Milling is a type of machining that has its origins in food preparation. Originally, people milled grain into flour using quern stones: a set with one flat stationary stone, and one rotating stone with a hole in the middle. The grain was fed into the hole, ground down by the rotating quern (a basic hand mill), and exited the set-up as flour. Though extremely primitive, this is the origin of all rotating machinery. These days, the term mill indicates the rotating tool-cutting machines for wood, metal, plastics, and stone.

What Does Milling Mean in Machining?

The manufacturing industry mostly uses milling to cut materials from a workpiece, and make lots of different items in many sizes and shapes. Milling machines are highly precise and have very tight tolerances. That’s important for industries where accuracy is essential; aerospace, for instance, more often than not needs lightweight and complex parts for its flight-engineered products. Parts such as airframe components, controls, jet and rocket engine components, and flight-surface actuator parts all come from milling. Similarly, being able to process a variety of material that is both biodegradable and easily sterilized make milling the common choice for surgical tools and medical implants.

Milling allows you to make all sorts of shapes and contours in materials that can otherwise be difficult or even impossible with other machining methods. Lots of materials are compatible with machining, including metals like aluminum, steel, brass, and copper; acrylic, Kevlar, polycarbonate, nylon, Delrin, fiberglass, hardwood, softwood, ceramics, cermets, graphite, and glass, just to name a few.

Versatility of material is just one advantage of milling, along with the size, quality, and precision it provides. It’s super quick, and doesn’t produce much waste, either. It’s also economical and simple to automate. The milling process isn’t ideal if you need to cut hardened materials, and heavier cuts understandably take longer to do. The machines, although they’re clearly useful, can be challenging to use, and tend to suffer with wear and tear. They also generate a good amount of heat, chatter, and vibration.

What Is the Origin of Milling?

The origin of metal milling can be traced back to the development of metalworking processes in ancient civilizations. Early metalworkers used hand tools such as chisels and files to shape and manipulate metals. The concept of rotary cutting was crystalized during the Industrial Revolution in the 18th and 19th centuries when mechanical milling machines were invented. These early machines used rotating cutters to remove metal from workpieces, marking the advent of metal milling as a distinct machining process.

Over time, milling technology advanced, leading to the development of highly precise and automated milling machines, including computer numerical control (CNC) machines, which play a vital role in modern metalworking and manufacturing industries.

What Is the Other Term for Milling?

Another term often used interchangeably with milling in machining is machining. Machining is a broader term that encompasses various processes for shaping and removing material from a workpiece, and milling is one of those specific processes. Other machining processes include: turning, drilling, grinding, and electrical discharge machining (EDM).

As the family of metal processing technologies has broadened, milling has become one of many processes encompassed by machining and more recently CNC machining.

How Does Milling Work?

At its most basic level, a hardened steel or exotic material cutter rotates against the workpiece to remove material. Most commonly the cutter moves on a fixed X-Y-axis, but can be adjusted to move on the Z-axis as well. A 3-axis milling machine as described is the most basic option, but there are 4, 5, and even 7-axis machines available.

