Crystallization of polymeric materials occurs when polymer chains have become sufficiently aligned to form ordered, repeating structures. These ordered regions are known as lamellae, which are typically thin, plate-like formations. Crystallization can be driven by various factors, including cooling rate, molecular structure, and processing conditions. These influences may lead to irregular and localized crystal regions that lack orientation, or to uniform, aligned structures, often referred to as spherulites when viewed under a microscope. These crystalline regions can be extensive and interconnected or remain isolated and dispersed within the amorphous matrix.

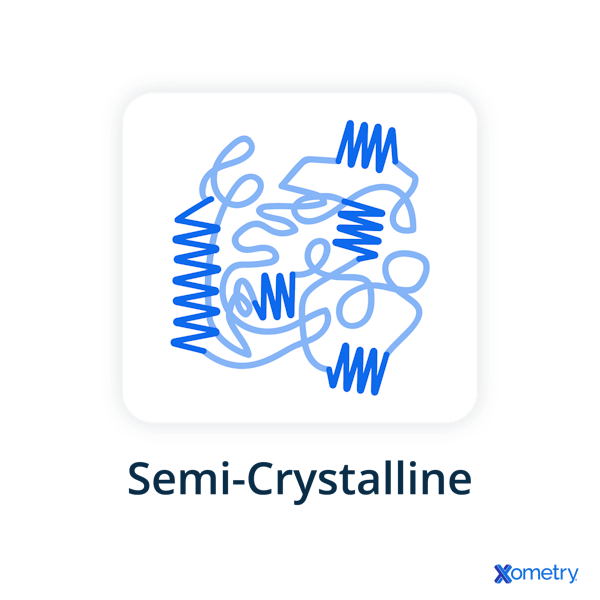

When lamellae make up at least 10% of the polymer's volume, the material is classified as semi-crystalline. If crystalline content exceeds 80% by mass, it is considered highly crystalline. Note that "fully crystalline" is a misnomer, as polymers never achieve 100% crystallinity due to chain entanglement and branching. Because molecular chains in crystalline polymers are more tightly packed than in amorphous polymers, they exhibit higher density and often increased stiffness.

This article will explore crystalline polymers, including their definition, characteristics, applications, and benefits.

What Is a Crystalline Polymer?

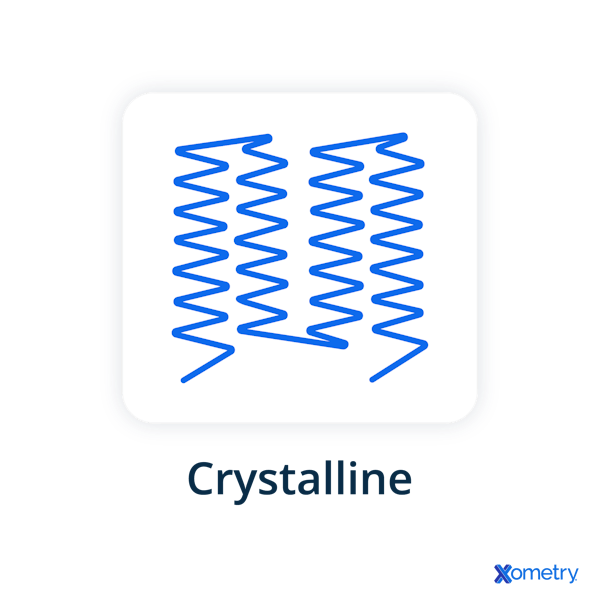

A crystalline polymer is a type of long-chain organic material characterized by the presence of lamellae, which are ordered zones of aligned molecular chains. Crystalline polymers have highly structured regions and can, in some cases, be entirely composed of a single crystal aligned along one axis. The degree of crystallinity and mutual alignment is highly affected by the crystallization process, which can be triggered and driven by a variety of mechanisms.

You can, for example, heat-treat a polymer component by holding it at a temperature between the glass transition temperature (Tg) and the melting point to let its molecules shift and crystallize. This can be a very slow process. It is difficult to maintain dimensional stability this way for extended periods, so this method typically only gives you a limited degree of molecular alignment.

Some polymers naturally “drift” towards crystallization over time. High molecular motility and elevated temperatures can induce this, resulting in either progressive strengthening or embrittlement.

By controlling the flow of liquid polymer in the manufacturing process, you can influence local and bulk crystallization. A restricted outlet for the molten polymer can generate highly crystalline material. This can create a uniaxial high-strength region that can, for example, be used as a living hinge. Extrusion of polymer can induce molecular alignment, driving a generalized change that makes the material stronger on the primary axis. Extension can similarly align molecule chains. Such extension can be uniaxial (simple stretching), biaxial (X and Y axis combined stretching), or essentially annular (such as when vacuum-forming a dome). These result in differing forms of molecular alignment.

