Normalizing is a heat treatment process used primarily for ferrous metals to refine grain structure, relieve internal stresses, and improve mechanical properties. It is similar to annealing, but it is typically performed with less stringent control over heating and cooling rates, resulting in a harder, stronger microstructure than full annealing. The process involves heating the metal to a temperature above its upper critical point (typically between 750°C and 980°C, depending on the alloy) but well below its melting point. For steels, this is above the A3 or Acm critical temperature, not the glass transition temperature (which is relevant for polymers, not metals). The component is held at this temperature for a specified time, often calculated based on its cross-section, and then allowed to cool naturally in still air to room temperature.

Normalizing is applied to materials that have been work-hardened or heat-treated (e.g., quenched) to restore ductility, reduce hardness, and improve machinability or toughness. By allowing recrystallization and transformation of the distorted or brittle microstructure, the material regains a more uniform and refined grain structure, often balancing strength and ductility.

This process is beneficial for preparing materials for subsequent machining, forming, or additional heat treatments. It helps reduce the likelihood of cracking or distortion in later processing stages.

This article will examine the normalizing process in detail, including its purpose, mechanism, applications, and the distinct stages involved.

What Is Normalizing?

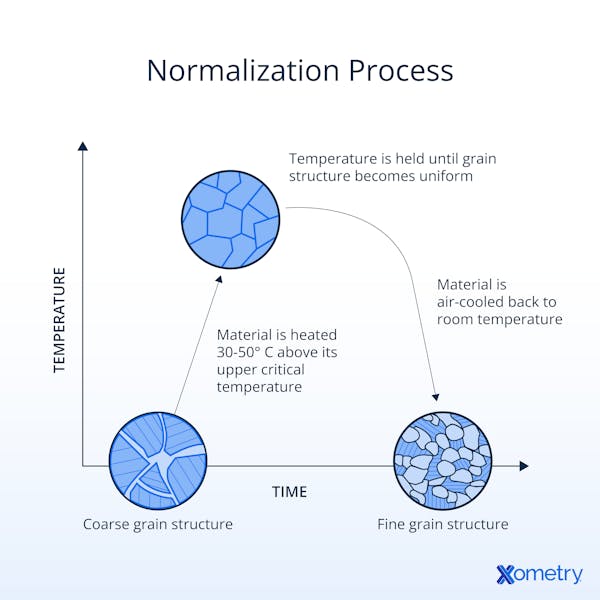

Normalizing is a simple heat treatment process applied to metals, particularly steel and its alloys, as well as to various other materials. It helps to improve their mechanical properties, reduce internal stresses, and achieve a more uniform and refined microstructure. Normalizing involves three main stages, each performed in a moderately controlled manner: heating, soaking (in a maintained, elevated temperature), and cooling.

Specific parameters of the normalizing process, including heating temperature and soaking time, depend on the material type, its initial hardness condition, and the desired degree of change in its properties. Normalizing is widely employed in the automotive, aerospace, construction, and manufacturing industries to prepare materials for further processing and to achieve the desired mechanical characteristics.

What Is Normalizing Also Known As?

Normalizing is often named interchangeably with annealing. Though the processes use the exact basic mechanisms, normalizing generally has a lesser effect on the resultant properties. Its intervention is less controlled, particularly in the cooling phase, during which normalizing involves the natural pace of convective/radiative cooling in an ambient atmosphere, without any effort to restrain or reduce that rate.

What Is the Purpose of Normalizing?

Normalizing regularizes the grain structure of the material, resulting in smaller and more uniform grains throughout and improved anisotropy. This alters mechanical properties, increasing strength and toughness while reducing hardness. Normalizing helps relieve internal stresses that develop during previous manufacturing processes, particularly bending, forging, and welding. This reduces the risk of distortion or cracking in the material, in the “worked” zone, which will have become relatively harder and more brittle.

