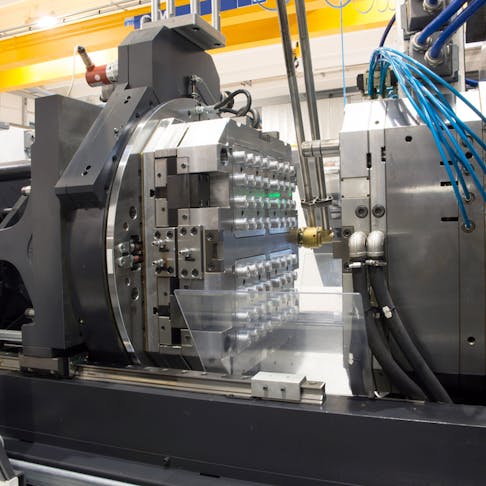

Gas-Assisted Injection Molding supports the production of lightweight plastic components with hollow sections and reduced material usage. Gas assist molding refers to a low-pressure injection technique that introduces assist gas (nitrogen) into the mold cavity after the initial injection of molten plastic.

The process begins with plastic melt injection into the mold, followed by the controlled entry of assist gas through designated channels. The gas displaces part of the molten plastic, forcing it against the mold walls and forming hollow areas within the part. The displacement reduces the volume of plastic required, lowers part weight, and supports structural integrity without compromising surface quality. The mold undergoes cooling to solidify the part before ejection once the cavity is packed. Gas assist injection molding supports design flexibility and reduces cycle time, which contributes to production efficiency in high-volume manufacturing.

The method is applied across industries that require durable, lightweight, and geometrically complex plastic components. For example, the automotive industry uses it for interior panels and handles, while electronics manufacturers rely on it for producing housings and enclosures that require precise wall thickness. Furniture and appliance manufacturers take advantage of the process to produce ergonomic, lightweight parts with high aesthetic appeal and minimal material waste.

What is Gas-Assisted Injection Molding?

Gas-Assisted Injection Molding is an advanced manufacturing technique in which pressurized nitrogen gas is injected into the mold cavity during the injection molding cycle. The assist gas displaces part of the molten material, forcing it against the mold walls and creating internal voids or hollow sections within the part after the molten plastic is injected into the mold. The process reduces material usage, leading to lighter components while maintaining the structural integrity and overall strength of the part.

Parts produced using gas-assisted molding have wall thicknesses ranging from 2 to 6 millimeters, although the thickness varies depending on the design’s geometry and structural requirements. Gas-assisted molding not only reduces material consumption but also helps ensure consistent surface quality, dimensional stability, and a reduction in common defects such as sink marks and internal stresses.

The method is widely used in industries where lightweight, durable parts are required, such as in the automotive industry for interior components like dashboards, in consumer products for handles, and in medical devices for housings. Gas-assisted injection molding is particularly advantageous for manufacturing complex geometries with uniform wall thickness, making it ideal for high-volume production environments that demand both efficiency and precision.

How does Gas-Assisted Injection Molding Work?

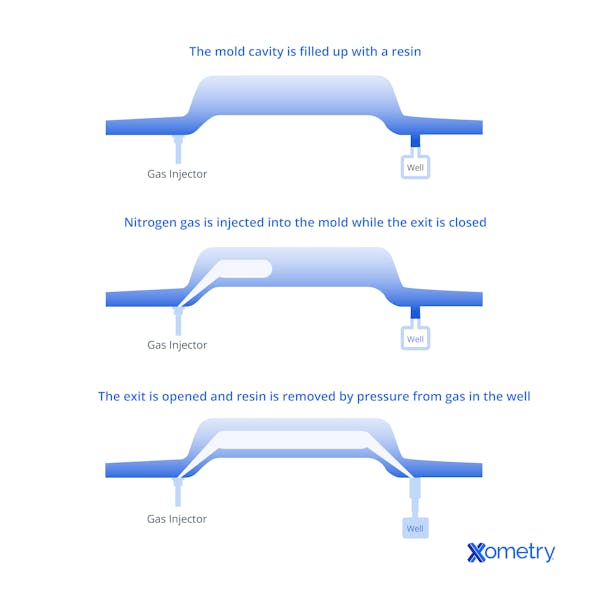

Gas-assisted injection molding works by channeling pressurized assist gas (typically nitrogen) into molten polymer after the mold cavity receives a partial fill. The process begins with the injection of plastic melt into the cavity, followed by the introduction of nitrogen gas through designated channels. Nitrogen gas is then injected through specific channels within the mold, displacing part of the molten plastic. The gas pressure forces the material outward, ensuring it fills the mold and creates hollow sections within the part.

