A comprehensive guide to plastic injection molding provides a detailed understanding of how plastic parts are created through precision engineering and manufacturing. The process involves melting plastic materials and injecting them into a mold to form a specific shape under controlled pressure and temperature. Plastic injection molding is used in automotive, medical, electronics, packaging, and consumer goods for producing durable, consistent, and high-quality components.

The guide explains how the injection molding process operates, covering every stage from mold design and material selection to production and finishing. Readers learn how molds are designed to create complex shapes and how different materials (thermoplastics and thermosets) are chosen based on performance requirements. The guide explores the main steps of the injection molding process (injection, cooling, and part release) to show how precision and efficiency are achieved in mass production.

Key sections outline the advantages of using the plastic injection molding method, emphasizing its cost-effectiveness for high-volume manufacturing, material versatility, and ability to maintain tight dimensional tolerances. The discussion extends to factors influencing production costs (mold complexity, volume, and material type). Comprehensive insights in the guide help readers understand why plastic injection molding remains a cornerstone of modern manufacturing and how it continues to shape products across multiple industries.

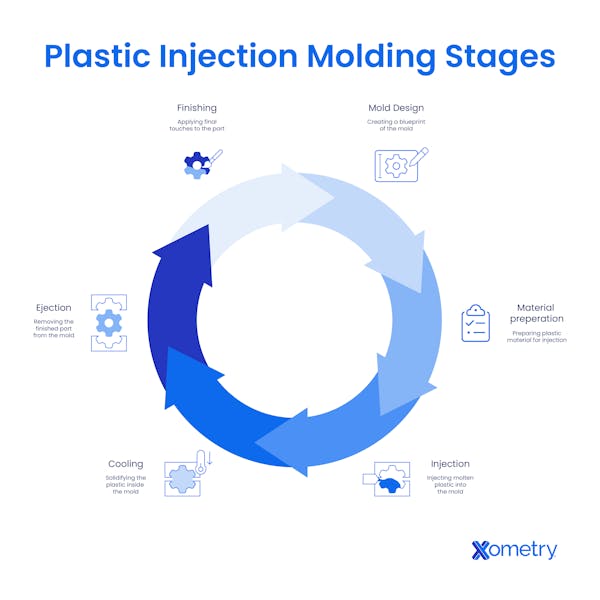

How Does the Plastic Injection Molding Process Work?

The plastic injection molding process works by following six steps. First, mold design involves creating a detailed blueprint using CAD software. Engineers select appropriate materials (typically hardened tool steel for production molds or aluminum for prototypes) for the mold and design cooling channels, venting systems, and ejection mechanisms to ensure efficient and high-quality production. Engineers use computer-aided design (CAD) software to ensure the mold produces the desired part with accuracy. Second, material preparation involves selecting and feeding plastic pellets into the injection unit. The pellets are melted and homogenized by a reciprocating screw inside a heated barrel before injection. The material is heated to a molten state, making it ready for injection.

Third, inject the molten plastic into the mold cavity under high pressure. The molten plastic is injected into the mold cavity under high pressure and controlled speed, ensuring the material fills the mold completely, including intricate details. Proper injection and packing pressure are crucial to prevent defects such as voids or sink marks and to ensure complete cavity filling. Fourth, the molten material is cooled within the mold, which solidifies it into the desired shape. Cooling time varies depending on the thickness of the part, mold material, and temperature. The cooling process must be carefully controlled to minimize shrinkage, warping, and internal stresses. Cooling time varies depending on the complexity and thickness of the part.

Fifth, ejection occurs after the part has cooled. The mold opens, and the finished part is ejected using systems like ejection pins or air blasts once the part has cooled and solidified. The ejection speed and force are carefully controlled to prevent part deformation or damage. Lastly, finishing processes, such as trimming, polishing, and painting, are applied to remove excess material, such as flash, and to enhance the part's final appearance. Secondary operations like overmolding, in-mold labeling, or assembly are often required, depending on the complexity of the part.

The steps are critical for the success of the plastic injection molding process because it relies on precise control of variables (temperature, pressure, and cycle time) to produce high-quality, accurate plastic parts. The plastic injection molding process ensures consistent, repeatable production with minimal waste.

What Are the Injection Molding Types?

The Injection Molding Types are listed below.

