Sometimes called liquid metal forging, squeeze casting is a method used in metal manufacturing that’s a bit of a blend of two other processes: forging and casting. It’s used in aerospace, automotive, defense, and many other industries, for things like bevel gears, mortar shells, architectural domes… and the list goes on. Keep on reading to learn more about it and all its wonderful benefits.

What is Squeeze Casting?

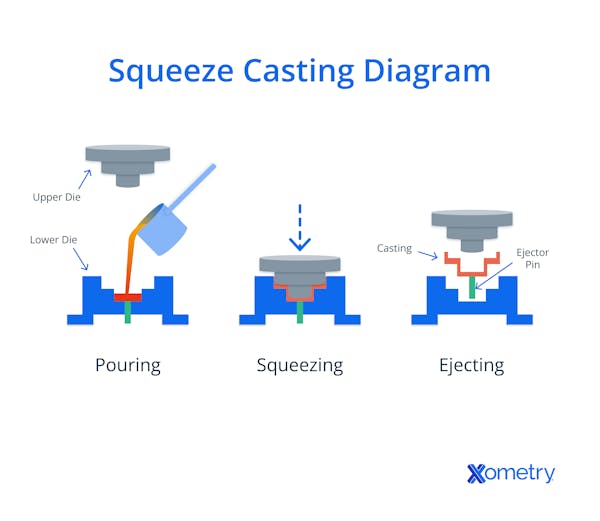

Able to make high-quality parts at practically the exact net shape you planned for, squeeze casting is a technique that can make extremely high-quality parts that don’t go through much shrinkage during the procedure. The process involved molten metal being poured into a heated die, and then left to cool down and solidify. The die on the top closes and pushes the metal to fill out the mold cavity—it’s this part that ensures accuracy and quality, and prevents the shrinkage. Comparable to die casting in terms of accuracy, squeeze casting tolerances range from around 0.25 mm for 100 mm parts to 0.6 mm for 500 mm parts. You can see how the process works in the below picture:

What Is the History of Squeeze Casting?

This process dates back to 1819, when it was first patented by Hollinggrak (although rumor has it that it was created long before the patent by others). Later on, in 1878, it was improved by Chernov, and consisted of 15,000 psi and high temperatures. The process was invented to try to improve on already existing metalworking techniques and make parts with better properties. And it definitely worked because squeeze casting allows for reinforcement wettability (basically bonding), mass production, and precise control over process parameters, and it enhances metallurgical quality because of the pressure used during solidification.

What Is the Importance of Squeeze Casting in Manufacturing?

Squeeze casting is a crucial manufacturing technique. It enables enhanced wettability of reinforcements, efficient mass production, precise process parameter control, superior metallurgical quality through pressure-assisted solidification, and the ability to selectively reinforce specific regions in components. These attributes make it a top choice for producing high-quality metal matrix composites.

How Does Squeeze Casting Work?

Squeeze casting works by introducing liquid metal into a heated die alongside a preform created through powder metallurgy. Once the die is full, pressure is applied and the metal is allowed to solidify. This controlled environment minimizes porosity within the metal matrix and facilitates the creation of near-net-shaped components. Consequently, you’re left with less need for post-processing operations, making it an efficient and cost-effective manufacturing method for complex parts.

What Makes Squeeze Casting Stand Out Among Other Types of Casting?

Squeeze casting distinguishes itself from other casting methods through its unique combination of high-pressure solidification and near-net-shaped component production. The technique reduces porosity, improves material properties, and minimizes post-processing, making it a preferred choice for manufacturing complex, high-quality metal components.

To learn more, see our article on Type of Casting.

Is Squeeze Casting the Same as Die Casting?

Basically, you can view squeeze casting as an adaptation of standard die casting, which also includes forging. Die casting machines will force the liquid metal into a mold cavity, but with squeeze casting, extra pressure is used. As we already alluded to earlier, this is what gives the final part better mechanical properties and not as many defects.

