Bismuth bronze is a useful alloy that combines the unique properties of bismuth and bronze. Also known as lead-free bronze, bismuth bronze is a bronze alloy that can duplicate many of the same properties as leaded tin bronze without lead in its composition. Different types of bismuth bronze alloys with varying concentrations of bismuth, tin, and zinc exist. Generally, bismuth bronze exhibits high tensile strength, high thermal conductivity, good corrosion resistance, and good machinability, making it useful for a variety of applications. From pipes and fittings to fasteners and bearings, bismuth bronze is a versatile material.

This article will review some important things to know about bismuth bronze—from its composition and properties to its applications.

What Is Bismuth Bronze?

Bismuth bronze is an alloy primarily composed of copper, tin, and bismuth, with varying concentrations of other elements, such as zinc and nickel. Bismuth bronze can provide many if not all, of the properties that tin bronze offers—from strength and machinability to corrosion resistance. Bismuth has a low melting temperature of 271 °C. When added to bronze, it reduces the melting point of the alloy. This improves the ability to cast bismuth bronze into intricate shapes and designs compared to other bronze alloys. The addition of bismuth also improves the alloy’s machinability due to the high lubricity of bismuth. Because of these properties, bismuth bronze is most often used in plumbing, bearing, and fastener applications, but may also be found in artwork, sculptures, and musical instruments.

What Is the History of Bismuth Bronze?

While bronze has been used by humans since the 2nd millennium BCE, the earliest bismuth bronze artifacts date from the 15th century. A set of ceremonial knives from the Inca civilization discovered at Machu Picchu in Peru is considered the earliest evidence of the intentional addition of bismuth to bronze. In the 1880s, bismuth bronze began to be refined for use in telegraph wires, mirrors, kitchenware, and piano wire due to its durability. Then, in the late 20th century, bismuth bronze began to see more extensive use as an alternative to commonly used lead-containing bronze alloys.

Are Bismuth Bronze and Bismuth Brass the Same?

Yes, bismuth bronze and bismuth brass can be considered the same thing despite their different names. While bronze is primarily composed of copper and tin and brass is primarily composed of copper and zinc, the addition of bismuth in both alloys acts as a substitute to lead. Both bismuth bronze and bismuth brass contain around 1–3% of bismuth.

What Is Bismuth Bronze Made Of?

Bismuth bronze is an alloy primarily composed of copper, tin, and bismuth, though the exact composition varies depending on the desired properties and applications of the alloy. A typical composition of bismuth bronze alloy is 70-90% copper, 10-20% tin, and 1-6% bismuth, with the remainder being made up of other, minor additions.

What Is the Ratio of Copper to Bismuth in Bismuth Bronze?

Generally, the ratio of copper to bismuth in bismuth bronze is about 10:1. However, the ratio may differ based on the intended use of the alloy, and the desired properties.

How Is Bismuth Bronze Made?

Bismuth bronze, like other alloys, is made by melting and combining the constituent elements into a homogenous mixture. The mixture can then be poured into ingots for later processing to saleable forms or for remelting to make castings, or it can be continuously cast directly into bars, rods, or tubes.

What Are the Characteristics of Bismuth Bronze?

Bismuth bronze has numerous desirable characteristics. The characteristics of bismuth bronze are listed and described below:

- Corrosion-Resistant: Bismuth bronze has great corrosion resistance due to the combination of copper, tin, and bismuth in its composition. All three of these elements react with the oxygen in the air to form a protective oxide layer on the surface of the material. This contributes to the alloy’s ability to resist deterioration over time and leads to a longer-lasting part.

- Formability: Bismuth bronze exhibits great formability due to its lower hardness and similar or higher ductility compared to other types of bronze. This property can be attributed to the presence of bismuth in the alloy’s composition. Due to bismuth bronze’s properties, casting, machining, extrusion, and other shaping processes used to fabricate complex shapes are much easier.

- Nontoxicity: Bismuth bronze is nontoxic due to the insignificant amount of lead in its composition. This makes the use of bismuth bronze advantageous in industries and applications where the health and safety of users is critical, particularly in the manufacturing of lead-free piping, medical components, and jewelry.

What Is the Color of Bismuth Bronze?

Like other types of bronze, bismuth bronze has a reddish-brown metallic color. This is due to the large concentration of copper present in the alloy.