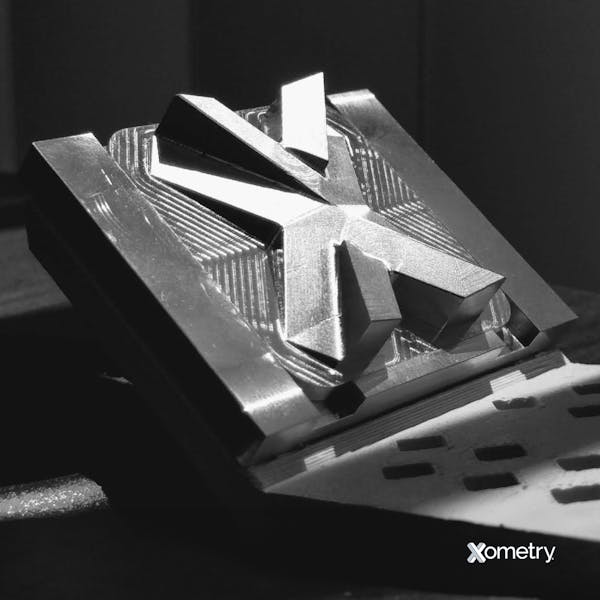

The process starts by loading the workpieces, then clamping them to the table with something like a vise. This will prevent accidental offset cuts and drifting or broken parts while you’re working on the piece. Next, you select the proper tool for the material and project at hand. Then you have to set up the machine, adjusting things like spindle speed and cutting depth. Once all that is set, you’re ready to start milling. The process can be automated or manual, but both need care and attention for an ideal finished product. Here’s an example of a part made via milling by the Xometry team.

The first thing to do is rough up the material by making deep cuts that remove large, unwanted chunks so that it starts to take the form of the final part. It’s then semi-finished with slower, shallower, and more precise cuts, before moving onto full finishing. Once the milling is done, you have to unload the workpiece. Typically people clean the machine at this point too. After you unload the piece, check that the measurements and surface quality meet expectations. Finally, you’ll have to do some post-processing, which could include steps like deburring, heat treatments, surface coatings, and storing. Xometry’s suppliers take all these steps on behalf of our customers, should their projects require it.

What Is the Purpose of Milling in the Manufacturing Industry?

Milling is primarily employed in the manufacturing industry to remove material from a workpiece. It allows manufacturers to shape raw materials into specific forms, creating components with desired dimensions and geometries. Milling machines can also achieve extremely tight tolerances and high precision. This is vital in industries like aerospace and medical device manufacturing, in which accuracy is paramount.

Furthermore, milling can provide a range of surface finishes, from rough to highly polished, depending on the cutter and machining parameters. It enables the creation of complex 3D shapes, contours, and features that may be difficult or impossible to achieve with other machining methods. CNC milling machines, in particular, can produce large quantities of identical parts with high repeatability. Milling can be applied to a wide range of materials, including: metals, plastics, and composites.

What Are the Industries That Use Milling?

Milling is used in various industries and plays a central and pivotal role in the manufacturing of virtually all product classes. For example, in the aerospace industry, the milling of high-value, lightweight, and complex parts for any aspect of flight-engineered products is undertaken widely. From airframe components to controls, from flight-surface actuator parts to jet and rocket-engine components, multi-axis CNC milling is the normal production method for most parts.

Milling is also extensively used in the manufacture of surgical tools and medical implants. The ability to process a wide range of biocompatible and easily sterilized materials with high precision and repeatability is greatly valued in these high-value applications. Other industries that use milling are: manufacturing, oil & gas, and infrastructure.

What Are the Different Types of Milling Machines?

There are loads of different milling machine types, and we briefly explain the most common in the table below. Most of these machines are available through Xometry’s supplier network.

| Milling Machine | Spindle Orientation | Features | Applications |

|---|---|---|---|

Milling Machine Vertical | Spindle Orientation Vertical | Features Simple design | Applications Face milling, end milling, best for smaller workpieces |

Milling Machine Horizontal | Spindle Orientation Horizontal | Features Cuts along entire length of workpiece | Applications Mass production, heavy-duty cutting |

Milling Machine Universal | Spindle Orientation Either | Features Swiveling table for easy angle adjustment | Applications Versatile, angular cuts |

Milling Machine Turret | Spindle Orientation Vertical | Features Rotating turret for multi-tool use | Applications Precision, repetitive cuts |

Milling Machine Bed | Spindle Orientation Vertical | Features Moving spindle, stationary bed | Applications Large, heavy workpieces |

Milling Machine Knee | Spindle Orientation Vertical | Features Adjustable knee | Applications Quick and easy height changes |

Milling Machine Ram | Spindle Orientation Both | Features Movable ram, can cut in both directions | Applications Various types of cuts |

Milling Machine Planer | Spindle Orientation Horizontal | Features Moving work table, vertical cutter adjustment | Applications Large flat surfaces, precise cuts |

Milling Machine CNC | Spindle Orientation Either | Features Automated, highly precise | Applications Minimal manual labor, complex designs |

Milling Machine Gantry | Spindle Orientation Either | Features Bridge structure, spindle moves across workpiece | Applications Large, heavy workpieces |

What Is the Step-by-Step Process of Milling in Machining?

