Metal Injection Molding (MIM) is a manufacturing process that combines the versatility of plastic injection molding with the strength of metal. MIM enables the production of complex metal parts with high precision. The process begins with preparing metal powders mixed with binders to form a feedstock. The feedstock is injected into molds under high pressure. The part undergoes sintering after injection, where heat is applied to remove the binder and fuse the metal powder into a solid form. The final step is cooling, which solidifies the metal part.

MIM is used in the automotive, medical devices, electronics, and firearms industries. MIM is used for fuel system parts and sensor components in automotive applications. Medical devices benefit from the process by producing intricate and precise surgical tools. Electronics manufacturers use MIM for connectors and heat sinks. MIM is ideal for producing small, complex gun components in firearms.

The metal injection molding process provides significant advantages in terms of cost-effectiveness for high-volume production of small parts. Metal injection molding is an essential technology in industries that require strong, intricate parts with minimal waste. It offers flexibility in design and allows for efficient production of both simple and complex geometries. MIM continues to evolve, making it an indispensable solution for numerous applications. The combination of precision, material strength, and efficiency in the metal injection molding process makes it a preferred choice in manufacturing. The Injection Molding technology (MIM) continues to expand the possibilities of what is achieved with metal parts.

What is Metal Injection Molding?

Metal injection molding combines metal powders with a binder to create a feedstock, which is injected into a mold to form a part. The part undergoes sintering after injection, where heat is applied to remove the binder and densify the metal, creating a solid, durable component.

MIM is used for parts with small to medium sizes, featuring intricate details and thin walls as thin as 1 mm. The precision of the process makes it ideal for producing complex shapes that are difficult or costly to achieve through traditional metalworking methods.

Industries that use metal injection molding include automotive, medical, electronics, and firearms. MIM is used for gears and valves in the automotive industry. Medical devices (surgical instruments) benefit from the precision MIM offers. Electronics companies use MIM for components like connectors, while firearms manufacturers rely on the process for producing small, high-precision gun components.

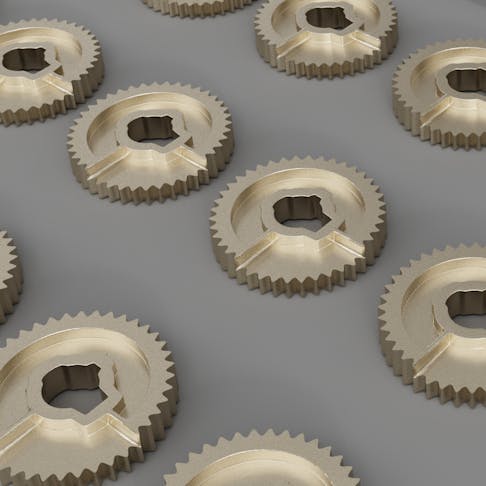

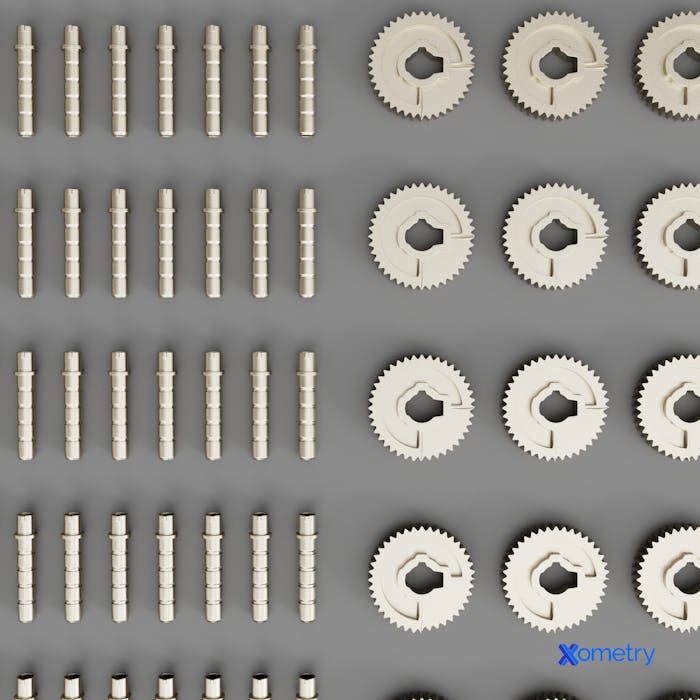

An array of various metal injection molded parts.

