Two materials that are often said in the same breath are polycarbonate and polyethylene. They’re both plastics but they bring very different properties and uses to the table for manufacturers. This article is a written Venn diagram of sorts that will compare the two plastics to help you best decide which will be the most useful in the products you have in mind.

What is Polycarbonate?

Plastics might literally be known for their plasticity and flexibility, but polycarbonate (PC) is one such material that’s renowned for its impact strength, toughness, and durability. This thermoplastic is made up of polymers surrounding carbonate groups in their chemical structure. When compared to other similar manufacturing materials, PC is relatively inexpensive, but prices will vary depending on its weight and any extra properties. The image below shows an example of a PC part made by Xometry.

What is Polyethylene?

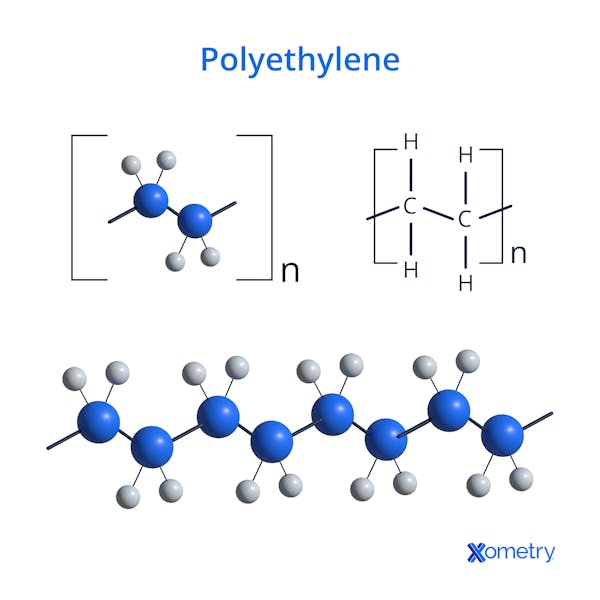

Polyethylene (PE) ranks high up there when it comes to other extremely popular thermoplastics in the world of manufacturing. It’s a homopolymer with chains of ethene molecules and is a useful material for everything from plastic bags to medical implants. The most common formats of this plastic are low-density (LDPE) and high-density (HDPE) polyethylene. LDPE is more elastic as it has a lower density and its chains are made up of side branches within its chemical structure. As shown in the below diagram, HDPE has more closely packed chains, which makes it denser.

Polycarbonate vs. Polyethylene: Applications and Uses

Listed here are the leading market sectors that utilize polycarbonate (extruded/calendered sheet, and molded items) and their applications:

- Medical Equipment: Cameras, lenses, medical aids.

- Protective Eyewear: Safety goggles, and face shields.

- Optical Components: Human vision corrective and instrument lenses, light guides.

- Automotive: Light covers and lenses.

- Media Discs: Blu-ray, DVDs.

- Domestic and Commercial Paneling: Cupboards, kitchen paneling, handles.

- Display Stands/weatherproofing: Advertising displays, protective covers for advertising, weather shields, barriers in public spaces, and bus stops.

- Agriculture: Greenhouse roofing/windows.

- Lightweight Luggage: Bags and suitcases.

Polyethylene has applications across many sectors including:

- Packaging: Used for crates, trays, milk bottles, caps for PET bottles, fuel cans, drums, and industrial fluid containers.

- Consumer Goods: Trash bins, garden equipment and furniture, storage bins, children's toys, and playground equipment.

- Textiles and Fibers: HDPE is widely used for agricultural applications, such as in ropes, fishing, sports nets, and industrial and decorative fabrics.

- Pipes and Fittings: For gas, water, sewage, drainage, outfalls, rain collectors, and septic tanks.

- Cable sheaths, steel pipe corrosion coatings, chemical tanks, and fittings.

- Automotive: Fuel tanks, wiring & cables, cable ties and retainers, body-mounted clips.

Polycarbonate vs. Polyethylene: Physical Properties

This table shows the differences in physical properties and applications between PC and both high- and low-density PE.

| Property | Polycarbonate | LDPE | HDPE |

|---|---|---|---|

Property Optical transmission | Polycarbonate Very high (better than glass) | LDPE Moderate, which can be improved through biaxial orientation | HDPE Poor to none |

Property Density | Polycarbonate 1.2 g/cm^3 | LDPE 0.915–0.96 g/cm^3 | HDPE 0.933–1.27 g/cm^3 |

Property Hardness (Shore D) | Polycarbonate 90–95 | LDPE 42–56 | HDPE 55–69 |

Property Tensile strength (ultimate) | Polycarbonate 28–75 MPa | LDPE 8.96–54 MPa | HDPE 15.2–45 MPa |

Property Yield strength | Polycarbonate 39–70 MPa | LDPE 7.6–14 MPa | HDPE 2.69–200 MPa |

Property Elongation at break | Polycarbonate 10–138% | LDPE 226–650% | HDPE 3–1900% |