The pressure-flow interaction helps reduce internal stress, minimizes the formation of sink marks, and prevents warping by promoting uniform wall thickness and consistent surface contact. The process significantly reduces material usage and lowers the overall weight of the molded part by creating hollow sections.

Industrial applications of gas-assisted injection molding include components such as automotive panels, which require structural integrity with reduced weight, and television frames. It is used for parts that demand high-dimensional accuracy and a smooth surface finish, such as ergonomically designed handles for appliances and equipment where strength and low weight are crucial.

What are the Key Benefits of Gas-Assisted Injection Molding?

The Key Benefits of Gas-Assisted Injection Molding are listed below.

- Material Savings: Gas-assisted injection molding reduces the amount of resin required by forming hollow sections within the part. The assist gas displaces part of the molten plastic, lowering material consumption and reducing waste during production.

- Reduced Cycle Time: The thinner wall sections created during gas assist molding cool more rapidly, which shortens mold dwell time and increases throughput.

- Improved Surface Quality: The injection of gas ensures even distribution of molten plastic against the mold walls, minimizing defects such as sink marks and reducing the likelihood of warpage. It results in smoother surfaces and higher-quality finishes, especially for parts with complex geometries.

- Structural Strength: Internal gas channels form hollow cores that maintain rigidity while decreasing part weight, which supports durable yet lightweight designs.

- Design Flexibility: Gas assist molding supports intricate shapes with integrated channels, which allows manufacturers to produce complex components without compromising structural integrity.

What are the Limitations of Gas-Assisted Injection Molding?

The Limitations of Gas-Assisted Injection Molding are listed below.

- Design Constraints: Successful gas-assisted injection molding requires precise channel placement for optimal gas flow and even cavity filling. Poor channel design can lead to uneven gas flow, incomplete filling, or localized weak spots, making uniform gas distribution critical to part strength.

- Equipment Costs: Gas-assisted injection molding involves specialized equipment, including injection systems and assist gas control units. The components increase the initial setup costs and the complexity of maintenance, making the process more expensive compared to traditional injection molding methods.

- Limited Part Size: Gas-assisted molding is generally unsuitable for very large parts or for components with extremely thin or delicate walls. The need for consistent gas displacement is challenging in larger molds, potentially affecting the structural integrity and material flow, which likely leads to defects in larger or complex designs.

- Process Control: Gas-assisted molding requires precise control over parameters such as pressure, timing, and gas injection rates. Improper control of pressure, timing, or gas injection rate can cause defects such as blow-through (gas breaching the surface), gas fingering (irregular gas fronts), or incomplete cavity packing (short shots). Effective process control is critical to avoid such issues.

What Factors Affect the Performance of Gas-Assisted Injection Molding?

The factors affecting the performance of gas-assisted injection are material properties, mold design, and processing parameters. Material properties such as melt viscosity, flowability, and thermal stability play a critical role in determining how effectively the assist gas penetrates the molten polymer. Materials with stable flow characteristics support uniform gas channeling, reducing the likelihood of defects such as incomplete cavity filling or inconsistent part formation.

Mold design is equally crucial, as the placement of gas pins, the layout of cooling channels, and the wall thickness influence the distribution of the assist gas and the cooling rate of the part. Proper mold design ensures uniform gas flow and minimizes issues (uneven wall thickness, sink marks, and warping).

Processing parameters (including injection speed, gas pressure, and hold time) directly affect the interaction between the molten plastic and the assist gas during cavity formation. The parameters control the material's flow behavior, gas penetration, and solidification rate, all of which are key to maintaining dimensional accuracy, surface finish, and structural integrity. Proper control of these variables ensures high-quality molded parts with reduced weight, improved surface consistency, and minimized defects.