How does Metal Injection Molding Work?

Metal injection molding works by mixing fine metal powders with a binder to create a feedstock. The feedstock is injected into a mold cavity under high pressure, which forces the material into intricate shapes. The binder in the feedstock allows for smooth flow and shape retention during injection. It undergoes a sintering process where heat is applied to remove the binder once the part is formed, leaving behind a dense, solid metal part.

The high pressure during injection ensures that the metal feedstock fills the mold completely, while the binder plays a crucial role in maintaining the flow and the part's shape until the sintering process is completed. The interaction of pressure and flow is key to producing precise, complex geometries.

The metal injection molding process is used in industries that require high precision and complex shapes. MIM is used to create certain turbocharger components, such as precision parts in variable turbine geometry systems. Medical tools (orthopedic devices) rely on the high accuracy of MIM for their production. Electronics (heat sinks) benefit from the ability to create intricate metal parts with minimal waste and high strength. The metal injection molding process is a necessary technology for other high-precision applications.

To offset the shrinkage that occurs in the parts between their green stage and sintered stage, manufacturers scale the part, just like injection molding. So the green part is usually 15%-20% larger then the finished part.Kevin ChoateSenior Solutions Engineer

What are the Key Benefits of Metal Injection Molding?

The key benefits of Metal Injection Molding are listed below.

- High Precision: Metal injection molding offers exceptional accuracy, making it ideal for producing parts with intricate designs and tight tolerances. The precision reduces the need for additional machining and ensures parts meet stringent quality standards.

- Complex Geometries: MIM allows for the production of complex shapes that are difficult or impossible to achieve using traditional methods (casting or machining). The process enables the creation of parts with intricate internal features and thin walls.

- Cost-Effective for High-Volume Production: Metal injection molding is highly cost-effective for large-scale production runs when producing small to medium-sized parts. The process minimizes material waste and reduces the production cost compared to traditional metalworking methods.

- Material Versatility: A wide range of metal powders (stainless steel, titanium, and tool steels) is used in MIM, offering versatility in material selection. It allows manufacturers to choose materials that meet specific mechanical and thermal requirements for various industries.

- Reduced Lead Times: The MIM process reduces lead times for complex small parts by minimizing post-processing compared to some traditional metalworking methods. Parts are produced with minimal post-processing, reducing the lead time from design to delivery.

- Improved Strength and Durability: Parts produced through MIM are dense and durable, offering excellent mechanical properties (high strength and resistance) to wear and corrosion. The characteristics make MIM ideal for demanding applications in the automotive, medical, and electronics industries.

What are the Limitations of Metal Injection Molding?

The limitations of Metal Injection Molding are listed below.

- Design Complexity: The need for specialized molds in metal injection molding increases tooling complexity and costs. Custom molds for intricate designs are expensive to produce and maintain, making the process less cost-effective for low-volume production runs.

- Binder Removal: The binder removal and sintering process leads to defects or dimensional changes if not carefully controlled. Improper removal of the binder or uneven sintering causes warping, cracking, or shrinkage, which affect the part’s quality and functionality.

- Material Constraints: MIM is limited to certain metals and metal alloys, restricting its use for parts requiring specific material properties. It is not suitable for all metal types or applications with unique requirements, while the process works well with stainless steel, titanium, and tool steel materials.

- Cycle Time: The sintering process in MIM is time-consuming and extends production times. MIM’s extended cycle time increases leads to longer lead times for large production volumes compared to other molding methods (plastic injection molding).

What are the Factors that Affect the Performance of Metal Injection Molding?

The factors that affect the Performance of Metal Injection Molding are listed below.