How Are Crystalline Polymers Made?

Some polymers can be engineered to exhibit high crystallinity, while others remain largely amorphous due to their molecular structure. In all cases, manufacturing methods and post-processing conditions strongly influence the final degree of crystallinity.

Intrinsic Chemistry and Polymerization Process:

Polymers with linear, unbranched molecular chains are more capable of forming crystalline regions. For example, high-density polyethylene (HDPE) has minimal side branching, allowing chains to align and pack into ordered structures efficiently. In contrast, low-density polyethylene (LDPE), although chemically similar, contains numerous side branches that hinder chain alignment and reduce crystallinity.

However, even in crystallization-prone polymers like HDPE, the degree of crystallinity is variable and process-dependent. HDPE typically exhibits about 60% crystallinity in its cast form, but this can increase to around 80% with heat treatment. Many polymers exhibit some level of crystallinity in their native state, but this can be modified by thermal and mechanical processing. However, even in crystallization-prone polymers like HDPE, the degree of crystallinity is variable and process-dependent. HDPE typically exhibits about 60% crystallinity in its cast form, but this can increase to around 80% with heat treatment. Many polymers exhibit some level of crystallinity in their native state, but this can be modified by thermal and mechanical processing.

Manufacturing and Handling Variations:

Manufacturing techniques can significantly influence polymer crystallinity and, in some cases, induce partial crystallization in otherwise amorphous polymers.

- Extrusion: This process aligns polymer chains by forcing the melt through a narrow die, promoting flow-induced crystallization. Extruded polymers often appear fibrous and are useful in applications requiring flexibility, such as living hinges (e.g., toothpaste tube caps). Post-extrusion mechanical compression (e.g., pinching) further enhances chain alignment and minimizes internal shear.

- Drawing: Similar to extrusion, drawing stretches polymer materials—often to more than double their original length—forcing chains into alignment. This significantly increases crystallinity and tensile strength. Drawing can be applied uniaxially or biaxially to produce oriented films, such as shrink wraps or packaging materials.

- Vacuum Forming: When a thermoplastic is vacuum-formed, stretched regions (especially corners and walls) undergo chain orientation and partial crystallization. Domed or bubble-like areas may adopt biaxial orientations, depending on forming conditions.

- Heat Treatment During Raw Material Production: Some polymers are pre-treated during pelletization or raw material preparation to promote initial crystallization. This involves controlled cooling rates, temperature gradients, and nucleating agents to guide crystal growth and orientation.

How Do Crystalline Polymers Differ From Regular Polymers?

Many polymer chains can be crystallized. Materials such as nylon, syndiotactic polypropylene, isotactic polystyrene, and acetal (POM) are nearly always crystalline.

Other thermoplastic polymers are intrinsically amorphous and cannot form crystals. Examples include: polymethyl methacrylate (PMMA/Acrylic), polystyrene (PS), polycarbonate (PC), polysulfone (PSU), polyvinyl chloride (PVC), and acrylonitrile butadiene styrene (ABS). Their molecular structures remain randomized and nonlinear enough that they cannot be aligned uniformly. Thermoset plastics are all considered low- or non-crystalline materials, though researchers are working to create semi-crystalline versions.

To learn more, see our guide on Polymer Material.

Is There a Difference Between Crystalline Polymers and Semi-Crystalline Polymers?

Yes, there is a difference between crystalline and semi-crystalline polymers. A polymer is called crystalline if more than 80% of its polymer chains are aligned. Semi-crystalline polymers exhibit anywhere from 10% to 80% crystalline alignment. Materials that fall below the 10% mark are known as amorphous.

The spectrum of crystallinity is caused by side branching and randomness within the polymers’ molecular structure. Some polymer chains inherently tend to align with one another, while others come in nonlinear shapes and can’t align. Material processing can also make a polymer more crystalline. For example, molding, extruding, drawing, or heat treatment all help polymers crystallize.

What Are the Characteristics of Crystalline Polymers?

Crystalline thermoplastic polymers differ significantly from amorphous ones.

- Crystalline thermoplastics are typically denser. It’s especially evident when comparing chemically similar materials with different polymer chain structures. LDPE and HDPE have respective densities of 0.92 g/cm3 and 0.96 g/cm3, for example.

- A crystalline structure makes for better tensile strength. For example, LDPE has a tensile strength of 10-15 MPa, whereas HDPE reaches over 21 MPa, despite being nearly identical in chemical composition.

