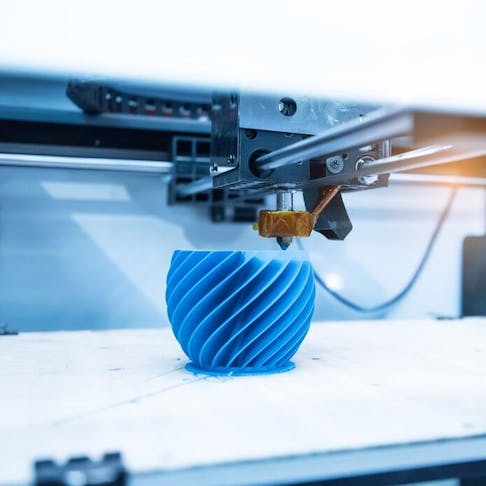

3D printing utilizes a diverse range of materials, each with distinct properties and applications. Choosing the right material for 3D printing is crucial, as it directly impacts the quality, durability, and functionality of your printed objects. Each material has its unique properties and use cases, making it essential to understand the strengths and weaknesses of each option.

This article will discuss the most common and best materials used for 3D printing, their properties, and their applications.

| Material | Advantages | Disadvantages |

|---|---|---|

Material ABS (Acrylonitrile Butadiene Styrene) | Advantages Impact-resistant, wear-resistant, low-cost | Disadvantages Difficult to print due to warping, poor bed adhesion |

Material ASA (Acrylic Styrene Acrylonitrile) | Advantages UV-resistant, impact-resistant, wear-resistant | Disadvantages High cost, dangerous fumes during printing |

Material PP (Polypropylene) | Advantages Impact-resistant, fatigue-resistant, good surface finish, good chemical resistance | Disadvantages Difficult to print due to warping and poor bed adhesion |

Material PLA (Polylactic Acid) | Advantages Cheap and easy to print | Disadvantages Brittle, degrades in outdoor environments |

Material Carbon Fiber Filled | Advantages High-strength parts | Disadvantages Can block nozzles, high cost |

Material Nylon (Synthetic Polymers) | Advantages Excellent mechanical properties, low friction | Disadvantages Absorbs moisture |

Material HIPS (High Impact Polystyrene) | Advantages Low weight, can be dissolved with a solvent | Disadvantages High printing temperature |

Material PC (Polycarbonate) | Advantages One of the strongest 3D printer filaments, transparent | Disadvantages Difficult to print, high cost |

Material PVA (Polyvinyl Alcohol) | Advantages Dissolves in water | Disadvantages Can only be used for support material |

Material Resins | Advantages Smooth surface, versatile | Disadvantages Design limits, high cost |

Material Nitinol | Advantages Withstand substantial bending, one of the strongest materials | Disadvantages Difficult to print |

Material Flexible (made of Thermoplastic Elastomers) | Advantages Rubber-like behavior | Disadvantages High cost, difficult to print |

Material Wood-Based Filament | Advantages Aesthetically pleasing finish | Disadvantages Poor overall strength, can block the nozzle |

Material Metal Filled Filaments | Advantages Aesthetically pleasing finish | Disadvantages Poor overall strength |

Material PETG (Glycol Modified version of PET) | Advantages Excellent mechanical properties, easier to print than ABS | Disadvantages Imperfect interlayer adhesion |

Material Graphite and Graphene | Advantages High strength, remarkable electrical conductivity | Disadvantages High cost, poor efficiency |

The Best Materials for 3D Printing

Table 1 summarizes the advantages and disadvantages of the most common 3D printing materials. Listed below is a brief description of these 3D printing materials:

1. ABS (Acrylonitrile Butadiene Styrene)

ABS is one of the most widely adopted thermoplastics in 3D printing, especially in Fused Deposition Modeling (FDM) processes. ABS is derived from petroleum-based feedstocks and is well-known for its role in injection molding. It is commonly used in household and consumer products such as Lego® bricks, protective phone cases, and bicycle helmets. These applications leverage ABS's notable properties, including high impact resistance, good tensile strength, and moderate heat resistance.

