To create 3D-printed molds for casting, there are ten steps to follow (CAD model creation to pour the silicone). 3D‑printed casting molds are digitally designed mold structures produced through additive manufacturing to support accurate and efficient casting processes across multiple industries. Detailed cavity geometry forms the foundation of each mold, which establishes strong dimensional control during metal, resin, or elastomer casting. Material selection determines heat resistance, strength, and surface texture, which influences mold durability and casting quality. Printing methods shape layer resolution and structural stability, which guide performance during filling, curing, or thermal exposure. The combination of precise design, stable materials, and adaptable production techniques creates a versatile mold‑making approach suited for prototyping, short‑run manufacturing, and specialized casting applications.

1. Create or Import the CAD Model

Create or import the Computer-Aided Design (CAD) model by defining accurate geometry that reflects the intended casting shape with balanced proportions and clear boundaries. Establish detailed contours that support mold formation and maintain consistent dimensional accuracy. Finalize the model by confirming that every feature contributes to stable mold construction and predictable casting performance.

2. Decide Whether the Part Should Be Hollow or Solid

Decide whether the part should be hollow or solid by examining strength demands, weight goals, and thermal behavior during casting. Evaluate how each configuration influences durability, curing stability, and material usage. Select the structure that aligns with the required performance, so the mold supports reliable shaping and consistent final quality.

3. Add Internal Structure if the Model Is Hollow

Add internal structure if the model is hollow by forming reinforcing elements that stabilize the walls during printing and casting. Shape internal ribs or lattice zones to distribute stress evenly and prevent collapse under pressure. Maintain smooth transitions within the structure, so material flow remains steady and dimensional accuracy remains protected.

4. Add Mold Keys and Alignment Features

Add mold keys and alignment features to maintain precise registration between mold sections during assembly. Form interlocking shapes that prevent shifting and preserve cavity accuracy under clamping force. Position alignment points along the parting line so sealing strength and structural stability remain consistent throughout the casting process.

5. Create a Mold Block Around the Model

Create a mold block around the model by enclosing the geometry in a solid volume that forms the outer structure of the mold. Establish uniform wall thickness to resist heat and pressure during casting. Shape internal boundaries to support clean separation after curing and maintain the integrity of the final part.

6. Split the Mold Block Into Two or More Sections

Split the mold block into two or more sections by defining parting lines that follow the natural geometry of the model. Form clean separation planes that allow easy removal of the finished casting without damaging fine details. Balance the division so each section maintains structural strength and accurate reassembly.

7. Embed the Model Into the Mold Block and Add Vents/Pour Spouts

Embed the model into the mold block by positioning it within the solid volume so the cavity forms accurately around it. Add vents to release trapped air and pour spouts to guide material into the cavity with a steady flow. Arrange each feature to support uniform filling and reduce the risk of voids or incomplete curing.

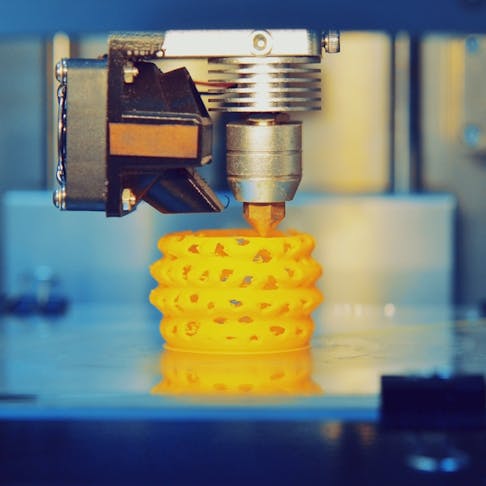

8. Prepare the 3D Printer and Print the Mold

Prepare the 3D printer by calibrating the build platform, selecting a material with adequate strength and heat resistance, and applying slicing settings that support dimensional accuracy. Arrange mold sections on the build plate to reduce distortion and maintain stable geometry. Start the print once all parameters align with the mold’s structural requirements in 3D Printing.

9. Clean, Sand, and Post-Process the Mold

Clean the mold by removing residue from printing and smoothing surfaces to refine contact points. Sanding reduces layer lines and strengthens sealing during casting. Inspect each section to confirm dimensional accuracy and ensure that the mold fits together with stable alignment.