- Standard Injection Molding: Standard injection molding is the most commonly used method for high-volume part production. It involves melting plastic pellets in a heated barrel and injecting the molten material into a mold cavity under high pressure. The mold opens, and the part is ejected once the part cools and solidifies. The process is ideal for producing precise, repeatable components efficiently and with consistent dimensional accuracy. Cycle times vary based on part size and complexity.

- Injection Blow Molding: Injection blow molding is used to produce small, hollow parts, such as bottles and vials. First, molten plastic is injected into a preform mold around a core rod. The preform is then transferred to a blow mold, where compressed air expands it into the final shape.

- Gas-Assisted Injection Molding: Gas-assisted injection molding injects nitrogen gas into the molten plastic during or immediately after filling the cavity to form hollow channels and thicker sections. The process displaces plastic from thicker areas, reducing sink marks, weight, and cycle time.

- Overmolding: Overmolding involves injecting one material over an existing part made from a different material, often using a two-shot process. The technique is commonly used for combining hard and soft materials, such as molding rubber over a plastic base. Overmolding creates durable, multi-material products that offer enhanced functionality, combining properties like flexibility, grip, and protection.

- Insert Molding: Insert molding involves placing a metal or plastic insert into the mold cavity before injecting molten plastic around the insert. The plastic encapsulates the insert, resulting in a part with embedded materials that provide enhanced strength, electrical conductivity, or thermal stability. The method is commonly used for producing automotive parts, electrical connectors, or products requiring added durability and functionality.

- Micro Injection Molding: Micro injection molding is one of the injection molding types used to produce extremely small parts with high precision, often at tolerances in the range of a few micrometers. The process involves injecting tiny amounts of molten plastic into very fine cavities, making it ideal for creating intricate components used in medical devices, electronics, or micro-connectors. The method is key for industries requiring high-precision, small-scale components.

FREE Injection Molding Principles E-Book

What Is the Difference Between Injection Molding and Other Molding Techniques?

The difference between injection molding and other molding techniques is in the process and material handling. Injection molding is a process used for shaping thermoplastic and thermoset materials by heating plastic pellets until molten and injecting them into a precisely designed mold cavity under high pressure. The process is highly repeatable, efficient, and capable of producing parts with intricate geometries and tight tolerances, making it ideal for mass production of complex shapes. Blow, compression, and rotational molding are other techniques that utilize different processes to shape materials.

Blow molding involves creating hollow parts by using air pressure to inflate a heated plastic tube (parison) inside a mold. Different types of blow molding, such as extrusion blow molding (used for bottles) and injection blow molding (for smaller, more intricate containers), are employed depending on the part’s size and complexity. Compression molding is used to form thermosetting plastics by applying heat and pressure to the material, which causes it to cure and take the shape of the mold. The technique is ideal for producing thicker parts with high strength (electrical connectors and automotive components) and is particularly well-suited for materials that are incapable of being re-melted once cured. Rotational molding involves heating plastic powder inside a mold that is rotated on two axes, allowing the material to coat the inside surface and form hollow parts with a uniform wall thickness. The technique is ideal for producing large, durable items (storage tanks, kayaks, and playground equipment).

Injection molding generally provides higher precision, shorter cycle times, and the capability to produce parts with more intricate designs compared to blow molding, compression molding, and rotational molding. However, other methods, such as rotational molding, are more suitable for large hollow objects, while injection molding excels in precision and speed for small to medium-sized parts. Each molding technique has its own advantages depending on the material, complexity, and production volume required. The injection molding types allow for superior accuracy and consistency in mass production.

What are the Advantages of Plastic Injection Molding?

The Advantages of Plastic Injection Molding are listed below.

- High Precision and Accuracy: Plastic injection molding achieves high dimensional accuracy and tight tolerance levels, typically around ±0.005 inches, though ±0.001 inches can be achieved in precision applications, due to advanced mold designs that utilize precise cavity geometry, temperature control, and optimized cooling systems. The level of accuracy is critical in industries (medical devices and automotive components) where consistency and quality are paramount. The use of advanced molds ensures that each part meets exact specifications. The level of accuracy is ideal for industries where quality and consistency are critical (medical devices and automotive components).

- Fast Production Cycle: Injection molding enables rapid production cycles, typically ranging from seconds to minutes, depending on the part geometry, material type, mold design, and machine capabilities. The cooling time often constitutes a significant portion of the cycle, especially for thicker parts or higher-melting-point materials. The efficiency makes it an ideal choice for the mass production of plastic parts.