When designing parts for gas-assisted molding, think like the gas: plan every channel, corner, and wall to guide flow naturally. The best designs balance strength, weight, and surface quality before the mold is even made.

What Challenges Do Manufacturers Face When Using Gas-Assisted Injection Molding?

The challenges that manufacturers face when using gas-assisted injection molding include technical and economic difficulties that influence part quality and production efficiency. One significant challenge is maintaining consistent wall thickness, as variations lead to gas fingering, a defect where assist gas creates irregular flow paths, compromising the part's structural integrity. This issue can lead to weak spots and uneven filling, ultimately affecting product performance.

Complex part geometries also present difficulties, especially when trying to achieve uniform cooling. The uneven cooling rates during solidification lead to distortion or dimensional instability, which reduces part accuracy. Narrow or thin-walled sections present additional complications, as limited flow paths hinder the molten plastic’s ability to fill the mold cavity before the assist gas is injected. Incomplete mold filling likely leaves air pockets or weak areas in the final product.

Manufacturers face the challenge of balancing production costs with the need for high-quality surface finishes. Maintaining high surface quality while managing production costs is crucial in industries such as automotive interiors, where visual appeal and mechanical performance are vital. Achieving such a balance requires precise control over processing parameters, mold design, and material selection to ensure parts meet strict specifications without increasing production costs.

What are the Materials Used in Gas-Assisted Injection Molding?

The materials used in Gas-Assisted Injection Molding are listed below.

- Polypropylene (PP): Provides excellent flowability and fatigue resistance, suitable for lightweight, cost-efficient parts with hollow sections.

- Polycarbonate (PC): PC is used for durable components that need clarity and precise tolerances. It is recognized for its high impact strength and excellent dimensional stability.

- Acrylonitrile Butadiene Styrene (ABS): Combines durability and ease of molding, suitable for complex geometries and consumer-grade products with aesthetic finishes.

- High-Density Polyethylene (HDPE): Offers excellent chemical resistance and very low moisture absorption, making it ideal for industrial and packaging uses with hollow profiles.

- High Impact Polystyrene (HIPS): HIPS is used for disposable products and packaging where moderate strength and surface quality are important. It is cost-effective and simple to process.

- Polylactic Acid (PLA): PLA facilitates eco-friendly molding of thin-walled consumer products. It is a biodegradable choice suitable for low-temperature uses.

- Polyethylene Terephthalate (PET): Provides a high strength-to-weight ratio and good clarity, commonly used in food-grade containers and cosmetic packaging.

- Nylon (PA): Provides excellent wear resistance and mechanical strength, suitable for semi-structural parts that can substitute for metal in some automotive and industrial applications.

- Polybutylene Terephthalate (PBT): PBT is used in connectors, housings, and precision components. It is recognized for its dimensional stability and electrical insulation.

- Acetal (POM): Offers low friction and high stiffness, ideal for gears, fasteners, and mechanical parts requiring smooth movement and durability.

Which Material is Best for Gas-Assisted Injection Molding?

Polypropylene (PP) is generally the most widely used material for gas-assisted injection molding due to its balanced flow behavior, strength, and cost-efficiency. Material selection for gas-assisted molding hinges on factors such as melt flow behavior, mechanical strength, and thermal stability during the molding process. Polypropylene exhibits excellent flow characteristics under moderate pressure, which facilitates uniform filling of the mold cavity and the effective creation of hollow sections. PP maintains dimensional stability during cooling, minimizing warpage and ensuring consistent part quality. Its low density and cost-efficiency make it ideal for high-volume production, especially in industries such as automotive and consumer goods.

Polycarbonate (PC) offers superior impact resistance and high thermal durability, making it suitable for semi-structural parts requiring toughness and optical clarity; however, it is a material with higher viscosity. The characteristic necessitates more precise control of gas pressure and mold temperature to ensure optimal cavity filling and prevent incomplete mold packing.

Acrylonitrile Butadiene Styrene (ABS) strikes a balance between rigidity and moderate flowability. It is well-suited for parts requiring defined geometry and surface finish. ABS's thermal properties accommodate assist gas without significant shrinkage, but its cost and susceptibility to environmental stress (UV exposure) likely limit its use in certain applications. Polypropylene is favored for its versatility, minimal processing challenges, and ability to produce high-quality, consistent parts, particularly when compared to other materials like Polycarbonate and ABS in gas-assisted injection molding.