In commercial and industrial settings, ABS is often chosen for functional prototyping and end-use parts due to its mechanical strength and cost-effectiveness. However, among hobbyists, ABS is less favored compared to easier-to-print alternatives like PLA or PETG. This is mainly due to ABS's tendency to warp during printing, which typically requires a heated print bed and an enclosed build chamber to maintain dimensional accuracy.

ABS boasts affordability and an impressive strength-to-weight ratio. In addition, it facilitates straightforward post-processing and offers a diverse color palette. It's important to note that ABS emits odorous and potentially harmful volatile organic compounds (VOCs) during the printing process. To mitigate this, it's advisable to print in well-ventilated spaces or within an enclosure, and maintaining distance from the printing area is a prudent precaution.

To learn more, see our full guide on What is ABS Plastic?

2. ASA (Acrylic Styrene Acrylonitrile)

ASA is an engineering-grade thermoplastic commonly viewed as a UV-stable alternative to ABS in both 3D printing and injection molding. It shares a similar chemical structure with ABS but replaces the butadiene component with an acrylate rubber, significantly enhancing its resistance to ultraviolet light, weathering, and environmental stress cracking. As a result, ASA is especially well-suited for outdoor applications where long-term exposure to sunlight would cause ABS to fade or degrade.

ASA offers comparable strength, impact, and thermal resistance to ABS. Its glass transition temperature is typically around 105 °C. However, its superior color stability under UV exposure, along with greater resistance to yellowing, makes it advantageous in applications requiring long-term aesthetic durability. ASA also exhibits lower warping tendencies during 3D printing, contributing to more consistent print quality, particularly in semi-enclosed or well-calibrated desktop printers.

3. PP (Polypropylene)

Polypropylene (PP) is a semi-crystalline thermoplastic widely used across various industries for its excellent chemical resistance, low moisture absorption, and high fatigue endurance. In 3D printing, PP is valued for applications such as living hinges and flexible containers, thanks to its durability under repeated stress. However, it presents printing challenges, including poor adhesion to the build surface and a strong tendency to warp. These issues often require specialized build plates or adhesion techniques. Despite this, PP remains a practical choice for functional prototypes and lightweight, chemically resistant parts.

For more information, see our guide on PP (Polypropylene).

4. PLA (Polylactic Acid)

PLA (polylactic acid) is the most widely used filament in desktop 3D printing, favored for its ease of use and low environmental impact. Derived from renewable resources such as corn starch or sugarcane, PLA is considered an eco-friendly material. However, it is industrially compostable rather than home-biodegradable and typically recyclable only through specialized facilities. With a relatively low printing temperature (190–215 °C), minimal warping, and virtually no odor during extrusion, PLA is ideal for visual prototypes, models, and low-stress applications. It is also considered safe for limited food contact, depending on additives and local regulations. However, PLA has limitations—including lower impact resistance, brittleness, and poor heat resistance, making it unsuitable for functional parts exposed to mechanical stress or temperatures above ~60 °C.

PLA is available in a wide range of variants, including silk-like, lightweight, recycled, glow-in-the-dark, color-changing, carbon-fiber-infused, wood-filled, and metal-infused formulations, as well as flexible, translucent, and high-temperature PLA grades for specialized use cases.

To learn more, see our guide on PLA (Polylactic Acid).

5. Carbon Fiber

Carbon fiber-reinforced filaments are composite materials created by infusing short carbon fiber strands into standard thermoplastics such as PLA, ABS, or PETG. This reinforcement significantly improves stiffness and dimensional stability while reducing overall weight, making these filaments ideal for functional parts requiring high rigidity. Unlike other fillers such as wood or metal powders, which often minimize mechanical performance, carbon fiber tends to enhance structural properties. However, due to the abrasive nature of carbon fibers, these materials can cause accelerated wear on standard brass nozzles and may increase the risk of clogs. To prevent equipment damage and maintain print quality, it is recommended to use hardened steel, ruby-tipped, or other abrasion-resistant nozzles when printing with carbon fiber-infused filaments.