- Cost-Effective for High Volumes: Injection molding becomes highly cost-effective at larger production volumes, although the initial mold creation cost is high due to the complexity of mold design and material selection. The per-unit cost decreases significantly, benefiting from economies of scale and the efficiency of automated high-volume production as production quantities increase. The cost per unit decreases as production quantities increase, making it ideal for large-scale manufacturing.

- Material Versatility: Injection molding accommodates a broad range of materials, including various thermoplastics like polypropylene (PP) for cost-effective applications, polymethyl methacrylate (PMMA) for optical clarity, nylon (PA) for strength and durability, and polycarbonate (PC) for high-impact resistance. Additionally, thermoplastic elastomers (TPEs) and elastomers are used to provide flexibility, while thermosets are selected mainly for heat and chemical resistance. The versatility allows manufacturers to choose the best material for the desired application, whether it requires strength, flexibility, or heat resistance.

- Minimal Waste: Plastic injection molding produces minimal waste due to the precise material injection into the mold cavity. Excess material, known as sprue, runners, or gates, is often recycled through regrind (ground-up material), making the process more sustainable and reducing material costs over time.

- Complex Part Design: Injection molding excels in producing parts with complex geometries, including undercuts, thin walls, and detailed textures. Advanced techniques like insert molding, overmolding, and textured mold surfaces allow for intricate designs, though part geometry limitations, such as the need for precise cooling and material flow, impact mold complexity and production costs. The capability allows for greater design flexibility, leading to more advanced products that meet specific requirements. It is one of the plastic injection molding advantages, offering manufacturers the ability to produce complex and highly detailed parts.

What are the Disadvantages of Plastic Injection Molding?

The Disadvantages of Plastic Injection Molding are listed below.

- High Initial Cost: The initial cost for plastic injection molding is high, primarily due to the design and manufacturing of molds, which require precise engineering and high-quality materials (typically hardened tool steel for production or aluminum for prototypes). The machinery setup, including investment in injection molding machines, automation, and material handling systems, further increases the overall cost. It makes injection molding less attractive for low-volume production, as the initial investment is amortized over larger production runs. It makes the process less attractive for small production runs, as the investment is justified with large-volume production.

- Mold Design and Modification Challenges: The mold design process is complex and time-consuming, requiring careful consideration of factors such as cooling channel design, draft angles, and ejection mechanisms to optimize part quality and cycle times. Making modifications is costly and technically challenging once a mold is created, as it involves retooling, mold repair, and the potential for re-engineering mold features, leading to significant delays and added costs. The limitation leads to delays or additional costs if adjustments to the mold are required after production begins.

- Limited Material Options for Some Applications: Certain specialized materials, such as composites or those with high filler content, low flowability, or high viscosity, can pose significant challenges, while plastic injection molding supports a wide range of materials, including thermoplastics and thermosets. The materials likely clog injection channels, lead to incomplete mold filling, or degrade during the injection process, limiting their applicability for injection molding. For example, composites or materials with high filler content do not flow properly during injection, limiting the choice of materials for specific applications.

- Production Time for Low Volumes: Injection molding is highly efficient for high-volume production due to the ability to amortize the high setup costs (mold creation, machine setup, and tooling) over a large number of units. However, for low-volume runs, the setup time, tooling cost, and mold preparation make the cost per unit disproportionately high, rendering it uneconomical for small-batch production. The time spent on mold creation and setup makes small batches disproportionately expensive, which is not ideal for companies with low demand for a product.

- Environmental Impact of Plastic Waste: The ecological impact of plastic waste remains a concern, particularly when non-recyclable materials are used, while plastic injection molding generates minimal waste compared to other molding techniques. The process does allow for the recycling of post-industrial plastic (regrind material), but the recyclability of the final product depends on the material type. Efforts are being made to incorporate biodegradable plastics and other eco-friendly materials in manufacturing processes, reducing the environmental footprint to address sustainability.

What are the Common Problems in the Injection Molding Process?

Common Problems in the Injection Molding Process are listed below.

- Short Shots: Short shots occur when the mold cavity is not completely filled, leading to incomplete parts. The issue is typically caused by insufficient fill pressure, melt viscosity, low injection pressure, or poor mold venting. Inadequate packing pressure, particularly in the packing phase of the cycle, can prevent the cavity from filling, even after the initial injection.

