom machining often yielding cheaper results with complex geometrics that need little post-processing before installationGreg PaulsenDirector, Applications Engineering

How Long Does the Casting Process Take To Finish?

The duration of the casting process can vary significantly and is influenced by several factors. The time required for casting depends on: the size of the product, the specific type of casting performed, the sample size of production, and the level of labor involved in the process. Consequently, there is no fixed or standard time for casting. The time frame can range from as little as one hour to as long as 2–10 weeks, depending on these variables.

What Are the Common Materials Used in Casting?

Below are some common materials used in casting manufacturing:

1. Magnesium

This material is lightweight with a good strength-to-weight ratio and is used to make lightweight and durable parts for aerospace and automotive.

2. Aluminum

Thanks to aluminum’s high thermal conductivity, mechanical properties, and corrosion resistance, parts can be made with many different casting methods. It’s used everywhere from automotive and aerospace to consumer goods.

3. Iron

Iron is a tough metal that also has high thermal conductivity and is commonly used metal for engine blocks, pipes, automotive parts, and other load-bearing components.

4. Zinc

Zinc has a low melting point and offers excellent flow and stability. It is used to make complex or delicate parts in automotive, electronics, consumer products, and many other industries.

5. Steel

Steel, known for its strength and durability, is ideal for making heavy-duty parts, i.e. machinery parts, tools and construction equipment, that need to survive harsh conditions.

6. Copper Alloys

These offer electrical and thermal conductivity and corrosion resistance, making them ideal for use in electrical and plumbing parts, and even music instruments.

7. Lead Alloys

Lead alloys have a low melting point and are malleable. The use of lead is carefully regulated due to its potential environmental and health hazards, but it’s still used in areas like radiation shielding, and battery manufacturing.

What Are the Industrial Applications of Casting?

Because it’s versatile, easy, and one of the more cost-effective manufacturing methods, casting is understandably popular in many industries. Products made with the casting method are all around us — tools, accessories, cell phones, appliances, brackets, gears, housings … all cast. In automotive, it’s used to make engine blocks, cylinder heads, transmission cases, and other essential parts. It’s also used for more specialized applications like chemical process equipment (reactors, heat exchangers, pumps), or plant machinery (impellers, casings, and valves).

What Are Examples of Casting Products?

Casting is a versatile manufacturing process that produces a wide range of products for various industries. Here are some examples of casting products:

- Hydrants, used for water supply systems.

- Firefighting equipment such as: fire hydrants, couplings, and fittings.

- Plumbing components like: pipe fittings, valves, and connectors.

- Components for military vehicles and transportation equipment, such as: engine parts, brackets, and structural elements.

- Electrical hardware components, including: electrical enclosures, connectors, and terminal blocks.

- Precision machinery parts, such as: gears, housings, and brackets.

How Durable Are Casting Products?

Cast metal products, especially those that have undergone heat treatment, are durable. Depending on the metal alloy and application, their service life might range from a few months to several decades. Once the service life of a casting ends, the cycle begins again. It is collected by a scrap yard, recycled, and recast into a new object.

Does the Casting Product's Thickness Vary?

Yes, the thickness of casting products can vary. The casting process allows for the production of components with varying wall thicknesses, depending on the design requirements and the capabilities of the casting method. Different sections of casting can have different thicknesses to achieve the desired strength, weight, and functionality of the final product.

What Is the Future of Casting?

The future of casting holds significant potential with the integration of advanced technologies. Optical measuring systems, such as the ATOS 3D Digitizer, are revolutionizing the industry by enabling efficient and accurate measurement of complex surfaces. These systems eliminate the laborious and time-consuming nature of traditional measuring methods, providing full-field measurements and faster validation. Embracing such technological advancements will enhance productivity, quality control, and overall efficiency in the casting process.

Is Casting Still Used Today?

Yes, casting is still widely used today in various industries. It remains a popular manufacturing process for creating complex metal components with excellent strength and durability. Casting methods, such as: sand casting, investment casting, and die casting, continue to be essential in sectors like: automotive, aerospace, and construction.

What Are the Advantages of Casting?

Advantages of the casting process include:

- Ability to produce complex shapes easily.

- Versatility—a wide variety of metals and other materials can be cast.

- Cost-effectiveness, especially for small quantities.

- Capability to produce large-sized castings up to 200 tons.

- Cost and time savings compared to other manufacturing methods.

- Suitable for materials that cannot be mechanically worked.

- Simplifies the production of large and heavy components.

What Are the Disadvantages of Casting?

Disadvantages of the casting process include:

- The surface finish may require additional finishing operations.

- Limited mechanical properties compared to wrought materials.

- The possible presence of casting defects like porosity.

- The dimensional accuracy of castings can be compromised due to shrinkage during the solidification process.

- High initial tooling and equipment costs for certain casting methods.

- The casting process is typically restricted to metals with lower melting points.

Is Casting Expensive?

Yes, casting can be expensive due to various factors. The cost of casting includes: tooling costs, such as mold and fixture expenses, as well as the unit cost of the material used, which can be higher for stainless steel. Additionally, factors like complexity, volume, and required finishing operations can impact the overall cost of casting. The mold cost of stainless steel casting typically ranges from $1,200 to $2,500.

How Xometry Can Help

Xometry offers a wide range of manufacturing services. We focus on on-demand precise manufacturing with methods such as die casting, urethane and silicone casting, injection molding, CNC machining, milling, turning, 3D printing, and sheet metal fabrication. To learn more, or get your free quote, please reach out to a Xometry representative.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.