Among the concepts out there that are important to successful engineering, bending stress is right up there. Without understanding bending stress, we wouldn’t be able to design safe buildings in industrial settings or pick the best materials for other structures, like bridges and airplanes. We’ll take a look at exactly what bending stress is, why it happens, and how to calculate it.

What is Bending Stress?

Bending stress is another word for flexural stress and it happens when you subject a material to a bending load or force — leading it to bow, bend, or flex. It’s different from strain, which is the actual deformation or change that comes from the force being applied.

The stress component comes from the internal resistance going on when a beam, arch, or other structural part’s cross-section begins to deform under the stress and tries to counteract it. While the whole structure might have some bending stress, that doesn’t mean each part of it experiences it equally. Depending on how it’s designed, where its neutral access is, and where the force is coming from, the stress will be distributed in different ways.

Knowing where bending stress happens and how it impacts specific metals, alloys, or composites can be the difference between making a well-built bridge or building and one that can’t hold intended loads. It’s also something engineers should think about when determining the lifespan of these structures and understanding the behavior of how a material will move and bend before reaching a point that jeopardizes the safety and integrity of a part.

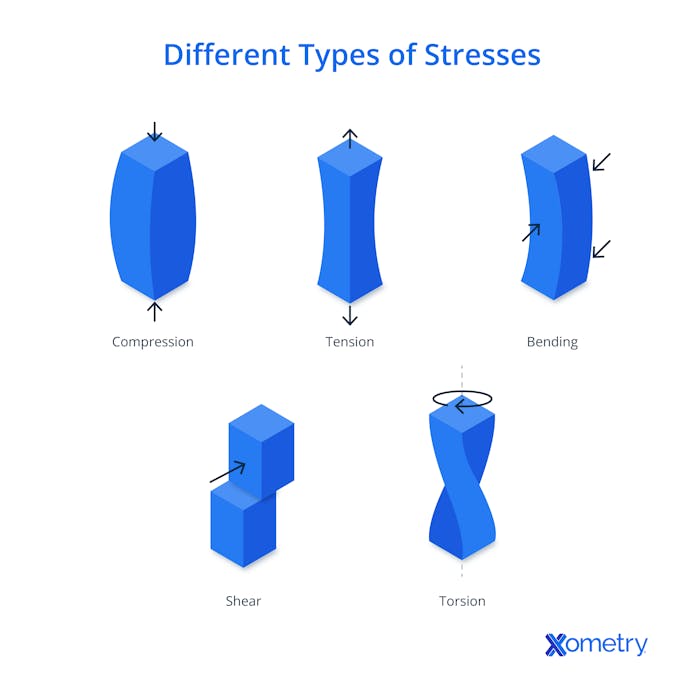

When a force or load is placed on an object (like a beam, for instance), the bending force will begin to take place, causing the material to flex or bend. This leads to a combo of stresses that are called bending stress. This usually consists of tensile stress and compressive stress, which will impact specific parts of the object, and the neutral axis will also move as the force applied moves. A visualization of bending stress compared to other types of stresses is shown below:

What Is the Other Term for Bending Stress?

Bending stress is also called flexural stress. The stress is caused by a bending moment applied on a part.

Is Bending Stress the Same as Shear Stress?

No. Bending and shear are two distinct mechanical behaviors encountered in structural elements. Bending occurs when external forces act on a structural element in a way that induces it to deform by curving or flexing. Bending stress causes some parts of the material to experience tension (stretching) and others to experience compression. Shear, on the other hand, represents a different type of internal force within structural elements. Shear forces arise when external loads cause one portion of the element to shift or slide parallel to another. The internal resistance generated by these forces is referred to as shear stress, and it acts parallel to the item’s cross-section. Shear stress causes adjacent layers of material to slide past each other horizontally without bending or curving the object. Shear behavior plays a crucial role in structural stability and must be considered in engineering designs to prevent structural failures, especially in components like bolts and rivets.

How Does a Bending Stress Work?

Bending stress arises internally when an external bending force or moment is exerted upon a component. This external bending moment causes the component’s curvature to change, causing tensile and compressive stresses to accumulate in its structure. These combined stresses are commonly referred to as bending stresses. For example, picture a balance beam. It is supported at both ends and a force is applied in the middle when you walk on it. With your weight in the middle of the beam, it experiences a bending moment. This moment causes the top surface of the beam to go into compression, trying to shrink, while the bottom surface goes into tension, attempting to stretch. The material within the balance beam resists these changes, creating internal stresses. At some point between the compression and tension sides, there's a neutral axis that sees neither compression nor tension.