- Flash Formation: Flash formation occurs when excess material escapes along the parting line due to insufficient clamping force or worn mold surfaces. The material seeps out of the cavity and solidifies, creating unwanted material at the mold's edge. Flash is minimized by ensuring proper clamping force and mold maintenance.

- Warping: Warping occurs when there are thermal gradients within the molded part, where different sections cool at different rates, leading to distortion (bending or twisting). Variations in wall thickness, material shrinkage rates, and uneven mold cooling are key contributors. Maintaining uniform cooling conditions throughout the mold can reduce the risk of warping.

- Sink Marks: Sink marks occur due to material shrinkage and thermal contraction during cooling, particularly in thicker sections of the part. Uneven cooling rates cause depressions on the surface as the material solidifies. Modifying wall thickness and optimizing the cooling time help prevent sink marks.

- Burn Marks: Burn marks occur due to trapped gases or thermal degradation of the material, resulting in dark discolorations. Excessive injection speed, combined with insufficient mold venting, leads to the entrapment of gases such as oxygen, causing overheating and discoloration during the injection cycle.

- Weld Lines: Weld lines occur when two melt fronts meet during injection but do not fuse properly, creating visible lines or weak spots in the part. It happens when melt temperatures are too low or the flow fronts meet too far apart. Optimizing gate design and increasing the melt temperature help reduce weld line formation.

- Bubbles (Voids): Bubbles or voids form when trapped gases or moisture from improperly dried material are unable to escape during injection. These voids are further exacerbated by insufficient pack-hold pressure. Ensuring proper material drying and adjusting the packing pressure can help reduce the occurrence of voids.

- Jetting: Jetting occurs when the molten plastic enters the mold at a high injection speed, causing turbulence and a wavy surface pattern. Poor gate design or improper placement of gates can exacerbate this issue. Reducing injection speed and optimizing gate placement can reduce jetting.

Are Injection Molding Defects Common?

Yes, injection molding defects are common in high-volume production or complex part designs. Defects occur due to factors like poor material quality (high moisture content, inconsistent resin batches), improper mold temperature (leading to thermal gradients), uneven cooling (especially in thick-walled components), and incorrect injection pressure (affecting packing pressure). The issues, including short shots, warping, sink marks, flash, weld lines, and voids, require careful process control and quality assurance to minimize their impact. Human error during setup, such as incorrect machine calibration or failure to adjust parameters like injection speed or clamping force, can also lead to defects. The presence of defects does not indicate a failure of the injection molding process but rather highlights the need for strict process control and quality assurance throughout the production cycle.

To learn more, see our full guide on Injection Molding Defects.

What are Plastic Injection Molding Materials?

Plastic injection molding materials are specialized polymers engineered for controlled processing and high-performance applications. The materials are broadly classified into thermoplastics, thermosets, and elastomers, each exhibiting distinct molecular behaviors during molding. Thermoplastics, which account for most injection molding applications, soften upon heating and solidify upon cooling, allowing repeated reprocessing. Common examples include polyethylene (PE), polypropylene (PP), polystyrene (PS), acrylonitrile butadiene styrene (ABS), polycarbonate (PC), polyamide (nylon), and polyvinyl chloride (PVC). Thermosets, in contrast, undergo irreversible crosslinking reactions during molding, resulting in rigid, heat-resistant structures. Elastomers display rubber-like elasticity and are processed under controlled curing conditions. The selection of material depends on desired mechanical strength, thermal resistance, chemical durability, and application-specific requirements, making injection molding an adaptable method for a wide range of industries.

Polyethylene (PE) is a semi-crystalline thermoplastic valued for its flexibility, chemical resistance, and impact toughness, making it ideal for consumer containers, tubing, and protective components. Polypropylene (PP), another semi-crystalline polymer, exhibits exceptional fatigue resistance and chemical inertness, making it suitable for living hinges, automotive components, and reusable packaging. Acrylonitrile butadiene styrene (ABS) is an amorphous polymer recognized for its high impact strength and smooth surface finish, frequently used in electronic housings, appliance panels, and consumer goods. Polycarbonate (PC) combines optical transparency with high impact strength and dimensional stability, making it preferred for safety eyewear, lenses, and structural enclosures. Polyamide (Nylon, PA), a semi-crystalline polymer, offers excellent wear resistance, toughness, and thermal stability, widely applied in gears, bearings, and automotive under-the-hood components. Polyvinyl chloride (PVC) is a partially crystalline polymer noted for its flame retardancy, rigidity, and chemical resistance, commonly used in construction profiles, plumbing systems, and some packaging applications.

