Both laser and plasma cutting are computer numerical control (CNC) cutting processes Xometry offers via our sheet metal cutting services. They’re useful for thermally cutting different types of materials and are used in many different industries. Although similar, they have a few important differences, which we’ll cover in this article.

What Is Laser Cutting and How Does it Work?

Laser cutting allows cuts through a material with a concentrated laser beam that melts and separates a local part of it. In most cases, the process will be accompanied by a gas that blows the melted material out of the way, or the freshly cut material will be turned from a solid to a gas (called sublimation), also getting it out of the way, but this time in vapor form. Laser cutting is quite versatile, as it can be used to cut structural and pipe materials in addition to thin sheets. At Xometry, we use laser cutting most often when it comes to cutting sheet materials.

There are three main types of lasers you can use for laser cutting—they all basically do the same thing, but some are better for thicker materials. They are CO2, neodymium, and fiber laser systems:

- CO2 cutters, the most popular of the three, use electrically stimulated CO2. They’re versatile, inexpensive, and don’t need a lot of power.

- Neodymium cutters, also known as crystal laser cutters, use Nd: YVO (neodymium-doped yttrium ortho-vanadate) to produce the beam.

- Fiber cutters use fiberglass to cut through surfaces. Some special fibers are then used to amplify the seed laser, and this is what creates the final beam.

Laser cutting is used almost everywhere, from electronics to medicine, and aircraft to transportation. It’s also a great way to get precise cuts and finishes, and that’s why many Xometry customers opt for laser cutting when it comes to materials like tungsten, steel, aluminum, brass, and nickel. But it can also cut non-metals like silicon, wood, and ceramics. Here are what some laser-cut piece from aluminum can look like:

Laser Cutting Advantages vs. Plasma Cutting

Laser cutting machines have the following advantages over their plasma cutter counterparts:

- Accuracy: The energy of a laser beam is concentrated on a single tiny area, penetrating the material and cutting it. This process produces a thin cutting seam (kerf) in the workpiece, as opposed to the wider kerf produced by plasma cutting. The thinner cut made by a laser makes it useful for complex, delicate cutting tasks that cannot be accomplished by a plasma cutter.

- Wide Range of Materials: Laser cutters are capable of cutting a wide range of materials, including: metal, wood, plastics, and ceramics. Plasma cutters, on the other hand, are limited to cutting conductive materials.

- Speed: Laser cutters are a more energy-efficient and faster option for cutting metal compared to plasma cutters, making them a better choice for the environment.

Laser Cutting Disadvantages vs. Plasma Cutting

Laser cutters have the following disadvantages when compared to plasma cutting machines:

- Reflective Materials: Compared to plasma cutting, laser cutting does not perform as well on highly reflective surfaces like metal.

- Material Thickness: In general, laser machines do not have enough power to cut through materials thicker than 19 mm, whereas plasma cutters are able to cut metal plates with a thickness of up to 38 mm.

- Capital Investment: Capital costs for a laser cutter are significantly higher than for a plasma cutter.

What Is Plasma Cutting and How Does it Work

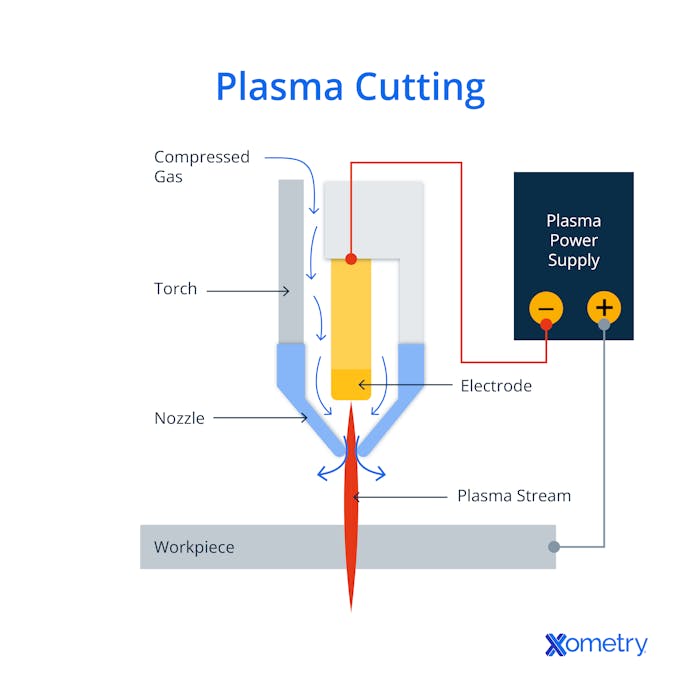

Unlike laser cutting, plasma cutting forces a hot, electrically charged gas like argon or nitrogen through a small nozzle. It hits the surface with speed and high pressure, essentially melting and eroding the material as it passes through. The similarity, however, is that, like laser cutting, plasma cutting is a thermal cutting process because the plasma it forms can reach up to 20,000°C.