- Material Properties: The flowability and viscosity of the metal powder feedstock, along with the type of binder used, impact the mold filling process and part quality. Poor material properties lead to incomplete mold filling or inconsistencies in the final product.

- Mold Design: Proper mold design is critical for ensuring successful metal injection molding. Venting, cooling channels, and wall thickness need to be carefully engineered to allow for uniform material flow and to prevent defects during the injection and sintering stages.

- Injection Speed and Pressure: Controlling the injection speed and pressure is necessary for consistent material flow. Too high or too low a speed leads to incomplete filling of the mold, while improper pressure causes defects (voids or misalignment). Consistent injection ensures that the mold is filled, and parts are produced with high precision.

When Do Manufacturers Face Challenges with Metal Injection Molding?

Manufacturers face challenges with metal injection molding when maintaining consistent part thickness. Variations in powder distribution or binder content cause inconsistencies in thickness, leading to defects (warping or cracking) during the sintering process.

Efficient cooling is another challenge because the need for uniform cooling during sintering is necessary to avoid part distortion and ensure dimensional accuracy. Uneven cooling results in parts that are not uniform or structurally sound.

Achieving smooth material flow is challenging when working with complex geometries. Fine metal powders do not flow smoothly through intricate designs, leading to short shots or incomplete fills, which compromise the final part quality.

What are the Materials Used in Metal Injection Molding?

The Materials Used in Metal Injection Molding are listed below.

- Stainless Steel (SS): Stainless steel is used in metal injection molding due to its excellent corrosion resistance and strength. It is ideal for applications in automotive, medical, and aerospace industries where durability and resistance to harsh environments are required.

- Carbon Steel (CS): Carbon steel is used in MIM for parts requiring high strength and hardness. It is cost-effective and suitable for various industrial applications (the manufacturing of gears, fasteners, and automotive components).

- Cobalt-Chromium (Co-Cr): Cobalt-chromium alloys are known for their high strength, wear resistance, and corrosion resistance. The materials are used in the medical industry for implants and surgical tools, where reliability is crucial.

- M2 Tool Steel: M2 tool steel is used in MIM for producing high-performance tools and dies. It offers excellent hardness, toughness, and wear resistance, making it ideal for cutting tools, industrial applications, and high-stress environments.

- Titanium (Ti): Titanium (Ti) is used in metal injection molding for its light weight, strength, and corrosion resistance, but it requires carefully controlled debinding and sintering conditions to maintain its properties. It is used in the aerospace, medical, and sporting goods industries for applications (implants and structural components).

- Copper: Copper can be used in MIM, but it requires highly controlled sintering atmospheres, so it is less common than steels and nickel alloys.

- Nickel Alloys (Inconel): Nickel alloys (Inconel) are known for their high-temperature resistance and strength. The materials are used in aerospace, power generation, and chemical processing industries, where extreme conditions are prevalent.

- 6061 Aluminum Alloy: 6061 Aluminum Alloy can be processed by MIM in specialized cases, but it is not commonly used because aluminum requires non-standard sintering conditions.

- 7075 Aluminum Alloy: 7075 Aluminum Alloy can be processed by MIM in specialized cases, but it is not commonly used because aluminum requires non-standard sintering conditions.

- Iron-Carbon Alloys: Iron-carbon alloys are used in MIM for parts requiring good strength and machinability. They are used in automotive and industrial applications (parts such as valves and gears).

Which Material is Best for Metal Injection Molding?

The best material for metal injection molding is Stainless Steel (SS) for applications requiring high strength, precision, and corrosion resistance. Common grades of stainless steel used in MIM are 17-4 PH and 316L. 17-4 PH is popular in aerospace, medical, and automotive applications due to its high strength and resistance to corrosion. 316L is frequently used in medical devices and surgical instruments because of its superior corrosion resistance in environments exposed to chloride and saline solutions. The alloys are ideal for applications requiring strength and resistance to harsh environments.