How do Material Properties Affect the Cost and Performance of Gas-Assisted Injection Molding?

Material properties affect the cost and performance of gas-assisted injection molding by determining structural reliability, processing efficiency, and suitability for demanding environments. Material strength is crucial as it determines the load-bearing capacity of parts and their ability to maintain shape after gas-assisted displacement. Stronger materials provide better resistance to deformation, ensuring that parts meet durability requirements without excessive material use. Parts likely deform or collapse, increasing the rejection rate and raising production costs due to the need for reprocessing if the material lacks strength.

Flowability affects how efficiently molten plastic fills the mold before gas injection begins. Materials with high flowability allow for faster filling of the cavity and smoother gas penetration, reducing cycle time and lowering energy consumption. Poor flowability results in incomplete mold filling, uneven wall thickness, and higher scrap rates, ultimately increasing production costs. High melt flow rate is essential to ensure uniform cavity filling and consistent surface quality since gas-assisted molding depends on the precise displacement of molten plastic by gas.

Heat resistance and thermal stability are critical properties for materials used in environments with high thermal demands, such as automotive and medical applications. Materials with good thermal stability maintain their mechanical properties during and after the molding process, preventing warping or distortion. High heat resistance reduces post-processing requirements and allows the molded parts to function effectively at elevated temperatures without degradation. Materials with low thermal stability often necessitate stricter process control and longer cooling times, increasing production costs and limiting their applicability in high-performance applications.

What are the Applications of Gas-Assisted Injection Molding?

The applications of Gas-Assisted Injection Molding are listed below.

- Automotive: Gas-assisted injection molding supports the production of lightweight semi-structural components (handles, trim, and brackets). Achieving consistent wall thickness and mechanical strength across complex geometries requires careful control of gas flow and material selection.

- Consumer Products: Hollow designs in furniture, appliance housings, and ergonomic items benefit from reduced weight and improved surface finish. Limitations arise when thin sections or decorative features demand precise gas pin placement and uniform cooling.

- Aerospace: Lightweight interior components and non-critical housings can be molded with reduced material usage. Design complexity and strict material standards restrict the use of specific polymers and require advanced mold engineering.

- Electronics: Enclosures and internal supports are formed with hollow sections to reduce mass and improve rigidity. Dimensional accuracy and thermal stability must be maintained when housing heat-sensitive components.

- Industrial Equipment: Panels, covers, and mechanical supports are molded with hollow cores to reduce cost and improve handling. Large part sizes and uneven wall thicknesses challenge the design of cooling systems and the placement of gas channels.

What are Examples of Gas-Assisted Injection Molding Products?

The examples of Gas-Assisted Molding products are listed below.

- Door Panels: Door panels benefit from reduced weight and improved rigidity through hollow rib structures. Maintaining consistent wall thickness is essential to prevent warping and ensure proper fit in automotive assemblies.

- Instrument Panels: Instrument panels achieve complex geometries with fewer sink marks and better surface finish. Structural integrity must be preserved to support embedded electronics and meet vibration resistance standards.

- Armrests: Armrests are molded with internal hollow sections to reduce material usage while retaining ergonomic strength. Uniform gas distribution is required to avoid surface defects and ensure comfort.

- Bicycle Frames: Bicycle frames can be produced using gas-assisted molding to form lightweight, aerodynamic shapes with internal support, though this method is uncommon compared to metal or carbon-fiber fabrication. Achieving high load-bearing capacity without compromising wall uniformity presents a design challenge.

- Golf Club Heads: Golf club heads incorporate hollow zones to optimize swing weight and impact response. Dimensional accuracy and surface quality must meet performance specifications for competitive use.

- Electronic Enclosures: Electronic enclosures are produced with internal cavities to reduce mass and accommodate wiring channels. Thermal stability and precise mold control are necessary to protect sensitive components.

- Motorcycle Helmets: Motorcycle helmets may use molded internal reinforcement inserts or vent structures to balance impact resistance and weight. Material selection must meet safety regulations while supporting complex curvature.