10. Pour the Silicone or Casting Material and Trim Excess After Curing

Pour the silicone or casting material into the prepared mold through the designated spout to fill the cavity completely. Allow the mixture to cure until the structure stabilizes and forms the intended shape. Remove the casting and trim excess material to restore clean edges and achieve a finished part with consistent detail and dependable strength.

Printing molds directly skips the need to make the pattern in the first place, giving you faster time to market and the ability to add even more complexity to your design than what can be traditionally produced using the old style of molding

What is a Mold for Casting?

A mold for casting functions as a shaped container that forms liquid material into a solid part with defined geometry and controlled surface detail. The mold creates a negative impression of the intended design, allowing resin, silicone, metal, or other casting materials to flow into every contour before curing. The structure establishes boundaries that guide dimensional accuracy, maintain consistent thickness, and support stable solidification. A well‑designed mold delivers a reliable reproduction of complex shapes, making it an essential tool for producing parts with uniform quality and predictable performance.

How are 3D-Printed Molds Used for Metal Casting?

3D-printed molds are used for metal casting by creating accurate patterns, cores, or indirect mold structures that define the final metal geometry. The process starts with a digital model that specifies every contour needed for the finished metal part. The printed components are produced from materials selected for dimensional accuracy or sacrificial burnout, depending on the casting method. Structural features support shape retention during mold preparation rather than direct metal flow. Vent paths and gating channels are incorporated into the overall mold system to guide molten metal and reduce trapped air. Once the metal solidifies and the mold system is removed, the casting reflects the accuracy and detail established during the digital design and printing stages.

How can 3D Printed Molds Be Used for Silicone Casting?

3D‑printed molds can be used for silicone casting by forming a rigid cavity that shapes liquid silicone into a stable, detailed part. The printed mold establishes precise boundaries that guide silicone flow and preserve fine surface features during curing. Dimensionally stable materials and reinforced walls maintain accuracy as the silicone settles into the cavity. Heat‑resistant materials and reinforced walls maintain dimensional accuracy as the silicone settles into the cavity. Vent paths and pour channels guide the material through the mold, minimizing trapped air and surface flaws. The mold releases cleanly after the silicone cures, resulting in a finished part that accurately reflects the precision and structural consistency established during printing.

“3D-printed molds give engineers a fast and flexible way to move from design to casting, but understanding how materials, temperatures, and indirect mold workflows interact is what separates successful results from trial-and-error. When those fundamentals are clear, additive manufacturing becomes a precise and reliable tool rather than a shortcut.”

How to make Custom 3D Molds?

To make custom 3D molds, follow the twelve steps below.

- Define project requirements. Establish part geometry, target dimensions, production quantity, and performance needs so the mold design supports the intended application.

- Select a suitable CAD platform. Choose modeling software that supports precise solid modeling, assembly features, and export formats compatible with 3D printing workflows.

- Create or import the part model. Build the 3D representation of the desired part or load an existing file, then confirm accurate scale and clean geometry.

- Plan mold type and parting strategy. Decide on single‑part, multi‑part, or insert‑style construction and outline parting lines, gating locations, and vent paths.

- Design the mold cavity and draft. Offset the part surfaces to form the cavity, add draft angles for release, and adjust wall thickness for strength and heat resistance.

- Add mold keys and alignment features. Integrate interlocking keys, guide faces, and orientation markers so repeated assembly maintains accurate cavity registration.

- Build the mold block and external supports. Enclose the cavity in a solid block with adequate margins, gripping features, and flange areas for clamping or fixtures.

- Integrate pour spouts and vent channels. Model inlets for the casting material and paths for trapped air to escape, while preserving structural integrity around each opening.

- Check printability and service conditions. Validate minimum feature sizes, overhangs, and thermal loads so the selected printing process and material match project demands.

- Export and slice the mold design. Save the mold bodies in a compatible format, import them into slicing software, and set layer height, infill, and orientation for accurate printing.

- Print the mold and inspect the parts. Produce the mold components, then examine surfaces, dimensions, and fit between sections to confirm readiness for casting.

- Post‑process and prepare for casting. Clean residual powder or support material, sand critical surfaces, seal porous regions if needed, and apply release agents to ready the mold for custom casting projects.

How to make a 3D Mold for Resin?

To make a 3D mold for resin, follow the twelve steps below.

- Define the resin part design. Establish target geometry, dimensions, and surface detail, so the mold cavity matches the intended resin part.

- Create or import the CAD model. Build the 3D model in CAD software or import an existing file, then clean the geometry to remove gaps and intersecting faces.