- Hardness is generally higher for this class of polymers.

- Crystalline and semi-crystalline polymers tend to be opaque or slightly translucent.

- Melting points tend to be more sharply defined as the degree of crystallization increases.

- These polymers tend to shrink more as they solidify because they change from a disordered liquid state to a highly ordered solid state.

- They are less chemically accessible and therefore more resistant to organic solvents and acids.

- Crystalline polymers aren’t as permeable because of their closer-packed atomic structure.

Is Crystalline Polymer Weldable?

Yes, crystalline polymers are weldable. The most common welding technique used on plastics is ultrasonic welding, which involves the application of focused high-frequency vibration. This technique is effective with both semi-crystalline and highly crystalline polymers. However, heat dissipates into the parts more easily than for amorphous polymers. Sound waves travel further in crystals before being transformed into heat. This makes the welding more challenging and requires higher contact pressure and more vibration energy.

Laser transmission welding (LTW) is an emerging technology that loses less energy to the polymer’s broader structure.

Thermal welding, meanwhile, is well-studied and practical for most amorphous and semi-crystalline polymers. There has been less study of the thermal welding of highly crystalline polymers. However, anecdotal evidence reports moderate success with thermal welding, even in advanced hot-melt glue applicators.

An important thing to remember is that crystallinity is often extrinsic — in other words, it is imposed on the material through post-production processes. The weld will likely alter the crystallinity in its heat-affected zone, causing the zone’s properties to shift.

Do Crystalline Polymers Rust?

No, crystalline polymers do not oxidize. They can, however, degrade under the influence of UV radiation, organic solvents, and some organic acids. Crystalline polymers resist these forces better than non-crystalline ones, though.

What Are the Physical Properties of Crystalline Polymers?

The typical physical properties of crystalline polymers are:

- Crystalline polymers tend to melt more suddenly than amorphous ones.

- The close molecular packing in the crystalline lattice results in a higher density in crystalline regions than in the amorphous volume.

- They are generally stiffer, stronger, and more rigid than other polymers. However, they become more brittle, which can offset some of the advantages.

- Highly crystalline polymers are often opaque, although the presence of distributed lamellae can still allow for good transparency.

- Crystalline polymers generally exhibit good thermal stability and resistance to high temperatures. The onset of weakening in the intramolecular Van der Waals forces is proportional to the molecules’ proximity to one another.

What Are the Chemical Properties of Crystalline Polymers?

The typical chemical properties of such polymers are:

- The polymer chains are arranged in an orderly, repeating fashion, generally in a straight rather than tangled configuration. This regularity defines crystalline regions.

- Polymer crystals are robust due to their strong intermolecular bonds. This makes them stronger and more resilient than the equivalent semi-crystalline or amorphous forms of the polymer.

- The bond integrity makes these polymers less susceptible to solvents, organic acids, alkalis, and radiation attacks than their less crystalline equivalents.

What Are Crystalline Polymers Composed of?

All thermoplastics consist of long-chain molecules or repeating units of simple chemicals, known as monomers. These monomers are strung together (polymerized) to form chains. The nature of the polymerization process and the intrinsic chemical properties of the monomers define the regularity or complexity of the resulting molecule. Crystalline polymers are composed of unbranched chains or chains with only minor branching.

What Are the Uses of Crystalline Polymers?

Crystalline polymers have many uses. Most engineering plastics, such as POM (polyoxymethylene), HDPE, and many nylon-based polymers, are tough and resilient. They offer excellent dimensional stability, good machining properties, respectable temperature tolerance, and durability against wear. This makes them ideal for engineering components and high-stress parts in machine construction, vehicle components, and street furniture applications. They are suitable for sliding and rotating bearing surfaces, particularly when paired with hard materials such as hardened and precision-ground stainless steel.

The chemical resilience of many crystalline thermoplastics enables them to withstand aggressive chemical environments. This allows fuel line components to be made using liquid crystal polymer, acetal (POM) copolymer, and fluoropolymers, all of which are essentially crystalline.

“Crystalline polymers are some of the most fascinating materials in modern manufacturing. Their ability to combine strength, rigidity, and chemical resistance makes them essential for demanding applications, from automotive components to chemical processing equipment. Working with these materials has shown me just how much control processing conditions have over performance—it's not just about the polymer type, but how it's formed and treated that defines its capabilities.”Mahder Tewolde, Ph.D.. PENote from the Editor

What Are Some Examples of Crystalline Polymers?

Most engineering polymers are at least semi-crystalline. They often have similar properties.