- Tool Handles and Grips: Tool handles and grips are molded with hollow cores for better balance and reduced fatigue during use. Achieving consistent texture and grip contour requires precise gas channel placement.

- Storage Containers: Containers utilize gas-assisted molding to form lightweight walls with reinforced edges. Uniform cooling and material flow are critical to prevent deformation and ensure stackability.

- Automotive Panels: Automotive panels are molded with hollow sections to reduce vehicle weight and improve fuel efficiency. Achieving uniform strength across large surfaces requires precise gas channel placement.

- Electronics Housings: Electronics housings incorporate hollow features to reduce material use and accommodate internal components. Dimensional control and thermal resistance are essential for long-term reliability.

- Appliance Parts: Appliance parts such as covers and handles benefit from reduced weight and improved aesthetics. Mold design must support consistent gas flow to avoid surface defects and ensure functional durability.

How does Gas-Assisted Injection Molding differ from Other Types of Injection Molding?

Gas-assisted injection molding differs from other types of injection molding by introducing pressurized gas (typically nitrogen) into the mold cavity after the initial injection of molten plastic. The gas helps displace part of the molten material, creating hollow sections within the part, which reduces both weight and material usage. The technique is advantageous for producing thick-walled parts or large, complex components without increasing cycle times or risking incomplete filling, which can occur in standard injection molding. The gas helps minimize surface defects (sink marks and warpage) by maintaining uniform pressure during the cooling phase. Gas-assisted molding uses internal gas channels to control material distribution, which enhances dimensional stability and overall part integrity, unlike standard injection molding, which relies solely on the flow of molten plastic. The method allows for the production of complex geometries with reduced material costs while ensuring that the final product maintains both strength and precision.

How Do Production Speeds in Gas-Assisted Injection Molding Compare to Other Molding Methods?

Production speeds in gas-assisted injection molding can be faster than other molding methods due to several key factors. The process reduces the material volume needed to fill the mold, shortening cycle times and decreasing energy consumption. Efficient mold designs with optimized gas channeling and venting enhance material flow, particularly in thin-walled components where uniform distribution is essential. The creation of hollow zones further accelerates cooling by reducing the thermal mass, which allows for quicker mold release and consistent, repeatable production cycles. The combined advantages result in higher throughput and increased manufacturing efficiency compared to traditional injection molding techniques.

Frequently Asked Questions About Gas-Assisted Injection Molding

Is Gas-Assisted Injection Molding More Cost-Effective than Liquid Silicone Rubber (LSR) Molding?

Yes, gas-assisted injection molding is generally more cost-effective than liquid silicone rubber (LSR) molding, especially when considering material usage, cycle times, and production throughput. Gas-assisted molding reduces material use by creating hollow sections, which lowers production costs and energy consumption. It works with standard thermoplastics, producing lightweight, reinforced parts with a high strength-to-weight ratio. LSR molding requires dosing, mixing, and heating equipment, longer curing times, and tighter temperature control, making it more costly and slower. LSR parts have lower rigidity and load-bearing capacity than thermoplastics but offer superior elasticity, chemical resistance, and biocompatibility. Gas-assisted molding is better suited for high-volume production of rigid components with good surface quality, while Liquid Silicone Rubber Molding is preferred for flexible, medical, or sealing parts despite higher tooling and processing costs.

Is Gas-Assisted Injection Molding More Suitable for Mass Production than Foam Injection Molding?

Yes. Gas-assisted injection molding is more suitable for mass production than foam injection molding when structural integrity, surface quality, and cycle efficiency are prioritized. Gas-assisted molding reduces material use by creating hollow sections, which lowers production costs and energy consumption. It works with standard thermoplastics, producing lightweight, reinforced parts with a high strength-to-weight ratio. Liquid silicone molding requires specialized equipment, longer curing times, and precise temperature control, making it more costly and slower. The biocompatibility and flexibility of silicone are balanced by its lower rigidity and load capacity when compared to thermoplastics. Gas-assisted molding is ideal for high-volume production of complex parts with good surface quality and minimal waste. Gas-assisted maintains a high strength-to-weight ratio by preserving mechanical integrity in hollow sections, offering design flexibility. Foam Injection Molding produces lightweight parts with reduced density, but generally lower surface finish quality and stiffness than gas-assisted parts. Choice depends on the part function and volume. Gas-assisted offers precision, speed, and durability, ideal for mass production in automotive, electronics, and consumer goods. Foam reduces weight, but is less suitable where surface quality or strength matters. Gas-assisted is scalable, efficient, and reliable for high-volume manufacturing.