Bending stress varies across the cross-section of the beam. The highest stress values occur at the top and bottom surfaces and decrease toward the neutral axis.

What Is the Importance of Bending Stress?

Bending stress plays a very important role in the overall durability and lifespan of structures, from beams to skyscrapers to bridges. Knowledge of bending behavior empowers engineers to make informed decisions about design, materials, and construction methods, so they may optimize load-bearing capacities and minimize the risk of failure due to excessive bending stress. It's a fundamental aspect of structural engineering that directly impacts structural integrity, ensuring that structures endure and remain safe over time.

What Is the Bending Stress Formula?

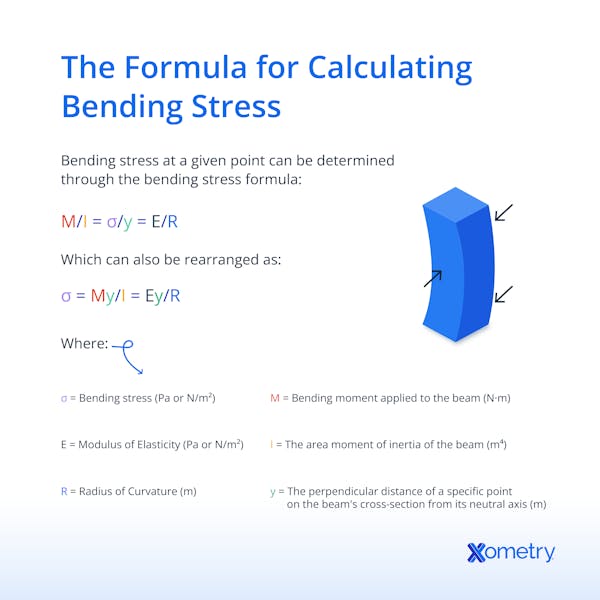

Here is the formula you should know in order to calculate bending stress:

M/I = σ/y = E/R

Or you can write it like this:

σ = My/I = Ey/R

Here is what the following letters and symbols mean within this formula:

- σ is bending stress (Pa or N/m²)

- M = Bending moment applied to the object (Nᐧm)

- y = the perpendicular distance between the neutral axis and a specific point on the object’s cross-section

- I = the area moment of inertia of the object (m⁴)

- E = modulus of elasticity or Young’s modulus (Pa or N/m²)

- R = radius of curvature (m)

How to Calculate the Bending Stress?

Bending stress is calculated through the bending stress equation:

σ = My/I

In this formula, M represents the moment, which is calculated by multiplying the applied force by its distance from a reference point. The variable y represents the perpendicular distance from the neutral axis to the specific point of interest, and I signify the moment of inertia for the item’s cross-sectional shape. It's essential to emphasize that this equation is valid only if we assume the material behaves elastically and adheres to Hooke's law. Hooke’s law describes the linear relationship between stress and strain in a material within its elastic limit.

What Is the Bending Stress of Metal?

The bending stress of a metal, or any material for that matter, depends on factors such as: the material's properties, the shape of the object, and the magnitude and distribution of the applied load. Each metal has a unique set of properties, including its own Young's Modulus and yield strength. The geometry of the component plays a crucial role as well. The moment of inertia, which quantifies an object's resistance to bending, and the distance from the neutral axis to the outer fibers are vital in calculating bending stress. The bending moment (whether it's uniform or concentrated) and the boundary conditions (such as whether the component is simply supported or cantilevered) also affect how bending stress is distributed. The bending equation can be used to calculate the bending stress for any given metal.

What Is the Bending Stress of Steel?

The bending stress of steel depends on various factors, including: the grade of steel, its yield strength (usually denoted as "fy"), and the specific application or structural element in which it is used. In general, the bending stress experienced by a steel beam or column is calculated based on the applied bending moment, the geometry of the section, and the material properties of the steel.

The allowable bending stress for steel is typically dictated by engineering design codes and standards. These provide guidelines for safe and efficient structural design. For example, in the context of steel design, the acceptable bending stress is often expressed as a fraction of the steel's yield strength. A common assumption is that a bending stress equal to two-thirds of the yield strength (0.66fy) is acceptable for both tension (bt) and compression (bc).

What Is the Bending Stress of Beams?