To learn more, see our article on Die casting.

Squeeze casting is highly versatile because it combines casting and forging principles, producing near-net-shape components with superior mechanical properties, minimal porosity, and excellent surface finish. Its ability to work with various metals, accommodate complex geometries, and reduce machining needs makes it ideal for industries like automotive and aerospace.Jake ThompsonSenior Solutions Engineer

What Are the Types of Squeeze Casting?

To make things even more interesting, there’s not one type of squeeze casting, but two: direct and indirect.

1. Indirect Squeeze Casting

For this, the molten metal is poured into a shot sleeve, which is then pushed through gates that are pretty big. It then makes its way into the die cavity at a velocity typically below 0.5 m/s—which is relatively low. The indirect part of the process actually comes from how the high pressure is applied—through the rather complex gating system. This all makes the process more controllable in terms of solidification and helps prevent any defects, but seeing as the gating is as complex as it is, you’ll end up using more material and energy.

2. Direct Squeeze Casting

Sometimes abbreviated as DSC (for Direct Squeeze Casting), this method relies more on pouring the metal in its liquid state inside a heated and lubricated die. The metal then gets forged as it hardens. When it starts to freeze, pressure gets applied and held there until the whole thing has become solid. In most cases, this technique is done using a vertical machine that looks kind of like a forging press.

What Are the Metals Used in Squeeze Casting?

While the process also works on stainless steel (it’s basically another metal that needs to be solidified in a controlled manner), there are four main metals used in squeeze casting.

1. Zinc

Zinc squeeze casting gets applied to zinc-based alloys, notable for their relatively low melting points. In this process, molten zinc alloy is carefully directed into a die cavity where pressure is applied to shape and solidify the item. Zinc's exceptional fluidity makes it ideal for intricate part geometries. Moreover, it demands less heat than most metals. However, that also means zinc-based alloy parts are only suited to cooler operating temperatures, and their mechanical properties may not match those of other metals.

2. Magnesium

Magnesium squeeze casting relies on magnesium alloys, celebrated for their lightweight characteristics and impressive strength. During magnesium squeeze casting, molten magnesium alloy is poured into a preheated die and pressurized while it solidifies. Magnesium alloys offer excellent strength-to-weight ratios, making them particularly attractive for industries seeking lightweight yet robust components. However, precise temperature control is critical due to magnesium's flammability and susceptibility to oxidation.

To learn more, see our article on Magnesium.

3. Aluminum

Aluminum squeeze casting centers around aluminum-based alloys, cherished for their strength and low density. Liquid aluminum alloy is introduced into a preheated die and molded under pressure during the solidification phase. The excellent strength, corrosion resistance, and versatility of aluminum alloys make them popular options for a variety of applications. However, good aluminum squeeze casting depends upon precise alloy selection and strict temperature management.

4. Copper Alloys

Squeeze casting with copper alloys encompasses materials like brass and bronze, valued for their durability and exceptional electrical conductivity. The procedure channels molten copper alloy into a heated die and shapes it under pressure as it solidifies. Copper alloys excel in applications where electrical and thermal conductivity, as well as wear resistance, are paramount. However, their cost and specific material properties limit their reach in the market.

Can Stainless Steel Be Used as a Casting Metal for Squeeze Casting?

Yes, stainless steel can be squeeze-cast. Squeeze casting is a versatile process that shares similarities with both casting and forging, making it ideal for alloys like stainless steel that require controlled solidification.

To learn more, see our article on stainless steel.

What Are the Applications of Squeeze Casting?

Many industries use squeeze casting to create complicated, high-quality metal components. A few examples are found in the production of: steel bevel gears for machinery, aluminum domes for architectural use, iron mortar shells, pistons for internal combustion engines, aluminum automotive wheels, and bronze and brass gear blanks. This procedure guarantees superior mechanical qualities and dimensional accuracy in these components.

