Design Guides

In-depth design guides full of best practices for all of Xometry's manufacturing processes.

eBook: PolyJet 3D Printing Mini Design Guide

Design Guide: Injection Molding

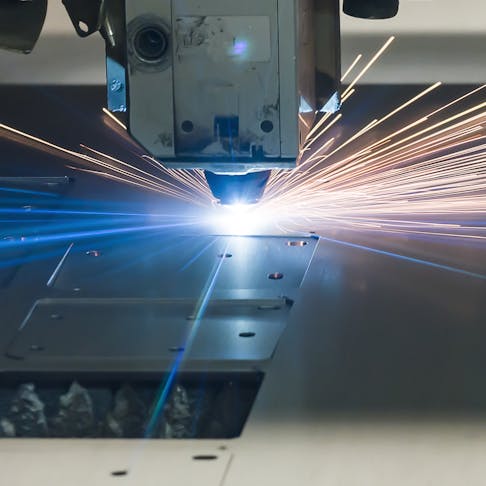

Design Guide: Laser and Sheet Cutting

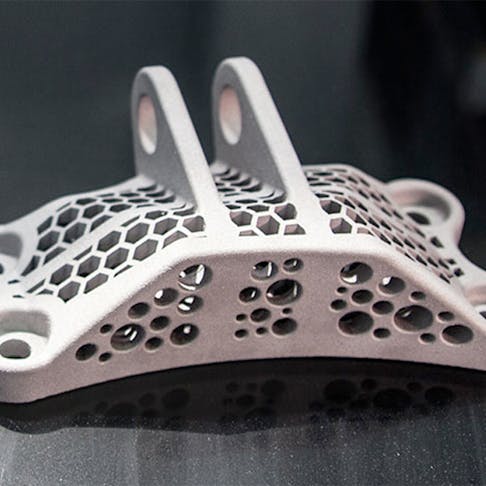

Design Guide: HP Multi Jet Fusion (MJF) 3D Printing

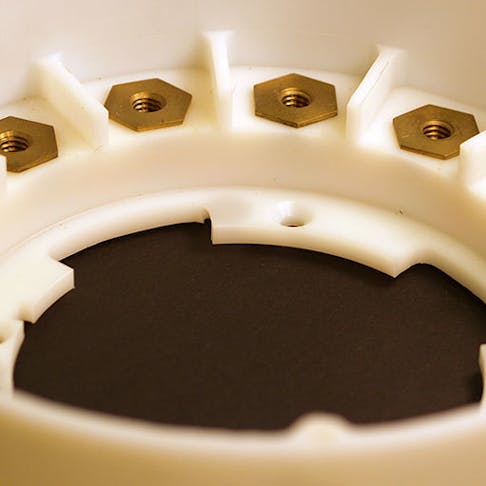

Design Guide: Fused Deposition Modeling (FDM) 3D Printing

Design Guide: Urethane Casting

Design Guide: Sheet Metal Fabrication

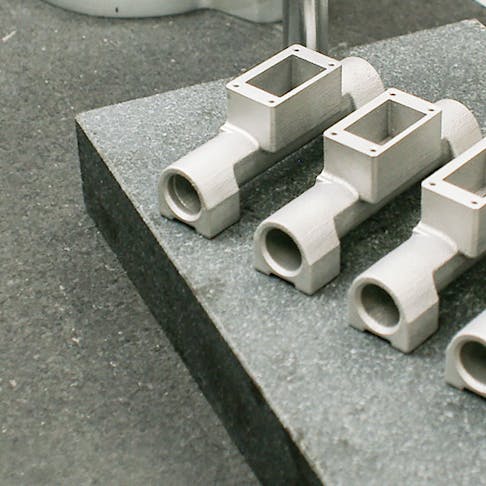

Design Guide: Binder Jet Metal 3D Printing

Design Guide: Carbon DLS 3D Printing