Property Modulus of elasticity | Polycarbonate 1.79–3.24 GPa | LDPE 0.152–0.29 GPa | HDPE 0.483–1.45 GPa |

Property Flexural yield strength | Polycarbonate 36–103 MPa | LDPE 14–21 MPa | HDPE 16.5–91 MPa |

Property Flexural modulus | Polycarbonate 0.971–3.1 GPa | LDPE 0.07–0.276 GPa | HDPE 0.5–4.83 GPa |

Property Dielectric constant | Polycarbonate 2.85–3.17 | LDPE 2.27–2.29 | HDPE 2.0–2.6 |

Property Melting point | Polycarbonate 288–316 °C | LDPE 102–113 °C | HDPE 120–130 °C |

Property Max service temperature | Polycarbonate 115–135 °C | LDPE 80–100 °C | HDPE 80–120 °C |

Property Applications | Polycarbonate Medical cameras, lenses, face shields, safety goggles, DVDs, cupboards, kitchen paneling, weather shields, bags, suitcases, windows, greenhouse roofing | LDPE Plastic bottles, plastic bags, trays, computer parts, tubes, containers, caps, fuel cans and drums, trash bins, cables, clips | HDPE Ropes, fishing, sports nets, industrial and decorative fabrics, recycling bins, food and beverage packaging, pipes, milk jugs, toys |

Property Cost | Polycarbonate Around $2.80 per kg or $1.60 per kg for recycled | LDPE About $0.90–$1.10 per kg for granules | HDPE About $8.50 per kg, or around $2.50 for recycled material |

Property Recyclability | Polycarbonate Highly recyclable through sorting, shredding, and remelting | LDPE Highly recyclable except for film products and often more expensive to recycle than to use virgin material | HDPE Highly recyclable except for film products and often more expensive to recycle than to use virgin material |

Polycarbonate vs. Polyethylene Physical Properties

Polycarbonate vs. Polyethylene: Recyclability and Sustainability

Polycarbonate (PC) is manufactured from hydrocarbon materials. It's a highly recyclable material that responds well to shredding and re-melt extrusion to make second-grade feedstock pellets. This requires rigorous sorting to avoid impurities, but the automotive sector has advanced in its recycling and circular use of PC. Very little effective recycling of PCs takes place otherwise. For thermoplastics, the recycling process is simple—sort, shred, wash, and extrude as pellets for reuse. The difficulty lies in that PC used outside the automotive industry is often in copolymer form, and the volumes of PC employed are low, so there is limited scope to establish collection and reuse.

PE (polyethylene) is among the most recyclable polymers, but most are film products that are very hard to handle. Huge volumes justify installation/processing, and the polymer chain is only minimally damaged by remelting. However, recycled material cannot compete with the price of virgin material. Recycled material maintains a fairly high price, but the process is barely profitable because of the sorting/handling difficulties. Very little LDPE is recycled, it ends up in incineration or landfill. HDPE film materials are generally used in heavier (thicker) sections, are colored, and are relatively easy to sort for high purity. The process does not require the separation of colored, natural, and clear materials at the sorting stage. The end result is high-quality, second-grade material of dark color that can be used for a range of applications. This material can be used as feedstock or more often as a second-grade additive in new material.

Polycarbonate vs. Polyethylene: Cost

PC (polycarbonate) is a low-volume, specialist, and high-cost material, priced at around $2.80 per kg. Recycled material of near-top grade can sell for $1.60 per kg, where a supply chain exists. Like all of the PE (polyethylene) family, HDPE is a low-price material that is manufactured in huge quantities and is generally considered a commodity material. The price for virgin material is around $8.50 per kg, falling to $2.50 for recycled material. LDPE is considerably lower cost than HDPE, generally selling as granules in the $0.90–$1.10 price range. Recycled, clear LDPE is available at a similar or slightly lower price; it is generally used as a 10–20% addition to virgin material, saving manufacturers a few cents per kg.

Alternative Materials to Polycarbonate and Polyethylene

There are a few materials that work in similar ways to PC and PE, and are good considerations depending on what application you’re sourcing for:

- Acrylic: While it’s not as strong as PC or PE, acrylic is perfectly workable for windows and other applications. One example is Trivex.

- Polystyrene: More transparent versions of PS can be a good swap for products like light guides, especially since PS is weaker and more easily broken than PC.

- Acrylonitrile butadiene styrene: ABS is perfect if you want a plastic that doesn’t need extreme flexural resilience or ultimate strength. It’s a popular choice for things like 3D printing and injection molding.

How Xometry Can Help

We’re extremely familiar with all the ways in which you can process and manufacture polycarbonate and polyethylene. Through our website, you can get free quotes for related services, like plastic 3D printing, injection molding, and compression molding.

Copyright and Trademark Notice

- Trivex™ is a registered trademark of PPG Industries Ohio, Inc.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.