Normalized materials are often easier to machine, making them more efficient and cost-effective for subsequent manufacturing processes. In particular, the hardness variations that result from local work hardening can be a barrier to consistent machining processes. Such hardness can also significantly reduce the quality of machined parts and the life of the tool. The method improves the homogenization of the material's composition. It ensures a more consistent distribution of alloying elements throughout the structure and reduces the uneven distribution of precipitates that can badly affect regional properties. Normalizing can return the materials to which it's applied to a more native ductility level, making subsequent processes easier and lowering the risk of fracture. Once normalized, materials are often more receptive to subsequent heat-treatment processes, allowing for more precise control over their final properties.

Why Is Normalizing Important in Manufacturing?

Normalizing is crucial in manufacturing because it enhances the mechanical properties of materials, alleviates internal stresses, and refines the microstructure. This improves the material's strength, toughness, and machinability, making it suitable for various manufacturing processes. Normalizing also promotes consistency and quality control in production.

“Normalizing is widely regarded as a practical and efficient heat treatment, especially for ferrous alloys. It offers a reliable method to refine grain structure, relieve internal stresses, and enhance mechanical properties, including strength, toughness, and ductility. While less controlled than processes like annealing or tempering, normalizing is effective in promoting material consistency and enhancing machinability. Its versatility and cost-efficiency make it a common choice in industries where large-scale processing and uniform performance are essential.”Mahder Tewolde, P.E, Ph.DNote from the Editor

Does Normalizing Materials Increase Ductility?

Yes, normalizing materials can increase ductility. Normalizing refines the microstructure of materials, leading to smaller and more uniform grain sizes. This finer-grain structure enhances ductility, making the material more malleable and easier to deform without fracturing.

To learn more, see our guide on the Definition of Ductility.

What Are the Different Types of Normalizing?

There are several variations and techniques of normalizing, each tailored to specific materials and desired outcomes. These types are listed below:

- Full Normalizing: The material is heated to a temperature slightly above its upper critical temperature (typically 30–50°C above the Ac₃ point for ferritic-pearlitic steels). It is held at this temperature (soaked) for a time proportional to the section thickness—commonly 1 hour per inch (25 mm)—and then cooled in still, ambient air. This process refines the grain structure, enhances uniformity, and relieves internal stresses. It is most commonly applied to low- and medium-carbon steels.

- Process Normalizing: A variation where the material undergoes the same heating and soaking cycle as full normalizing, but the cooling phase is accelerated by immersion in a medium such as water or oil. This leads to increased hardness and a finer grain structure compared to air cooling. Note that the difference between this and heat/quench hardening is that the peak temperature of the part is generally lower when the process normalizes.

- Isothermal Normalizing: In this method, after heating, the material is cooled to a specific intermediate temperature—typically within the pearlite transformation range (approximately 600–700°C)—and held at that temperature before being allowed to cool further. This technique yields a uniform and fine-grained microstructure, which is used to enhance machinability and mechanical strength.

- Air Normalizing: A term often used interchangeably with full normalizing. It refers to the same process in which the material is cooled in ambient air after being soaked above its critical temperature.

How Does Normalizing Work?

Normalizing is used to refine the microstructure and improve the mechanical properties of materials, particularly steel and its alloys.

The diverse, coarse, and often anisotropic grain structure of a material that resulted from prior manufacturing processes (particularly cold working) is refined to a moderately controllable degree. Internal stresses are relieved, reducing the risk of post-machining deformation or fracture. The mechanical properties are enhanced, resulting in increased strength, toughness, and ductility. The material is prepared for subsequent manufacturing processes or heat treatments, either reducing the stress and effort required for further forming or restoring the structure to a known and consistent quality that existed before heat treatment/hardening.

To learn more, see our guide on Steel Microstructure.

When To Normalize Materials?

Materials are normalized for a spectrum of reasons that are highly dependent on the specific material, its pre-existing condition, and the properties for the intended application or subsequent processes. Materials that have been heat-treated and then quenched for hardening will exhibit high internal stresses and brittleness. Normalizing can relieve these stresses and enhance toughness, at the cost of reduced hardness. Forged or welded materials often have irregular and highly regionalized grain structures and internal stresses, due to non-uniform heating. Where that irregularity/anisotropy is not a target of the production (as it can be in forgings), normalizing can revert the grain structure to the natural state and relieve stresses. Materials with uneven composition or inconsistent properties may benefit from normalizing to achieve a more uniform distribution of alloying elements and mechanical properties. This can be due to thermal, work, or other processes creating uneven condensates in some regions, dramatically altering local properties.