- Plan mold type and parting line. Decide on single‑piece or multi‑part mold construction and trace a parting line that supports easy demolding and protects critical features.

- Add draft and adjust wall thickness. Apply gentle tapers on vertical faces and set uniform wall thickness, so the printed mold supports resin flow and structural stability.

- Design the mold block and cavity. Enclose the part in a solid block, offset the surfaces to form the negative cavity, and leave margins for strength and handling.

- Integrate keys, vents, and pour spouts. Add alignment keys for accurate assembly, model vent channels for air escape, and create pour openings sized for controlled resin filling.

- Choose a suitable printing material and process. Select a printing resin or filament with good dimensional accuracy, chemical resistance to casting resin, and adequate heat tolerance.

- Orient and slice the mold for printing. Position mold halves in the slicer to reduce support scars on sealing surfaces, set layer height and infill, and generate print files.

- Print the mold and check the fit. Produce the mold parts, inspect surfaces and dimensions, and verify that all sections assemble without gaps or misalignment.

- Post‑process the mold surfaces. Remove supports, wash or clean residues, sand mating faces, and seal porous areas if necessary to reduce resin leakage.

- Apply a suitable mold release. Coat the cavity and contact faces with a compatible release agent so cured resin separates cleanly from the mold.

- Cast the resin and finish the part. Fill the mold through the pour spout, allow complete curing according to resin specifications, demold the part, and trim any flash or excess material.

How does 3D Printing Improve Jewelry Mold making?

3D printing improves jewelry mold making by delivering precise cavities that capture fine ornamental detail with consistent accuracy. The printed structure forms a stable framework that preserves delicate contours during wax, resin, or investment casting workflows. High‑resolution printing materials support sharp edges, smooth surfaces, and balanced wall thickness, which strengthens the reliability of each mold. Digital modeling streamlines adjustments to size, pattern, and texture, creating a direct path from design to production without manual sculpting. The controlled geometry produced through additive manufacturing reduces defects, strengthens repeatability, and supports the creation of intricate jewelry pieces with dependable quality.

What Are the Best 3D Printers for Mold Making?

The best 3D printers for mold making are listed below.

- Formlabs Form 3+: The Form 3+ delivers high‑resolution prints that support mold cavities with sharp detail and smooth internal surfaces. Its resin formulations maintain dimensional stability, creating reliable molds for silicone, resin, and low‑temperature casting projects.

- Prusa SL1S Speed: The SL1S Speed produces precise layers that capture fine geometric features required for accurate mold reproduction. Its fast-curing system supports efficient production while preserving structural consistency across complex mold designs.

- Anycubic Photon Mono X 6K: The Photon Mono X 6K offers a large build area and detailed resolution that benefits multi‑part molds and intricate cavity structures. Its stable light engine maintains uniform exposure, resulting in consistent accuracy across every printed mold section.

- Elegoo Saturn 3 Ultra: The Saturn 3 Ultra provides high‑definition printing that supports molds with refined textures and balanced wall thickness. Its reinforced frame and steady projection system reduce print distortion, strengthening the reliability of finished molds.

- Bambu Lab X1 Carbon: The X1 Carbon delivers strong filament‑based molds with excellent rigidity for casting applications that require durable tooling. Its controlled motion system maintains tight tolerances, producing mold components that assemble with dependable alignment.

What Are Other Types of Casting?

The other types of casting are listed below.

- Sand Casting: Printed molds support intricate patterns that guide molten metal into detailed cavities with strong dimensional control. Reduced tooling steps shorten preparation time and strengthen flexibility for prototype metal parts.

- Investment Casting: Printed patterns create precise wax replacements that form highly accurate ceramic shells. Fine geometric detail strengthens surface quality and supports complex metal components.

- Die Casting: Printed inserts assist in shaping trial components without full‑scale metal tooling. Faster design adjustments support efficient testing of part geometry before committing to hardened dies.

- Centrifugal Casting: Printed molds form balanced internal channels that guide molten metal under rotational force. Controlled geometry strengthens uniform distribution and supports consistent structural integrity.

- Shell Casting: Printed patterns establish smooth surfaces that transfer clean detail into hardened shells. Accurate pattern geometry supports reliable reproduction of thin‑walled metal parts.

- Plaster Casting: Printed molds create refined cavities that support smooth plaster flow and detailed reproduction. Stable printed structures maintain shape during curing and strengthen dimensional accuracy.

