To fully understand how a product will function and hold up over time, you need to understand the specific physical characteristics of its materials—including its hardness. Finding this value comes down to using several interesting measuring techniques, depending on the material at hand, and when it comes to rubber and hard plastics, look no further than the Shore D Hardness scale.

With the help of this scale and its measuring device, manufacturers get more insight into how a material responds to pressure and can select the best material for their products. Below, you can learn about how it all works and how it’s used.

What is the Shore D Hardness Scale?

The Shore D Hardness Scale is a method and reference system for measuring the hardness of materials such as rubber and plastic with a tool called a durometer. The exact measurement points to how much force a material can handle before an indent is created.

This is done with the pointed tip of a durometer, which presses into the surface of your material and is controlled by a spring with a force that you or the operator will set. The depth of the indent that the pointed steel rod or needle creates translates into a certain rating on the scale. The scale runs from 0 to 100, and the higher the number the more difficult it is to indent the material (and therefore, the harder it is). The chart also gives users a good understanding of the best types of rubbers and plastics to use based on the durometer reading and the application for which it will be used.

How Is the Shore D Hardness Scale Used in Industry?

In an industrial setting, hard plastics, rubbers, and other materials are measured using the Shore D hardness scale. The Shore D scale utilizes a durometer to gauge how deeply a pointed object can pierce a material under a known, constant force. The material's hardness is then calculated using this depth measurement.

What Type of Materials Can Be Tested Using the Shore D Hardness Scale?

The Shore D scale can help manufacturers figure out what materials are best for applications like car doors, sports equipment, or contact lenses as it’s an ideal indicator of hardness. There are so many types of plastics and rubbers, but here’s a small sampling of how it’s an effective system for the following types of materials and applications:

- Thermoplastic polyurethane (TPUs) are a type of bendable and elastic plastics that are part of everything from footwear to medical equipment that can be tested with a durometer.

- ABS or acrylonitrile butadiene styrene is a popular material tested with the Shore D system, which helps manufacturers understand how it works for FDM printing, toys, car parts, or home appliances.

- Polycarbonate or PC is found in everyday objects like corrective contact lenses or automotive parts and is another plastic with a hardness that can be measured through a durometer.

- PET plastic—an acronym for polyethylene terephthalate—is another familiar material found in food and beverage containers and packaging that’s tested this way.

What Are the Benefits of Using the Shore D Hardness Scale for Material Testing?

There are a handful of benefits that come with using the Shore D scale, including:

- Precise results: It’s possible to get specific and precise readings with a durometer, making it a great option for finding the hardness of plastics and rubbers.

- Many materials: It’s possible to test a wide range of plastics and rubbers for different applications and it’s not just limited to a few industries.

- Quick and efficient: Durometers are small and easy to transport, and their size and simplicity mean it’s a fast and easy way to get a material hardness reading.

- Non-destructive: A durometer doesn’t render a material useless or completely ruin it, so it can be used after testing.

What Are the Limitations of the Shore D Hardness Scale?

Conversely, this scale also has a few limitations, such as:

- Compatibility issues: The Shore D Hardness Scale is only capable of testing different types of plastics and rubbers, so you’ll have to rely on another method for other materials.

- Material differences: The same material can show two different Shore D ratings depending on the surface finish it has, which can cause inconsistencies.

- Temperature effects: Some materials will soften or harden in heat or cold, so you’ll want to work with the same temperature when testing them to avoid different readings.

- Room for error: Inconsistencies in a durometer’s precision or in how the operator takes measurements can lead to an incorrect reading.

How Is the Shore D Hardness Scale Determined?

The depth to which a specific indenter penetrates the material being tested under particular circumstances determines the Shore D value. A steel rod with a pointed, spring-loaded tip gets pressed with a certain amount of force into the material. The hardness value is then determined by measuring the depth of penetration and selecting the corresponding value from a durometer chart. Rubber, hard plastics, and similar materials are the most common targets for this technique.

If you’re using rubber, the durometer chart will offer suggestions on what level of rubber hardness would be appropriate for your particular application. For instance, if you want your material to absorb shocks and provide cushioning, you might want to select a rubber material with a lower durometer rating, which denotes a softer, more malleable rubber. A material with a higher durometer rating, indicating a harder, less pliable rubber, may be preferable if you need it to provide support or resist deformation.

How Does Temperature Affect Shore D Hardness Measurements?

Temperature has an impact on Shore D hardness measurements. Hardness values drop as the temperature rises. This is because the materials themselves soften with higher temperatures and allow for easier penetration by the indenter.

What Is the Range of Hardness Values on the Shore D Hardness Scale?

The Shore D hardness scale outputs values between 0 and 100. Higher values denote harder materials and greater resistance to indentation. A material is said to be very soft if it has a Shore D value of 0.

For What Applications Is Shore D Scale Used?

Materials' hardness can be compared based on their Shore D rating. Here are a few examples of items or substances that are typically measured using the Shore D scale:

- Thermoplastic Polyurethanes (TPUs): Numerous products, including footwear, automotive parts, and medical equipment, use TPUs. The relative hardnesses of TPUs are typically compared using the Shore D scale.

- Acrylonitrile Butadiene Styrene (ABS): ABS is a thermoplastic polymer used to make car parts, home appliances, and toys. The Shore D scale is used to evaluate grades of ABS.

- Polycarbonate (PC): PC is a thermoplastic polymer used in a wide range of products, including automotive parts, medical equipment, and eyeglass lenses. PC hardness is typically measured using the Shore D scale.