Normalizing can improve the machinability of materials by essentially softening them, rendering them easier to machine, shape, or fabricate, easing manufacturability. Normalizing is often used as an intermediate step before other heat treatment processes such as hardening. It prepares the material for these subsequent treatments, improving the uniformity of the final treatment. Normalizing is often used to ensure consistent material properties in production, promoting better quality control and minimizing inter- and intra-batch variations in properties.

What Are the Applications of Normalizing?

Normalizing is a widely used heat-treatment process with applications across various industries. It is employed in the production of steel to refine grain structures, relieve internal stresses, and optimize uniformity and mechanical properties. It is crucial for manufacturing components in the automotive, construction, and machinery industries. Forged materials often undergo normalizing after one or more forging steps to eliminate irregular grain structures and internal stresses, thereby enhancing strength and restoring toughness. Normalizing is used to relieve stresses and refine the microstructure of welded materials, ensuring weld integrity, uniformity of properties across the weld zone, and prevention of fracture.

Aerospace components, such as landing gear and engine parts, undergo normalizing to meet stringent strength and durability requirements. Durability is restored after forming by normalizing the material. Normalizing is applied to automotive components, such as crankshafts and axles, to enhance their toughness and performance. Tools and dies are often normalized to improve durability and wear resistance. Steel beams, rods, and structural components are normalized to meet safety and durability standards in construction. Components for the oil and gas industry, such as drill-string components and valves, are normalized for improved toughness performance and longevity.

What Are the Different Stages of the Normalizing Process?

The different stages of the normalizing process are listed below:

1. The Recovery Stage

The recovery stage is the initiating phase of the normalizing process. It occurs when the metal is heated close to the upper critical temperature. The material is heated to a temperature slightly above its upper critical temperature, which varies depending on the material type and composition. This is between 815–925 °C for most steels. During this heating phase, recovery begins. This results in the progressive relief of defects and irregularities in the material's microstructure, which were introduced during prior manufacturing processes. These defects typically consist of dislocations, vacancies, and grain boundaries. As the material heats, the thermal energy allows the atoms in the crystal lattice to move more freely. This movement enables the reformation of many microscopic defects, relieving internal stresses and fracture initiation points.

The recovery stage prepares the material for subsequent transformations during the normalizing process.

2. The Recrystallization Stage

The recrystallization stage is the most critical phase in the normalizing process, following the commencement of recovery. During recrystallization, the material's microstructure undergoes significant changes through grain boundary dissolution and atomic diffusion.

The material is further heated to a temperature just above its upper critical temperature, an intrinsic property of each metal and alloy that varies significantly between metals. As the material reaches the recrystallization temperature, new grains begin to form within the existing microstructure. These new and smaller grains progressively consume all the existing grain structure in a new and more uniform matrix. Recrystallization helps eliminate the effects (and defects) of prior forming and heat/quenching. It replaces the deformed and disrupted grains with a new, strain-free structure that exhibits improved ductility and toughness.

The recrystallization stage is essential for normalizing because it refines the grain structure and enhances its mechanical properties, eliminating the negative consequences of prior processing.

3. The Grain-Growth Stage

The grain-growth stage follows the recrystallization stage. During this stage, the newly formed grains within the material continue to grow and evolve in size, contributing to the final microstructure of the material. Grain growth will continue at a diminishing pace as the heat is maintained. This is the soak period, and its effect on the microstructure can be more significant than the prior phases.

After the material has undergone initial recrystallization, it is held at an elevated temperature. In the grain-growth stage, the small, newly formed grains that resulted from recrystallization continue to grow by consuming adjacent grains. The grain-growth stage allows for the development of a more uniform and consistent grain size throughout the material, resulting in larger, strain-free grains. The final microstructure achieved during the grain-growth stage depends on factors such as the material type, initial condition, the stable temperature, and the hold or dwell period. As the heat is removed, the grain-growth stage will slow and plateau due to air cooling, which progressively diminishes the atomic movements required for crystal matrix alterations.