Flowability, strength, and thermal properties are essential when selecting a material for MIM. Stainless Steel offers excellent flowability, making it ideal for molding intricate and precise components. It provides high tensile strength and superior corrosion resistance, making it a popular choice for a wide range of industries (automotive, medical, and aerospace).

Cost-efficiency and application suitability are essential considerations. Stainless Steel is cost-effective for mass production, providing a balance of performance and affordability. Titanium (Ti) is a strong contender for aerospace and medical applications due to its lightweight and high-strength properties. Titanium alloys (Ti-6Al-4V) are used in MIM for aerospace, medical, and sporting goods applications, but they require controlled oxygen-free debinding and sintering conditions. Ti-6Al-4V is favored in the aerospace industry for its high strength-to-weight ratio and excellent corrosion resistance, making it suitable for structural components and implants. Titanium is more expensive than stainless steel. Its combination of lightweight and high-strength properties makes it an attractive choice for high-performance applications where weight is a critical factor. However, it is more expensive than Stainless Steel. Tool Steel (M2) is best suited for industrial applications requiring wear resistance and toughness, but it is more difficult and costly to machine.

Stainless Steel is the best choice for MIM due to its combination of strength, corrosion resistance, cost-efficiency, and wide applicability across various industries. It provides well-rounded material that excels in applications requiring durability and precision.

How do Material Properties Affect the Cost and Performance of Metal Injection Molding?

The material properties affect the cost and performance of metal injection molding by directly influencing the durability, functionality, and efficiency of production processes according to the specific requirements of the application. For example, 17-4 PH stainless steel is chosen for aerospace and medical components requiring high strength and corrosion resistance. 316L stainless steel is preferred for medical implants due to its superior corrosion resistance. Titanium alloys (Ti-6Al-4V) are used for lightweight aerospace components or implants where the strength-to-weight ratio is critical. Tool steels (M2) are selected for industrial applications that require extreme hardness and wear resistance. Material strength plays a significant role in part performance. Stronger materials (stainless steel) provide longer-lasting, more durable parts, which are essential for high-stress applications. However, the increased strength leads to higher material costs and more intensive processing requirements, raising the cost of production.

Material flowability impacts cycle time and processing costs. Materials with higher flowability are easier to inject into molds, improving cycle time and reducing pressure requirements. It makes the production process more efficient and cost-effective for small to medium-sized components. Materials with lower flowability require more energy and time to inject, increasing the pressure and cycle time, which drives up costs.

Heat resistance and thermal stability are critical for parts that need to perform in high-temperature environments (automotive, aerospace, and electronics applications). Materials with higher heat resistance (titanium or certain tool steels) withstand extreme temperatures without degrading, ensuring the parts maintain their integrity. However, the materials are more expensive, in terms of material cost and processing challenges, as they require specialized equipment and longer processing times to maintain their thermal stability.

Material properties (strength, flowability, and heat resistance) affect the performance and cost of metal injection molding, with stronger, more heat-resistant materials generally leading to higher costs, while improved flowability reduces production expenses.

What are the Applications of Metal Injection Molding?

The applications of Metal Injection Molding are listed below.

- Part Size and Material Constraints: Metal injection molding is used for producing small to medium-sized parts with intricate details and high precision. Larger parts are more challenging for MIM due to the complexities involved in the molding process and material limitations. MIM excels in applications requiring specific material properties, such as stainless steel for medical devices or tool steel for industrial tools. Larger parts (automotive engine components) are not feasible due to the limitations of material flow and processing times.

- Design and Machine Constraints: The complexity of the mold design, injection pressure, and cycle time directly affect the efficiency and quality of the MIM process. Parts with intricate geometries (small turbine vanes or surgical instruments) require specialized molds, increasing production costs and time. Higher injection pressures are necessary to improve mold filling, but lead to defects (voids or misalignments) if not properly controlled. Longer cycle times reduce production efficiency for high-volume runs, which is a challenge when manufacturing larger components (automotive transmission gears).