Each material behaves differently during the injection molding process, affecting cooling time, flow behavior, and shrinkage. The selection of the correct plastic injection molding material plays a critical role in achieving product performance, manufacturing efficiency, and long-term durability.

When choosing the best material for a plastic injection molding project, it is important to consider what factors or elements the part is exposed to in the application. For example, not all materials can handle a lot of UV exposure.Kyra StawsonSenior Solutions Engineer

What Industries Use Plastic Injection Molding?

Automotive, medical, consumer goods, electronics, aerospace, and packaging are industries that use plastic injection molding. The automotive industry uses injection molding to manufacture components such as dashboards, bumpers, clips, and interior panels. The process enables high dimensional stability, impact resistance, and weight reduction, meeting stringent safety and performance standards such as those outlined in IATF 16949 (which incorporates ISO 9001 requirements).

The medical industry depends heavily on plastic injection molding to produce components such as syringes, surgical instruments, diagnostic housings, and implantable devices. These parts are manufactured using biocompatible thermoplastics like polypropylene (PP), polycarbonate (PC), and polyether ether ketone (PEEK), which offer chemical resistance, dimensional stability, and compatibility with sterilization methods such as gamma radiation and autoclaving. The process supports sterile, high-precision production under ISO 13485 and FDA regulatory standards, ensuring safety and consistency for medical applications.

The electronics industry utilizes plastic injection molding to produce housings, connectors, and switches that require precise dimensions, electrical insulation, and compact integration. Common engineering polymers include polycarbonate (PC), polybutylene terephthalate (PBT), and liquid crystal polymer (LCP), chosen for their high dielectric strength, flame retardancy (UL94 V-0 classification), and thermal stability. Injection molding allows for the creation of complex geometries with fine tolerances while maintaining excellent surface finish and consistent part integrity, critical in consumer electronics and industrial components.

Injection molding employs high-performance polymers such as polyether ether ketone (PEEK), polyphenylene sulfide (PPS), and polyetherimide (PEI) to produce components that must withstand extreme thermal, mechanical, and chemical environments in the aerospace industry. The process enables the fabrication of lightweight structural and interior parts that maintain high tensile strength, dimensional stability, and fatigue resistance. Injection molding contributes to mass reduction, uniformity, and repeatable quality (key requirements for aerospace-certified manufacturing under AS9100 standards).

The packaging industry depends on injection molding to manufacture caps, lids, closures, and containers with tight sealing performance and high production throughput. Materials such as high-density polyethylene (HDPE) and polypropylene (PP) are preferred for their low moisture absorption, flexibility, and recyclability. The process supports short cycle times and consistent dimensional accuracy, making it ideal for large-scale packaging of food, pharmaceuticals, and consumer goods.

Each sector benefits from the flexibility, efficiency, and quality control offered by the injection molding process, making it an essential tool across multiple fields.

To learn more, see our full guide on Industries That Use Plastic Injection Molding.

Which Industry Uses Plastic Injection Molding the Most?

Automotive manufacturing is one of the largest industries using plastic injection molding, alongside packaging and consumer goods, which lead in total production volume. Injection molding enables manufacturers to achieve tight dimensional tolerances, structural integrity, and mass-production efficiency while meeting ISO and safety standards. The method supports lightweight vehicle design, reducing overall mass and improving fuel efficiency and emission performance. Common polymers include polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polyamide (PA), selected for their mechanical strength, thermal resistance, and durability. Due to its scalability and cost-effectiveness, injection molding remains the dominant manufacturing process in the global automotive sector.

What Injection Molding Products are Used in Manufacturing?

