Juggling different 3D printing methods and determining which is right for the products you want to make isn’t easy. There are so many options, and it’s sometimes easiest to break it down by subcategory, whether by technology type or print attributes. That’s what we’re doing with SLS and DMLS printing. These two types of powder bed fusion methods work with different materials and don’t necessarily share the same benefits and disadvantages. Let’s get into it below.

SLS or Selective Laser Sintering, is a polymer-based laser powder bed fusion process. DMLS or Direct Metal Laser Sintering is the metals side of laser powder bed fusion. The primary difference being metals and plastics.Matt SchmidtSenior Solutions Engineer

SLS Definition and Comparison to DMLS

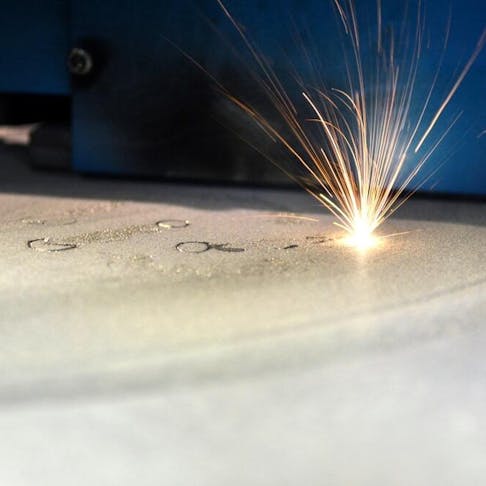

SLS is a powder bed fusion technology that works with plastic powders and was originally developed in the mid-1980s. It’s often compared to other methods like FDM and, of course, DMLS. It uses one or two types of lasers, most usually a CO2 laser, to trace out the cross-section of a part and sinter the plastic particles together. Once every layer is formed, you have your final build. For a visual example, you can see a photo of one of our SLS machines at Xometry in action below.

What are the Advantages of SLS Compared to DMLS?

Listed below are some key advantages of SLS vs.DMLS:

- SLS can produce cheaper prototypes like those used to check product form (i.e., visual properties) and product fit (i.e., interfacing with other components) compared to DMLS.

- SLS parts do not need support when printing.

- SLS parts can be dyed in multiple colors.

What are the Disadvantages of SLS Compared to DMLS?

Listed below are some key disadvantages of SLS vs. DMLS:

- SLS can only print plastic parts.

- Parts printed with SLS are significantly weaker than those printed with DMLS due to SLS parts being plastic.

DMLS Definition and Comparison to SLS

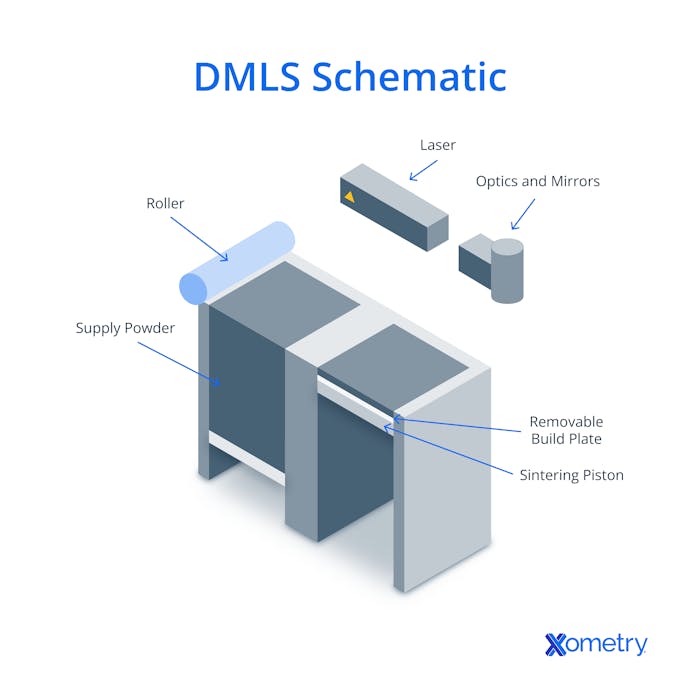

Like SLS, DMLS involves powder bed fusion tech and sintering, but it works with metals instead of plastics. It became a commercialized process back in 1995 and works by lasering metal powder particles together until every layer is complete. These printers also have a chamber that fills with inert gas to cut down on the possibility of combustion and oxidation. You can see a diagram showing the parts of a DMLS printer below.

What are the Advantages of DMLS Compared to SLS?

Listed below are some key advantages of DMLS vs. SLS:

- DMLS is capable of printing high-strength functional metal parts in a wide variety of metals.

- It is possible to print material mixtures of nylon and aluminum.

What are the Disadvantages of DMLS compared to SLS?

Listed below are some key disadvantages of DMLS vs. SLS:

- Due to the materials used, DMLS is significantly more expensive than SLS. It has higher energy requirements, a gas-filled build chamber, and a more expensive raw material.

- DMLS parts need support during printing. This is due to the increased mass of metal parts.