The grain growth stage is critical for the subsequent mechanical properties. A more uniform and controlled grain-size distribution can improve material performance, which is achieved through sufficient dwell time.

How Long Does the Normalizing Process Take?

Typically, the heating and soaking stages of normalizing may take up to several hours, depending on the degree of lattice adjustment required, the section thickness, and the material's properties. The cooling stage is considerably slower than quenching but still relatively fast.

The heat-up time will vary depending on the material's thickness and the heating method used. It may take anywhere from a few minutes to a few hours. Soaking times can range from a few minutes to several hours, again depending on the desired properties, the material, and its section thickness. The cooling stage, typically performed in still air, can take several hours to return the material to room temperature.

What Are the Metals Used for Normalizing?

Normalizing is most commonly applied to ferrous metals, particularly carbon steels, alloy steels, and tool steels, to refine grain structure, improve mechanical properties, and relieve internal stresses. Specific grades of stainless steel, especially ferritic and martensitic types, can also undergo normalizing to enhance uniformity and machinability. Austenitic stainless steels are generally not normalized due to their stable microstructure. Cast irons, such as malleable and ductile iron, may be normalized after casting to improve machinability and reduce residual stresses. Gray cast iron, however, is typically not normalized due to its graphite flake structure.

Some copper alloys, including brasses and bronzes, may undergo heat treatments similar to normalizing—typically recrystallization annealing—to restore ductility lost from work hardening. Although aluminum alloys do not experience the phase changes necessary for true normalizing, some may undergo annealing or homogenization to relieve stresses and enhance formability after cold working. Certain nickel-based alloys, such as Inconel® and Monel®, may undergo high-temperature treatments resembling normalizing to homogenize their structure and prepare them for further processing. While titanium alloys are not typically normalized, forged or heavily worked titanium parts may benefit from similar heat treatments to stabilize the microstructure and refine grain size.

How Does Tool Steel React to Normalizing?

Tool steel is greatly affected by normalizing, undergoing a range of beneficial changes. Normalizing refines the grain structure, forming smaller and more uniform grains (which have specific associated mechanical properties), and making subsequent machining easier. Tool steel often experiences internal stresses due to various manufacturing processes. Normalizing helps relieve these stresses. Normalizing ensures a consistent and uniform material structure, improving tool manufacturing quality. To learn more, see our full guide on Tool steel.

Can Aluminum Be Normalized?

Yes. Aluminum can be normalized, although the process is not commonly applied. Aluminum alloys, including those used in aerospace and engineering applications, typically undergo different heat treatment processes to achieve desired properties. While not generally used for aluminum alloys, it may be applied in certain specialized applications or research scenarios where specific microstructural changes are desired, such as for wire drawing.

To learn more, see our guide on the Physical Properties of Aluminum.

Can Normalizing Be Done to Brass?

Technically, brass does not undergo “normalizing” in the same metallurgical sense as ferrous metals, because it lacks the phase transformations (such as austenite to ferrite/pearlite) that define normalizing. However, a recrystallization annealing process—sometimes colloquially referred to as "normalizing"—can be applied to brass to restore ductility and reduce internal stresses after cold working or machining. Brass is typically heated to a temperature range of 500–700 °C, depending on the alloy composition and degree of prior work hardening. Once the brass reaches the target temperature, it is held (soaked) long enough to allow uniform recrystallization throughout the material. The component is then cooled in still air or under controlled conditions to prevent warping or distortion.

This heat treatment is particularly beneficial for brass components that have undergone significant plastic deformation, as it alleviates internal stresses, enhances dimensional stability, and restores toughness and ductility.

To learn more, see our article on Brass Elements.

At What Temperature Is Normalizing Done?

The normalizing temperature is specific to each family of materials (pure metals and alloys). In many cases, it is also varied according to the intended effect on the microstructure. For steel, temperatures typically lie between 815–925 °C, depending on the carbon and other alloying agents. For cast iron, normalizing temperatures are higher than steel, generally between 870–940 °C. For copper alloys, the temperatures are usually between 700 °C and 800 °C. For aluminum alloys, temperatures are precise to the alloy's properties if needed. For nickel alloys, Inconel® is normalized between 925-1010 °C, whereas Monel® is between 850–1050 °C. Normalizing of titanium alloys, when performed, is typically done at 700-785 °C, although alloying elements can significantly alter this temperature range.