Milling setup and operation is a sequence of skilled stages that must all be performed well, for the result to be useful. Listed and discussed below is the step-by-step process of milling in machining:

1. Loading Workpieces

Depending on the nature of the parts and the volume, the loading of workpieces to be machined can range from being quite low-skilled to highly skilled. Where parts are clamped in a generic restraint such as a vise, or bridge clamped into place using T bolts, the task requires extreme care and precision. Misplacement or poor clamping will result in offset cuts, parts drifting during processing, or parts breaking out during machine operations.

Whenever higher volume dictates the need for specialist nests, these can make setup easy and repeatable, although great skill in such custom nest design and part clamping is required. In extreme cases, for which the volume justifies the investment, loading can be performed by a general-purpose robotic setup or a dedicated loader built into the machine.

2. Selecting Milling Tools

The selection of milling tools can be considered a skilled operation. In a CNC machine with a tool changer, the cutters must be depth referenced and have the correct offsets applied, so the machine has correct awareness of tip and cylindrical positions. In CNC operations, the selection of tools will either occur as part of the automated toolpath generation or as a manual selection by the programmer. Errors in tool selection can have catastrophic results.

3. Setting Up the Machine

The setup of the machine involves clamping and tool selection as the first stages. After this, a range of critical operations must be performed. For a one-off part, the machine must be “taught” the workpiece position. A range of spatial calibration input methods and devices are used, but the central need is to reference the material on three sides (for X-Y-Z positioning) and if necessary “clock” the part as flat onto the table.

With material loaded and calibrated to the spatial reference of the machine, cutters set up for length and diametral offset, coolant supply assured and the guards closed, cutting can commence.

4. Executing Milling

In general, the great majority of milling is performed on CNC machines of varied capability: from 3 to 6+ axes (degrees of freedom). Whether the process is manual or programmed, a similar level of care and attention is required in the motion of the cutter.

The operator will either a) monitor the CNC operation as the machine executes the cutting process or b) operate the machine axes manually to direct the cutter according to the plan. A manual machine requires full operator engagement with all parts at every stage. This includes the constant need to stop operations and check dimensions to affirm correct operation and plan the next cut.

5. Roughing the Material

Roughing involves deep and fast traverse cuts that take off extensive material without much regard to precision—as long as the cut is completed well before reaching the “finished” surfaces to be extracted from the workpiece.

6. Performing Semi-Finishing

Semi-finishing requires shallower cuts and lower feed speeds, to start to impose higher accuracy.

7. Completing the Finishing

Finishing cuts are generally fine and more slowly fed, to deliver the required precision. Some areas will only require roughing, whereas others will require best-possible tolerances, achieved by slow-moving and fine cuts. Finishing is slower and can often consume the majority of the machine's time per part.

8. Unloading the Workpiece

Unloading simply requires the release of the clamping that engages the workpiece and its removal either manually or by a robot. Generally, machine cleaning is performed at this stage, to leave the machine prepared for its next use.

9. Inspecting for Quality

Various measurements and surface quality evaluations will be undertaken, either manually, or using advanced inspection equipment. On occasion, fully automated part checking can be used, for particularly high-volume parts.

10. Conducting Post-Processing

Post-processing can involve simple deburring and packing for storage or later use. It can also involve various types of heat treatment, surface coatings, chemical surface treatments, or plating.

What Are the Materials Suitable for Milling?

Milling is a versatile machining process that can be applied to a wide range of materials, including: metals, plastics, and composites. The suitability of a material for milling depends on factors such as its machinability, hardness, and the specific form of milling operation. Listed below are the materials suitable for milling:

- Metals such as: aluminum, steel, brass, copper, titanium, and nickel alloys

- Acrylic (PMMA)

- Polycarbonate (PC).