- Medical Devices: Achieving high precision in medical devices (orthopedic implants and surgical tools) is essential. The components must adhere to stringent regulatory standards for performance and reliability. The intricate designs of spinal implants or dental tools demand careful control over material flow, temperature, and pressure to ensure dimensional accuracy and reliability, as even the slightest defects compromise patient safety.

- Automotive Parts: Producing complex geometries for automotive components (valve components or turbocharger parts) presents challenges due to the need for high-strength materials and fine detail. MIM offers the ability to create parts with complex internal features (brake system components or gears). However, ensuring consistent quality across large production volumes is difficult due to the challenges in material flow and cooling requirements, which are critical in engine components that experience high temperatures and stress.

Metal Injection Molding is often confused with molten-metal casting, but MIM works more like ceramics. The metal does not melt. It flows as a powder and binder mix and becomes solid only after sintering. Once that difference is clear, the focus shifts to controlled shrinkage, uniform walls, and precise flow to achieve high-quality metal parts.Audrius Zidonis; Principal Engineer at Zidonis EngineeringNote from the Editor

What are Examples of Metal Injection Molding Products?

Examples of Metal Injection Molding Products are listed below.

- Automotive Components: Metal injection molding is used to produce high-strength automotive components (gears, turbocharger parts, and fuel system components). The parts benefit from MIM’s ability to create intricate geometries with fine details, ensuring high performance and durability in demanding conditions. MIM’s precision allows for the production of lightweight parts that maintain the required strength and functionality, which is valuable in automotive applications where reducing weight is key to improving fuel efficiency and vehicle performance.

- Electronics Housings: MIM is used to produce small, complex components (connectors, heat sinks, and housings) for electronic devices in the electronics industry. The process enables manufacturers to create parts with tight tolerances and optimized thermal properties, ensuring efficient heat dissipation in devices (computers, smartphones, and other electronic equipment). MIM’s capability to produce high-precision, durable parts while minimizing material waste makes it an ideal choice for electronics applications where compactness and performance are critical.

- Medical Devices: MIM is utilized in the medical industry for manufacturing components (surgical tools, implants, and dental devices). The products require extreme precision, durability, and biocompatibility, all of which are achievable through MIM. Surgical tools made using MIM allow for fine details and sharp edges, essential for precise operations. Medical implants (joint replacements) benefit from the ability to create complex geometries while maintaining the material’s strength and biocompatibility. MIM helps meet strict Food and Drug Administration (FDA) and sterilization requirements, ensuring safety and performance in medical applications.

- Design Improvements: MIM enables significant design improvements, such as lightweighting and miniaturization. Lightweighting is valuable in industries (automotive and aerospace) where reducing part weight improves performance and fuel efficiency. MIM allows manufacturers to create strong and lightweight parts that use less material without sacrificing strength. Miniaturization is another benefit, especially in electronics and medical devices, where producing small, exact parts is essential. MIM’s ability to create miniature components with high complexity allows for more compact and efficient designs in the industries, pushing the boundaries of what is achieved in modern manufacturing.

- Industry-Specific Challenges: Maintaining the structural integrity of parts (gears or turbocharger components) is necessary in automotive applications. Ensuring that these parts withstand high stresses without compromising durability remains a challenge, while MIM allows for lightweight designs. Meeting regulatory standards is a challenge on the medical side, ensuring that products (implants and surgical tools) are sterile and compliant with FDA guidelines. The medical products require rigorous quality control throughout the manufacturing process, ensuring that they are safe, reliable, and able to withstand the demanding conditions of medical use.

How does Metal Injection Molding differ from Other Types of Injection Molding?

Metal Injection Molding differs from other types of injection molding by utilizing metal powders mixed with binders, which are injected into molds and sintered to form solid metal parts. MIM requires a more complex process due to the nature of metal materials, unlike traditional plastic injection molding, which uses plastic pellets to form parts. The binder is removed through sintering after the injection, and the metal powder is fused together to create a strong, durable part.

MIM is optimized for creating small, precise, and complex metal parts, making it ideal for applications that require high strength and intricate designs. Traditional plastic injection molding is used to produce lightweight plastic parts. MIM offers superior strength, precision, and material performance, while plastic injection molding is more cost-effective and suited for mass production of less complex parts.