6. Nylon

Polyamide (PA), commonly referred to as nylon, is a robust and enduring 3D printing material renowned for its exceptional toughness and resistance to both high temperatures and impacts. It boasts commendable tensile and mechanical strength, making it a favored choice for a broad spectrum of applications.

Nylon is frequently reinforced with various fibers such as carbon, glass, and Kevlar®, or it can be embedded with continuous carbon fiber for enhanced reinforcement. Its utilization is widespread in high-end engineering domains, encompassing the creation of gears, jigs, fixtures, and tooling. Additionally, nylon is available in powder form, expanding its range of applications.

While not as easy to print with as materials like PLA or PETG, nylon remains a viable choice. To work with nylon effectively, a high-temperature nozzle, capable of reaching up to 300 °C, may be necessary. Furthermore, proper storage is essential, as nylon readily absorbs moisture when exposed to open air. Moisture absorption can lead to material degradation, resulting in subpar print quality and reduced strength.

7. HIPS (High-impact polystyrene)

High-impact polystyrene (HIPS) is a unique 3D printing material composed of a blend of polystyrene plastic and polybutadiene rubber. This combination yields a material that boasts impressive toughness and flexibility.

While HIPS shares similarities with ABS, it distinguishes itself by its exceptional resistance to high-impact forces. Additionally, it offers versatility through ease of painting, machining capabilities, and compatibility with a wide range of adhesives. HIPS also holds an FDA-compliant status for food processing applications.

In 3D printing, HIPS is mainly used as a support material. Its key advantage lies in its solubility in limonene solution, eliminating the need for labor-intensive removal methods like abrasives or cutting tools. This property simplifies the printing process. Moreover, HIPS can be smoothed to achieve glossy surfaces, a feat often challenging with PLA. It's worth noting that while limonene is an accessible solution derived from lemon peels, it may have adverse effects on 3D printing materials other than HIPS.

8. Polycarbonate

Polycarbonate filament, often referred to as PC, is a transparent and durable material well-suited for high-temperature applications due to its exceptionally high transition temperature (approximately 150 °C). PC exhibits natural flexibility, making it suitable for various situations, even those involving significant stress on the printed object.

Nevertheless, it's important to note that PC filament is prone to absorbing moisture from its environment. This moisture absorption can lead to issues such as warping or layer separation during printing. To mitigate these challenges, it's advisable to store PC filament in an airtight container whenever possible. Additionally, given the high printing temperatures required, using heat protection measures is essential when working with PC.

For more information, see our guide on PC (Polycarbonate).

9. PVA (Polyvinyl Alcohol)

Polyvinyl Alcohol (PVA) is a water-soluble thermoplastic primarily used as a support material in dual-extrusion 3D printing, particularly with PLA and other low-temperature filaments. Unlike HIPS, which requires limonene for dissolution, PVA fully dissolves in warm water, simplifying post-processing and reducing the need for harsh chemicals. Due to its soft and biodegradable nature, PVA is not suitable for standalone functional parts. However, it is ideal for complex geometries with internal cavities or overhangs that require removable supports.

A key drawback is its tendency to clog nozzles if left heated without extrusion, and it is highly hygroscopic, meaning it must be stored in a dry, airtight environment to avoid moisture absorption that can degrade print quality.

10. Resins

Resin is a versatile material in 3D printing. It encompasses various technologies like stereolithography (SLA), digital light processing (DLP), and liquid crystal display (LCD) in vat polymerization, as well as material jetting methods like PolyJet. Resin excels in high-detail printing and is often strong enough for post-print machining.

High-temperature resins are cost-effective for creating injection molds for small-scale prototypes. Standard resins suit applications like conceptual and functional models. Rapid resins, also known as "raft resin," cure quickly and prevent part deformation. Tough resins mimic ABS and are ideal for functional parts. Water-washable resins simplify cleaning with water instead of alcohol. Flexible resins offer elasticity, similar to TPU, for applications requiring high flexibility. Plant-based resins use eco-friendly sources like soybeans. Castable and wax resins facilitate jewelry manufacturing by creating wax molds. Transparent/clear resins, although requiring post-processing, are suitable for medical and model-making applications. Glow-in-the-dark resin produces luminescent models, and biocompatible and dental resins meet medical and dental requirements, but compliance with varying regulations is essential for medical applications.