Comparison Table Between SLS and DMLS

| Attribute | SLS | DMLS |

|---|---|---|

Attribute Typical layer height | SLS 100–120 microns | DMLS 30–40 microns |

Attribute Typical tolerance standards | SLS ± 0.015” or ± 0.002" per inch — whichever is greater* | DMLS +/- 0.005” for the first inch, plus +/- 0.002” for every inch that comes after |

Attribute Typical build volume | SLS 330 x 330 x 580 mm | DMLS 250 x 250 x 250 mm |

Attribute Minimum recommended feature size | SLS 1 mm | DMLS 0.5 mm |

Attribute Parts need support structures | SLS No | DMLS Yes |

Attribute Has isotropic material properties | SLS Yes | DMLS Yes |

Attribute Material types | SLS Thermoplastics like polyamides and nylons, metal, ceramic, and glass | DMLS Metals and alloys such as aluminum, copper, and stainless steel |

Attribute Print volume | SLS Can print builds around 2 feet in length | DMLS Smaller builds, around a 10-inch cube in size |

Attribute Can print in metal | SLS No | DMLS Yes |

Attribute Advantages | SLS

| DMLS

|

Attribute Disadvantages | SLS

| DMLS

|

* The tolerances we’ve listed for SLS are when working with nylon 12 material, but tolerances will differ depending on what material you choose for printing.

DMLS and SLS have similar resolution and minimum feature size. However, DMLS can print in metal and the powder is more recyclable. SLS parts do not need any support structures, unlike DMLS parts.

SLS vs. DMLS: Technology Comparison

Fundamentally SLS and DMLS share the same technology, i.e., powder bed fusion. The difference lies in the power of the laser and the fact that DMLS machines need to have their build volumes filled with an inert gas during printing.

SLS vs. DMLS: Material Comparison

SLS can print in a variety of polyamides including: Nylon 12 and elastomeric materials like TPU (Thermoplastic Polyurethane). DMLS is primarily a metal printing technology that can print in stainless steel, titanium, aluminum, nickel alloys, and some precious metals. DMLS is also able to print in nylon.

SLS vs. DMLS: Product Applications Comparison

SLS is primarily used for products that don’t need to be used in high-load and high-temperature environments. SLS parts are also used for functional and visual prototypes. DMLS, however, is better suited to printing high-performance products and components that are exposed to extreme environments like those found in the aerospace and automotive industries.

SLS vs. DMLS: Print Volume Comparison

SLS and DMLS have comparable build volumes, with SLS machines having slightly larger volumes than more high-end machines. DMLS parts become significantly more expensive as their size increases.

SLS vs. DMLS: Surface Finish Comparison

Due to the nature of the sintering process, both technologies will produce parts that have a rough/matte surface finish. Both technologies can have their parts post-processed to improve surface quality. Typical processes can include: tumbling, bead blasting, and polishing; whereas only polishing is possible on DMLS metal parts.

SLS vs. DMLS: Cost Comparison

SLS is significantly cheaper than DMLS. This is due to the high cost of the metal powder, high energy consumption, as well as the more expensive machines used for DMLS printing.

What are the Mutual Alternatives to SLS and DMLS?

While SLS and DMLS have their fair share of perks, there are a couple of alternative printing options you can consider depending on the project you have in mind.

- Multi-jet fusion (MJF): This is also a type of powder-bed fusion process (and one that we offer, too). MJF is a good alternative for SLS because it works with similar polyamide materials but uses a printer head that deposits the materials more like an inkjet printer as opposed to the laser that SLS uses.

- Metal binder jetting: We also offer metal binder jetting, which also involves working with metal like DMLS. It also uses a print head to lay out a binding agent that fuses metal layers together, and then it’s left to cure and later sintered or infiltrated with bronze. It’s much cheaper than DMLS but has a higher chance of shrinkage and more pores (and often not as fine of features).

What are the Other Comparisons for SLS Besides DMLS?

Other comparison technologies for SLS include:

- SLS vs. MJF: Multi Jet Fusion is a suitable alternative to SLS. It can print with similar resolution and materials. MJF also has improved mechanical properties.

- SLS vs. Binder Jetting: Binder jetting is functionally similar to MJF. But, instead of a laser fusing the powder, a binding agent is applied with an inkjet-type printing head to fuse the particles. Post-curing is required to create strong parts.

What are the Other Comparisons for DMLS Besides SLS?

Other comparison technologies for DMLS include:

- DMLS vs. EBM: Electron Beam Melting is also a powder bed fusion technology. But, instead of using a laser, an electron beam is used to melt the metal powder into a final part. This produces parts that have homogenous mechanical properties.

- DMLS vs. DED: Directed-energy Deposition is a metal printing technology that feeds a metal wire to a printing nozzle. The metal is then melted at the nozzle and deposited on the build plate layer by layer, similar to FDM printing. This produces parts that have homogenous mechanical properties.

Frequently Asked Questions About SLS and DMLS

What are the costs for SLS and DMLS printing?

When you compare the prices of SLS and DMLS printing, you’ll find that DMLS is almost always more expensive than the former. This is because printing with metal powder is much more expensive than printing with other materials, like plastic.

How do the surface finishes compare between SLS and DMLS?

With both SLS and DMLS printing, you can expect pretty rough and matte surface finishes. DMLS tends to have a slightly smoother finish because of the finer layer height that the printer produces, but both will usually need post-processing done, whether through bead blasting, tumbling, or polishing.

How Xometry Can Help

You won’t be short of custom 3D printing options here at Xometry. Speak to our team for customized help or use our online quote generator to get pricing for metal 3D printing, carbon digital light synthesis, stereolithography, and more.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.