The advantages of MIM include its ability to produce high-performance parts with fine details and tight tolerances. It makes it beneficial for industries (aerospace, automotive, and medical) where the need for durability, strength, and precision is critical. MIM allows manufacturers to produce complex, small parts that are difficult or impossible to achieve with other metalworking methods.

How do Production Speeds in Metal Injection Molding Compare to Other Molding Methods?

Production speed in metal injection molding compared to other molding methods is slower due to the additional post-processing steps (sintering). MIM requires additional time for binder removal and sintering, which extends production time, while traditional plastic injection molding offers faster cycle times in the range of seconds to a few minutes. MIM is efficient for high-precision, small parts in industries where complex geometries and high material strength are essential.

The injection speed in MIM is similar to that of plastic injection molding. However, the total production time is impacted by the post-processing steps. The binder must be removed through a thermal or chemical process, followed by sintering after injection, where heat is applied to fuse the metal particles. The post-processing steps take several hours, depending on the material and part size, which makes MIM slower than traditional plastic molding.

MIM is more time-consuming than plastic molding due to the sintering process, but it remains highly effective for producing complex, small metal parts that require high precision and strength. MIM offers significant advantages by allowing manufacturers to produce intricate metal components at a relatively lower cost per part, despite the longer cycle times in high-volume production.

Is Metal Injection Molding More Cost-Effective than Liquid Silicone Injection Molding?

No, Metal Injection Molding is generally not more cost-effective than Liquid Silicone Injection Molding, but the decision depends on the specific application. Liquid Silicone Injection Molding is more cost-effective for applications requiring flexible, lightweight parts in industries like medical, automotive, and consumer products. It offers fast cycle times and efficient production of complex shapes, reducing material waste. Silicone materials have lower upfront costs and do not require the same high-temperature processes as metal molding.

Metal Injection Molding involves higher material costs due to the use of metal powders and the additional sintering process, which requires more time and energy. However, MIM is ideal for producing small, high-precision metal parts with superior strength and durability, which is difficult to achieve with Liquid Silicone Injection Molding. The trade-offs involve performance versus cost. MIM excels in strength and precision but is more time-consuming and expensive, while Liquid Silicone Injection Molding provides fast production and is better for flexible parts with lower performance requirements.

The choice between metal and liquid silicone injection molding depends on the specific goals of the project (the priority is cost reduction, energy efficiency, or achieving a high strength-to-weight ratio) in the final product. Liquid Silicone Injection Molding offers faster and more cost-efficient production for certain applications. Metal Injection Molding is preferred for parts requiring high strength and durability.

Is Metal Injection Molding More Suitable for Mass Production than Thin-Wall Injection Molding?

No, Metal Injection Molding is not more suitable for mass production than Thin-Wall Injection Molding, especially for plastic components. Thin-Wall Injection Molding is designed for high-speed, high-efficiency production of thin, lightweight parts, making it more suitable for mass production in industries (consumer goods, packaging, and automotive). It allows for rapid cycle times, lower material usage, and reduced production costs due to its ability to mold parts with thin walls that maintain strength and durability. The efficiency of the process is maximized with lighter, less expensive materials (plastics) and faster cycle times.

Metal Injection Molding (MIM) is more suited for producing small, complex metal parts with high precision and strength, but it is slower and more expensive than Thin-Wall Injection Molding. The need for post-processing steps such as sintering and binder removal increases the cost and cycle time, making MIM less efficient for high-volume production of parts with simple designs. Metal materials used in MIM are more costly compared to the plastics commonly used in Thin-Wall Injection Molding.

Thin-Wall Injection Molding is more suitable for mass production due to its efficiency, lower material costs, and rapid cycle times. Metal Injection Molding is ideal for high-precision metal parts, albeit with slower production rates and higher costs. The choice depends on the specific goals (cost reduction, production speed, or the need for high-strength materials).

Is Metal Injection Molding More Energy-Efficient than Foam Injection Molding?