FREE SLA 3D Printing Design Guide

11. Nitinol

Nitinol is a nickel–titanium alloy best known for its unique combination of shape memory and superelastic properties, making it a valuable material in medical devices such as stents, guidewires, and orthodontic components. It can undergo significant deformation, such as bending or twisting, and still return to its original shape when exposed to heat or upon unloading, depending on the application. This behavior is due to a reversible phase transformation between austenite and martensite crystal structures. While not the strongest material in terms of tensile strength alone, Nitinol is known for its ability to withstand extreme flexing without permanent deformation or fracture, setting it apart for use in applications requiring both durability and flexibility.

12. Flexible Filaments

TPEs, or thermoplastic elastomers, belong to a class of materials that combine plastic and rubber properties. Notable examples include TPU (thermoplastic polyurethane) and TPC (thermoplastic copolyester), among others. These plastics exhibit remarkable softness and flexibility. This makes them increasingly popular in additive manufacturing for creating deformable parts that can be stretched or bent without losing their shape. TPUs, in particular, offer exceptional durability and excel in resisting abrasion, oils, chemicals, and extreme temperatures, outperforming TPE filaments. On the other hand, TPC stands out with its high-temperature resilience and excellent UV resistance, finding valuable applications in the biomedical field, wearable tech, and medical devices. TPEs are also available in powder and resin forms.

While these materials offer versatility, achieving successful 3D prints requires precise control over the printing process, including the use of properly dried filament, appropriate bed heating, nozzle temperatures, and print speeds.

13. Wood

Wood 3D filament is a composite material typically consisting of PLA infused with wood fibers. There's a wide variety of wood-PLA 3D printer filaments available today, offering options like pine, cedar, birch, ebony, willow, cherry, bamboo, cork, coconut, and olive. However, using wood-based filament comes with trade-offs. While it provides an aesthetically pleasing and tactile appeal, it sacrifices some flexibility and strength compared to other materials. Additionally, wood-filled filament can accelerate the wear and tear of your 3D printer's nozzle, so be mindful when using it. It's essential to control the printing temperature, as excessive heat can lead to a burnt or caramelized appearance. Nonetheless, you can enhance the final look of your wooden creations with post-print processing techniques such as cutting, sanding, or painting.

To learn more, see our full guide on Wood-Based Filament.

14. Metal

Metal is one of the fastest-growing material categories in additive manufacturing, particularly in industrial and high-performance applications. It is primarily processed through Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM). Metal Fused Filament Fabrication (commonly called metal FDM) is also used, typically for prototyping or low-volume production, though it involves a secondary debinding and sintering step.

DMLS and SLM have been widely adopted in the aerospace, automotive, and medical sectors due to their ability to produce complex, high-strength metal parts with reduced lead times and less material waste than traditional machining or casting methods. Unlike casting, which requires molds and multiple steps, metal 3D printing can fabricate near-net-shape components directly from CAD models, reducing both tooling costs and assembly complexity.

In DMLS and SLM, metal powder is selectively melted or sintered layer by layer, enabling precise control over internal structures and geometry. Common materials used in metal additive manufacturing include titanium, stainless steel, aluminum, tool steels, bronze, and nickel-based superalloys. These materials support a wide range of applications, from functional prototypes to end-use parts in aerospace, medical implants, and industrial tooling.

15. PET and PETG Filaments

PETG is a filament derived from polyethylene terephthalate (PET), the same material found in plastic water bottles. However, in PETG, a portion of the ethylene glycol is substituted with CHDM (cyclohexanedimethanol), signified by the "G" in its name, which stands for "glycol-modified." This modification yields a filament that boasts greater clarity, reduced brittleness, and enhanced ease of use compared to its unmodified PET counterpart.

PETG is a suitable alternative to ABS, offering heat-resistant properties without the production of toxic fumes. It is also popular for being food-safe. Additionally, PETG can be post-processed by sanding, akin to PLA. While most FDM printers compatible with PLA can also handle PETG, it may require more calibration and effort for optimal results.