Injection-molded products used in manufacturing include automotive components, electronic housings, medical devices, industrial parts, and packaging materials. Dashboards, grilles, air vents, and bumper clips in the automotive sector are produced using polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polyamide (PA) for their dimensional stability, impact strength, and heat resistance. The electronics industry manufactures device housings and enclosures from ABS and polycarbonate (PC), valued for their dielectric insulation and mechanical toughness. In medical applications, biocompatible polymers such as polypropylene (PP) and polycarbonate (PC) are used to produce syringe barrels, inhaler casings, and surgical handles, ensuring sterility and regulatory compliance. Industrial components (gears, levers, and spacers) are molded from engineering-grade plastics, including nylon (PA) and polyether ether ketone (PEEK), offering high load-bearing strength and wear resistance. The packaging industry applies injection molding for caps, lids, and food containers, using polyethylene (PE) and polypropylene (PP) to achieve tight sealing and high-speed production. Injection molding supports precision manufacturing, material efficiency, and scalability, making it a cornerstone process across modern industrial production.

Is Injection Molding Good for Mass Production?

Yes, injection molding is good for mass production. The injection molding process enables the rapid fabrication of large volumes of identical parts with exceptional dimensional consistency and surface precision. Each production cycle typically lasts a few seconds to minutes once the mold is manufactured, allowing manufacturers to produce thousands to millions of components efficiently. The per-unit cost decreases sharply at high production volumes because the initial tooling expense is amortized across many parts.

Injection molding supports automation and process control, minimizing human error and ensuring uniform part quality. The method’s repeatability and scalability make it the preferred manufacturing solution for industries such as automotive, electronics, medical devices, and packaging, where high throughput and structural accuracy are essential.

What is a Plastic Injection Molding Prototype?

A plastic injection molding prototype is a preliminary molded part produced to evaluate the form, fit, and functional performance of a design before transitioning to full-scale production. It enables engineers to assess dimensional accuracy, material behavior, and manufacturability, ensuring that the design meets performance and tolerance requirements. Prototype molds are typically fabricated from aluminum or soft tool steel, which allows for rapid tooling and lower production costs during the development phase.

Prototype molds accurately replicate the geometry and surface finish of the final product, although they have limited durability compared to hardened steel production molds. Creating a prototype is a critical step in the product development cycle, as it reduces the likelihood of design errors, supports process optimization, and provides validation data before investing in long-term production tooling.

How Much Does Plastic Injection Molding Cost?

Plastic molding costs range from $3,000 to $100,000 for mold creation, with average costs depending on factors (part complexity, material choice, and production volume). For example, simpler molds for small consumer goods parts cost around $1,000 to $5,000, while more complex molds for automotive or medical components exceed $50,000.

The per-unit cost decreases as production quantity increases because the initial tooling expense is amortized across a larger volume of parts.

The per-part cost can fall below one dollar, and in some high-volume consumer goods applications, to just a few cents per part. Low-volume or prototype production may cost $5–$10 per part, depending on material choice and cycle time. Additional variables influencing total cost include part geometry, tolerance requirements, surface finish, and machine time. The costs are influenced by the specifics of the project, making the injection molding cost highly variable across different industries and production scenarios.

Is Plastic Injection Molding Expensive?

Yes, plastic injection molding is expensive during the initial phase due to the cost of mold fabrication and setup. Tooling costs typically range from $1,000 to over $100,000, depending on mold complexity, part geometry, and tooling material (aluminum or hardened steel). The upfront investment makes injection molding less economical for low-volume production runs.

The per-part cost decreases substantially because the tooling expense is distributed over a large production volume once the mold is manufactured. The cost per component likely drops to a few cents, making injection molding one of the most cost-effective methods for mass manufacturing for high-volume production. The process delivers high-dimensional accuracy, repeatability, and surface quality, justifying the initial expenditure. Automotive, medical, consumer goods, electronics, and packaging industries continue to rely on injection molding for large-scale production due to its long-term economic efficiency and manufacturing precision.

What is an Injection Molding Machine?

An injection molding machine is a specialized industrial system designed to manufacture plastic components by injecting molten polymer into a precision-engineered mold cavity under controlled temperature and pressure. The machine consists of three core subsystems: the injection unit, the clamping unit, and the mold assembly. The injection unit melts and meters the plastic pellets before delivering the molten material into the mold through a nozzle and sprue system. The clamping unit secures the mold halves together with precise force during injection and cooling, ensuring dimensional stability and preventing flash formation. The mold defines the geometry and surface finish of the final product.

Injection molding machines vary in clamping force capacity (ranging from a few tons to several thousand tons) and are capable of processing thermoplastics, thermosets, and elastomers. The systems are essential in automotive, medical, consumer goods, and electronics manufacturing, enabling high-volume, repeatable, and accurate production. The integration of servo-hydraulic or electric drive systems enhances energy efficiency and cycle control, making the injection molding machine a cornerstone of modern polymer manufacturing. The injection molding machine is essential to the injection molding process, enabling efficient, precise, and high-volume production of plastic components.