No, Metal Injection Molding is not more energy-efficient than Foam Injection Molding. Foam Injection Molding is more energy-efficient than Metal Injection Molding due to its lower material density and reduced cycle times. Foam molding involves injecting a gas or blowing agent into the material, which creates a foam structure that reduces the amount of material used. The process requires less energy because the material is lighter, and the reduced density helps decrease the cycle time. Foam molding results in parts with better insulation properties, making it suitable for applications where thermal efficiency is essential.

Metal Injection Molding (MIM) involves higher material costs due to the use of metal powders, and the process requires energy-intensive post-processing steps like sintering to fuse the metal particles. The high temperature and longer cycle times in MIM lead to greater energy consumption compared to Foam Injection Molding, which relies on lighter materials and faster molding cycles.

To learn more, see our full guide on Foam Injection Molding.

Does Metal Injection Molding Provide a Higher Strength-to-Weight Ratio than Gas Assisted Injection Molding?

Yes, Metal Injection Molding provides a higher strength-to-weight ratio than Gas Assisted Injection Molding. Gas Assisted Injection Molding involves the use of gas to create hollow sections or reduce material usage in parts made from plastic. The method is effective for producing lightweight parts with complex shapes and internal cavities, but the strength of the parts is lower compared to metal components. It does not match the strength and durability of metal parts produced through Metal Injection Molding, while Gas Assisted Injection Molding allows for efficient production with reduced material usage.

Metal Injection Molding uses metal powders combined with binders, which are then sintered to form solid metal parts. The result is a part with a higher strength-to-weight ratio due to the inherent strength of metals (stainless steel, titanium, and tool steel). The materials provide superior strength under high stress or extreme conditions, making MIM ideal for applications where performance and durability are critical.

Can Metal Injection Molding Be Used for Multi-Component Parts?

Yes, Combining multiple materials or components in Metal Injection Molding (MIM) is possible, but it requires advanced techniques like carefully controlled co-sintering. The techniques involve injecting different materials into a single mold in successive steps, allowing for the integration of multiple components within one part. However, incorporating the additional steps increases mold complexity and extends cycle times, which impacts production efficiency and cost.

The primary challenges when creating multi-component parts using MIM involve ensuring proper material bonding, precise alignment, and consistent material flow. Different materials have varying viscosities and flow characteristics, which cause defects like poor bonding or misalignment of components. Achieving reliable material integration and maintaining tight tolerances between components are crucial to ensuring the part’s performance and quality.

MIM is used for multi-component parts, the process requires careful design and advanced molding techniques to address the challenges of material compatibility, mold complexity, and cycle time. The factors must be considered to avoid defects and ensure the desired performance of the final product.

Is Metal Injection Molding Suitable for Low-Volume Production?

No, Metal Injection Molding is not a suitable method for low-volume production compared to other methods (thin-wall injection molding). Metal Injection Molding (MIM) offers benefits such as high precision and the ability to produce complex metal parts, and it is more cost-effective for medium to high-volume production rather than low-volume runs. MIM involves significant setup time, specialized molds, and additional post-processing steps (sintering), which increase the cost per part. The costs are justified in larger production runs where the economies of scale offset the initial investment in tooling and setup.

Thin-wall injection molding is more cost-effective for low-volume production. Thin-wall injection molding allows for faster cycle times, simpler tooling, and lower material waste, making it more efficient for producing plastic parts in small batches. MIM requires more extensive setup time and higher mold costs, which are not as cost-efficient when only a small quantity of parts is needed.

MIM is ideal for small to medium-volume production where precision and strength are necessary in automotive, medical devices, and electronics. However, the quick cycle times and lower setup costs of alternative methods (thin-wall injection molding) offer a more cost-effective solution for low-volume manufacturing.

How Xometry Can Help

We hope we answered all your MIM-related queries, but if you happen to have more, please feel free to reach out to one of our representatives, who will be happy to help you out. You can also use any of our manufacturing services, from metal injection molding to laser cutting to 3D printing, and it’s quick, easy, and free to get a no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.