Do You Quench After Normalizing?

No, normalizing applies heat and then a relatively slow cooling process, exposing the heated sample to ambient air to allow the temperature to fall naturally.

What Are the Advantages of Normalizing?

Normalizing offers several advantages in manufacturing metal parts, including:

- Enhances mechanical properties by refining the microstructure, which increases strength, toughness, and ductility.

- Reduces residual internal stresses induced by prior manufacturing processes, minimizing the risk of distortion, cracking, or warping during or after machining.

- Produces a uniform, fine-grained microstructure, resulting in greater material consistency and reduced anisotropy.

- Improved uniformity and ductility facilitate subsequent machining, forming, and fabrication processes.

- Improves batch-to-batch consistency by standardizing the microstructure and mechanical properties across different heats of material.

- Optimizes the material’s response to subsequent heat treatments, such as hardening or tempering, by providing a more uniform starting condition.

What Are the Disadvantages of Normalizing?

While normalizing offers numerous metallurgical benefits, it also has some limitations and potential disadvantages:

- Primarily applicable to ferrous alloys, such as carbon steels, alloy steels, and cast iron.

- Requires high energy input to reach and sustain elevated temperatures (typically 750°C to 980°C), resulting in increased operational costs compared to lower-temperature processes, such as stress relieving.

- Air cooling is slower than quenching, which can limit production throughput and increase cycle times, particularly in high-volume manufacturing environments.

- May cause minor dimensional changes or warping, especially in components with non-uniform cross-sections or complex geometries, due to differential thermal expansion and cooling rates.

Frequently Asked Questions About Normalizing

Is Normalizing Metal More Expensive Than Tempering?

No, normalizing is a less controlled and less refined process than tempering. It requires similar temperatures during the heating phase, but no enclosed or controlled cool-down equipment is needed, so process times are lower, allowing for faster throughput and, consequently, reduced costs.

How Common Is Normalizing?

Normalizing is a relatively common heat treatment process, particularly in industries that extensively utilize steel and cast iron components. Its prevalence can vary depending on factors such as the specific industry, the type of materials being processed, and the desired properties of the end products.

Normalizing is a standard practice in the production of various steel products, including structural components, automotive parts, and machinery components. Forged and cast components often require the microstructural refinement and stress relief of normalizing. Welded materials benefit from normalizing to relieve stresses and improve the material's properties in the heat-affected zone. Steels used in tool and die manufacturing are typically normalized to enhance machinability between process stages and toughness in finished parts.

What Is the Difference Between Normalizing and Annealing?

Normalizing and annealing are both heat-treatment processes used to alter the microstructure and properties of metals, but they differ in their objectives and methods.

Normalizing aims to refine the grain structure, enhance mechanical properties, and alleviate internal stresses within the material. It produces a more uniform and fine-grained microstructure, improving strength and toughness.

Annealing similarly relieves internal stresses and improves grain structure and machinability. It allows for greater time for grain growth than does normalization, due to the extended cooling period, which additionally softens the material.

How Does the Color of Steel Change When Normalized?

During normalizing, the color of steel changes as it is heated, soaked, and cooled. Initially, it appears dull red, progressing to brighter red, orange, and yellow hues as it reaches the normalizing temperature. During cooling, it returns to its original gray or silver color.

How Many Times Can You Normalize Steel?

There is no limit to the number of normalization cycles that a steel part can undergo if relief of process hardening is required after intermediate manufacturing stages. For example, when steel wire is drawn from a large to a small diameter, restoring ductility after each drawing stage is necessary, so that the next drawing stage can proceed without fracture.

Summary

This article presented normalizing, explained it, and discussed its purpose and how it works. To learn more about normalizing, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Copyright and Trademark Notices

- Monel® is a registered trademark of Special Metals Corporation.

- Inconel® is a registered trademark of Special Metals Corporation.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.