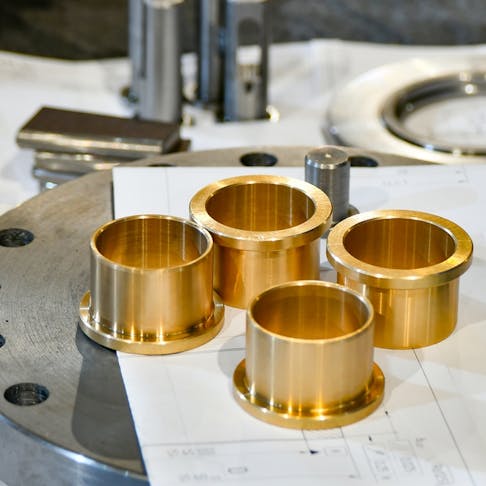

What Does Bismuth Bronze Look Like?

Similar to other bronze alloys, bismuth bronze is a lustrous, reddish-brown, metallic material.

How Does Bismuth Bronze Differ From Other Types of Bronze?

The primary difference between bismuth bronze and other types of bronze is the presence of the rare metal bismuth in bismuth bronze. Bismuth gives this alloy family unique characteristics that differ from other types of bronze. Additionally, bismuth bronze offers similar properties as leaded-tin bronze without significant levels of lead in its composition. Some of the properties of bismuth bronze include: lower melting point, better fluidity during casting, higher machinability, and non-toxicity compared to other bronze alloys.

To learn more, see our full guide on the Different Types of Bronze.

What Are the Physical and Mechanical Properties of Bismuth Bronze?

Table 1 below shows some of the mechanical properties of bismuth bronze:

| Property | Description |

|---|---|

Property Density | Description 0.310–0.330 lb/in^3 |

Property Liquidus melting point | Description 1010–1020 °C |

Property Yield strength | Description 14.5–29.0 ksi |

Property Elongation % | Description 15–30% |

Property Hardness | Description 50–70 HB |

Property Machinability (based on SAE 1112) | Description 80–90% |

Is Bismuth Bronze Harder Than Tin Bronze?

No, bismuth bronze is not harder than tin bronze. The hardness of bismuth bronze alloys ranges between 50–70 HB, while the hardness of leaded-tin bronze alloys ranges between 75–95HB. The presence of bismuth in bismuth bronze reduces the hardness of the alloy compared to tin bronze.

Is Bismuth Bronze Strong?

Yes, bismuth bronze is strong but is weaker than other bronze alloys. The tensile strength of bismuth bronze ranges from 100–200 MPa while leaded bronze alloys have tensile strengths up to 300 MPa. Bismuth bronze is designed to be easily formed and machined and is not often selected for its strength.

What Are the Chemical Properties of Bismuth Bronze?

Table 2 below shows some of the chemical properties of bismuth bronze.

| Chemical Property | Description |

|---|---|

Chemical Property Corrosion resistance | Description Copper and tin in bismuth bronze naturally form oxides as the elements react with the air. These oxide layers contribute to the corrosion resistance of the alloy. The addition of bismuth to the composition further improves the alloy’s corrosion resistance. |

Chemical Property Toxicity | Description Nontoxic |

What Is Bismuth Bronze Used For?

Bismuth bronze has many uses in a variety of industries and applications. Some bismuth bronze uses include: bearings and bushings for machinery and automotive components, lead-free piping and pipe fittings, jewelry, and more.

What Manufacturing Processes Are Suitable for Bismuth Bronze?

Bismuth bronze can be made into products using several different manufacturing and fabrication processes. The most common of these are listed below:

1. Casting

Casting is a commonly used manufacturing process for bismuth bronze. Due to its low melting temperature and excellent fluidity compared to other metals and alloys, the production of bismuth bronze castings has lower energy costs. Consequently, creating complex shapes is easier, which makes bismuth bronze a great option for the production of cast components such as: pipe fittings, sculptures, and more.

To learn more, see our How Does Casting Work full guide.

2. Annealing

Annealing is a heat treatment process during which a material is heated to a specific temperature and then air-cooled to the ambient temperature. During the annealing process, atoms in the crystal structure of the material move around and form new, strain-free grains, which causes an increase in the material’s ductility and a reduction in its hardness. For bismuth bronze, annealing helps to relieve stresses imparted to the material during casting or other shaping processes. This helps to improve its mechanical properties.