How Does an Injection Molding Machine Work?

An injection molding machine works by following a series of steps to produce plastic parts. Plastic pellets or raw material are fed into the hopper, where they are transferred to the injection unit. The plastic is heated to its molten state by heaters and is injected into the mold cavity under high pressure.

The clamping unit holds the two halves of the mold together while the plastic cools and solidifies. The cooling process takes place over a set period, allowing the material to take the shape of the mold. The mold opens, and the part is ejected using an ejection system once the part is cooled.

The process is automated, with injection molding machine components like the injection unit, clamping unit, and mold ensuring the efficient, precise, and repeatable production of parts. Each component plays a critical role in creating high-quality plastic parts for industries such as automotive, medical, and consumer goods.

What is the History of Plastic Injection Molding?

The history of plastic injection molding is rooted in the late 19th century and has evolved over time to become one of the most widely used manufacturing methods in the modern world. American inventors John Wesley Hyatt and his brother Isaiah patented the first injection molding machine in 1872. Their machine used a basic plunger mechanism to inject heated celluloid into a mold. The early version was simple but laid the foundation for future developments. New materials (polystyrene and polyethylene) were introduced by the 1930s and 1940s, which expanded the scope of injection molding.

The demand for mass production of plastic parts surged for military equipment, which led to further advances in molding technology during World War II. James Watson Hendry developed the first screw injection molding machine in 1946. The innovation allowed for more precise control over material flow, temperature, and injection speed, transforming the industry and enabling the production of more complex parts.

The process became more automated and efficient in the decades that followed. The introduction of microprocessors and computer-controlled machinery in the 1970s and 1980s improved accuracy, consistency, and speed. Injection molding supports a wide range of thermoplastics and thermosets and is used in nearly every industry (automotive, electronics, medical devices, and consumer goods).

Advancements continue to refine the technique, with modern Injection Molding Machine Components supporting sustainable practices, reduced cycle times, and higher production precision. The development from a basic plunger system to highly automated machines represents a significant part of Injection Molding History.

Injection molding continues to evolve through automation and advanced materials, yet its core strength remains the same: transforming design precision into scalable, repeatable manufacturing.

Why is Injection Molding Preferred Over Other Methods?

Injection molding is preferred over other methods because it allows for high-volume production of precise, repeatable, and complex plastic parts at a low cost per unit. The process produces thousands to millions of parts quickly once the mold is created, making it ideal for mass manufacturing.

The process supports a wide variety of materials (thermoplastics, thermosets, and elastomers), giving manufacturers flexibility in selecting materials based on strength, flexibility, or thermal resistance. Injection molding allows for intricate shapes, thin walls, and tight tolerances that are difficult to achieve with methods like compression molding or thermoforming.

Injection molding reduces waste through precise material control and automation. The short cycle times and high repeatability make it more consistent and reliable than other plastic-forming methods.

Durability, speed, and cost efficiency contribute to why automotive, medical, electronics, and consumer products rely on the injection molding process for their high-demand production needs. The use of specialized Injection Molding Machine Components further improves production quality and operational efficiency.

Is Injection Molding the Most Common Manufacturing Method?

Yes, injection molding is the most common manufacturing method for producing plastic parts in large quantities. The process is used across industries due to its ability to create highly accurate, repeatable, and complex components at a low cost per unit after the initial mold is made. Automotive, medical, packaging, electronics, and consumer goods depend on the injection molding process for manufacturing everything from car dashboards and medical syringes to bottle caps and mobile phone housings.

Injection molding supports faster production cycles, better dimensional control, and minimal post-processing compared to other methods (compression molding, blow molding, or thermoforming). The automation of injection molding machine components (the clamping and injection units) further increases speed and consistency. Its dominance in global manufacturing stems from scalability, design flexibility, and material versatility, making it the preferred choice for plastic part production.

How Xometry Can Help

We hope this article answers all your questions on this manufacturing process, but if you have any more, please reach out to one of our representatives. Xometry offers a full range of injection molding capabilities to help with your production needs. You can get started today by uploading your designs to the Xometry Instant Quoting Engine® to get your free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.