To learn more, see our full guide on Foam Injection Molding.

Is Gas-Assisted Injection Molding More Energy-Efficient than Metal Injection Molding?

Yes, gas-assisted injection molding is more energy-efficient than metal injection molding due to lower processing temperatures, reduced material volume, and faster cycle times. The gas-assisted process creates hollow sections within parts, which reduces material volume while maintaining structural integrity. The pressurized gas displaces the molten plastic and forms internal channels that distribute load more effectively, increasing the part’s strength without adding bulk. This method improves resistance to mechanical stress, cost-efficiency, and allows for the production of complex and strong parts. It requires tight control to avoid defects such as warping and may not achieve the same strength-to-weight ratio in some complex designs, while thin-wall injection molding also results in lightweight components. The two methods offer advantages depending on the design requirements, with gas-assisted molding being more suited for parts requiring hollow structures and thin-wall molding excelling in parts with uniform thickness and precision. Metal Injection Molding yields very high-strength parts but involves sintering and debinding steps, making it costlier and slower than thermoplastic processes. Gas-assisted molding optimizes energy efficiency, material control, and speed for weight reduction and structural uses.

Does Gas-Assisted Injection Molding provide a Higher Strength-to-Weight Ratio than Thin-Wall Injection Molding?

Yes, gas-assisted injection molding can achieve a higher apparent strength-to-weight ratio than thin-wall injection molding, depending on design and geometry. The process uses pressurized gas to create hollow cavities, improving load distribution and increasing part strength while maintaining reduced bulk. However, thin-wall injection molding also achieves a high strength-to-weight ratio through the creation of uniformly thin, solid walls, which are ideal for applications where material distribution and uniformity are critical. Thin-wall molding excels in creating lightweight, solid components with precise tolerances, while gas-assisted molding allows for more complex designs with internal channels. The two methods are highly efficient, but the best choice depends on the specific requirements of the part's design and intended use. The gas-assisted process provides durability and efficiency, balancing speed, material use, and performance for an optimal strength-to-weight ratio, unlike Thin-Wall Injection Molding, which needs tight control to prevent defects.

Can Gas-Assisted Injection Molding Be Used for Multi-Component Parts?

Yes, gas-assisted injection molding can be adapted for multi-component parts when mold design and material compatibility allow, but this approach is complex and less common than standard two-shot molding. Gas-assisted molding has traditionally been associated with hollow sections, but it is capable of accommodating multi-material components when designed carefully. However, combining different materials in a single mold introduces additional design complexity, particularly in coordinating gas injection timing and material flow. Multi-component designs likely require precise mold cavities and the management of sequential filling or cooling stages, which increase cycle time. Material bonding between different polymers may present a challenge, particularly if the materials are incompatible, requiring careful control of temperature and pressure to ensure proper adhesion. The gas-assisted molding process facilitates the formation of hollow parts, but maintaining dimensional accuracy and alignment throughout the process is essential for consistent part quality. Success in multi-component gas-assisted molding depends on detailed planning, effective material selection, and precise control of processing parameters.

Is Gas-Assisted Injection Molding Suitable for Low-Volume Production?

Yes, gas-assisted injection molding can be applied to low-volume production, though its higher tooling and gas-channel costs make it most economical for medium- to high-volume runs. The method offers material savings by creating hollow sections, which reduces per-unit cost even in small batches. Injection molding setup time is comparable to standard injection molding, but mold costs are higher because of the complexity of gas channel integration and venting design. Efficiency is improved in low-volume manufacturing due to reduced cycle times, thanks to quicker cooling and faster mold release. The use of pressurized gas for material displacement results in cost savings while maintaining the part’s structural integrity and surface quality. Gas-assisted molding provides reliable performance and cost-effectiveness across varying production volumes, making it a suitable choice for high- and low-volume production runs.

Summary

This article presented gas assist injection molding, explained it, and discussed its process and purpose. To learn more about gas assist injection molding, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including injection molding and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.