The advantages of PETG include its ease of printing compared to ABS, the ability to maintain a smooth finish, and convenient storage properties. However, it comes with certain drawbacks, such as the requirement for high printing temperatures, which can lead to wear and tear on printer components over time. While PETG may not excel in bridging due to its high stickiness, this attribute translates into excellent layer adhesion. It is worth noting that PETG is more hygroscopic than PLA, making it susceptible to issues like substantial stringing and moisture absorption from the air if left exposed.

16. Graphite and Graphene

Graphene and graphite are emerging materials in 3D printing, valued for their unique electrical, thermal, and mechanical properties. Graphene—a single layer of carbon atoms arranged in a hexagonal lattice—is particularly noted for its exceptional electrical conductivity, mechanical strength, and lightweight structure. In 3D printing, graphene is often used as a filler material in polymer composites to enhance conductivity and strength, rather than as a standalone printable material.

These graphene-enhanced filaments are suitable for producing flexible electronic components such as touch sensors and EMI shielding parts. Graphene is also being researched in advanced applications like energy storage devices, solar cells, and structural composites. While still in the early stages of commercialization, graphene's combination of flexibility, strength, and conductivity makes it a promising additive in functional and multi-material printing.

Why You Should Know the Materials Used in 3D Printing

Knowing the different material options in 3D printing allows users to make informed decisions on which material will be best suited for various applications. This also ensures that the printed object meets the standards and functional requirements. Secondly, it helps users make cost-efficient choices, optimizing their printing processes and budgets. Thirdly, awareness of the environmental impact of different materials promotes sustainable and eco-friendly printing practices. Additionally, knowledge of material compatibility with specific 3D printers ensures a smooth printing process and minimizes equipment damage. Moreover, in industries like healthcare and aerospace, compliance with strict regulations regarding materials is essential to avoid legal and safety issues.

For more information, see our article on the guide to 3D printing.

What are the Most Commonly Used Materials in 3D Printing?

PLA (Polylactic Acid) is the most popular 3D printing plastic for non-industrial use, while nylon is the most common plastic for industrial applications.

The selection of material for a 3D printed component largely relies on its intended purpose, with crucial attributes tailored to the specific application. Here are several fundamental properties essential for general 3D printing:

- Elongation

- Melting Temperature

- Heat Deflection Temperature

- Impact Strength

- Flexural Strength

- Tensile Strength

- Hardness

Navigating 3D printing materials reveals that material selection is less about variety and more about engineering trade-offs. Each material presents distinct constraints in terms of mechanical performance, thermal stability, and print behavior, which must be aligned with the application’s functional requirements. Factors such as moisture sensitivity, warping, and interlayer adhesion often determine print success more than tensile strength alone. In practice, the interaction between material properties and process parameters becomes central to achieving consistent, high-quality parts. Material choice is not just a design input but a key factor in manufacturing reliability and end-use performance.

The Best Materials for Stereolithography (SLA) 3D Printing

SLA 3D printing boasts exceptional versatility. It suits a variety of resin formulations with extensive optical, mechanical, and thermal properties that can align with standard, engineering, and industrial thermoplastics. Common resins that are used in 3D printing include:

- Standard resin

- Clear resin

- Draft resin

- Tough and durable resin

- Rigid resin

- Polyurethane resin

- Flexible and elastic resin

- Medical and dental resin

- ESD (electrostatic discharge) resin

- Flame-retardant resin

- Ceramic resin

The Best Materials for Selective Laser Sintering (SLS) 3D Printing

While SLS has a more limited material selection compared to FDM and SLA, the available materials exhibit outstanding mechanical properties. The materials that can be printed with SLS 3D printing include:

- Nylon and composites

- TPU

The Best Materials for Fused Deposition Modeling (FDM) 3D Printing

The primary materials for FDM 3D printing are ABS and PLA, with various combinations available. Advanced FDM printers can also accommodate specialized materials known for enhanced characteristics such as increased heat tolerance, impact resistance, chemical resilience, and rigidity. Some of the other materials that can be used for FDM 3D printing include:

- PETG

- Nylon

- TPU

- PVA

- HIPS

- Composites (e.g., fiberglass, carbon fiber, Kevlar®)

The Best Materials for Digital Light Process (DLP) 3D Printing

Digital Light Processing (DLP) 3D printers typically work with photopolymer resins. These resins are specially formulated for use in DLP technology and are designed to be cured or solidified when exposed to UV light. Some common types of DLP resin materials include:

- Standard resins

- Engineering resins

- Dental resins

- Jewelry resins

- Castable resins

- Flexible resins

The Best Materials for Multi Jet Fusion (MJF) 3D Printing

Multi Jet Fusion (MJF) 3D printing was originally limited to nylon PA 12 powder, which remains the most widely used material due to its balanced mechanical properties and reusability. However, the material portfolio has expanded significantly through industry partnerships and ongoing development. Some MJF-compatible materials include:

- Estane 3D TPU – M95A from Lubrizol

- Estane 3D TPU M88A

- High Reusability (HR) PA 12 Nylon

- HR PA 11

- HR PA 12 Glass Bead (GB)

- HR PA 12 W (white)

- HR PP enabled by BASF Production

- TPA from Evonik/HP

- Ultrasint® TPU01 from BASF

The Best Materials for Direct Metal Laser Sintering (DMLS) 3D Printing

Direct Metal Laser Sintering (DMLS) is a metal 3D printing technology that uses powdered metal materials. DMLS is suitable for creating strong, complex metal components. Common materials for DMLS include:

- Stainless Steel

- Aluminum

- Titanium

- Cobalt Chrome

- Inconel®

The Best Materials for PolyJet 3D Printing

PolyJet is a 3D printing technology that utilizes an inkjet-style process to create highly detailed and precise 3D objects. It operates by jetting tiny droplets of photopolymer resin onto a build platform layer by layer, which are then cured with UV light to solidify. Here is a list of materials that can be printed with PolyJet 3D printing:

- Digital materials

- Digital ABS plastic

- Rubber-Like materials

- High-Temperature Materials

- Transparent materials

- Rigid Opaque Materials

- Simulated Polypropylene materials

- Biocompatible Materials

The Best Materials for Electron Beam Melting (EBM) 3D Printing

Electron Beam Melting (EBM) 3D printing is limited to a select group of electrically conductive metals due to its use of a high-energy electron beam in a vacuum environment. The most commonly used materials include titanium alloys (especially Ti-6Al-4V), cobalt-chromium alloys, and nickel-based superalloys such as Inconel® 718. These metals are valued for their strength, heat resistance, and suitability for aerospace, medical, and industrial applications. While some steel powders have been explored, their use is less common. Non-metallic materials like polymers and ceramics are incompatible with EBM, as they cannot conduct electricity or withstand the vacuum processing conditions.

Materials That Can Be 3D Printed at Home

Here’s a list of some materials that have been successfully printed in a home environment:

- PLA

- ABS

- PVA

- Nylon

- Polycarbonate

- Ethylene

- Wood filament

- Printing pastes (e.g., sugar, chocolate, silicone, wax, and clay)

Materials That Cannot Be 3D Printed

The list of materials that cannot be 3D printed includes:

- Flammable materials

- Stone or other hard natural materials

- Cloth/fabrics

- Liquids (other than resin) and gases

How to Select the Best 3D Printing Material

To select the correct material, it is crucial to define the application. Below is a list of general rules to follow when choosing the best 3D printing material:

- If high strength is needed, a polycarbonate or carbon-fiber-filled material may be ideal.

- If a basic jig is required, then a cheaper material like PLA may be better suited.

- If the application is a safety-critical component, then it is always safest to consult with the machine supplier as well as the material supplier to understand how any given material will perform.

How Xometry Can Help

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a 3D printing quote.

Copyright and Trademark Notices

- Kevlar® is a trademark of E. I. DuPont de Nemours and Company.

- Inconel® is a registered trademark of Special Metals Corporation.

- Ultrasint® is a registered trademark of the BASF Group

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.