- Continuous Casting: Produces long, uniform metal sections by pouring molten metal into a water-cooled mold where it solidifies progressively during continuous withdrawal.

- Vacuum Casting: Uses negative pressure to draw resin or metal into a sealed mold, reducing trapped air and improving surface quality and dimensional accuracy.

1. Sand Casting

Sand casting forms metal parts by packing sand around a pattern to create a stable mold cavity. The sand structure withstands high temperatures, which supports molten metal during pouring. The process accommodates large components because the mold material adapts to substantial volumes. The packed sand captures moderate detail, which supports functional shapes with reliable dimensional control. The method of Sand Casting remains valuable for industrial environments that require durable castings with flexible mold preparation.

Explore sand casting services to achieve durable metal parts shaped through flexible and cost‑efficient molding.

2. Investment Casting

Investment casting creates precise metal components by forming a ceramic shell around a detailed pattern. The hardened shell preserves fine geometry, which supports intricate features during metal flow. The process delivers smooth surfaces because the ceramic material transfers detail accurately. The shell withstands high temperatures, which maintains dimensional stability during casting. The method of Casting Works serves industries that require refined shapes with strong mechanical performance.

Start an investment casting project to produce detailed components with refined surfaces and reliable dimensional accuracy.

3. Die Casting

Die casting forces molten metal into a hardened steel mold under high pressure to create consistent and durable parts. The rigid tooling maintains tight tolerances, which support uniform geometry across repeated cycles. The process of Die Casting produces smooth surfaces because the metal solidifies against polished mold walls. The high‑pressure environment strengthens density and structural integrity. The method suits high‑volume production where accuracy and repeatability remain essential.

Begin a die casting order to obtain high‑volume metal parts formed with strength, precision, and consistent repeatability.

4. Centrifugal Casting

Centrifugal casting forms metal parts by rotating a mold at high speed so centrifugal force distributes molten metal evenly against the mold walls. The rotational force improves density and reduces internal defects, particularly in cylindrical or tubular components. The process of Centrifugal Casting supports uniform wall thickness and strong mechanical properties without the use of high-pressure injection.

Initiate a centrifugal casting request to create dense, uniform cylindrical parts formed under controlled rotational force.

5. Shell Casting

Shell casting uses resin‑coated sand to form a thin, hardened shell mold that captures fine detail. The shell structure provides smooth surfaces, which support high‑quality metal finishes. The lightweight mold improves handling during preparation and pouring. The hardened shell maintains dimensional accuracy because the resin binder strengthens the sand. The method suits parts that require refined geometry with moderate production efficiency.

Move forward with shell casting solutions to generate thin‑walled components supported by smooth surfaces and stable geometry.

6. Plaster Casting

Plaster casting forms detailed cavities using a plaster‑based mold that supports non‑ferrous metal components. The plaster material captures fine features, which improves surface quality. The mold structure maintains stability during controlled cooling, which protects dimensional accuracy. The process of Plaster Casting supports intricate shapes because the plaster flows around complex patterns. The method serves applications that require smooth finishes and moderate production volumes.

Request plaster casting support to produce intricate shapes with fine detail and dependable dimensional control.

7. Continuous Casting

Continuous casting produces long, uniform metal sections by pouring molten metal into a water‑cooled mold. The steady flow creates consistent cross‑sectional profiles, which strengthen material uniformity. The cooling system solidifies metal rapidly, which supports efficient production. The process reduces defects because the metal moves continuously through the mold. Large‑scale manufacturing that demands reliable and repeatable output is suitable for the Continuous Casting method.

Utilize continuous casting to produce long, uniform metal sections with consistent quality from beginning to end.

8. Vacuum Casting

Vacuum casting draws resin into a sealed mold using vacuum pressure to eliminate trapped air. The controlled environment improves clarity and precision, which supports high‑quality surfaces. The process maintains dimensional accuracy because the vacuum distributes material evenly. The sealed mold reduces defects by preventing bubble formation. The method suits applications that require detailed reproduction with strong surface uniformity.

Start a vacuum casting project to produce prototypes or short‑run parts with smooth surfaces and uniform material flow.

Can you Use PLA for Casting?