- Nylon

- Polyethylene (PE)

- Polypropylene (PP)

- Delrin® (polyoxymethylene, POM)

- Carbon fiber reinforced composites

- Fiberglass (GRP)

- Resin-bonded Kevlar®

- Wood (hardwood, softwood, and man-made boards)

- Ceramics and cermets like alumina, zirconia, and silicon nitride

- Graphite

- Glass

What Are the Two Main Milling Methods?

1. Climb Milling

Climb and conventional are the two most widely used milling methods in manufacturing. Climb milling (sometimes called “down milling”) rotates the tool against the direction of the workpiece’s motion, so the tool moves in the same direction as the material feed, with the cutter climbing over the workpiece. This method offers smooth surfaces with hardly any material deviation, and it won’t overheat or quickly wear out your tools, either. It’s best for high-quality parts and thinner sections and can help you better manage chips.

2. Conventional Milling

Conventional milling (or “up milling”) has the cutting tool rotating in the same direction as the workpiece, which makes the tool move in the opposite direction of the material feed. It works best with more malleable materials, and offers a faster machining process. It also results in a rougher finish, reduced precision, and increased tool wear.

How Long Does It Take for Milling To Finish?

It depends. There are too many varied applications of milling to make a general definition of timing possible. However, for the majority of one-off and low-volume components, few alternative processes can compete for speed of outcome, except by sacrificing either material qualities (3D printing for example) or precision (fabrication).

What Is the Precision of Milling in Machining?

The accuracy of a milling machine can vary widely depending on the machine design, component (particularly slide) quality, and the operator.

For many standard milling machines, positional accuracy can range from a few thou (0.001” or 0.0254 mm) to a few ten-thousandths of an inch (0.0001” or 0.00254 mm). Repeatability is the ability of the machine to return to a specific position consistently. Repeatability varies between machines but is generally considered to be 0.001” in well-maintained equipment. Tolerances within a few thousandths of an inch are generally expected, but better machines and user techniques can achieve higher tolerances. All screw feeds (manual or CNC) suffer from a degree of hysteresis (or slack motion), so the direction of motion must be considered, to take up any slack before cutting commences.

Is a Milling Machine Accurate?

Yes. Milling machines are high-value assets that are generally manufactured to precise tolerances and with low hysteresis in their linear and rotary positioning systems. On that basis, the best milling machines are among the most precise instruments made. However, their operation and maintenance can have a marked effect both on their precision and repeatability in a given task and their ability to maintain these criteria long-term. A badly operated or badly maintained machine will deliver poor accuracy and repeatability in the parts it produces.

What Are the Advantages of Milling in Machining?

Milling is a near-universal machining process in manufacturing due to its advantages. Such as:

- Versatility of material

- Size

- Quality

- Precision

- Delivering complex geometry

- Surface finish

- Adaptive to low- and high-volume

- Low material wastage

- Speed of processing

- Ability to automate

- Overall cost efficiency

What Are the Disadvantages of Milling in Machining?

Although milling is a versatile and broad-spectrum machining-process family, it carries some disadvantages and limitations. These are:

- Slow processing of heavy cuts

- Machine complexity/wear

- Chatter and vibration

- Slow processing of compound curvatures

- Tool wear

- Poor processing of hardened materials

- Heat generation

Is Milling Expensive?

It depends. The relative costs of milling and alternative manufacturing processes are highly varied and dependent on a range of factors. At one-off component manufacture, milling is generally the low-cost production method. For simple geometries, hand production by a skilled craftsman is feasible, but considerably slower and more costly. It can, for larger parts with low general tolerances, be cost-effective to sand cast a part and only use milling when higher precision is required as a post-casting treatment. At serial production levels, in which tens to a few hundred parts are required, milling can still be cost-effective when compared with molded plastics or die-cast metal parts. At high-volume production levels (thousands of parts), other methods become highly competitive, against full milling of parts. This can include lower-precision first-step part production such as sand or investment casting, which must often be followed by milling for precision finishing of areas of higher tolerance. This is the norm in large steel and aluminum parts in the automotive sector, for example. For the highest-volume parts, die casting and plastic molding are primary methods for cost reduction, and milling is generally uncompetitive.