What Industries Use Squeeze Casting Products?

Squeeze casting products find use in: automotive, defense, aerospace, and manufacturing industries, among others. In the automotive sector, components like pistons and wheels enhance engine efficiency and vehicle performance. The defense industry relies on squeeze-cast iron mortar shells. Critical aircraft structural elements also get cast this way.

What Is the Quality of Squeeze Casting Products?

Squeeze casting products exhibit exceptional quality and durability. The process generates high-density, nonporous structures by reducing solidification shrinkage and eliminating gas compression. This results in excellent surface quality and superior mechanical properties, making squeeze-cast components highly durable and reliable.

Are the Squeeze Casting Products Ductile?

Yes, squeeze casting products are ductile. The rapid solidification in squeeze casting results in fine secondary dendrite arm spacing within castings, which enhances their strength and ductility. This microstructural refinement contributes to their ability to withstand deformation without fracturing. Specific ductility properties depend on the material, though.

Are the Squeeze Casting Products Brittle?

No, squeeze casting products are not inherently brittle. However, some alloys are naturally more brittle than others, no matter how they’re cast. Be careful to make design, material, and process parameter choices that will meet your ductility, toughness, and other mechanical property requirements.

What Is the Accuracy of Squeeze Casting?

Squeeze casting precision typically ranges from 0.25 mm in 100 mm to 0.6 mm in 500 mm, making it comparable to die casting. The great dimensional accuracy means it can be used in applications that demand exact tolerances.

What Is the Lifespan of Squeeze Casting Products?

Material choice, usage circumstances, and maintenance are only a few of the variables that affect how long squeeze casting products last. These components typically have long lifespans when made with the proper materials and maintained properly.

What Are the Advantages of Squeeze Casting?

- Parts are high-quality, strong, dense, ductile, and dense with low porosity

- Consistent results

- Allows you to reinforce specific areas in a part

- Repeatable process

- Parts can be further heat-treated

- Minimal (if any) post-processing required

What Are the Disadvantages of Squeeze Casting?

- Expensive—needs special tools/equipment

- Extensive machining needed for highly precise tolerances

- Less versatile than other casting methods, especially for complex shapes

How Much Does Squeeze Casting Cost?

The cost of squeeze casting can vary significantly depending on factors such as: the complexity of the part, the material used, and production volume. The initial tooling and equipment are typically more expensive than for other casting methods.

Centrifugal casting is generally considered more cost-effective as it doesn't demand expensive tools or materials. The process is relatively simple and doesn't require highly skilled labor. Centrifugal castings usually have smooth, high-quality finishes.

Frequently Asked Questions on Squeeze Casting

What Is the Alternative for Squeeze Casting?

Quite a few, but if you’re looking for the closest in terms of quality and production style, we’d say the best alternative is HPDC, mentioned earlier. It usually works really well with magnesium, zinc, and aluminum. If you’re trying to avoid the higher costs of squeeze casting tools and equipment, you could try centrifugal casting. This process doesn’t need extreme skills and can produce parts with high-quality, smooth finishes at a more affordable cost.

What Is the Difference Between Squeeze Casting and High-Pressure Casting?

It can be rather easy to confuse these particular techniques because they sound like they do the same thing. But they’re different when it comes to pressure application. In this article, we spoke about how squeeze casting uses high pressure, but even so, the pressure it uses is considered low to medium in comparison with high-pressure die casting, also known as HPDC. In even simpler terms, HPDC is an even more enhanced version of squeeze casting, and it can make parts that are even more intricate and higher in quality.

To learn more, see our full guide on high-pressure casting.

How Xometry Can Help

To learn more about squeeze casting and how you might be able to use it for your projects, contact us, and one of our representatives will guide you in the right direction. We also offer a whole bunch of manufacturing services, from CNC machining and laser cutting to our forte, 3D printing. Your free, no-obligation quote is just a click away.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.