- Polyethylene Terephthalate (PET): PET is a thermoplastic polymer used to create beverage bottles, food containers, and packaging materials. The hardness of PET is assessed using the Shore D scale.

What Are the Types of Materials Used To Test ASTM D2240?

Products and materials that are typically tested via the ASTM D2240 standard include:

- Thermoplastic Elastomers: This group of materials exhibits traits common to both elastomers and thermoplastics. They have elastic qualities similar to vulcanized rubber, but they can also be melted and remolded like thermoplastics.

- Vulcanized Rubber: This kind of rubber has undergone the chemical process of vulcanization, which involves heating it and adding sulfur to increase its elasticity, tensile strength, and durability. It is usually applied in goods like tires, hoses, and seals.

- Elastomeric Materials: These are materials with the capacity to stretch and then snap back to their original dimensions once released. To ensure a snug and secure fit, they are frequently used in goods like gaskets, seals, and O-rings. Neoprene, silicone, and polyurethane are some examples.

The ASTM D2240 standard covers Type A, D, and M durometer testing methods. It is not advisable to compare the outcomes of this method with those of other indentation hardness techniques; other methods use different tools and generate results that will appear inconsistent with Type A, D, and M results.

What Are Examples of Shore D Scale Standards?

To give you a better idea of the scale and where certain products and materials fall within the spectrum, we’ve listed out a few common objects below—some made of rubber and plastic and others not—and their values for reference:

- Hardback book cover: Shore D-40

- Golf ball: Shore D-50

- Swivel wheel: Shore D-60

- Wooden ruler: Shore D-70

- Computer casing: Shore D-80

- Bone: Shore D-90

Frequently Asked Questions About Shore D Hardness Scale

Can Shore D Hardness Scale Measure Rubber Tires?

Yes, rubber tires can be measured using the Shore D scale. In fact, this scale was created especially to assess the toughness of materials like hard plastics and rubbers. Automotive tires tend to come in at a value of around 70.

Is Shore D Hardness Scale an ASTM Standard?

Yes, ASTM maintains a standard for the Shore D hardness scale. The ASTM D2240-15 Standard Test Method for Rubber Property—Durometer Hardness outlines the procedures for measuring the hardness of materials using the Shore D scale. This standard is widely used in industries that involve rubber and plastics.

Is Shore D Harder Than Shore A Scale?

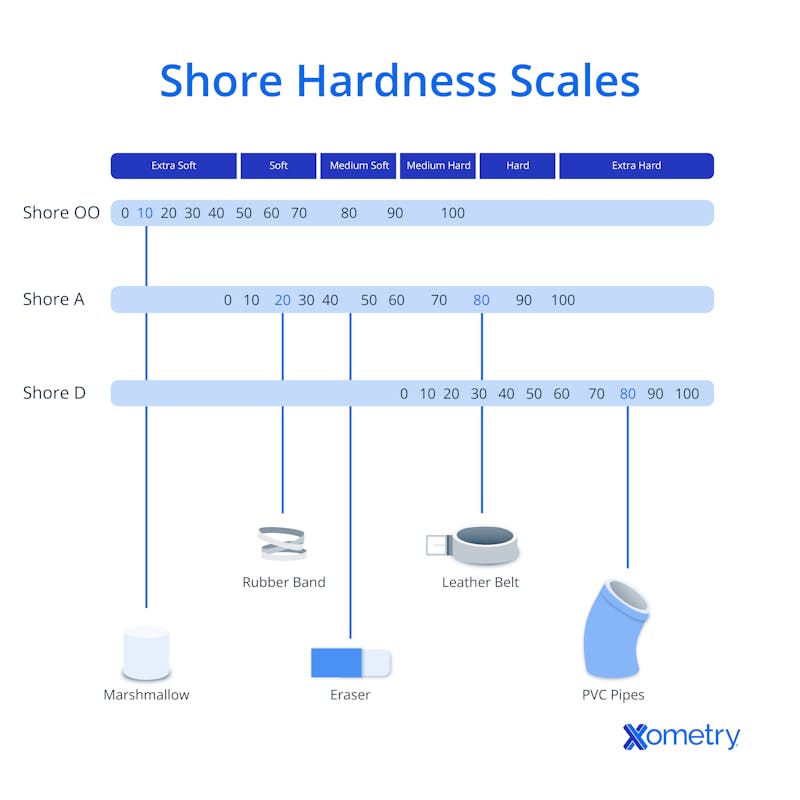

Yes, Shore D is harder than Shore A. Shore A is designed for softer materials, whereas Shore D measures the hardness of harder materials. Both standards' output values run from 0 to 100, but the scales are not identical.

What Is the Difference of Between Shore D Hardness Scales from Shore A Hardness Scale?

The Shore D and A scales actually measure the same thing and work on the same type of spectrum, but the former is reserved for harder plastics and rubbers, whereas the latter is better suited for softer plastics. The durometers used for each are built differently so they can best cater to the types of materials they’re pressing into. For the Shore D scale, the tip of the durometer indenter is sharper and pointed, whereas for the shore A scale, it’s rounded so that it doesn’t puncture or fully damage the softer materials. Examples of items you could test with the Shore A system include rubber bands, erasers, and even marshmallows.

How Xometry Can Help

Our team at Xometry is familiar with numerous processes that involve the exact materials the Shore D hardness scale tests. Whether you’re interested in plastic injection molding, plastic 3D printing, rubber 3D printing, or bridge molding, you can get a free quote today on these services and more.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.