With plasma cutting, you can only use conductive metals like steel, stainless steel, and copper, because these complete the electrical circuit. That’s why most of our customers who use plasma cutters are often in sectors like auto repair and restoration, fabrication shops, and industrial construction. This diagram breaks down the plasma-cutting process:

Plasma Cutting Advantages vs. Laser Cutting

Compared to laser cutting, plasma cutting has the advantage in:

- Cost: Laser cutters are typically more expensive to operate than plasma cutters.

- Thicker Plates: In general, plasma cutters are able to cut thicker plates (up to 38 mm) compared to laser cutters that can cut 12.7 mm thick aluminum, 19 mm thick stainless steel, and 25.4 mm thick steel.

- Low Maintenance: Plasma technologies require significantly less maintenance than laser cutters.

Plasma Cutting Disadvantages vs. Laser Cutting

Plasma cutting has some disadvantages compared to laser cutting. These include:

- Larger Kerf: The larger kerf size of plasma cutting means that it is less accurate, and therefore is more limited compared to laser cutting.

- Limited Functionality: Plasma cutting does not offer engraving functionality as laser cutting machines do.

- Radiation: Plasma cutters, unlike laser cutters, create radiation. This necessitates the use of protective equipment, including goggles or glasses for workers.

- Limited Materials: Plasma cutters are limited to use on electrically conductive materials.

Comparing Laser Cutting vs. Plasma Cutting

The main area where these two cutting processes differ is their power source. Laser cutting machines cut through materials using a narrow and intense ray of light, but plasma cutters emit a directed flow of plasma instead. Both methods are mainly used to cut metals, but laser cutting can also be used for cutting other materials, like ceramic and wood. T

Laser Cutting vs. Plasma Cutting: Speed

Overall, laser cutters have a higher cutting speed compared to their plasma cutting counterparts, especially for thin metal sections. However, plasma cutters are faster when thicker metal sheets are being cut.

Laser Cutting vs. Plasma Cutting: Materials

Plasma cutting can be used with any type of conductive metal or material, but cannot be used with non-conductive materials like plastic and wood. Meanwhile, laser cutting can be used with a wide variety of materials, including metals, plastics, and wood.

Laser Cutting vs. Plasma Cutting: Cost

Laser cutting equipment has higher investment costs than plasma cutting machines. Operational costs for laser cutters typically average around $20/hour, whereas plasma cutters usually average around $15/hour.

Laser Cutting vs. Plasma Cutting: Sheet Thickness

Although this is changing as technology advances, the majority of laser equipment is not powerful enough to cut materials that are thicker than 19 mm. Laser cutters can cut 12.7 mm thick aluminum, 19 mm thick stainless steel, and 25.4 thick steel. Plasma cutters, on the other hand, can cut through metal plates up to an inch and a half thick.

Laser Cutting vs. Plasma Cutting: Cutting Surface

The cutting surface of laser cutters is without burrs, smooth, and has good cut quality. Plasma cutters, on the other hand, are known to have poor perpendicularity. They create cuts with more cutting slag that needs to be removed by grinding, thus increasing the labor cost. Overall, laser cutters have a better surface finish, making laser cutting ideal for intricate designs.

Laser cutters produce cuts with very narrow slot widths of approximately ±0.15 mm and high precision of 0.01 mm or less. Plasma cutters, on the other hand, have a larger slot width (larger than 3.8 mm) and a precision of about 0.5-1 mm. The precision of both these cutters is influenced by the thickness of the material that is being cut. More power will be required for thicker materials, which leads to larger nozzles and a higher electrical current and results in a larger cut width.

Mutual Alternatives to Laser Cutting and Plasma Cutting

The main alternatives to laser and plasma cutting technologies are:

- Water Jet Cutting: On thicker plates, water jet cutting is more cost-effective than plasma or laser cutting. However, plasma and laser cutters are better for quick, tiny cuts.

- Oxy-Fuel Cutting: Oxy-fuel cutting is mainly used to cut thick metals and has relatively low accuracy.

- Wire EDM (Electrical Discharge Machining): Wire EDM is an accurate but very slow cutting technique.

If, after reading this article, you decide that neither laser cutting nor plasma cutting is right for you, you can consider alternative methods like water jet cutting, oxy-fuel cutting, or wire EDM (electrical discharge machining).

How Xometry Can Help

Xometry provides a wide range of manufacturing capabilities, including sheet cutting and other value-added services for all of your prototyping and production needs. Want to learn more about our custom CNC cutting services, and get an instant quote? A Xometry representative is always available to help.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.