Yes, you can use Polylactic Acid (PLA) in casting workflows, and its suitability depends on the temperature and curing behavior of the chosen casting medium. Polylactic Acid is most commonly used to create detailed patterns or sacrificial models that define the final cavity rather than serving as a reusable mold. PLA supports fine surface reproduction, allowing accurate geometry to be transferred to sand molds or burnout-based systems. Heat-sensitive applications require careful control because PLA softens at relatively low temperatures, which limits its use in direct mold applications. Low-temperature casting materials and indirect processes remain compatible with Polylactic Acid, while high-temperature casting methods require alternative pattern or mold materials with greater thermal resistance.

What Are the Advantages of 3D-Printed Molds for Casting?

The advantages of 3D-printed molds for casting are listed below.

- Fast Production: Rapid mold fabrication shortens development timelines and supports quicker transitions from design to casting. Accelerated turnaround strengthens prototyping efficiency and reduces delays in testing new parts.

- Lower Production Cost: Reduced material use and simplified tooling decrease expenses associated with traditional mold‑making. Streamlined fabrication limits labor requirements and supports economical short‑run manufacturing.

- High Customization: Flexible digital modeling supports intricate geometries and tailored mold features for unique casting needs. Adaptable design control strengthens accuracy and supports specialized project requirements.

- Improved Design Freedom: Additive manufacturing supports complex internal structures that remain difficult to achieve with conventional tooling, particularly for patterns and indirect mold systems. Expanded geometric capability increases functional possibilities for advanced casting applications.

- Efficient Iteration: Quick design adjustments support frequent refinements without major production interruptions. Consistent digital control strengthens accuracy across multiple mold versions.

3D printing can be used both to make cast patterns using a low ash resin or wax or can directly print molds by binding either ceramics or sand media together.Greg PaulsenDirector, Applications Engineering

Why 3D Printed Mold Cheaper?

A 3D printed mold is cheaper due to the reasons listed below.

- Reduced Tooling Investment: A 3D‑printed mold removes the need for machined metal tooling, which lowers upfront expenses for custom projects. The printed structure forms directly from a digital model, reducing labor hours tied to manual fabrication.

- Lower Material Consumption: Additive manufacturing uses material efficiently by building the mold layer by layer, which decreases waste compared to subtractive machining. The controlled deposition process supports cost savings when producing molds with complex geometry.

- Faster Production Timeline: Digital fabrication shortens lead time by eliminating long machining cycles and setup procedures. A shorter timeline reduces labor costs and accelerates the start of casting work.

- Affordable Design Adjustments: Design changes require only a revised digital file rather than retooling, which reduces modification costs. Rapid iteration supports economical refinement for prototypes and short‑run production.

- Minimal Specialized Equipment: A printed mold relies on accessible additive manufacturing systems rather than large industrial machines, which lowers operational expenses. The simplified workflow reduces overhead tied to maintenance and tooling storage.

What Is the Disadvantage of 3D-Printed Molds for Casting?

The disadvantages of 3D-printed molds for casting are listed below.

- Limited Durability: Printed molds wear faster than traditional tooling because layered structures introduce weaker points under repeated casting cycles. Reduced longevity increases replacement frequency and affects long‑term production planning.

- Restricted Temperature Resistance: Many printing materials struggle under high thermal loads, which limits use with molten metals or high‑heat curing systems. Lower heat tolerance narrows the range of casting materials that remain compatible with printed molds.

- Surface Texture Limitations: Layer lines create subtle ridges that influence the finish of cast parts, which increases the need for post‑processing. Additional smoothing steps extend preparation time before casting begins.

- Dimensional Shift Under Stress: Some printed molds can experience deformation when exposed to pressure or heat, depending on material selection and casting conditions. Structural movement reduces consistency across multiple production runs.

- Size Constraints: Build‑volume limits restrict mold dimensions, which prevents the fabrication of large casting tools in a single print. Multi‑part assemblies introduce alignment challenges that influence final mold performance.

How Xometry Can Help

Xometry offers a wide range of manufacturing services. We focus on on-demand precise manufacturing with methods such as die casting, urethane and silicone casting, injection molding, CNC machining, milling, turning, 3D printing, and sheet metal fabrication. To learn more, or get your free quote, please reach out to a Xometry representative.

Copyright and Trademark Notices

- Fusion®, Tinkercad®, and AutoCAD® are trademarks of Autodesk, Inc., and/or its subsidiaries and/or affiliates, in the United States

- SolidWorks® is a registered trademark of Dassault Systèmes SolidWorks Corp

- Rhino3D® is a registered trademark of Robert McNeel & Associates

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.