Is Milling Popular?

Yes. Milling is among the most centrally important methods used across all manufacturing sectors. It finds application at every level in every sector, from medical to consumer goods, from one-off to mass production, and in the manufacture of alternative tooling that handles the volumes above which milling loses cost-effectiveness. For volume, precision, repeatability, prototyping, too

What Are the Precautions of Using a Milling Machine?

You absolutely have to closely follow safety rules when using a milling machine. A strict maintenance schedule will help you keep on top of things and notice potential hazards, like damage, loose parts, and general wear and tear. Top of your checklist should be making sure all the safety features, like the stop buttons, are working properly, and that you—and everyone who uses the machine — know exactly where they are and how to use them. All technicians have to be well trained, particularly in the operation process, safety procedures, and possible dangers. It should go without saying, but please don’t sidestep the guards and interlocks—these are here for your safety.

The first thing on your milling to-do list should be personal protective gear. This includes safety glasses, hearing protection, gloves, etc.) Your work area should be clean and tidy, and well-lit. The settings, including the cutting speed and feed rate, will need to be adjusted according to the type, size, and thickness of the material you’re working on, and the workpiece should be clamped securely in place so that it doesn’t move around during the process. Keep hands and hair far away from moving parts at all times, and when you’re changing tools, make sure to switch the machine off first.

What Is the Difference Between Milling and Cutting in Machining?

Generally, all milling involves cutting with rotating tools that pass over a part. It precisely removes pieces of material as the teeth cut through the billet to “extract” the required part from a blank. Cutting as a standalone process usually involves a broaching type action, during which teeth pass over the surface of a part in a linear motion to remove an elongated kerf the entire length of the part, resulting in a slot being cut that separates the material into two parts. The motion can be reciprocating, like a saw blade using a cut and return sequence, or continuous. The continuous cut can come from a bandsaw blade that passes the material in one direction, or it can be a circular slitter/wheel saw that moves the part in a linear motion as it rotates. The distinction between milling and cutting isn’t super clear in many cases, because milling cutters are often used for simple cutting jobs. That said, linear cutters aren’t typically used in milling operations.

What Is the Difference Between Milling and Taper Turning?

Milling has developed into a multi-axis methodology that blurs the differentials with other methods/equipment. A 5+ axis CNC mill can perform turning operations as part of its normal programming, with workpieces held in a rotating chuck and presented to rotating or stationary tools to complete full circumferential cuts. Equally, a 3.5-axis CNC machine can perform a tapered (assumed cylindrical) cut-by-side cutting of a circular profile while adjusting the tilt of the arbor/quill to maintain the cylindrical form of the cut.

Taper turning is generally performed on a lathe, with the part spun in a chuck and a non-rotating tool traversed at an angle to the primary axis of the machine, to cut a tapered cylindrical surface. This generally involves setting the compound slide of the lathe to traverse the tool at the required angle, but it can equally be achieved on a CNC lathe by cooperative motion of the longitudinal and transverse axes of the tool motion.

What Is the Difference Between Milling and Swiss Machining?

Swiss machines are, in reality, early versions of multi-axis machining centers, developed for the mass production of clocks and watches in the 19th century. The addition of cutter rotation that can work alone or in combination with the part rotation in the chuck allowed the production of flat and square features on otherwise cylindrical workpieces, held still in the chuck and cut by the movement of rotating cutters. It wasn’t until the 1970s that lathes began to encompass these types of combined features, and it’s taken the development of 6-axis CNC machines to truly compete with the functionality of Swiss machines.

How Xometry Can Help

Xometry works with more than 10,000 manufacturing partners, so whatever material or service you need, including CNC milling, we’ll be happy to help. You can either reach out to one of our reps, or get started straight away by uploading your designs to the Xometry Instant Quoting Engine®.

Copyright and Trademark Notice

- Delrin® and Kevlar® are registered trademarks of DuPont.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.