To learn more, see our full guide on What is Annealing.

3. Extruding

Extrusion is the process of forcing material through a die to produce a continuous profile or shape. If completed at room temperature, extrusion can change the mechanical properties of a material due to strain hardening. Bismuth bronze is often cold-extruded into parts like rods, pipes, and tubes.

4. Water Atomization

Water atomization is the process of creating metal powders by spraying water into a stream of flowing molten metal. The water instantly cools the metal into granules or powder. For bismuth bronze, water atomization creates bismuth bronze powders that can be used in additive manufacturing or powder metallurgy.

What Are the Advantages of Bismuth Bronze?

Bismuth bronze has many advantages that make it great for use in a variety of applications in different industries. The advantages of bismuth bronze are listed below:

- Low Melting Point: Bismuth bronze has a lower melting point than other bronzes due to the presence of bismuth in its composition. This makes casting at lower temperatures possible, which helps to reduce manufacturing costs.

- Fluidity During Casting: Bismuth bronze alloys exhibit great fluidity, and pour easily during casting. This makes bismuth bronze ideal for complex castings and detailed designs.

- Machinability: Bismuth bronze is known for its machinability (80-90% based on SAE 1112) due to the lubricity of bismuth. Because of its excellent machinability, cutting tools wear down more slowly, which reduces the need to replace tools. Additionally, its high machinability rating compared to that of other bronze alloys facilitates the fabrication of complex parts, such as gears and bearings.

- Nontoxic: Bismuth is considered nontoxic. Since bismuth replaces lead in traditional leaded bronze alloys, bismuth bronze is nontoxic. Its nontoxicity makes it great for use in applications that involve regular contact with the product, such as: kitchenware, jewelry automotive components, and more. Additionally, the replacement of old, leaded plumbing systems with lead-free plumbing is another application of bismuth bronze.

What Are the Disadvantages of Bismuth Bronze?

Bismuth bronze also has some disadvantages. Some of the disadvantages of bismuth bronze are listed below:

- Scarcity and Cost: Bismuth is a rare element, which makes obtaining and refining the metal for alloying difficult. Its scarcity directly impacts the cost of bismuth bronze. Consequently, the price of bismuth bronze may be higher than that of other bronze alloys, depending on market conditions.

- Lower Strength: Bismuth bronze has lower tensile strength than leaded bronze alloys due to the replacement of lead with bismuth. It can be difficult to justify the use of bismuth bronze in high-strength applications when other leaded bronze alloys can satisfy the application.

- Unsuitable for High-Temperature Applications: The low melting temperature of bismuth bronze may restrict its use for high-temperature applications. While the product may not melt, its mechanical properties may be diminished as temperatures increase, which could lead to unexpected failure.

- Embrittlement Over Time: Bismuth bronze may become brittle over time due to circumstances like exposure to moisture, sulfides, or chlorides. Without proper maintenance and environmental control, bismuth bronze may exhibit “bronze disease,” becoming discolored and brittle.

Is Bismuth Bronze Toxic?

No, bismuth bronze is not toxic. Bismuth can act as a substitute for the lead which is commonly present in other types of bronze. Because of its nontoxic properties, bismuth bronze is often used in plumbing for drinking water applications.

Does Bismuth Bronze Rust?

No, bismuth bronze does not rust since it does not contain iron. Rust is iron oxide, the reddish-brown material that forms as a result of the chemical reaction between iron and oxygen in the air.

Does Bismuth Bronze Turn Green?

Yes, bismuth bronze will eventually turn green over time. The green color is attributed to copper oxide, which forms after the copper present in bismuth bronze chemically reacts with the oxygen present in the air. Unlike iron oxide or rust, copper oxide provides a protective layer to the bismuth bronze, inhibiting further corrosion.

What Is the Difference Between Bismuth Bronze and Copper?

Bismuth bronze is an alloy composed of different metal elements, primarily copper, tin, and bismuth. Copper is an element in the periodic table, and is one constituent of a bismuth bronze alloy.

To learn more, see our full guide on the Characteristics of Copper.

Summary

This article presented bismuth bronze, explained it, and discussed its composition and properties. To learn more about bismuth bronze, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.