1. Polypropylene (PP)

Polypropylene (PP) is not typically regarded as an engineering plastic due to its relatively soft and ductile properties; however, it is highly versatile. It belongs to the polyolefin group and is highly crystalline. This material consists of repeated propylene monomer units. Its chemical formula is (C3H6)n, where “n” is the repeat step that forms it into a chain molecule. It is formed from a chemically simple monomer and possesses no side branching.

Polypropylene is widely exploited for its resistance to solvents and aggressive/reactive chemicals. It is formed into containers and pipes for chemical processing and storage, as well as for food and medical storage and packaging.

To learn more, see our guide on Polypropylene Material.

2. Polybutylene Terephthalate (PBT)

Polybutylene terephthalate (PBT) is a thermoplastic engineering polymer from the polyester family. It has beneficial mechanical, thermal, and electrical properties. PBT is a linear polyester consisting of repeating butylene terephthalate units. Its chemical formula is (C10H10O4)n, where "n" represents the number of repeated units in the polymer chain. The melting temperature ranges between 225 and 260 °C. Since it doesn’t absorb water, PBT is ideal for use in piping and humid and wet conditions. PBT is an electrically insulating material that does not react with most solvents or other chemicals.

To learn more, see our guide on Polybutylene Terephthalate.

3. Polyethylene (PE)

Low-density polyethylene is highly amorphous and is generally not viewed as an engineering material. However, high-density polyethylene (HDPE) is very crystalline and sees significant use in engineering settings. HDPE is composed of minimally side-branched chains of ethylene monomers. Its chemical formula is (C2H4)n, where "n" represents the number of repeated units in the polymer chain. It is much stronger and more rigid than its low-density form.

HDPE resists acids, alkalis, and organic solvents far better than most polymers, so it gets used alongside corrosive substances. HDPE can withstand temperatures ranging from -50 to 120 °C without significant deformation, making it a valuable material in power generators, engine bays, and environments with aggressive chemicals. The material barely absorbs any moisture throughout the entire temperature range. The polymer is highly resistant to ultraviolet (UV) radiation, making it suitable for outdoor applications. It's also an excellent electrical insulator, ideal for high-voltage applications.

To learn more, see our guide on Polyethylene.

Is Polyoxymethylene (POM) a Crystalline Polymer?

Yes, Polyoxymethylene (POM) is a chemically simple macromolecule that does not form side branches. This results in a highly crystalline material.

What Are the Advantages of Crystalline Polymers?

Compared to other polymers, crystalline ones are:

- Generally stronger, tougher, and more dimensionally stable

- More heat-tolerant

- Easy to machine

- More rigid

What Are the Disadvantages of Crystalline Polymers?

Some disadvantages of crystalline polymers include:

- Less ductile and can display brittle behavior, particularly under high strain rates. Intramolecular movement within a crystalline structure is much more restricted than in amorphous material. Strain can generate microfractures that amass and compound over time.

- They are generally opaque. They won’t work if you need a translucent material.

- They are generally more expensive than their amorphous equivalents.

- Their chemical stability makes them hard to solvent-weld or paint. And though ultrasonic welding works, it’s more difficult than for amorphous polymers.

Frequently Asked Questions About Crystal Polymers

Are Crystalline Polymers Expensive?

Yes, crystalline polymers typically cost more than amorphous ones — mainly because less of the raw material is produced worldwide. For example, the price of LDPE is approximately $1,750 per ton, whereas HDPE sells for around $2,100 per ton.

An exception to this higher-cost principle is polypropylene (PP), which is among the most affordable polymers and is used in huge quantities — as much as 80 million tonnes per annum. The simplicity of the monomer, the relative ease of polymerization, and the high production volumes make this material cost around $1,200 per ton.

Are Crystalline Polymers Hard To Find?

No, crystalline polymers are not hard to find. They are among the most common polymer materials and are widely manufactured and supplied across the planet. Sourcing is simple, even in remote locales, because they’re so fundamental to virtually all technologies and products.

What Is the Difference Between Crystalline Polymers and Amorphous Polymers?

Crystalline polymers are those in which the proportion of lamellae (crystal regions) makes up 80% or more of the structure. Amorphous polymers, on the other hand, are those whose structure is below 10% crystalline lamellae.

What Is the Difference Between Semi-Crystalline Polymers and Amorphous Polymers?

Semi-crystalline polymers are those whose structure consists of between 10% and 80% crystalline regions. Amorphous structure contains less than 10% crystalline regions, and their polymers are highly disordered.

Summary

This article presented crystalline polymers, explained them, and discussed their properties and uses. To learn more about crystalline polymers, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.