The bending stress in beams, no matter what they’re made of, depends on various factors related to the specific beam design and loading conditions. The bending stress formula can be used to calculate stresses within the beam. To do so, you need to know the applied bending moment, the dimensions of the beam's cross-section, and the material properties of the beam (such as its modulus of elasticity, E). Additionally, the type of loading (uniform or varying) and the boundary conditions (e.g., simply supported or cantilevered) play significant roles.

The calculated bending stress should be compared to the allowable bending stress, which is typically specified by engineering design codes and standards. All beams must be designed with a margin of safety so they can safely carry the applied loads without failure or excessive deformation.

What Is the Bending Stress of Stainless Steel?

The allowable bending stress for stainless steel, like other materials, depends on factors such as the grade or type of stainless steel, the specific application, the item’s geometry, plus safety factors built into the item. However, as a general guideline, stainless steel can typically accept more bending stress than mild steel due to its superior strength and corrosion resistance properties. The exact bending stress values can be calculated using the bending stress equation.

What Are the Different Types of Bending Stress?

Bending stress is actually a catch-all term for a few different types that are worth familiarizing yourself with so you can better understand what a beam is undergoing:

1. Pure Bending

In this form of bending stress, an object will only experience a bending moment from the force that’s being applied, as opposed to having other stresses and forces working on it, too — such as shear stress, axial stress, or torsional force. The right conditions will need to be in place for pure bending and shear stress should be equal to zero, so while it might not be the most realistic scenario, it gives engineers a good idea of how a material will respond to this stress alone.

2. Symmetric Bending

This happens when the cross-section of the beam and the neutral access are symmetrical. Therefore, the force or stress is applied evenly and results in symmetric bending, which is another idealized situation like pure bending, which may not always match up with the environment this beam or structure would actually exist in.

3. Unsymmetric Bending

Logically, with how symmetric bending works, you’ll find that unsymmetric bending happens when the cross-section and beam aren’t symmetrical. Stress is then distributed more unevenly leading to this style of bending stress.

4. Non-Uniform Bending

When you’re thinking of day-to-day scenarios that feature slightly less perfect conditions, non-uniform bending will come up. This type of bending stress happens when forces or loads are unevenly applied and shear stress is present, too. This tends to be the most realistic because bridges and structures existing in everyday life will have far more forces, stresses, and tensions working on them.

What Type of Bending Stress is Used in 3D Printing?

Items made in 3D printers experience the same sorts of bending stresses as those made via any other manufacturing method. Bending stress is a result of forces applied to the part rather than a consequence of manufacturing.

What Are Examples of Bending Stress?

Bending stress is present in all kinds of everyday objects and structures, a few of which we list out below.

- Bridges: With a large mix of pedestrians, pets, cyclists, cars, trucks, and passengers going across bridges, it’s fair to say this is one of the most obvious and clear examples of bending stress and what beams and structures undergo when they’re put to work.

- Airplane wings: Planes are another great example of bending stress in action, particularly when applied to their wings. With gravity and aerodynamic forces working against the wings, bending stress is an important factor to consider when designing them so they can move successfully, especially while these forces are at play.

- Buildings and architectural structures: The beams and columns that makeup skyscrapers, office buildings, and homes have to account for bending stress, too, so engineers can understand how much force and how heavy of a load they can manage.

What Is the Relationship Between Bending Stress and Compressive Stress?

Compressive stress is a component of bending stress within a bending member. As the beam bends, the convex side is subjected to tensile stress, which tends to elongate the material, while the concave side experiences compressive stress, which squeezes the material.

This relationship is governed by the fundamental principles of equilibrium and stress distribution. The distribution of stresses across the cross-section of the beam follows a linear pattern, transitioning from maximum compressive stress at the concave side to maximum tensile stress at the convex side, with a neutral axis where stress is zero.

What Is the Difference Between Bending Stress and Tensile Stress?

Bending stress and tensile stress are two distinct types of stress that affect structural elements differently. Bending stress emerges when external forces or moments cause a component like a beam to bend. This stress combines both tension and compression, affecting different parts of the material. In contrast, pure tensile stress occurs when a material is pulled along its axis, resulting in uniform tension forces. Bending stress induces stretching and squeezing within a material simultaneously, while tensile stress exclusively elongates the material along its axis. Moreover, bending stress varies across the material's cross-section, while tensile stress remains uniform under pure tension.

How Xometry Can Help

Xometry provides dozens of different materials across a wide range of manufacturing capabilities that are important to the engineering, medical, and scientific fields, including compression molding, medical CNC, 3D printing, rapid prototyping, and laser cutting. Get started by uploading your 3D CAD to get an instant quote for various manufacturing options today!

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.